Professional Documents

Culture Documents

Renr3008 01

Renr3008 01

Uploaded by

ReymartinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Renr3008 01

Renr3008 01

Uploaded by

ReymartinCopyright:

Available Formats

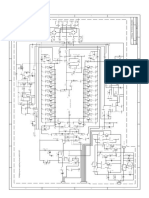

RENR3008-01

February 2000

HH45, HH55, HH65, and HH75

Harvester Heads

Electrical System

2JZ1-UP

3MZ1-UP

4RZ1-UP

5WZ1-UP

© 2000 Caterpillar Printed in U.S.A.

All Rights Reserved

9 8 7 6 5 4 3 2 1

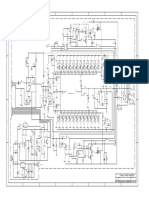

CONN 1

BU

7 DK PRESS MAIN CONTROL VALVE

Descriptions: CONNECTOR 8 REV/FOR

RS232 PORT PRINTER PORT ON STICK 8 REV/FOR

REC'D LIN SIG DETECTOR DCD

GROUND

GROUND

HA = HOLDING ARM

TRANS DATA TD

DATA SET READY DSR

GROUND

TRANS DATA TD

+12V

CLEAR TO SEND CTS

RECEIVED DATA RD

REQUEST TO SEND RTS

+12V

CLEAR TO SEND CTS

RI

DTR

9 RETURN

FRA = FEED ROLLER ARM 24 +

DK = DELIMBING KNIFE 10 HA PRESS 1 LEFT FEED

G -

* FRA ON HH45 8

11 CLOSE 2 ROLLER MOTOR

* HA ON HH55/HH65/HH75

3 PROP SOL

CONN 2

12 OPEN

10A POWER 3 OUT SENSORS

GRAPPLE CLOSE (OPTIONAL)

REF. VDC POTENTIOMETERS

GRAPPLE OPEN (OPTIONAL)

FR/HA POTENTIOMETERS

SPARE DIGITAL OUTPUT

OPEN

HA BYPASS RELIEF VALVE

13

SAW POSITION SENSOR

STUMP COATING SYSTEM

SPARE DIGITAL OUTPUT

HA/FRA* ADJ PRESSURE

SPARE ANALOG OUTPUT

SPARE ANALOG OUTPUT

SPARE ANALOG OUTPUT

SPARE DIGITAL INPUT

SPARE DIGITAL INPUT

SPARE DIGITAL INPUT

DK POTENTIOMETERS

SPARE ANALOG INPUT

SPARE ANALOG INPUT

HIGH PRESS FRA/HA*

CLOSE

F

DIAMETER PULSE 1

F CONNECTOR 14

POWER 1 (10A FUSE)

POWER 1 (10A FUSE)

PULSE OPEN DK & HA

SPARE DIGITAL OUT

DIAMETER PULSE 2

24

SAW HOME SENSOR

+

DK ADJ PRESSURE

LENGTH PULSE 1

+12VDC OUTPUT

1

+VDC TO KEYPADS

IN CAB DOWN

LENGTH PULSE 2

RIGHT FEED

SAWBAR RETURN

15 -

3A POWER 3 OUT

N/A PHOTOCELL

GRAPPLE CLOSE

FEED REVERSE

PULSE OPEN DK

FEED FORWARD

HIGH PRESS DK

10A POWER 2 IN

G

3A POWER 2 IN

GRAPPLE OPEN

PUMP SIGNAL

FEED FOR/REV

MATRIX BIT 1

HA PRESSURE

1 UP 8 ROLLER MOTOR

MATRIX BIT 0

MATRIX BIT 2

MATRIX BIT 3

MATRIX BIT 4

STEER RIGHT

16

STEER RIGHT

STOP/PAUSE

2

STEER LEFT

STEER LEFT

16

PULP WOOD

FRA CLOSE

TILT DOWN

TILT DOWN

2 CLOSE PROP SOL

FRA OPEN

3

HA CLOSE

DK CLOSE

SAW CUT

COLOR 1

SAW CUT

POWER 1

HA OPEN

GROUND

GROUND

GROUND

DK OPEN

COLOR 2

GROUND

GROUND

HA OPEN

3 CLOSE

GROUND

GROUND

17

TILT UP

TILT UP

EXTRA

EXTRA

SHIFT

START

4

CONN 3

5 18 CUT

6 22 OPEN

7 22 OPEN

11

24 +24 VDC

16

19

10

12

13

15

17

18

21

31

D16

D10

D12

D18

18

14

B16

D14

B10

B12

B18

Z16

B14

Z10

Z12

Z18

+

Z14

D26

8

26

29

36

D20

D22

D28

D30

D32

20

22

23

25

27

28

30

32

33

35

37

B26

D24

24

34

B20

B22

B28

B30

B32

Z26

B24

Z20

Z22

Z28

Z30

Z32

Z24

1

2

3

4

5

6

7

8

9

D6

D2

D8

B6

D4

B2

B8

Z6

B4

Z2

Z8

1

Z4

24 +24 VDC

9

25 G

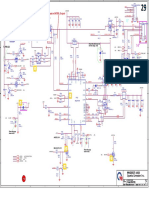

- CUTTING SYSTEM 17

10 9

RD/WH

BK

PK

BK

BU

WH/YL

GY/PK

GN/BR

BR/GN

PK/YL

RD

BR/BU

WH/GY

WH/GN

WH

BR

RD/BU

GN/BR

BR/BK

WH/BK

GN

GY

WH/BU

PU

BU

YL

GN/GY

YL/BR

RD

RD/BU

GN/YL

PK/BR

PK/GN

PK

2 ON/OFF SOLENOID

BR

11 CONN 4

PK

3

12

CONNECTOR FROM KEYPADS 13

YL

PK

CONNECTOR 14

RD/BR

YL WH

TO MACHINE 15

16

BR

1 2

RD PUMP 17 12 +

1

2 18 GN

1

-

DELIMBING KNIFE 3 4 5 6 7 8 9 10

11 G

WH/GN 3 GRAPPLE CLOSE 19

2

CYLINDERS

20 CONN 5

YL 4 GRAPPLE OPEN 3 ON/OFF SOL

GY/PK 21

BR 5 3A POWER YL

6 22

WH 23 WH

PK 7 10A POWER

BU 8 GROUND 24

BK

RD/BU

BR/GN

9

10

OFF-ROAD STEERING RH 25

26

BR

22 +

15

OFF-ROAD STEERING LH 1

FEED ROLLER

11 27 GN -

28 17 G

12 2 ARM CYLINDER

GY 13 63K RESISTOR 29

YL WH BR GN 3 ON/OFF SOL

1 WH/GN PU 14 30K RESISTOR 30

2 WH/YL 15 15K RESISTOR

YL

3

4

YL/BR YL/BR 16 GRAPPLE OPEN (OPTIONAL) E

E 5

PU

GY

CONNECTOR IN CAB CONN 6 13

1 +

- HOLDING ARM

DASA 280/380

6 GN/BR

WH/YL 1 14 G CYLINDERS

PU 2

2

GY 3 ON/OFF SOL

BK

BK

BR

BU

3

PK

RD/BR

4

F G H J

BR

BU

YL 5

6

GN/BR 7

WH/G

RD/WHY 8 16 +

1 TILT

9 -

BR/BU G

WH/BU 10 15 2

CYLINDERS 11 A B C D E 14 12 13

11

WH/YL ON/OFF SOL

G

G 3

26

27

G

12 4

GN E58104

GN

BR

WH

YL

13 E58105

PK/GN 14

WH/GN

15

1

2

3

4

RD/BU 16 22 +

PK/YL 17 STUMP COATING COLOR 2 COLOR 1 1 MEASURING ARM

-

GROUND

GROUND

YL/BR

+24VDC

G

+24VDC

SIGNAL

SIGNAL

18 17 CYLINDER

BU 2

RETURN

PUMP SOLENOID

+24VDC

RD

19 SOLENOID SOLENOID SOLENOID

SIGNAL 1

3

SIGNAL 2

20

WH/BK 21

BR SAW BAR SAW BAR

22

GN

BR

YL

WH

BK BYPASS RELIEF VALVE

23 HOME POSITION

PK/BR

BK

24

SENSOR

LENGTH 3

25 SENSOR CONN 7

3

2

5

4

GN/GY 26

SENSOR

GN/YL 27

1 HOLDING ARM

CONNECTOR TO DASA UNIT BR/BK G

BK 28 CROSS LED 1 25 2 OPEN

29 CALIBRATION LED 2 3 ON/OFF SOL 4

16

19

10

11

12

13

15

17

18

21

31

14

30 BOX

26

29

36

20

22

23

25

27

28

30

32

33

35

37

5

24

34

1

2

3

4

5

6

7

8

9

D D

WH/YL

WH/BK

BR

BR

WH/GN

YL

YL

BU

GY

WH

RD/WH

GY/BR

BR/PK

WH/PK

PU

GN

BK

WH/BU

BR/RD

RD

GY/PK

BR/GN

GY/BU

WH/GY

RD/BU

YL/BR

PK

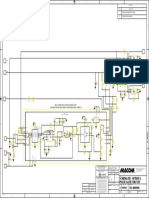

PRESSURE REDUCING VALVE

CONN 8 LED 3

SIGNAL 1 4 WH 1 LED 4 3

SIGNAL 2 5 YL 2 LED 5 1 ADJUSTABLE PRESS

+24VDC 2 BR 3 LED 6 G

RETURN 7 DK CYLINDER

3 GN 4

LED 7

2

3 5

HH75 RIGHT DIAMETER SENSOR PROP SOLENOID

4

CONN 9

1

HARVESTER HEAD SIGNAL 1

SIGNAL 2

4

5

YL

WH

1

2

1 ADJUSTABLE PRESS

6

22K

+24VDC 2 BR 3 10 G HA CYLINDERS

EXTERNAL FUSE 1 1

RETURN 3 GN 4

2 6

3 PROP SOLENOID

1A 15K

LEFT DIAMETER SENSOR

1

7

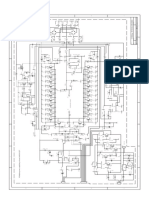

CONN 1

BU 7

1

CONNECTOR 7 DK PRESS

15K 8 REV/FOR

1 ON STICK 8 REV/FOR 8

BR 9 RETURN 8

YL

1

10 HA PRESS MAIN CONTROL VALVE

2

1 PK

3

BU CLOSE

33K 4

11 9

GY 5

1 WH

6

CONN 2

12 OPEN

18

1 +

1 2 9

- CUTTING SYSTEM

9 G 1 2

13 OPEN 2 ON/OFF SOLENOID

CONNECTOR 14 CLOSE 3 10

CONNECTOR TO DASA UNIT

IN CAB DOWN

C 1 UP C

16

19

10

11

12

13

15

17

18

21

31

14

26

29

36

20

22

23

25

27

28

30

32

33

35

37

24

34

1

2

3

4

5

6

7

8

9

2

3 17 CLOSE

WH

YL

OR

BR

BU

YL

24

OR

OR

BU

GN

OR

GN

GN

BR

PK

GY

PU

BU

PK

PK

WH

OR

GY

PU

+

GN

PU

PU

BU

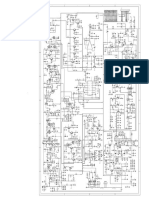

4 1 LEFT FEED

CONN 3 18 -

5 CUT G

8 2 ROLLER MOTOR

6

22 OPEN

7 3 PROP SOL

24 +24 VDC

8

+24 VDC

11

9 24

25

10 11

WH/GY

WH/BK

WH/YL

WH/GN

BR/GN

BR/RD

WH/PK

WH/BU

GY/BU

RD/WH

GY/BR

BR/PK

RD/BU

GY/PK

YL/BR

11

CONN 4 YL

WH

RD

GN

1 12

GY

BU

PK

PU

BR

BK

24

YL

1 +

2 13

WH - RIGHT FEED

3 14

8 G ROLLER MOTOR

EXTERNAL FUSE YL

16

19

2

10

11

12

13

15

17

18

21

31

4 15

14

26

29

36

20

22

23

25

27

28

30

32

33

35

37

24

34

1

2

3

4

5

6

7

8

9

5 16 3 PROP SOL

1A 1 BR

6 17

810

18 GN

DASA INTERFACE BOX 1

19

20 CONN 5

YL

HH45, HH55, and HH65 HH75 Solenoid Valves

21

12 +

Solenoid Valves

1

810 22 WH 1 DELIMBING KNIFE

-

23 G

10

10

10

10

11 CYLINDERS

C

A

B

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1 24 2

1 33K BR 3 ON/OFF SOL

PU

1

BK

WH/GN

25

WH

GN

WH/YL

YL

WH/GN

RD/BU

RD/BU

BR/GN

BR

WH/YL

BR

GY/PK

PK

GN/BR

PK

GY

GY/PK

GY

BK

YL

WH

WH

BU

GN

BU

RD

RD

PU

YL/BR

BR

GN

YL/BR

22K

26 GN

1 27

1

28

1

2.2K 1

15K

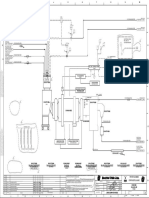

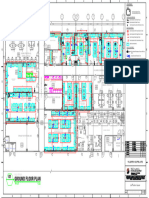

29 Chart A Chart B

Harvester Head Electrical System Component Locations Harvester Head Electrical System Connector Location

30

1 YL WH BR GN 22 1 +

1 2.2K FEED ROLLER

1 -

17 G

ARM CYLINDER Location Location Schematic

1 1 2 Item No. Component Item Connector

15K

CONN 6 3 HH45/58/65 HH75 Location

ON/OFF SOL

B 1

B 1 Adjustable Pressure DK Cylinder Prop Sol A1 D1 A Conn 1 Al

2 Adjustthle Pressure HA/FR Prop Sol * A1 D1 B Conn 2 Al

BK

BU

BR

BK

WH/YL

WH/GN

WH/GN

BR/GN

RD/BU

WH/YL

YL/BR

GN/BR

GY/PK

RD/BU

13

GY/PK

YL/BR

1 + 3 Left Feed Roller Motor Prop Sol B1 F1 C Conn 3 B1

HOLDING ARM

GN

WH

RD

PU

GY

PK

BR

YL

BU

RD

WH

BU

BK

GY

PK

-

PU

BR

BK

BU

YL

GN

BR

14 G CYLINDERS

2 4 Right Feed Roller Motor Prop Sol B1 F1 D Conn 4 Cl

16

13

10

11

12

15

14

3 ON/OFF SOL

16

13

10

11

12

15

14

1

2

3

4

5

6

7

8

9

5 Cutting System On/Off Solenoid C1 F1 E Conn 5 Cl

1

2

3

4

5

6

7

8

9

6 Delimbing Knife Cylinders On/Off Solenoid C1 E1 F Conn 6 D2

WH-18

GN-18

RD-18

OR-18

BK-18

BR-18

PU-18

PK-18

BU-18

YL-18

GY-18

WH-18

GN-18

TAN-18

RD-18

BU-18

OR-18

BK-18

BR-18

PU-18

PK-18

YL-18

GY-18

WH/BK-18

DK GN-18

TAN-18

BR/BK-18

DK BU-18

WH/BK-18

DK GN-18

BR/BK-18

DK BU-18

7 Feed Roller Arm Cylinder On/Off Solenoid D1 E1 G Conn 7 E3

G

26

27

G

G

4

16

GN

+

WH

BR

YL

1 TILT

- 8 Holding Arm Cylinder On/Off Solenoid E1 E1 H Conn 8* F2

15 G CYLINDERS

2

1

2

3

4

9 Tilt Cylinders On/Off Solenoid E1 E1 J Conn 9* G2

WH

ON/OFF SOL

GN

3

BR

STUMP COATING COLOR 2 COLOR 1 10 Measuring Arm Cylinder On/Off ** F1 D1 * Used only on HH65 and HH75 (Optional on HH55).

GROUND

GROUND

+24VDC

+24VDC

SIGNAL

SIGNAL

RETURN

+24VDC

PUMP SOLENOID SOLENOID SOLENOID 11 Holding Arm Open On/Off Solenoid B1 D1

SIGNAL 1

SIGNAL 2

12 Saw Bar Home Sensor A2 D3

SAW BAR SAW BAR

WH

RD

BR

RD

WH

RD

GY

WH

BU

PK

Chart C

PU

YL

BR

OR

PK

PU

BU

GN

BR

GY

GN

YL

OR

RD

PU

PK

LENGTH 13 Saw Bar Position Sensor A2 D2

LENGTH

DK OPEN

HOME POSITION

ADJ PRESS

TILT DN

SAW

GN

BR

YL

WH

HA/FRA

QUAL5

DK ADJ

LEN5

PRESS

Cross Calibration Box LED Function *

C

A

B

SENSOR 14 Length Sensor A2 D2

16

16

13

13

10

11

12

10

11

12

15

15

14

14

SENSOR

-

SENSOR

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

BYPASS RELIEF VALVE

RIGHT HAND 15 KEYPAD

LEFT HAND 15 KEYPAD

CONN 7 15 Cross Calibration Box** A2 D2 LED No. Function Displayed

3

2

4

5

WH

RD

BU

GY

RD

GY

PK

GN

OR

BR

PU

BR

YL

OR

WH

BK

BK

GN

PK

PU

BU

YL

LENGTH

SHIFT

PRESS

TILT UP

STOP

DK HI

QUAL4

16 Left Diometer Sensor A3 D3 LED 1 Pulse 1 to DASA

LEN4

WH

RD

BR

CROSS LED 1 1 HOLDING ARM

+

RD

CALIBRATION G 17 Right Diameter Sensor*** A3 D3 LED 2 Pulse 2 to DASA

LED 2 25 OPEN

POTENTIOMETERS BOX

2

HARDWOOD

FRA=HH45

HI PRESS

HA OPEN HA=HH55-75

3 ON/OFF SOL LED 3 +24 VDC

SPRUCE

WOOD

* Solenoid adjusts the pressure of the feed roller arm on the tree

PULP

SHIFT

QUAL3

LEN3

SPECIES

HIGH PRESS

SPECIES

A for the HH45 Solenoid adjusts the pressure of the holding arm

HA OPEN

COLOR 1

COLOR 2

LENGTH

A LED 4 Pulse 2 from Right Diameter Sensor

LENGTH

HA/DK OPEN

DK HIGH

PRESS

FRA/HA

START

on the tree for the HH55 HH65.

OPEN

DK

CONN 8 LED 3

+

DK ADJ HA/FRA LED 5 Pulse 1 from Right Diameter Sensor

RIGHT HAND KEYPAD

WH

-

LEFT HAND KEYPAD

PRESSURE REDUCING VALVE

COLOR 2

SIGNAL 1 1 LED 4

RIGHT

ADJ PRESS

STEER

PRESS 4 YL **Solenoid controls the movement of the measuring arm for the

PINE

FR REV

QUAL2

SIGNAL 2

LEN2

5 2 LED 5 LED 6 Pulse 2 from Left Diameter Sensor

BR HH75 only. HH45, HH55, HH65 use a pressure reducing valve.

+24VDC 2 GN

3 LED 6

RETURN 3 4 1 ADJUSTABLE PRESS *** Used only on HH65 and HH75 (Optional on HH55). LED 7 Pulse 1 from Left Diameter Sensor

POTENTIOMETERS LED 7

7 G

DK CYLINDER

TILT DN

TILT UP

COLOR 1

FR FWD

STEER

FR REV

RIGHT DIAMETER SENSOR 2

PAUSE

SHIFT

* Used only on HH65 and HH75 (Optional on HH55)

RIGHT

STEER

STEER

HA/DK

OPEN

LEN1

LEFT

FR FWD

WOOD

QUAL1

STOP/

PULP

LEFT

START

SAW

3

PROP SOLENOID

YL CONN 9

SIGNAL 1 4 1

WH

CONTROLS CONTROLS HH45/HH55/HH65 SIGNAL 2

+24VDC

5

2

BR

GN

2

3 1 ADJUSTABLE PRESS

RETURN 3 4

G HA/FR CYLINDERS*

LEFT HAND ARMREST

15 BUTTON KEYPAD

RIGHT HAND ARMREST

LEFT HAND ARMREST 10 BUTTON KEYPAD RIGHT HAND ARMREST

HARVESTER HEAD LEFT DIAMETER SENSOR

10 2

3 PROP SOLENOID

e96500

7 6 5 4 3 2 1

You might also like

- 793B Truck With VIMS Electrical System: 1HL195-UPDocument2 pages793B Truck With VIMS Electrical System: 1HL195-UPGilvan JuniorNo ratings yet

- 914G Wheel Loader and Electrical System IT14G Intergrated ToolcarrierDocument2 pages914G Wheel Loader and Electrical System IT14G Intergrated ToolcarrierGilvan Junior100% (1)

- TDS-11SH Top Drive D392004689-MKT-001 Rev. 01Document2 pagesTDS-11SH Top Drive D392004689-MKT-001 Rev. 01Israel Medina100% (2)

- 25635-220-M6-0210-00001-R2 Chancadora 1Document1 page25635-220-M6-0210-00001-R2 Chancadora 1Victor Guzman PretellNo ratings yet

- American Audio V5000-Plus Audio Pa 2004 SCH PDFDocument1 pageAmerican Audio V5000-Plus Audio Pa 2004 SCH PDFRomlly Voice Elektro100% (2)

- V5000amp SectionDocument1 pageV5000amp SectionGafar Ys100% (1)

- DYNROT: A Matlab Toolbox For Rotordynamics Analysis: January 1994Document27 pagesDYNROT: A Matlab Toolbox For Rotordynamics Analysis: January 1994saurabhchandrakerNo ratings yet

- Mpd-Ug0: 04A-Mobilization and ConstructionDocument1 pageMpd-Ug0: 04A-Mobilization and ConstructioneopokandilNo ratings yet

- TH336C, TH337C, TH406C, TH407C, TH414C, TH514C, TH417C Electrical Schematic 31200832 TH336C, TH337C, TH406C, TH407C, TH414C, TH514C, TH417CDocument15 pagesTH336C, TH337C, TH406C, TH407C, TH414C, TH514C, TH417C Electrical Schematic 31200832 TH336C, TH337C, TH406C, TH407C, TH414C, TH514C, TH417CEduardo67% (3)

- Planos 9978Document34 pagesPlanos 9978Omar50% (2)

- Power Schematic Diagram (For 47PFL) BoardDocument1 pagePower Schematic Diagram (For 47PFL) BoardSamuel OdeiaddoNo ratings yet

- SystemC TLMDocument33 pagesSystemC TLMVarun NagpalNo ratings yet

- 621E & 623E Wheel Tractor-Scrapers Electrical System: Machine Harness Connector and Component LocationsDocument2 pages621E & 623E Wheel Tractor-Scrapers Electrical System: Machine Harness Connector and Component LocationsGilvan JuniorNo ratings yet

- Plan EvaluationDocument56 pagesPlan EvaluationSidhartha Dev100% (1)

- American Audio V5000-Plus Audio Pa 2004 SCHDocument1 pageAmerican Audio V5000-Plus Audio Pa 2004 SCHMoises Shente75% (4)

- Mte MBL-9000Document1 pageMte MBL-9000Francisco Sanabria Najera100% (7)

- Where Does NBDP Fit in GMDSS and How To Use ItDocument14 pagesWhere Does NBDP Fit in GMDSS and How To Use ItKunal SinghNo ratings yet

- Grove RT890E-Product GuideDocument24 pagesGrove RT890E-Product GuideFabian Andres CelyNo ratings yet

- 220 M6 0310 00032Document1 page220 M6 0310 00032nestor159357No ratings yet

- Sci9 Q3 Module6Document27 pagesSci9 Q3 Module6Sherwin Lee PascualNo ratings yet

- Polybed PSADocument2 pagesPolybed PSAJeEJyZaNo ratings yet

- Coo 4Document1 pageCoo 4Jok PrasNo ratings yet

- Ebs TC 4001Document1 pageEbs TC 4001Cahya RezaNo ratings yet

- 426-5051-00 - Turck Breakout & BoxRemote ModuleDocument6 pages426-5051-00 - Turck Breakout & BoxRemote ModulejNo ratings yet

- To Control Unit OCS, See Circuit Diagram 2081507Document1 pageTo Control Unit OCS, See Circuit Diagram 2081507andrestkaNo ratings yet

- Eec Serie KDocument1 pageEec Serie KmiltonNo ratings yet

- Schematic Diagram NV-5001Document1 pageSchematic Diagram NV-5001Marco Kersul100% (3)

- PID Turbcompr Desc1raEtapaDocument1 pagePID Turbcompr Desc1raEtapaJholman SanchezNo ratings yet

- BC-6800 Fluidic DiagramDocument24 pagesBC-6800 Fluidic DiagramFENGNo ratings yet

- TPD MS338 PC799Document14 pagesTPD MS338 PC799José SoeiroNo ratings yet

- T-4.002.788 A 1 PublicationDocument1 pageT-4.002.788 A 1 PublicationNadeem AkramNo ratings yet

- President Lincoln II Version 3 SchematicDocument13 pagesPresident Lincoln II Version 3 Schematicalf100% (1)

- HP 840 G1 - Mec1322Document1 pageHP 840 G1 - Mec1322Ramdas KambleNo ratings yet

- ESP32-EVB Rev DDocument1 pageESP32-EVB Rev DAlexNo ratings yet

- KENR5951Document2 pagesKENR5951vova0lopuxNo ratings yet

- CB 1645 CombinedDocument7 pagesCB 1645 CombinedQuerubin RamirezNo ratings yet

- P&id Demineralized Water DistributionDocument1 pageP&id Demineralized Water DistributionAjeng OctaviaNo ratings yet

- C20 J V3.0 SCH-WG5013-S50 PDFDocument8 pagesC20 J V3.0 SCH-WG5013-S50 PDFMuhammad yunusNo ratings yet

- Caterpillar 3500B and 3500C. SchematicDocument2 pagesCaterpillar 3500B and 3500C. SchematicАлексейNo ratings yet

- Pim1013 Pim1014 Pim1013 Pim1014: Piq101 Piq101Document1 pagePim1013 Pim1014 Pim1013 Pim1014: Piq101 Piq101Alexsei BordaNo ratings yet

- MARGHERA Preliminary Stowage Plan MV Beautrident - Rev.11.03.2022Document1 pageMARGHERA Preliminary Stowage Plan MV Beautrident - Rev.11.03.2022Oleksandr ShcherbynaNo ratings yet

- Schematic Anytone at 5555 V6 7 ENGDocument4 pagesSchematic Anytone at 5555 V6 7 ENGTimmyNo ratings yet

- ZF Ecolife K280Document1 pageZF Ecolife K280miltonNo ratings yet

- Fileshare - Ro - PLATINIUM RML-20 OTXT (PTLM 04-1 (20AL) ) (WWW - Pieseelectronice.go - Ro)Document1 pageFileshare - Ro - PLATINIUM RML-20 OTXT (PTLM 04-1 (20AL) ) (WWW - Pieseelectronice.go - Ro)ERYNo ratings yet

- RT400Document6 pagesRT400RASMAJON100% (1)

- Power Schematic Diagram (For 47PFL) BoardDocument1 pagePower Schematic Diagram (For 47PFL) BoardSamuel OdeiaddoNo ratings yet

- Anexo 5 - PlanoDocument1 pageAnexo 5 - PlanoMIGUEL ANGEL MIRANDA UGARTENo ratings yet

- Enq-439-Drainage R01Document6 pagesEnq-439-Drainage R01abdullah sahibNo ratings yet

- P1 SP7731G V3.0 SCHDocument9 pagesP1 SP7731G V3.0 SCHchanel kreasiNo ratings yet

- 220 M6 0310 00010r001Document1 page220 M6 0310 00010r001Luis BernedoNo ratings yet

- 3516 Remolcador Kin Diagrama Electrico Motor Propulsion BaborDocument2 pages3516 Remolcador Kin Diagrama Electrico Motor Propulsion BaborNiza VidalNo ratings yet

- V5000plus Power Amplifier PC Board 6003101297Document1 pageV5000plus Power Amplifier PC Board 6003101297Crdz Louis100% (2)

- V5000amp (1) SectionDocument1 pageV5000amp (1) Sectionmiguel perezNo ratings yet

- V5000amp (1) .Section Diacrama No Borrar American Audio 5000plusDocument1 pageV5000amp (1) .Section Diacrama No Borrar American Audio 5000plusfreddy davidNo ratings yet

- V5000amp SectionDocument1 pageV5000amp SectionRoberto DiazNo ratings yet

- 10 136033 4800000533 Sha Civ SHD 050851 BoxDocument1 page10 136033 4800000533 Sha Civ SHD 050851 BoxAfZaL MuHammeDNo ratings yet

- RRPR-OPR-PRB-BR1-SB71 - Rev 1Document1 pageRRPR-OPR-PRB-BR1-SB71 - Rev 1sanjeev sharmaNo ratings yet

- 220 M6 0310 00001r001Document1 page220 M6 0310 00001r001Luis BernedoNo ratings yet

- TPD - ms338.PC798 SchematicsDocument11 pagesTPD - ms338.PC798 SchematicsMaikol DominguezNo ratings yet

- 18 606000 1100001344 Asb Civ SHD 115075 - 01Document1 page18 606000 1100001344 Asb Civ SHD 115075 - 01mahmudulalam konokNo ratings yet

- BQ24738 With VoltagesDocument1 pageBQ24738 With VoltagesVISHALNo ratings yet

- Umc TP - Ms3393a.pa671 c14312 Main SCHDocument8 pagesUmc TP - Ms3393a.pa671 c14312 Main SCHalirio mendezNo ratings yet

- SL-PONTON C.V - L 21.0M - C01685014-PL-r00Document1 pageSL-PONTON C.V - L 21.0M - C01685014-PL-r00Jorge HONo ratings yet

- American Audio V5000 Plus (2004)Document1 pageAmerican Audio V5000 Plus (2004)OrlyNo ratings yet

- Hisense Rsag7.820.5536 Psu SCH Lhd32k20dweuDocument1 pageHisense Rsag7.820.5536 Psu SCH Lhd32k20dweuDIAGRAMAS CICAPNo ratings yet

- American Audio V5000-Plus Audio Pa 2004 SCH PDFDocument1 pageAmerican Audio V5000-Plus Audio Pa 2004 SCH PDFargenis centenoNo ratings yet

- American Audio V5000-Plus Audio Pa 2004 SCHDocument1 pageAmerican Audio V5000-Plus Audio Pa 2004 SCHsatanNo ratings yet

- Hisense LED42K20D - RSAG7.820.5338 - H162 PSU SchematicDocument1 pageHisense LED42K20D - RSAG7.820.5338 - H162 PSU SchematicRene G Orama100% (1)

- AmericanAudio V5000 PWR SCHDocument1 pageAmericanAudio V5000 PWR SCHWilmer YrausquinNo ratings yet

- 1RNZ - Lab Furniture Layout - R6-Layout1Document1 page1RNZ - Lab Furniture Layout - R6-Layout1zafrikhan875No ratings yet

- 12H, 140H, 160H Motor Grader Electrical System (ES Version) : Machine Harness Connector and Component LocationsDocument2 pages12H, 140H, 160H Motor Grader Electrical System (ES Version) : Machine Harness Connector and Component LocationsGilvan JuniorNo ratings yet

- SENR3615Document2 pagesSENR3615Gilvan JuniorNo ratings yet

- SENR6238Document2 pagesSENR6238Gilvan JuniorNo ratings yet

- 5230 Excavator Electrical System: Machine Harnes Connector and Component LocationsDocument2 pages5230 Excavator Electrical System: Machine Harnes Connector and Component LocationsGilvan JuniorNo ratings yet

- 793C Truck Electrical System: Aty1-UpDocument2 pages793C Truck Electrical System: Aty1-UpGilvan JuniorNo ratings yet

- 5230B Front Shovel and Mass Excavator Electrical System: Machine Harness Connector and Component LocationsDocument2 pages5230B Front Shovel and Mass Excavator Electrical System: Machine Harness Connector and Component LocationsGilvan JuniorNo ratings yet

- 769D Truck & 771D Quarry Truck Electrical System: Machine Harness Connector and Component LocationsDocument2 pages769D Truck & 771D Quarry Truck Electrical System: Machine Harness Connector and Component LocationsGilvan JuniorNo ratings yet

- 3500B Engine For Marine Auxiliary Power Electrical System: Component LocationsDocument2 pages3500B Engine For Marine Auxiliary Power Electrical System: Component LocationsGilvan JuniorNo ratings yet

- 3500B Engine For Electrical Power Conversion Generation (EPG) With SwitchgearDocument2 pages3500B Engine For Electrical Power Conversion Generation (EPG) With SwitchgearGilvan JuniorNo ratings yet

- 3500B For Marine Propulsion Electrical System: Component LocationsDocument2 pages3500B For Marine Propulsion Electrical System: Component LocationsGilvan JuniorNo ratings yet

- 657E Wheel Tractor-Scraper Electrical System: Tractor: 90Z225-UP 91Z461-UP Scraper: 86Z428-UP 6MB168-UPDocument2 pages657E Wheel Tractor-Scraper Electrical System: Tractor: 90Z225-UP 91Z461-UP Scraper: 86Z428-UP 6MB168-UPGilvan JuniorNo ratings yet

- 3500B Engine For Electrical Power Modular Control Panel (EMCP) Generation (EPG) With ElectronicDocument2 pages3500B Engine For Electrical Power Modular Control Panel (EMCP) Generation (EPG) With ElectronicGilvan JuniorNo ratings yet

- Granato 2018Document41 pagesGranato 2018An Bùi ĐứcNo ratings yet

- Spe14 PDFDocument12 pagesSpe14 PDFamarolimaNo ratings yet

- Csi Solar Ice MakerDocument18 pagesCsi Solar Ice Makerdead satanNo ratings yet

- CM011L - Lab ReportDocument11 pagesCM011L - Lab ReportwahahahhasiafiadgNo ratings yet

- Tomahawk Futura ManualDocument40 pagesTomahawk Futura ManualJORGE CONTRERAS100% (1)

- Direct and Indirect Speech: Instructor: Usama MuneerDocument26 pagesDirect and Indirect Speech: Instructor: Usama MuneerDoctor Muhammad JunaidNo ratings yet

- B. Hormones, General Principles by D SiwaleDocument73 pagesB. Hormones, General Principles by D SiwaleDonald SiwaleNo ratings yet

- Maths Lesson PlanDocument3 pagesMaths Lesson Planapi-339651962100% (1)

- 20CM004 Dsa MP ReportDocument6 pages20CM004 Dsa MP ReportChaitanya ParaskarNo ratings yet

- SSRN-id2580502 Kuriakose RobbinsDocument28 pagesSSRN-id2580502 Kuriakose Robbinskkarloss8No ratings yet

- Analisis Pengaruh Teknologi Informasi Dan Inovasi Terhadap Keunggulan Bersaing Untuk Meningkatkan Kinerja OrganisasiDocument17 pagesAnalisis Pengaruh Teknologi Informasi Dan Inovasi Terhadap Keunggulan Bersaing Untuk Meningkatkan Kinerja OrganisasiYan OfkNo ratings yet

- Log Cat 1676291731424Document2,093 pagesLog Cat 1676291731424Muhammad Ikhlas ridhoiNo ratings yet

- Neuro Ophtha Aillen Abines, MD: History and Physical ExaminationDocument2 pagesNeuro Ophtha Aillen Abines, MD: History and Physical ExaminationPrincess Cate MercadoNo ratings yet

- Brake System: SectionDocument54 pagesBrake System: Sectionwilder0l0pezNo ratings yet

- DMS Chapter 4 PL-SOL Programming NotesDocument39 pagesDMS Chapter 4 PL-SOL Programming NotesTanishq PatilNo ratings yet

- Pages From Operating Systems Design 19CS2106S Home Assignment CODocument1 pagePages From Operating Systems Design 19CS2106S Home Assignment COVISHNU TEJA RAYALACHERUVUNo ratings yet

- ZH40Document5 pagesZH40Игорь КулешNo ratings yet

- Shaft RollDocument1 pageShaft Rollindramora2003No ratings yet

- Fa e Ka 3 GBDocument6 pagesFa e Ka 3 GBGabrielito PachacamaNo ratings yet

- Dynamic LUN AddressingDocument22 pagesDynamic LUN AddressingEnrico Ciarma100% (1)

- Epro - System III MBDocument2 pagesEpro - System III MBBaugh Graphic DesignNo ratings yet

- Lab 345Document22 pagesLab 345Nadhira ShazlynNo ratings yet