Professional Documents

Culture Documents

Black Pepper Extract (Pieperine 5-6%) : Cambridge Commodities

Uploaded by

TanChantreaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Black Pepper Extract (Pieperine 5-6%) : Cambridge Commodities

Uploaded by

TanChantreaCopyright:

Available Formats

Black Pepper Extract (Pieperine 5-6%)

Cambridge Commodities Chemwatch Hazard Alert Code: 2

Part Number: P02102 Issue Date: 09/02/2023

Version No: 2.2 Print Date: 25/12/2023

Safety data sheet according to REACH Regulation (EC) No 1907/2006, as amended by UK REACH Regulations SI 2019/758 S.REACH.GB.EN

SECTION 1 Identification of the substance / mixture and of the company / undertaking

1.1. Product Identifier

Product name Black Pepper Extract (Pieperine 5-6%)

Chemical Name Not Applicable

Synonyms Not Available

Proper shipping name ENVIRONMENTALLY HAZARDOUS SUBSTANCE, SOLID, N.O.S. (contains piperine)

Chemical formula Not Applicable

Other means of

P02102

identification

1.2. Relevant identified uses of the substance or mixture and uses advised against

Relevant identified uses Therapeutic or pharmacologically-active agent.

Uses advised against No specific uses advised against are identified.

1.3. Details of the manufacturer or supplier of the safety data sheet

Registered company name Cambridge Commodities

Address Lancaster Way Business Park, Ely, Cambridgeshire Cambridgeshire CB6 3NX United Kingdom

Telephone +44 1353 667258

Fax Not Available

Website Not Available

Email enquiries@cambridgecommodities.com

1.4. Emergency telephone number

Association / Organisation Not Available

Emergency telephone

Not Available

numbers

Product code: P02102 Version No: 2.2 Page 1 of 25

S.REACH.GB.EN Lancaster Way Business Park

Safety Data Sheet (Conforms to Annex II of REACH (1907/2006) - Regulation 2020/878) Ely, Cambridgeshire, CB6 3NX, UK.

Chemwatch: 9-685419 +44 (0) 1353 667258

Issue Date: 09/02/2023 info@c-c-l.com

Print Date: 25/12/2023 www.c-c-l.com

Other emergency

Not Available

telephone numbers

SECTION 2 Hazards identification

2.1. Classification of the substance or mixture

Classified according to

GB-CLP Regulation, UK SI H317 - Sensitisation (Skin) Category 1, H361f - Reproductive Toxicity Category 2, H412 - Hazardous to the Aquatic Environment

2019/720 and UK SI Long-Term Hazard Category 3

2020/1567 [1]

Legend: 1. Classified by Chemwatch; 2. Classification drawn from GB-CLP Regulation, UK SI 2019/720 and UK SI 2020/1567

2.2. Label elements

Hazard pictogram(s)

Signal word Warning

Hazard statement(s)

H317 May cause an allergic skin reaction.

H361f Suspected of damaging fertility.

H412 Harmful to aquatic life with long lasting effects.

Supplementary statement(s)

Not Applicable

Precautionary statement(s) Prevention

P201 Obtain special instructions before use.

P280 Wear protective gloves and protective clothing.

P261 Avoid breathing dust/fumes.

P273 Avoid release to the environment.

P272 Contaminated work clothing should not be allowed out of the workplace.

Precautionary statement(s) Response

P308+P313 IF exposed or concerned: Get medical advice/ attention.

P302+P352 IF ON SKIN: Wash with plenty of water and soap.

P333+P313 If skin irritation or rash occurs: Get medical advice/attention.

Product code: P02102 Version No: 2.2 Page 2 of 25

S.REACH.GB.EN Lancaster Way Business Park

Safety Data Sheet (Conforms to Annex II of REACH (1907/2006) - Regulation 2020/878) Ely, Cambridgeshire, CB6 3NX, UK.

Chemwatch: 9-685419 +44 (0) 1353 667258

Issue Date: 09/02/2023 info@c-c-l.com

Print Date: 25/12/2023 www.c-c-l.com

P362+P364 Take off contaminated clothing and wash it before reuse.

Precautionary statement(s) Storage

P405 Store locked up.

Precautionary statement(s) Disposal

P501 Dispose of contents/container to authorised hazardous or special waste collection point in accordance with any local regulation.

2.3. Other hazards

Ingestion may produce health damage*.

Cumulative effects may result following exposure*.

Limited evidence of a carcinogenic effect*.

REACH - Art.57-59: The mixture does not contain Substances of Very High Concern (SVHC) at the SDS print date.

SECTION 3 Composition / information on ingredients

3.1.Substances

See 'Composition on ingredients' in Section 3.2

3.2.Mixtures

1. CAS No

2.EC No Classified according to GB-CLP Regulation, UK SI SCL / Nanoform Particle

%[weight] Name

3.Index No 2019/720 and UK SI 2020/1567 M-Factor Characteristics

4.REACH No

1. 94-62-2 Acute Toxicity (Oral) Category 4, Sensitisation (Skin)

2.202-348-0 Category 1, Reproductive Toxicity Category 2, Not

5-6 piperine Not Available

3.Not Available Hazardous to the Aquatic Environment Long-Term Available

4.Not Available Hazard Category 2; H302, H317, H361f, H411 [1]

1. 9050-36-6

2.232-940-4 Not

15-20 maltodextrin Not Classified [1] Not Available

3.Not Available Available

4.Not Available

1. Not Available

2.Not Available black pepper Not

70-74 Not Classified [1] Not Available

3.Not Available extract Available

4.Not Available

Legend: 1. Classified by Chemwatch; 2. Classification drawn from GB-CLP Regulation, UK SI 2019/720 and UK SI 2020/1567; 3.

Classification drawn from C&L; * EU IOELVs available; [e] Substance identified as having endocrine disrupting properties

SECTION 4 First aid measures

Product code: P02102 Version No: 2.2 Page 3 of 25

S.REACH.GB.EN Lancaster Way Business Park

Safety Data Sheet (Conforms to Annex II of REACH (1907/2006) - Regulation 2020/878) Ely, Cambridgeshire, CB6 3NX, UK.

Chemwatch: 9-685419 +44 (0) 1353 667258

Issue Date: 09/02/2023 info@c-c-l.com

Print Date: 25/12/2023 www.c-c-l.com

4.1. Description of first aid measures

If this product comes in contact with eyes:

Wash out immediately with water.

Eye Contact

If irritation continues, seek medical attention.

Removal of contact lenses after an eye injury should only be undertaken by skilled personnel.

If skin contact occurs:

Immediately remove all contaminated clothing, including footwear.

Skin Contact

Flush skin and hair with running water (and soap if available).

Seek medical attention in event of irritation.

If fumes, aerosols or combustion products are inhaled remove from contaminated area.

Inhalation

Other measures are usually unnecessary.

Immediately give a glass of water.

Ingestion

First aid is not generally required. If in doubt, contact a Poisons Information Centre or a doctor.

4.2 Most important symptoms and effects, both acute and delayed

See Section 11

4.3. Indication of any immediate medical attention and special treatment needed

Treat symptomatically.

SECTION 5 Firefighting measures

5.1. Extinguishing media

Foam.

Dry chemical powder.

BCF (where regulations permit).

Carbon dioxide.

Water spray or fog - Large fires only.

5.2. Special hazards arising from the substrate or mixture

Avoid contamination with oxidising agents i.e. nitrates, oxidising acids, chlorine bleaches, pool chlorine etc. as ignition may

Fire Incompatibility

result

5.3. Advice for firefighters

Alert Fire Brigade and tell them location and nature of hazard.

Wear breathing apparatus plus protective gloves.

Prevent, by any means available, spillage from entering drains or water courses.

Use water delivered as a fine spray to control fire and cool adjacent area.

Fire Fighting

DO NOT approach containers suspected to be hot.

Cool fire exposed containers with water spray from a protected location.

If safe to do so, remove containers from path of fire.

Equipment should be thoroughly decontaminated after use.

For starch/ air mixtures

Starch is a class St1 dust at normal moisture level:

Fire/Explosion Hazard Minimum Ignition Temperature (MIE): >30 mJ at normal moisture level

Pmax 9.5 Bar

Kst 170 bar.m/s

Product code: P02102 Version No: 2.2 Page 4 of 25

S.REACH.GB.EN Lancaster Way Business Park

Safety Data Sheet (Conforms to Annex II of REACH (1907/2006) - Regulation 2020/878) Ely, Cambridgeshire, CB6 3NX, UK.

Chemwatch: 9-685419 +44 (0) 1353 667258

Issue Date: 09/02/2023 info@c-c-l.com

Print Date: 25/12/2023 www.c-c-l.com

Layer Ignition Temperature: >450 deg C

Autoignition Temperature: 170 deg C (above this temperature starch will self-heat)

Dust Explosion Hazard Class 1

Dusts fall into one of three Kst* classes. Class 1 dusts; Kst 1-200 m3/sec; Class 2 dusts; 201-299 m3/sec. Class 3 dusts; Kst 300

or more. Most agricultural dusts (grains, flour etc.) are Class 1; pharmaceuticals and other speciality chemicals are typically

Class 1 or 2; most unoxidised metallic dusts are Class 3. The higher the Kst, the more energetically the dust will burn and the

greater is the explosion risk and the greater is the speed of the explosion..

Standard test conditions, used to derive the Kst, are representative of industrial conditions, but do not represent and absolute

worst case. Increased levels of turbulence increase the speed of the explosion dramatically.

* Kst - a normalised expression of the burning dust pressure rise rate over time.

Dusts with Minimum Ignition Energies (MIEs) ranging between 20 and 100 mJ may be sensitive to ignition. They require that:

· plant is grounded

· personnel might also need to be grounded

· the use of high resistivity materials (such as plastics) should be restricted or avoided during handling or in

packaging

The majority of ignition accidents occur within or below this range.

The MIE of a dust/air mix depends on the particle size the water content and the temperature of the dust. The finer and the dryer

the dust the lower the MIE. Higher temperatures cause lower MIE and an increased risk of dust explosion.

Quoted values for MIE generally are only representative. Characteristics may change depending upon the process and

conditions of use or any changes made to the dust during use, including further grinding or mixing with other products. In order to

obtain more specific data for dust, as used, it is recommended that further characterisation testing.is performed.

Combustible solid which burns but propagates flame with difficulty; it is estimated that most organic dusts are combustible

(circa 70%) - according to the circumstances under which the combustion process occurs, such materials may cause fires

and / or dust explosions.

Organic powders when finely divided over a range of concentrations regardless of particulate size or shape and suspended in

air or some other oxidizing medium may form explosive dust-air mixtures and result in a fire or dust explosion (including

secondary explosions).

Avoid generating dust, particularly clouds of dust in a confined or unventilated space as dusts may form an explosive mixture

with air, and any source of ignition, i.e. flame or spark, will cause fire or explosion. Dust clouds generated by the fine grinding

of the solid are a particular hazard; accumulations of fine dust (420 micron or less) may burn rapidly and fiercely if ignited -

particles exceeding this limit will generally not form flammable dust clouds; once initiated, however, larger particles up to 1400

microns diameter will contribute to the propagation of an explosion.

In the same way as gases and vapours, dusts in the form of a cloud are only ignitable over a range of concentrations; in

principle, the concepts of lower explosive limit (LEL) and upper explosive limit (UEL) are applicable to dust clouds but only

the LEL is of practical use; - this is because of the inherent difficulty of achieving homogeneous dust clouds at high

temperatures (for dusts the LEL is often called the "Minimum Explosible Concentration", MEC).

When processed with flammable liquids/vapors/mists,ignitable (hybrid) mixtures may be formed with combustible dusts.

Ignitable mixtures will increase the rate of explosion pressure rise and the Minimum Ignition Energy (the minimum amount of

energy required to ignite dust clouds - MIE) will be lower than the pure dust in air mixture. The Lower Explosive Limit (LEL) of

the vapour/dust mixture will be lower than the individual LELs for the vapors/mists or dusts.

A dust explosion may release of large quantities of gaseous products; this in turn creates a subsequent pressure rise of

explosive force capable of damaging plant and buildings and injuring people.

Usually the initial or primary explosion takes place in a confined space such as plant or machinery, and can be of sufficient

force to damage or rupture the plant. If the shock wave from the primary explosion enters the surrounding area, it will disturb

any settled dust layers, forming a second dust cloud, and often initiate a much larger secondary explosion. All large scale

explosions have resulted from chain reactions of this type.

Dry dust can be charged electrostatically by turbulence, pneumatic transport, pouring, in exhaust ducts and during transport.

Build-up of electrostatic charge may be prevented by bonding and grounding.

Powder handling equipment such as dust collectors, dryers and mills may require additional protection measures such as

explosion venting.

All movable parts coming in contact with this material should have a speed of less than 1-meter/sec.

A sudden release of statically charged materials from storage or process equipment, particularly at elevated temperatures

Product code: P02102 Version No: 2.2 Page 5 of 25

S.REACH.GB.EN Lancaster Way Business Park

Safety Data Sheet (Conforms to Annex II of REACH (1907/2006) - Regulation 2020/878) Ely, Cambridgeshire, CB6 3NX, UK.

Chemwatch: 9-685419 +44 (0) 1353 667258

Issue Date: 09/02/2023 info@c-c-l.com

Print Date: 25/12/2023 www.c-c-l.com

and/ or pressure, may result in ignition especially in the absence of an apparent ignition source.

One important effect of the particulate nature of powders is that the surface area and surface structure (and often moisture

content) can vary widely from sample to sample, depending of how the powder was manufactured and handled; this means

that it is virtually impossible to use flammability data published in the literature for dusts (in contrast to that published for

gases and vapours).

Autoignition temperatures are often quoted for dust clouds (minimum ignition temperature (MIT)) and dust layers (layer

ignition temperature (LIT)); LIT generally falls as the thickness of the layer increases.

Combustion products include:

,

carbon monoxide (CO)

,

carbon dioxide (CO2)

,

other pyrolysis products typical of burning organic material.

SECTION 6 Accidental release measures

6.1. Personal precautions, protective equipment and emergency procedures

See section 8

6.2. Environmental precautions

See section 12

6.3. Methods and material for containment and cleaning up

Environmental hazard - contain spillage.

Clean up waste regularly and abnormal spills immediately.

Avoid breathing dust and contact with skin and eyes.

Wear protective clothing, gloves, safety glasses and dust respirator.

Use dry clean up procedures and avoid generating dust.

Minor Spills

Vacuum up or sweep up. NOTE: Vacuum cleaner must be fitted with an exhaust micro filter (H-Class HEPA type) (consider

explosion-proof machines designed to be grounded during storage and use). H-Class HEPA filtered industrial vacuum

cleaners should NOT be used on wet materials or surfaces.

Dampen with water to prevent dusting before sweeping.

Place in suitable containers for disposal.

Environmental hazard - contain spillage.

Moderate hazard.

CAUTION: Advise personnel in area.

Alert Emergency Services and tell them location and nature of hazard.

Control personal contact by wearing protective clothing.

Major Spills Prevent, by any means available, spillage from entering drains or water courses.

Recover product wherever possible.

IF DRY: Use dry clean up procedures and avoid generating dust. Collect residues and place in sealed plastic bags or other

containers for disposal. IF WET: Vacuum/shovel up and place in labelled containers for disposal.

ALWAYS: Wash area down with large amounts of water and prevent runoff into drains.

If contamination of drains or waterways occurs, advise Emergency Services.

6.4. Reference to other sections

Personal Protective Equipment advice is contained in Section 8 of the SDS.

Product code: P02102 Version No: 2.2 Page 6 of 25

S.REACH.GB.EN Lancaster Way Business Park

Safety Data Sheet (Conforms to Annex II of REACH (1907/2006) - Regulation 2020/878) Ely, Cambridgeshire, CB6 3NX, UK.

Chemwatch: 9-685419 +44 (0) 1353 667258

Issue Date: 09/02/2023 info@c-c-l.com

Print Date: 25/12/2023 www.c-c-l.com

SECTION 7 Handling and storage

7.1. Precautions for safe handling

In general personnel handling this material and all conducting equipment should be electrically earthed or grounded.

Consideration should be given to avoiding the use of insulating plastics.

Bulk bags (FIBC) used to contain this material should be Type C or Type D. Type C bags must be electrically grounded before

powder is charged to or discharged from the bag.

Bag filters used to scavenge dust from material handling processes should be conductive and electrically grounded during use.

If metal or fibre drums are used to contain this product, make certain that the metal parts are bonded to the filling equipment and

grounded.This material can become readily charged in most/ many operations.

Avoid all personal contact, including inhalation.

Wear protective clothing when risk of exposure occurs.

Use in a well-ventilated area.

Prevent concentration in hollows and sumps.

DO NOT enter confined spaces until atmosphere has been checked.

DO NOT allow material to contact humans, exposed food or food utensils.

Avoid contact with incompatible materials.

When handling, DO NOT eat, drink or smoke.

Keep containers securely sealed when not in use.

Avoid physical damage to containers.

Always wash hands with soap and water after handling.

Work clothes should be laundered separately. Launder contaminated clothing before re-use.

Use good occupational work practice.

Observe manufacturer's storage and handling recommendations contained within this SDS.

Atmosphere should be regularly checked against established exposure standards to ensure safe working conditions are

maintained.

Organic powders when finely divided over a range of concentrations regardless of particulate size or shape and suspended in

Safe handling

air or some other oxidizing medium may form explosive dust-air mixtures and result in a fire or dust explosion (including

secondary explosions)

Minimise airborne dust and eliminate all ignition sources. Keep away from heat, hot surfaces, sparks, and flame.

Establish good housekeeping practices.

Remove dust accumulations on a regular basis by vacuuming or gentle sweeping to avoid creating dust clouds.

Use continuous suction at points of dust generation to capture and minimise the accumulation of dusts. Particular attention

should be given to overhead and hidden horizontal surfaces to minimise the probability of a "secondary" explosion. According

to NFPA Standard 654, dust layers 1/32 in.(0.8 mm) thick can be sufficient to warrant immediate cleaning of the area.

Do not use air hoses for cleaning.

Minimise dry sweeping to avoid generation of dust clouds. Vacuum dust-accumulating surfaces and remove to a chemical

disposal area. Vacuums with explosion-proof motors should be used.

Control sources of static electricity. Dusts or their packages may accumulate static charges, and static discharge can be a

source of ignition.

Solids handling systems must be designed in accordance with applicable standards (e.g. NFPA including 654 and 77) and

other national guidance.

Do not empty directly into flammable solvents or in the presence of flammable vapors.

The operator, the packaging container and all equipment must be grounded with electrical bonding and grounding systems.

Plastic bags and plastics cannot be grounded, and antistatic bags do not completely protect against development of static

charges.

Empty containers may contain residual dust which has the potential to accumulate following settling. Such dusts may explode in

the presence of an appropriate ignition source.

Do NOT cut, drill, grind or weld such containers.

In addition ensure such activity is not performed near full, partially empty or empty containers without appropriate workplace

safety authorisation or permit.

Fire and explosion

See section 5

protection

Product code: P02102 Version No: 2.2 Page 7 of 25

S.REACH.GB.EN Lancaster Way Business Park

Safety Data Sheet (Conforms to Annex II of REACH (1907/2006) - Regulation 2020/878) Ely, Cambridgeshire, CB6 3NX, UK.

Chemwatch: 9-685419 +44 (0) 1353 667258

Issue Date: 09/02/2023 info@c-c-l.com

Print Date: 25/12/2023 www.c-c-l.com

Store in original containers.

Keep containers securely sealed.

Store in a cool, dry area protected from environmental extremes.

Store away from incompatible materials and foodstuff containers.

Protect containers against physical damage and check regularly for leaks.

Other information Observe manufacturer's storage and handling recommendations contained within this SDS.

For major quantities:

Consider storage in bunded areas - ensure storage areas are isolated from sources of community water (including

stormwater, ground water, lakes and streams}.

Ensure that accidental discharge to air or water is the subject of a contingency disaster management plan; this may require

consultation with local authorities.

7.2. Conditions for safe storage, including any incompatibilities

Glass container is suitable for laboratory quantities

Suitable container Polyethylene or polypropylene container.

Check all containers are clearly labelled and free from leaks.

Reducing sugar-based material.

Autooxidation of reducing sugars may produce up to 3000 ppm carbon monoxide under moderately alkaline conditions. High pH

aqueous solutions of saccharides (aldoses, ketoses) or polysaccharides based on these sugars may generate hazardous

atmospheres in confined spaces.

Reducing sugars contain an aldehyde or free hemiacetal in the open-chain form. Sugars with ketone groups in their open chain

form are capable of isomerising via a series of tautomeric shifts to produce an aldehyde group in solution. Therefore, ketone-

bearing sugars like fructose are considered reducing sugars but it is the isomer containing an aldehyde group which is reducing

since ketones cannot be oxidized without decomposition of the sugar.

Many disaccharides, like lactose and maltose, also have a reducing form, as one of the two units may have an open-chain form

Storage incompatibility

with an aldehyde group. However, sucrose and trehalose, in which the anomeric carbons of the two units are linked together, are

non-reducing disaccharides since neither of the rings is capable of opening.

In glucose polymers such as starch and starch-derivatives like glucose syrup, maltodextrin and dextrin the macromolecule begins

with a reducing sugar, a free aldehyde. More hydrolysed starch contains more reducing sugars. The percentage of reducing

sugars present in these starch derivatives is called dextrose equivalent (DE).

Dilute solutions of all sugars are subject to fermentation, either by yeast or by other microorganisms or enzymes derived from

these, producing gases which can pressurise and burst sealed containers.

Some microorganisms will produce hydrogen or methane, adding a fire and explosion hazard.

Avoid reaction with oxidising agents

Hazard categories in

accordance with

Not Available

Regulation (EC) No

1272/2008

Qualifying quantity

(tonnes) of dangerous

substances as referred to Not Available

in Article 3(10) for the

application of

7.3. Specific end use(s)

See section 1.2

SECTION 8 Exposure controls / personal protection

8.1. Control parameters

Product code: P02102 Version No: 2.2 Page 8 of 25

S.REACH.GB.EN Lancaster Way Business Park

Safety Data Sheet (Conforms to Annex II of REACH (1907/2006) - Regulation 2020/878) Ely, Cambridgeshire, CB6 3NX, UK.

Chemwatch: 9-685419 +44 (0) 1353 667258

Issue Date: 09/02/2023 info@c-c-l.com

Print Date: 25/12/2023 www.c-c-l.com

DNELs PNECs

Ingredient

Exposure Pattern Worker Compartment

Not Available Not Available Not Available

* Values for General Population

Occupational Exposure Limits (OEL)

INGREDIENT DATA

Source Ingredient Material name TWA STEL Peak Notes

Not Available Not Available Not Available Not Available Not Available Not Available Not Available

Not Applicable

Emergency Limits

Ingredient TEEL-1 TEEL-2 TEEL-3

Black Pepper Extract

Not Available Not Available Not Available

(Pieperine 5-6%)

Ingredient Original IDLH Revised IDLH

piperine Not Available Not Available

maltodextrin Not Available Not Available

black pepper extract Not Available Not Available

Occupational Exposure Banding

Ingredient Occupational Exposure Band Rating Occupational Exposure Band Limit

piperine E ≤ 0.01 mg/m³

Notes: Occupational exposure banding is a process of assigning chemicals into specific categories or bands based on a chemical's

potency and the adverse health outcomes associated with exposure. The output of this process is an occupational exposure

band (OEB), which corresponds to a range of exposure concentrations that are expected to protect worker health.

8.2. Exposure controls

Enclosed local exhaust ventilation is required at points of dust, fume or vapour generation.

HEPA terminated local exhaust ventilation should be considered at point of generation of dust, fumes or vapours.

Barrier protection or laminar flow cabinets should be considered for laboratory scale handling.

A fume hood or vented balance enclosure is recommended for weighing/ transferring quantities exceeding 500 mg.

When handling quantities up to 500 gram in either a standard laboratory with general dilution ventilation (e.g. 6-12 air changes

per hour) is preferred. Quantities up to 1 kilogram may require a designated laboratory using fume hood, biological safety

cabinet, or approved vented enclosures. Quantities exceeding 1 kilogram should be handled in a designated laboratory or

8.2.1. Appropriate containment laboratory using appropriate barrier/ containment technology.

engineering controls Manufacturing and pilot plant operations require barrier/ containment and direct coupling technologies.

Barrier/ containment technology and direct coupling (totally enclosed processes that create a barrier between the equipment and

the room) typically use double or split butterfly valves and hybrid unidirectional airflow/ local exhaust ventilation solutions (e.g.

powder containment booths). Glove bags, isolator glove box systems are optional. HEPA filtration of exhaust from dry product

handling areas is required.

Fume-hoods and other open-face containment devices are acceptable when face velocities of at least 1 m/s (200 feet/minute)

are achieved. Partitions, barriers, and other partial containment technologies are required to prevent migration of the material to

uncontrolled areas. For non-routine emergencies maximum local and general exhaust are necessary. Air contaminants

Product code: P02102 Version No: 2.2 Page 9 of 25

S.REACH.GB.EN Lancaster Way Business Park

Safety Data Sheet (Conforms to Annex II of REACH (1907/2006) - Regulation 2020/878) Ely, Cambridgeshire, CB6 3NX, UK.

Chemwatch: 9-685419 +44 (0) 1353 667258

Issue Date: 09/02/2023 info@c-c-l.com

Print Date: 25/12/2023 www.c-c-l.com

generated in the workplace possess varying "escape" velocities which, in turn, determine the "capture velocities" of fresh

circulating air required to effectively remove the contaminant.

Type of Contaminant: Air Speed:

0.25-0.5 m/s

solvent, vapours, etc. evaporating from tank (in still air)

(50-100 f/min.)

aerosols, fumes from pouring operations, intermittent container filling, low speed conveyer transfers 0.5-1 m/s (100-200

(released at low velocity into zone of active generation) f/min.)

direct spray, drum filling, conveyer loading, crusher dusts, gas discharge (active generation into zone 1-2.5 m/s (200-500

of rapid air motion) f/min.)

Within each range the appropriate value depends on:

Lower end of the range Upper end of the range

1: Room air currents minimal or favourable to capture 1: Disturbing room air currents

2: Contaminants of low toxicity or of nuisance value only. 2: Contaminants of high toxicity

3: Intermittent, low production. 3: High production, heavy use

4: Large hood or large air mass in motion 4: Small hood-local control only

Simple theory shows that air velocity falls rapidly with distance away from the opening of a simple extraction pipe. Velocity

generally decreases with the square of distance from the extraction point (in simple cases). Therefore the air speed at the

extraction point should be adjusted, accordingly, after reference to distance from the contaminating source. The air velocity at the

extraction fan, for example, should be a minimum of 1-2.5 m/s (200-500 f/min.) for extraction of gases discharged 2 meters

distant from the extraction point. Other mechanical considerations, producing performance deficits within the extraction

apparatus, make it essential that theoretical air velocities are multiplied by factors of 10 or more when extraction systems are

installed or used.

The need for respiratory protection should also be assessed where incidental or accidental exposure is anticipated: Dependent

on levels of contamination, PAPR, full face air purifying devices with P2 or P3 filters or air supplied respirators should be

evaluated.

The following protective devices are recommended where exposures exceed the recommended exposure control guidelines by

factors of:

10; high efficiency particulate (HEPA) filters or cartridges

10-25; loose-fitting (Tyvek or helmet type) HEPA powered-air purifying respirator.

25-50; a full face-piece negative pressure respirator with HEPA filters

50-100; tight-fitting, full face-piece HEPA PAPR

100-1000; a hood-shroud HEPA PAPR or full face-piece supplied air respirator operated in pressure demand or other positive

pressure mode.

Assess operations based upon available dust explosion information to determine the suitability of preventative or protective

systems as precautionary measures against possible dust explosions. If prevention is not possible, consider protection by use of

containment, venting or suppression of dust handling equipment. Where explosion venting is considered to be the most

appropriate method of protection, vent areas should preferably be calculated based on Kst rather than an St value. If nitrogen

purging is considered as the protective system, it must operate with an oxygen level below the limiting oxygen concentration. The

system should include an oxygen monitoring and shut-down facility in the event of excessive oxygen being detected.

The maximum surface temperature of enclosures potentially exposed to this material should be based on values obtained by

taking 2/3 of the minimum ignition temperature (MIE) of the dust cloud. The effect of dust layers should be reviewed.

An isolated (insulated) human body can readily produce electrostatic discharges in excess of 50 mJ, but have been recorded up

to 100 mJ.

8.2.2. Individual protection

measures, such as

personal protective

equipment

Product code: P02102 Version No: 2.2 Page 10 of 25

S.REACH.GB.EN Lancaster Way Business Park

Safety Data Sheet (Conforms to Annex II of REACH (1907/2006) - Regulation 2020/878) Ely, Cambridgeshire, CB6 3NX, UK.

Chemwatch: 9-685419 +44 (0) 1353 667258

Issue Date: 09/02/2023 info@c-c-l.com

Print Date: 25/12/2023 www.c-c-l.com

When handling very small quantities of the material eye protection may not be required.

For laboratory, larger scale or bulk handling or where regular exposure in an occupational setting occurs:

Chemical goggles. [AS/NZS 1337.1, EN166 or national equivalent]

Face shield. Full face shield may be required for supplementary but never for primary protection of eyes.

Contact lenses may pose a special hazard; soft contact lenses may absorb and concentrate irritants. A written policy

Eye and face protection document, describing the wearing of lenses or restrictions on use, should be created for each workplace or task. This should

include a review of lens absorption and adsorption for the class of chemicals in use and an account of injury experience.

Medical and first-aid personnel should be trained in their removal and suitable equipment should be readily available. In the

event of chemical exposure, begin eye irrigation immediately and remove contact lens as soon as practicable. Lens should

be removed at the first signs of eye redness or irritation - lens should be removed in a clean environment only after workers

have washed hands thoroughly. [CDC NIOSH Current Intelligence Bulletin 59].

Skin protection See Hand protection below

NOTE:

The material may produce skin sensitisation in predisposed individuals. Care must be taken, when removing gloves and other

protective equipment, to avoid all possible skin contact.

Contaminated leather items, such as shoes, belts and watch-bands should be removed and destroyed.

The selection of suitable gloves does not only depend on the material, but also on further marks of quality which vary from

manufacturer to manufacturer. Where the chemical is a preparation of several substances, the resistance of the glove material

can not be calculated in advance and has therefore to be checked prior to the application.

The exact break through time for substances has to be obtained from the manufacturer of the protective gloves and has to be

observed when making a final choice.

Personal hygiene is a key element of effective hand care. Gloves must only be worn on clean hands. After using gloves, hands

should be washed and dried thoroughly. Application of a non-perfumed moisturiser is recommended.

Suitability and durability of glove type is dependent on usage. Important factors in the selection of gloves include:

· frequency and duration of contact,

· chemical resistance of glove material,

· glove thickness and

· dexterity

Select gloves tested to a relevant standard (e.g. Europe EN 374, US F739, AS/NZS 2161.1 or national equivalent).

· When prolonged or frequently repeated contact may occur, a glove with a protection class of 5 or higher (breakthrough time

greater than 240 minutes according to EN 374, AS/NZS 2161.10.1 or national equivalent) is recommended.

· When only brief contact is expected, a glove with a protection class of 3 or higher (breakthrough time greater than 60 minutes

according to EN 374, AS/NZS 2161.10.1 or national equivalent) is recommended.

Hands/feet protection · Some glove polymer types are less affected by movement and this should be taken into account when considering gloves for

long-term use.

· Contaminated gloves should be replaced.

As defined in ASTM F-739-96 in any application, gloves are rated as:

· Excellent when breakthrough time > 480 min

· Good when breakthrough time > 20 min

· Fair when breakthrough time < 20 min

· Poor when glove material degrades

For general applications, gloves with a thickness typically greater than 0.35 mm, are recommended.

It should be emphasised that glove thickness is not necessarily a good predictor of glove resistance to a specific chemical, as the

permeation efficiency of the glove will be dependent on the exact composition of the glove material. Therefore, glove selection

should also be based on consideration of the task requirements and knowledge of breakthrough times.

Glove thickness may also vary depending on the glove manufacturer, the glove type and the glove model. Therefore, the

manufacturers technical data should always be taken into account to ensure selection of the most appropriate glove for the task.

Note: Depending on the activity being conducted, gloves of varying thickness may be required for specific tasks. For example:

· Thinner gloves (down to 0.1 mm or less) may be required where a high degree of manual dexterity is needed. However, these

gloves are only likely to give short duration protection and would normally be just for single use applications, then disposed of.

· Thicker gloves (up to 3 mm or more) may be required where there is a mechanical (as well as a chemical) risk i.e. where there

is abrasion or puncture potential

Gloves must only be worn on clean hands. After using gloves, hands should be washed and dried thoroughly. Application of a

non-perfumed moisturiser is recommended.

Product code: P02102 Version No: 2.2 Page 11 of 25

S.REACH.GB.EN Lancaster Way Business Park

Safety Data Sheet (Conforms to Annex II of REACH (1907/2006) - Regulation 2020/878) Ely, Cambridgeshire, CB6 3NX, UK.

Chemwatch: 9-685419 +44 (0) 1353 667258

Issue Date: 09/02/2023 info@c-c-l.com

Print Date: 25/12/2023 www.c-c-l.com

Rubber gloves (nitrile or low-protein, powder-free latex, latex/ nitrile). Employees allergic to latex gloves should use nitrile

gloves in preference.

Double gloving should be considered.

PVC gloves.

Change gloves frequently and when contaminated, punctured or torn.

Wash hands immediately after removing gloves.

Protective shoe covers. [AS/NZS 2210]

Head covering.

Experience indicates that the following polymers are suitable as glove materials for protection against undissolved, dry solids,

where abrasive particles are not present.

polychloroprene.

nitrile rubber.

butyl rubber.

fluorocaoutchouc.

polyvinyl chloride.

Gloves should be examined for wear and/ or degradation constantly.

Body protection See Other protection below

For quantities up to 500 grams a laboratory coat may be suitable.

For quantities up to 1 kilogram a disposable laboratory coat or coverall of low permeability is recommended. Coveralls should

be buttoned at collar and cuffs.

For quantities over 1 kilogram and manufacturing operations, wear disposable coverall of low permeability and disposable

shoe covers.

Other protection

For manufacturing operations, air-supplied full body suits may be required for the provision of advanced respiratory

protection.

Eye wash unit.

Ensure there is ready access to an emergency shower.

For Emergencies: Vinyl suit

Respiratory protection

Type -P Filter of sufficient capacity. (AS/NZS 1716 & 1715, EN 143:2000 & 149:2001, ANSI Z88 or national equivalent)

Required Minimum Protection Factor Half-Face Respirator Full-Face Respirator Powered Air Respirator

P1 - PAPR-P1

up to 10 x ES

Air-line* - -

up to 50 x ES Air-line** P2 PAPR-P2

up to 100 x ES - P3 -

Air-line* -

100+ x ES - Air-line** PAPR-P3

* - Negative pressure demand ** - Continuous flow

A(All classes) = Organic vapours, B AUS or B1 = Acid gasses, B2 = Acid gas or hydrogen cyanide(HCN), B3 = Acid gas or hydrogen cyanide(HCN), E = Sulfur

dioxide(SO2), G = Agricultural chemicals, K = Ammonia(NH3), Hg = Mercury, NO = Oxides of nitrogen, MB = Methyl bromide, AX = Low boiling point organic

compounds(below 65 degC)

· Respirators may be necessary when engineering and administrative controls do not adequately prevent exposures.

· The decision to use respiratory protection should be based on professional judgment that takes into account toxicity information, exposure measurement data,

and frequency and likelihood of the worker's exposure - ensure users are not subject to high thermal loads which may result in heat stress or distress due to

personal protective equipment (powered, positive flow, full face apparatus may be an option).

· Published occupational exposure limits, where they exist, will assist in determining the adequacy of the selected respiratory protection. These may be

government mandated or vendor recommended.

· Certified respirators will be useful for protecting workers from inhalation of particulates when properly selected and fit tested as part of a complete respiratory

Product code: P02102 Version No: 2.2 Page 12 of 25

S.REACH.GB.EN Lancaster Way Business Park

Safety Data Sheet (Conforms to Annex II of REACH (1907/2006) - Regulation 2020/878) Ely, Cambridgeshire, CB6 3NX, UK.

Chemwatch: 9-685419 +44 (0) 1353 667258

Issue Date: 09/02/2023 info@c-c-l.com

Print Date: 25/12/2023 www.c-c-l.com

protection program.

· Where protection from nuisance levels of dusts are desired, use type N95 (US) or type P1 (EN143) dust masks. Use respirators and components tested and

approved under appropriate government standards such as NIOSH (US) or CEN (EU)

· Use approved positive flow mask if significant quantities of dust becomes airborne.

· Try to avoid creating dust conditions.

Class P2 particulate filters are used for protection against mechanically and thermally generated particulates or both.

P2 is a respiratory filter rating under various international standards, Filters at least 94% of airborne particles

Suitable for:

· Relatively small particles generated by mechanical processes eg. grinding, cutting, sanding, drilling, sawing.

· Sub-micron thermally generated particles e.g. welding fumes, fertilizer and bushfire smoke.

· Biologically active airborne particles under specified infection control applications e.g. viruses, bacteria, COVID-19, SARS

8.2.3. Environmental exposure controls

See section 12

SECTION 9 Physical and chemical properties

9.1. Information on basic physical and chemical properties

Appearance Not Available

Relative density (Water =

Physical state Divided Solid|Powder Not Available

1)

Partition coefficient

Odour Not Available Not Available

n-octanol / water

Auto-ignition temperature

Odour threshold Not Available Not Available

(°C)

Decomposition

pH (as supplied) Not Available Not Available

temperature (°C)

Melting point / freezing

Not Available Viscosity (cSt) Not Available

point (°C)

Initial boiling point and

Not Available Molecular weight (g/mol) Not Available

boiling range (°C)

Flash point (°C) Not Available Taste Not Available

Evaporation rate Not Available Explosive properties Not Available

Flammability Not Available Oxidising properties Not Available

Surface Tension (dyn/cm

Upper Explosive Limit (%) Not Available Not Applicable

or mN/m)

Lower Explosive Limit (%) Not Available Volatile Component (%vol) Not Available

Vapour pressure (kPa) Not Available Gas group Not Available

Solubility in water Immiscible pH as a solution (1%) Not Available

Vapour density (Air = 1) Not Available VOC g/L Not Available

Nanoform Particle

Nanoform Solubility Not Available Not Available

Characteristics

Particle Size Not Available

Product code: P02102 Version No: 2.2 Page 13 of 25

S.REACH.GB.EN Lancaster Way Business Park

Safety Data Sheet (Conforms to Annex II of REACH (1907/2006) - Regulation 2020/878) Ely, Cambridgeshire, CB6 3NX, UK.

Chemwatch: 9-685419 +44 (0) 1353 667258

Issue Date: 09/02/2023 info@c-c-l.com

Print Date: 25/12/2023 www.c-c-l.com

9.2. Other information

Not Available

SECTION 10 Stability and reactivity

10.1.Reactivity See section 7.2

Unstable in the presence of incompatible materials.

10.2. Chemical stability Product is considered stable.

Hazardous polymerisation will not occur.

10.3. Possibility of

See section 7.2

hazardous reactions

10.4. Conditions to avoid See section 7.2

10.5. Incompatible

See section 7.2

materials

10.6. Hazardous

See section 5.3

decomposition products

SECTION 11 Toxicological information

11.1. Information on toxicological effects

The material is not thought to produce adverse health effects or irritation of the respiratory tract (as classified by EC Directives

using animal models). Nevertheless, good hygiene practice requires that exposure be kept to a minimum and that suitable control

measures be used in an occupational setting.

The LD50 for inhalation of the methylenedioxyphenol synergist, piperonyl butoxide ( PBO). by rats is greater than 5.9 g/k.

Inhalation of large amounts of PBO may cause tearing, salivation, labored breathing, accumulation of fluids in the lungs, and may

be linked to respiratory problems, including asthma.

Inhaled

Exposure to high concentrations of PBO vapour may cause asthma, inflammation of the nose and mucous membrane irritation.

Persons with impaired respiratory function, airway diseases and conditions such as emphysema or chronic bronchitis, may incur

further disability if excessive concentrations of particulate are inhaled.

If prior damage to the circulatory or nervous systems has occurred or if kidney damage has been sustained, proper screenings

should be conducted on individuals who may be exposed to further risk if handling and use of the material result in excessive

exposures.

Starch is generally of low toxicity. An abnormal craving for starch (amylophagia) during pregnancy has been recognized in certain

areas.

Studies suggest that by interfering with the metabolism of hormones, methylenedioxyphenol synergists such as the piperonyls

(as piperonyl butoxide - PBO) may damage humeral organs such as the thyroid, adrenal, and pituitary glands. PBO has a low to

moderate toxicity based on short-term laboratory animal studies. The acute oral LD50, or dose that kills half the test population,

was determined to be 6.15 g/kg for rats It is predicted that the oral lethal dose for a human is 5.15 g/kg, or between 1 pint and 1

quart for a 150 lb person. Symptoms caused by ingestion of PBO in large doses include nausea, cramps, vomiting, and diarrhea.

Overdoses of PBO have been shown to cause hyperexcitibility, unsteadiness, coma, seizures, and brain damage in animals.

Ingestion Laboratory animals exposed to single, large oral doses exhibit anorexia, vomiting, diarrhoea, unsteadiness, rough coat, watery

eyes, irritability, prostration, haemorrhagic enteritis, inanition, pulmonary haemorrhage, mild central system depression, bloody

discharge from eyes and nose, liver damage, coma and death. Onset may be as early as 20 minutes after dosing and death may

be delayed for a week. Most rat deaths in studies are attributed to hemorrhages in the digestive tract, particularly the large

intestine. Acute exposure in animals has also triggered hepatic (liver) changes and injury, anemia and loss of appetite, as well as

changes in the kidneys, nasal bleeding, loss of muscle coordination, and abdominal swelling.

Methylenedioxybenzene synergists cause loss of appetite, vomiting, diarrhoea, inflamed bowel with bleeding, bleeding from the

lung, wasting and possible central depression.

The material has NOT been classified by EC Directives or other classification systems as "harmful by ingestion". This is because

Product code: P02102 Version No: 2.2 Page 14 of 25

S.REACH.GB.EN Lancaster Way Business Park

Safety Data Sheet (Conforms to Annex II of REACH (1907/2006) - Regulation 2020/878) Ely, Cambridgeshire, CB6 3NX, UK.

Chemwatch: 9-685419 +44 (0) 1353 667258

Issue Date: 09/02/2023 info@c-c-l.com

Print Date: 25/12/2023 www.c-c-l.com

of the lack of corroborating animal or human evidence.

The material is not thought to produce adverse health effects or skin irritation following contact (as classified by EC Directives

using animal models). Nevertheless, good hygiene practice requires that exposure be kept to a minimum and that suitable gloves

be used in an occupational setting.

Acute and repeated dermal (skin) contact with piperonyls (as piperonyl butoxide - PBO) has been shown to be slightly irritating,

but is not linked to long-term damage.

Skin Contact In one study a lethal dose in rabbits by dermal absorption was 200 mg/kg but this result is thought to be anachronistic. A dermal

application of PBO, at the rate of 1880 mg/kg as a 20% solution in dimethyl phthalate, produced hyperexcitability and convulsions

in rabbits.

Open cuts, abraded or irritated skin should not be exposed to this material

Entry into the blood-stream, through, for example, cuts, abrasions or lesions, may produce systemic injury with harmful effects.

Examine the skin prior to the use of the material and ensure that any external damage is suitably protected.

Although the material is not thought to be an irritant (as classified by EC Directives), direct contact with the eye may cause

transient discomfort characterised by tearing or conjunctival redness (as with windburn). Slight abrasive damage may also result.

Eye

Acute and repeated eye contact with piperonyls (as piperonyl butoxide - PBO) has been shown to be slightly irritating, but is not

linked to long-term damage.

Skin contact with the material is more likely to cause a sensitisation reaction in some persons compared to the general

population.

Ample evidence from experiments exists that there is a suspicion this material directly reduces fertility.

The primary effect of long-term exposure to methylenedioxyphenol insect synergists such as the piperonyls (such as piperonyl

butoxide - PBO) in animals is an increase in liver and thyroid weight, liver and kidney damage, and a decrease in body weight.

These symptoms were observed in a diet of 52.8 mg/kg or more a day in a chronic study with dogs.

PBO is a possible human carcinogen. Currently there is no data from accidental exposure available regarding its carcinogenicity

in humans; the only information is from animal studies. Several studies have shown that PBO treatment in rats causes an

increase in liver cancer at high doses. The incidence of hepatocellular carcinoma, in male and female rats given 2.4% piperonyl

butoxide was 80.0% and 57.7% respectively. Preneoplastic hepatic lesions such as nodular hyperplasia, cholangiofibrosis, and

modular hyperplasia were also seen.

Some studies have shown that PBO treatment in rats corresponds with a very slight increase in thyroid cancer.

Rats fed diets containing from 0.6 to 2.4% piperonyl butoxide for approximately two years showed dose-related decreases in

body weight. Roughened hair, lethargy, epistaxis, abdominal swelling, and decreased food consumption were observed at 2.4%.

All dose rates induced skin tumours after about 1 year. Cumulative mortality varied from around 15 to 50%. Caecal haemorrhage

was the cause of death. Dead rats with hepatic tumours were seen from week 74, but caecal haemorrhage or possible leukaemia

was the cause of death. At necroscopy in rats surviving to the end of the study, hepatocellular adenomas and carcinomas

occurred in both sexes in a dose-related manner. A dose-related increase in thrombocythemia was seen in male rats. The

authors * of this study concluded that the primary feature of chronic piperonyl-butoxide toxicity is hepatocarcinogenicity.

Chronic

It is generally accepted that PBO does not demonstrate any significant potential for mutagenicity (genetic damage) but debate

still exists.

PBO weakens the immune system by inhibiting lymphocyte response. Lymphocytes are a class of white blood cells that consume

potentially dangerous pathogens and release antibodies. Inhibiting lymphocyte response weakens the body's ability to defend

against foreign invaders. Preventing the breakdown of toxic chemicals, may exacerbate potentially toxic effects.

PBO has been shown to adversely affect a variety of reproductive functions. Two-generational laboratory studies on rats show

that litter weight and size are less for mothers exposed to high concentrations of PBO, and there is an increase in birth defects

and fetal death. In one study the difference in the average weight of PBO-exposed offspring immediately after birth is negligible,

but 7-14 days post-natal is significantly greater for those mothers that are exposed to PBO than for those that are not. The U.S.

EPA maintains that results for teratogenicity (the ability to produce birth defects) in animals have been mixed, and while some

studies suggest some teratogenicity, most do not. PBO may also interfere with sexual development because the enzymes it

inhibits are responsible not only for the breakdown of toxic chemicals but also for the metabolism of other compounds such as

steroids, which include the sex hormones. Rats exposed to PBO over the course of two years experience an atrophy of the

testes a decrease in weight of the seminal vesicles (sperm producing structures), and an increase in ovarian weights. There is no

evidence that PBO affects fertility.

Data has shown that PBO alone interferes with enzymes that maintain homeostasis of sodium and calcium in the brain and

nervous system, possibly affecting neural response. Additionally, it increases the neurotoxicity of other compounds. Despite this

data, EPA believes that these neurotoxic effects are slight and maintains that PBO poses no neurological risk.

Behavioral changes have been noted with PBO as well. In a laboratory experiment, exposed rats experience more trouble

Product code: P02102 Version No: 2.2 Page 15 of 25

S.REACH.GB.EN Lancaster Way Business Park

Safety Data Sheet (Conforms to Annex II of REACH (1907/2006) - Regulation 2020/878) Ely, Cambridgeshire, CB6 3NX, UK.

Chemwatch: 9-685419 +44 (0) 1353 667258

Issue Date: 09/02/2023 info@c-c-l.com

Print Date: 25/12/2023 www.c-c-l.com

navigating a maze than unexposed rats. The exposed rats travel longer distances and turned more frequently in the maze. PBO

also induces changes in olfactory behavior of the offspring of exposed mothers. Offspring of exposed mothers are less likely to

enter a compartment that smells like home than unexposed mothers. Exploratory behavior in mice increases as the dose of PBO

they were treated with increased. This data shows that PBO has the ability to affect behaviors in mammals.

Research on rats has found that PBO can cause intestinal ulcers and bleeding. Liver damage is common in studies,and kidney

damage has been found as well. Long-term ingestion of PBO causes anemia, a decrease in the amount of hemoglobin (oxygen-

transporting molecules) in blood, and increases the blood cholesterol level in rats. PBO can also damage the larynx, and there

have been reports that it can cause labored breathing, an accumulation of fluid in the lungs, nasal bleeding, abdominal swelling,

and loss of the ability to coordinate muscle movement. There has been a fair amount of investigation into the effects of dermal

contact with PBO since it is used as a topical agent for lice, but there has been no evidence of it causing any local or systemic

toxicity, and the amount of PBO absorbed from skin contact is characterized by some researchers as low.

ChemicalWatch Fact Sheet

Takahashi, O.,S. et al: Fundamental and Applied Toxicology: Vol 22., pp 293-303, Feb 1994

Some workers may develop chronic occupational dermatitis (generally mild) through the handling of starch products.

When starch is used as a lubricant in surgical gloves, small amounts, released into the patient during the course of surgery, have

resulted in granulomas and peritonitis.

Long term exposure to high dust concentrations may cause changes in lung function i.e. pneumoconiosis, caused by particles

less than 0.5 micron penetrating and remaining in the lung.

There has been some concern that this material can cause cancer or mutations but there is not enough data to make an

assessment.

Black Pepper Extract TOXICITY IRRITATION

(Pieperine 5-6%) Not Available Not Available

TOXICITY IRRITATION

piperine

Oral (Mouse) LD50; 430 mg/kg[2] Not Available

TOXICITY IRRITATION

maltodextrin

Not Available Not Available

TOXICITY IRRITATION

black pepper extract

Not Available Not Available

Legend: 1. Value obtained from Europe ECHA Registered Substances - Acute toxicity 2. Value obtained from manufacturer's SDS.

Unless otherwise specified data extracted from RTECS - Register of Toxic Effect of chemical Substances

Excitement, abortion, fetotoxicity recorded.

1,3-Benzodioxole derivatives are found widely in nature. Certain such derivatives such as as safrole bind to and inhibit

cytochrome P450. Cytochrome P450 enzymes function to metabolize potentially toxic compounds,

A lipophilic substituent placed para to the methylenedioxy group increases this activity, e.g. piperonyl butoxide . Safrole is of

PIPERINE further interest since it produces liver tumors in mice This toxicity is probably mediated via the propenyl side chain, either by

metabolism to 1-hydroxysafrole and the subsequent formation of a reactive ester derivative or by the direct formation of a

reactive epoxide. A particularly interesting example of the separation of two toxicities by structural modification is provided by

estragole which is a mouse liver carcinogen but does not inhibit hepatic cytochrome P450 Equally dramatic is the fact that

substitution of safrole with a methoxy group yields myristicin a reported hallucinogen derived from the nutmeg tree

MALTODEXTRIN No significant acute toxicological data identified in literature search.

Black Pepper Extract The following information refers to contact allergens as a group and may not be specific to this product.

(Pieperine 5-6%) & Contact allergies quickly manifest themselves as contact eczema, more rarely as urticaria or Quincke's oedema. The

PIPERINE pathogenesis of contact eczema involves a cell-mediated (T lymphocytes) immune reaction of the delayed type. Other allergic

Product code: P02102 Version No: 2.2 Page 16 of 25

S.REACH.GB.EN Lancaster Way Business Park

Safety Data Sheet (Conforms to Annex II of REACH (1907/2006) - Regulation 2020/878) Ely, Cambridgeshire, CB6 3NX, UK.

Chemwatch: 9-685419 +44 (0) 1353 667258

Issue Date: 09/02/2023 info@c-c-l.com

Print Date: 25/12/2023 www.c-c-l.com

skin reactions, e.g. contact urticaria, involve antibody-mediated immune reactions. The significance of the contact allergen is not

simply determined by its sensitisation potential: the distribution of the substance and the opportunities for contact with it are

equally important. A weakly sensitising substance which is widely distributed can be a more important allergen than one with

stronger sensitising potential with which few individuals come into contact. From a clinical point of view, substances are

noteworthy if they produce an allergic test reaction in more than 1% of the persons tested.

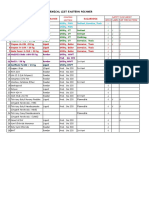

Acute Toxicity Carcinogenicity

Skin Irritation/Corrosion Reproductivity

Serious Eye

STOT - Single Exposure

Damage/Irritation

Respiratory or Skin

STOT - Repeated Exposure

sensitisation

Mutagenicity Aspiration Hazard

Legend: – Data either not available or does not fill the criteria for classification

– Data available to make classification

11.2 Information on other hazards

11.2.1. Endocrine disrupting properties

No evidence of endocrine disrupting properties were found in the current literature.

11.2.2. Other information

See Section 11.1

SECTION 12 Ecological information

12.1. Toxicity

Endpoint Test Duration (hr) Species Value Source

Black Pepper Extract

Not Not Not

(Pieperine 5-6%) Not Available Not Available

Available Available Available

Endpoint Test Duration (hr) Species Value Source

piperine

LC50 96h Fish 7.04-8.73mg/l 4

Endpoint Test Duration (hr) Species Value Source

maltodextrin Not Not Not

Not Available Not Available

Available Available Available

Endpoint Test Duration (hr) Species Value Source

black pepper extract Not Not Not

Not Available Not Available

Available Available Available

Legend: Extracted from 1. IUCLID Toxicity Data 2. Europe ECHA Registered Substances - Ecotoxicological Information - Aquatic Toxicity

4. US EPA, Ecotox database - Aquatic Toxicity Data 5. ECETOC Aquatic Hazard Assessment Data 6. NITE (Japan) -

Bioconcentration Data 7. METI (Japan) - Bioconcentration Data 8. Vendor Data

Harmful to aquatic organisms, may cause long-term adverse effects in the aquatic environment.

Product code: P02102 Version No: 2.2 Page 17 of 25

S.REACH.GB.EN Lancaster Way Business Park

Safety Data Sheet (Conforms to Annex II of REACH (1907/2006) - Regulation 2020/878) Ely, Cambridgeshire, CB6 3NX, UK.

Chemwatch: 9-685419 +44 (0) 1353 667258

Issue Date: 09/02/2023 info@c-c-l.com

Print Date: 25/12/2023 www.c-c-l.com

Do NOT allow product to come in contact with surface waters or to intertidal areas below the mean high water mark. Do not contaminate water when cleaning

equipment or disposing of equipment wash-waters.

Wastes resulting from use of the product must be disposed of on site or at approved waste sites.

For piperidine :log Kow : 0.84 Half-life (hr) air : 81.6Henry's atm m3 /mol: 4.45E-06Bioaccumulation : not signficant.

Environmental Fate: Terrestrial Fate - Piperidine is expected to have high mobility in soil. However, as this compound primarily exists in the cation form in the

environment it is likely to adsorb more strongly to soils containing organic carbon and clay than their neutral counterparts. While cations do not volatilise from

moist soil surfaces, Piperidine is expected to volatilise from dry soil surfaces and biodegradation may be an important environmental fate process in soil. Aquatic

fate: Piperidine is not expected to adsorb to suspended solids and sediments. Volatilisation from water surfaces is not expected to be an important fate process.

An estimated BCF of 3 suggests the potential for bioconcentration in aquatic organisms is low. Piperidine was found to degrade anaerobically via denitrification in

12-15 days by microbial action in freshwater sediments, estuarine sediments and activated sludge. Atmospheric Fate - Models indicate that piperidine is expected

to exist solely as a vapor in the ambient atmosphere, where it is degraded by reaction with photochemically-produced hydroxyl radicals; the half-life for this

reaction in air is estimated to be 4 hours.

Ecotoxicity: Daphnia magna LC50 948 h): 8.234 mg/l; Fish LC50 (96 h): fathead minnow (Pimephales promelas) 129.6 mg/l

For piperonyls (as piperonyl butoxide - PBO):

Environmental fate:

PBO is relatively short-lived in the environment and has a low to moderate potential to contaminate groundwater. One study found PBO in river water at a

concentration of 9.7 ug/L. It is rapidly degraded when exposed to sunlight, with a degradation half life of about one day in soil exposed to sunlight, and 14 days in

soil without sunlight. The rate of degradation is also affected by how much oxygen is in the environment (particularly in aquatic systems), moisture levels, and

application methods. There is less information available about PBO's persistence indoors, but one study found that PBO persisted for at least two weeks after a

cockroach treatment on toys and in dust in a kindergarten

Ecotoxicity:

Piperonyl is considered moderately toxic to fish, moderately to highly toxic to invertebrates (including crustaceans and insects), and highly toxic to amphibians. In

one study, concentrations of less than one part per million (ppm) killed water fleas, shrimp, and oysters. It is also very toxic to a common type of earthworm.

Ingested PBO has a low to very low toxicity in birds

Not only does PBO kill organisms, it is known to interfere with the reproduction of many types of wildlife at much lower concentrations than those required for

mortality. The bio-concentration potential for PBO is low but can be moderate in some aquatic organisms. PBO also inhibits the breakdown of toxic chemicals in

wildlife and the soil, increasing the concentrations of other, more acutely potent, pesticides.

Chemical Watch Fact Sheet

DO NOT discharge into sewer or waterways.

12.2. Persistence and degradability

Ingredient Persistence: Water/Soil Persistence: Air

piperine HIGH HIGH

12.3. Bioaccumulative potential

Ingredient Bioaccumulation

piperine LOW (LogKOW = 3.6889)

12.4. Mobility in soil

Ingredient Mobility

piperine LOW (KOC = 5867)

12.5. Results of PBT and vPvB assessment

P B T

Relevant available data Not Available Not Available Not Available

PBT

Product code: P02102 Version No: 2.2 Page 18 of 25

S.REACH.GB.EN Lancaster Way Business Park

Safety Data Sheet (Conforms to Annex II of REACH (1907/2006) - Regulation 2020/878) Ely, Cambridgeshire, CB6 3NX, UK.

Chemwatch: 9-685419 +44 (0) 1353 667258

Issue Date: 09/02/2023 info@c-c-l.com

Print Date: 25/12/2023 www.c-c-l.com

P B T

vPvB

PBT Criteria fulfilled? No

vPvB No

12.6. Endocrine disrupting properties

No evidence of endocrine disrupting properties were found in the current literature.

12.7. Other adverse effects

No evidence of ozone depleting properties were found in the current literature.

SECTION 13 Disposal considerations

13.1. Waste treatment methods

Containers may still present a chemical hazard/ danger when empty.

Return to supplier for reuse/ recycling if possible.

Otherwise:

If container can not be cleaned sufficiently well to ensure that residuals do not remain or if the container cannot be used to

store the same product, then puncture containers, to prevent re-use, and bury at an authorised landfill.

Where possible retain label warnings and SDS and observe all notices pertaining to the product.

Legislation addressing waste disposal requirements may differ by country, state and/ or territory. Each user must refer to laws

operating in their area. In some areas, certain wastes must be tracked.

A Hierarchy of Controls seems to be common - the user should investigate:

Product / Packaging Reduction

disposal Reuse

Recycling

Disposal (if all else fails)

This material may be recycled if unused, or if it has not been contaminated so as to make it unsuitable for its intended use. Shelf

life considerations should also be applied in making decisions of this type. Note that properties of a material may change in use,

and recycling or reuse may not always be appropriate. In most instances the supplier of the material should be consulted.

DO NOT allow wash water from cleaning or process equipment to enter drains.

It may be necessary to collect all wash water for treatment before disposal.

In all cases disposal to sewer may be subject to local laws and regulations and these should be considered first.

Where in doubt contact the responsible authority.

Waste treatment options Not Available

Sewage disposal options Not Available

SECTION 14 Transport information

Labels Required

Product code: P02102 Version No: 2.2 Page 19 of 25

S.REACH.GB.EN Lancaster Way Business Park

Safety Data Sheet (Conforms to Annex II of REACH (1907/2006) - Regulation 2020/878) Ely, Cambridgeshire, CB6 3NX, UK.

Chemwatch: 9-685419 +44 (0) 1353 667258

Issue Date: 09/02/2023 info@c-c-l.com

Print Date: 25/12/2023 www.c-c-l.com

Marine Pollutant NO

HAZCHEM 2Z

Land transport (ADR-RID)

14.1. UN number or ID

3077

number

14.2. UN proper shipping

ENVIRONMENTALLY HAZARDOUS SUBSTANCE, SOLID, N.O.S. (contains piperine)

name

14.3. Transport hazard Class 9

class(es) Subsidiary Hazard Not Applicable

14.4. Packing group III

14.5. Environmental

Not Applicable

hazard

Hazard identification (Kemler) 90

Classification code M7

14.6. Special precautions Hazard Label 9

for user Special provisions 274 335 375 601

Limited quantity 5 kg

Tunnel Restriction Code Not Applicable

Air transport (ICAO-IATA / DGR)

14.1. UN number 3077

14.2. UN proper shipping

Environmentally hazardous substance, solid, n.o.s. (contains piperine)

name

ICAO/IATA Class 9

14.3. Transport hazard

ICAO / IATA Subsidiary Hazard Not Applicable

class(es)

ERG Code 9L

14.4. Packing group III

14.5. Environmental

Not Applicable

hazard

Special provisions A97 A158 A179 A197 A215

Cargo Only Packing Instructions 956

Cargo Only Maximum Qty / Pack 400 kg

14.6. Special precautions

Passenger and Cargo Packing Instructions 956

for user

Passenger and Cargo Maximum Qty / Pack 400 kg

Passenger and Cargo Limited Quantity Packing Instructions Y956

Passenger and Cargo Limited Maximum Qty / Pack 30 kg G

Product code: P02102 Version No: 2.2 Page 20 of 25

S.REACH.GB.EN Lancaster Way Business Park

Safety Data Sheet (Conforms to Annex II of REACH (1907/2006) - Regulation 2020/878) Ely, Cambridgeshire, CB6 3NX, UK.

Chemwatch: 9-685419 +44 (0) 1353 667258

Issue Date: 09/02/2023 info@c-c-l.com

Print Date: 25/12/2023 www.c-c-l.com

Sea transport (IMDG-Code / GGVSee)

14.1. UN number 3077

14.2. UN proper shipping

ENVIRONMENTALLY HAZARDOUS SUBSTANCE, SOLID, N.O.S. (contains piperine)

name

14.3. Transport hazard IMDG Class 9

class(es) IMDG Subsidiary Hazard Not Applicable

14.4. Packing group III

14.5 Environmental hazard Not Applicable

EMS Number F-A , S-F

14.6. Special precautions

Special provisions 274 335 966 967 969

for user

Limited Quantities 5 kg

Inland waterways transport (ADN)

14.1. UN number 3077

14.2. UN proper shipping

ENVIRONMENTALLY HAZARDOUS SUBSTANCE, SOLID, N.O.S. (contains piperine)

name

14.3. Transport hazard

9 Not Applicable

class(es)

14.4. Packing group III

14.5. Environmental

Not Applicable

hazard

Classification code M7

Special provisions 274; 335; 375; 601

14.6. Special precautions

Limited quantity 5 kg

for user

Equipment required PP, A***

Fire cones number 0

14.7.1. Transport in bulk according to Annex II of MARPOL and the IBC code

Not Applicable

14.7.2. Transport in bulk in accordance with MARPOL Annex V and the IMSBC Code

Product name Group

piperine Not Available

maltodextrin Not Available

black pepper extract Not Available

14.7.3. Transport in bulk in accordance with the IGC Code

Product name Ship Type

Product code: P02102 Version No: 2.2 Page 21 of 25

S.REACH.GB.EN Lancaster Way Business Park

Safety Data Sheet (Conforms to Annex II of REACH (1907/2006) - Regulation 2020/878) Ely, Cambridgeshire, CB6 3NX, UK.

Chemwatch: 9-685419 +44 (0) 1353 667258

Issue Date: 09/02/2023 info@c-c-l.com

Print Date: 25/12/2023 www.c-c-l.com

Product name Ship Type

piperine Not Available

maltodextrin Not Available

black pepper extract Not Available

SECTION 15 Regulatory information

15.1. Safety, health and environmental regulations / legislation specific for the substance or mixture

piperine is found on the following regulatory lists

Not Applicable

maltodextrin is found on the following regulatory lists

Not Applicable

black pepper extract is found on the following regulatory lists

Not Applicable

Additional Regulatory Information

Not Applicable

This safety data sheet is in compliance with the following EU legislation and its adaptations - as far as applicable - : Directives 98/24/EC, - 92/85/EEC, - 94/33/EC,

- 2008/98/EC, - 2010/75/EU; Commission Regulation (EU) 2020/878; Regulation (EC) No 1272/2008 as updated through ATPs.

Information according to 2012/18/EU (Seveso III):

Seveso Category Not Available

15.2. Chemical safety assessment

No Chemical Safety Assessment has been carried out for this substance/mixture by the supplier.

National Inventory Status

National Inventory Status

Australia - AIIC / Australia

Yes

Non-Industrial Use

Canada - DSL Yes

Canada - NDSL No (piperine; maltodextrin)

China - IECSC Yes

Europe - EINEC / ELINCS /

Yes

NLP

Japan - ENCS No (piperine; maltodextrin)

Korea - KECI No (piperine)

New Zealand - NZIoC Yes

Philippines - PICCS Yes

Product code: P02102 Version No: 2.2 Page 22 of 25

S.REACH.GB.EN Lancaster Way Business Park

Safety Data Sheet (Conforms to Annex II of REACH (1907/2006) - Regulation 2020/878) Ely, Cambridgeshire, CB6 3NX, UK.

Chemwatch: 9-685419 +44 (0) 1353 667258

Issue Date: 09/02/2023 info@c-c-l.com

Print Date: 25/12/2023 www.c-c-l.com

National Inventory Status

USA - TSCA Yes

Taiwan - TCSI Yes

Mexico - INSQ No (piperine)

Vietnam - NCI Yes

Russia - FBEPH Yes

Yes = All CAS declared ingredients are on the inventory

Legend: No = One or more of the CAS listed ingredients are not on the inventory. These ingredients may be exempt or will require

registration.

SECTION 16 Other information

Revision Date 09/02/2023

Initial Date 17/09/2019

Full text Risk and Hazard codes

H302 Harmful if swallowed.

H411 Toxic to aquatic life with long lasting effects.

SDS Version Summary

Date of

Version Sections Updated

Update

Toxicological information - Acute Health (eye), Toxicological information - Acute Health (inhaled), Toxicological

information - Acute Health (skin), Toxicological information - Acute Health (swallowed), Toxicological information -

Chronic Health, Hazards identification - Classification, Exposure controls / personal protection - Engineering

Control, Ecological Information - Environmental, Exposure controls / personal protection - Exposure Standard,

Handling and storage - Handling Procedure, Composition / information on ingredients - Ingredients, Exposure

1.2 09/02/2023

controls / personal protection - Personal Protection (other), Exposure controls / personal protection - Personal

Protection (Respirator), Exposure controls / personal protection - Personal Protection (eye), Exposure controls /

personal protection - Personal Protection (hands/feet), Accidental release measures - Spills (minor), Handling

and storage - Storage (suitable container), Identification of the substance / mixture and of the company /

undertaking - Use

Other information

Classification of the preparation and its individual components has drawn on official and authoritative sources as well as independent review by the Chemwatch

Classification committee using available literature references.

The SDS is a Hazard Communication tool and should be used to assist in the Risk Assessment. Many factors determine whether the reported Hazards are Risks

in the workplace or other settings. Risks may be determined by reference to Exposures Scenarios. Scale of use, frequency of use and current or available

engineering controls must be considered.

For detailed advice on Personal Protective Equipment, refer to the following EU CEN Standards:

EN 166 Personal eye-protection

EN 340 Protective clothing