Professional Documents

Culture Documents

(ASTM D4991-07 - 2015) Standard Test Method For Leakage Testing of Empty Rigid Containers by Vacuum Method

(ASTM D4991-07 - 2015) Standard Test Method For Leakage Testing of Empty Rigid Containers by Vacuum Method

Uploaded by

Xavier0 ratings0% found this document useful (0 votes)

24 views2 pagesOriginal Title

(ASTM D4991-07_2015) Standard Test Method for Leakage Testing of Empty Rigid Containers by Vacuum Method

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views2 pages(ASTM D4991-07 - 2015) Standard Test Method For Leakage Testing of Empty Rigid Containers by Vacuum Method

(ASTM D4991-07 - 2015) Standard Test Method For Leakage Testing of Empty Rigid Containers by Vacuum Method

Uploaded by

XavierCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

GET ccsianstion: pases 07 (Reapproved 2018)

ae

Standard Test Method for

Leakage Testing of Empty Rigid Containers by Vacuum

Method"

Spenco epilor (inte: eon stg

1, Scope

1.1 This test method covers the testing oF emply containers.

lor sesistance to leakage under ditlerentil pressure conditions

uch as those which ean occur during air transport, Its suitable

for testing rigi¢ containers intended for the transponstion of

some hazardous liguids in accordance with the United Nations

Recommendations On The Transport OF Dangerous. Good's

(UN TDG) and the International Civil Aviation Organization

‘Technical Instructions For The Safe Transport OF Dangerous.

Goods By Aur (ICAO ‘Tis,

1.2 This standard does wot p

safety concerns

responsibility of the user of this standard to establish appro-

port to address all of the

if any, associated swith iis use, It is the

priate safety and health practices and determine the applica:

bility of regulatory fi

2, Referenced Documents

21 ASTY Standards?

D996 Terminology of Packaging and Distribution Environ-

ments,

‘3018 Test Method for Determination of Leaks in Flexible

Packaging by Bubble Emission

2.2 United Nations Document

STSGIAC.10/1 Recommendations On The Transport OI

Dangerous Goods?

2.3 International Civ Aviation Organization:

DOC 9284-AN905 Technical Instructions For The Safe

‘Transport OF Dangerous Goods By Air*

Fyckaging ans he et regensibty oF Sohcormts 1IN.2T on Spins

CConuicts and Systems" Agp.citon of Rfarauace Tos Matos

‘Cares tion spread May 2015, Poe ay 2015. nelly app

coat ASTM Customer Seti tag Fo Ava Bo AST

‘vel rm United Nations 8

100

Section, Urital Nav

1

Tew mon oe apg

3. Terminology

3. Definitions: Terms and definitions used in this test

method may be found in Terminology D996,

2 Definitions of Terms Specific to This Standart:

2.1 rigid containers comainer sufficiently rigid that

under a positive pressure of 1O0-KPa gaye the volumetric

expansion does not exceed 0.5 %, such as a glass bottle

4. Su

4.1 An empty rigid container to be tested is pressurized by

immersion ip an ethylene glyeobwater solution ina transparent

test chamber and subjected 10 2 gradually increasing partial

vacuum. The container is observed for signs of leakage, 2s

evidenced by escaping air bubbles during depressurization or

Huid in the container alter re-pressurization

mary of Test Method

Signifi

5.1 Containers may be pressurized in accordance with this

test method without modification to the closure or to the body

of the container, This test methexl may be used For testing rigid

‘containers intended Lor the trassportation of some liquids by’ ai

in accordance with the ICAO Ts or in accordance with the UN

TDG.

5.2 This test method establishes the point at which leakage

commences, with a limit of approximately 95-KPa (13.8-psi)

differential. See Test Method D3078 for ‘lexible packages.

5.3 This test method! may not he suitable For some packsges,

such as packages with puper cup seals, where the test fluid

rapidly deteriorate the packsging,

ce and Use

6. Apparatus

6.1 Transparent Vessel, large enough 10 permit the test

speciments) to be immersed in the test ‘uid with a misimum

headspace of 20 %, capable 0° withstanding at least 145-atm

pressure ditlerential, lied with a Hat vacuum-tight cover is

required

2 Vactnm Gage, Inlet Tube from a Source of Viscum, and

Outlet Tube to the Atmosphere, shall be sealed into the cover

‘The inlet ard outlet tubes shall be eguippedl with undoperated.

valves. The vacuum gage shall be Laboratory quality with a

full-scale range rom 0 to 100 kPa (0 1 14.5 psi) with

fly Da991 - 07 (2015)

minimum graduations no greater than 2 kPs (0.3 psi) and

to within 1%. A suitable moismee trap, 10 prevent

‘ack-flow of liquid, should be fitted between the vacuum gage

and the source of vacuum,

6.3 Solution of Ethylene Glycol in Water, 50% by Volume

For use as a test uid, al anbient temperature unless otherwise

specified, is required. Where a test temperature other than

ambient is specified, the solution shall be atthe specified test

temperature, Other solutions may be required for high and low

temperatures,

Nom: 1! ethylene glycol amircere solution is sed, shone be

lanied by Alone thr activ charcok.

6.4 A suitable means to hold the test specimen(s) with the

losure(S) not more thar 25 nan (1 jn.) under the surface oF the

test uid is required. The method of restraint should rot allect,

the results of the test

7. Test Specimens,

FAA Test specimens shall consist of containers. including

theie closures. Test specimens of containers which are in

production shall be representative samples. taken at random,

7.2 Containers shall be empty containers which previously

contained any substance and were cleaned af the contents prior

1 testing. New containers and closures. where available.

should be used,

7.3 Fach container shull be closed for esting in the same

‘manner as it would be closed for actual shipmest, AU closures

shall be installed using the techniques ot torques specitied by

the closure manufacturer, container manufscturer, oF shipper.

Close contsiners at ambient pressure and temperature,

7.4 Where atest temperature other than ambient is specified,

the sample containers shall be conditioned at the test temper

tute for at least 24 b, and until they reach equilibrium of

‘temperature with the conditioning atmosphere.

7.5. Unless otherwise specitied. test at least three specimens.

8, Preparation of Apparatus

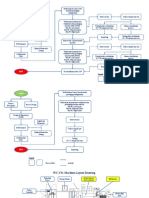

8.1 Assemble the apparatus in accordanee with Fig. 1

FIG. + Typical Test Setup for Leakage Testing of Containers by

Vacuum Method

82 Prior to testing, draw a vacuum to at least 95-KPa

13.8 psi) differential and maintain this vacuum for 10 min in

fonder (0 remove gir eissolved in the test lu.

9. Procedure

9.1 Immerse the test specimens in the ethylene glycol-water

solution inside the transparent test chamber. Remove as many

bubbles as possible from the outer suriace ofthe test specimens

by agitation or other me:

9.11 More than one specimen can be tested at one time

provided that there is sufficient space in the test chamber 10

allow clear observation of each specimen. If this is done, alix

the test specimens so closures are sulliciently sepsrated to

permit individual observation of each, to detect leakage.

9.2 Seal the lid, open the hand valve on the inlet tube, and

close the hand valve on the ovtlet tbe to the atmesphere, Turn

fon the vacuum So that the a

rnin) to a pressure differentia) of 95 KPu (13.8 psi) or other

specitied pressure differential. The vacuum can be controlled

by cracking open the hand valve or the outlet tube, During the

suum, observe the test specimen(s) for leakage 2s

evidenced by a continuous stream or recurring succession of

small bubbles. Isolated bubbles caused by trapped air are not

considered evidence of Teukage, Maintain the vacuum for a

minimum of 10 min, For test specimens which ate single

packagings or combination packagings in whole or part of

plastic materia, mintain the vacuom for 30 min, Then turn the

nd release it slowly by opening the hand valve on

the outlet (ube. Keep the test specinnen(s) immersed for atleast

30 § al ambient pressure. Remove the test specimen(s) and

examine the inside for uid.

rises slowly (from 30 $10 1

vacuum off

9.3 Leakage is indicated by a continuous stream or recurring.

succession of bubbles. Fluid within the test specimen is alse

evidence of leakage.

10, Report

10.1. Report the following information:

10.1.1 Ikentification oF the continers and closures, using

ranufacturer’s part numbers and descriptions or using ex-

ploded view drawings of cross-sectional drawings, including

detailed data of material construction,

10.1.2 ‘Total number of specimens tested

10.13 Nuraber of specimens tested at one tine

10.1.4 Test pressure requirement, where applicable,

10.1.5 Whether test was performed at ambient temperature

and if not, the test temperature, Ifa test solution other than

50 6 etltylene glyvol wats used, ently the solution,

10.1.6 Whether test specimens passed or failed the test

where applicable,

10.7 Whether each test specimen leaked and st what

pressure differential

10.1.8 Whether test duid was appar

atler testing,

10.1.9 A statement (© the effect that all (ests were mle im

lull compliance with the requirements of this test method. of

noting any variations and detiling them, ancl

atin each test specimen

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- (ASTM F1886 - F1886M-16) Standard Test Method For Determining Integrity of Seals For Flexible Packaging by Visual InspectionDocument4 pages(ASTM F1886 - F1886M-16) Standard Test Method For Determining Integrity of Seals For Flexible Packaging by Visual InspectionXavierNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- (ASTM F2096!11!2019) Standard Test Method For Detecting Gross Leaks in Packaging by Internal Pressurization (Bubble Test)Document3 pages(ASTM F2096!11!2019) Standard Test Method For Detecting Gross Leaks in Packaging by Internal Pressurization (Bubble Test)XavierNo ratings yet

- (ASTM F2054 - F2054M-13) Standard Test Method For Busrt Tetsing of Flexible Package Seals Using Internal Air Pressurization Within Testraining PlatesDocument9 pages(ASTM F2054 - F2054M-13) Standard Test Method For Busrt Tetsing of Flexible Package Seals Using Internal Air Pressurization Within Testraining PlatesXavierNo ratings yet

- (ASTM D4991-07 - 2023) Standard Test Method For Leakage Testing of Empty Rigid Containers by Vacuum MethodDocument2 pages(ASTM D4991-07 - 2023) Standard Test Method For Leakage Testing of Empty Rigid Containers by Vacuum MethodXavierNo ratings yet

- (ASTM F1929-15) Standard Test Method For Detecting Seal Leaks in Porous Medical Packaging by Dye PenetrationDocument3 pages(ASTM F1929-15) Standard Test Method For Detecting Seal Leaks in Porous Medical Packaging by Dye PenetrationXavierNo ratings yet

- Machine Layout DrawingDocument30 pagesMachine Layout DrawingXavierNo ratings yet

- Domino Printer For Colimatic WC-179 and WC-228 (Change Control For Functionally Equivalent Like-For-Like Change)Document8 pagesDomino Printer For Colimatic WC-179 and WC-228 (Change Control For Functionally Equivalent Like-For-Like Change)XavierNo ratings yet

- Kaizen Closure TemplateDocument2 pagesKaizen Closure TemplateXavierNo ratings yet

- Risk AssessmentDocument2 pagesRisk AssessmentXavierNo ratings yet

- 8D Methodology - Problem Solving Method - Example - ExcelDocument11 pages8D Methodology - Problem Solving Method - Example - ExcelXavierNo ratings yet

- Like-4F-Like Decision-Making ToolDocument1 pageLike-4F-Like Decision-Making ToolXavierNo ratings yet

- GeneMANIAReport PI3K SignalingDocument22 pagesGeneMANIAReport PI3K SignalingXavierNo ratings yet

- Data Experiment Minitab DiscoveryDocument1 pageData Experiment Minitab DiscoveryXavierNo ratings yet

- GeneMANIA Report - Transcription SignalingDocument23 pagesGeneMANIA Report - Transcription SignalingXavierNo ratings yet

- Sustainability-14-09618 FMEA Filling Station SterileDocument13 pagesSustainability-14-09618 FMEA Filling Station SterileXavierNo ratings yet

- Investigating Multi-Cancer Biomarkers and Their Cross-Predictability in The Expression Profiles of Multiple Cancer TypesDocument23 pagesInvestigating Multi-Cancer Biomarkers and Their Cross-Predictability in The Expression Profiles of Multiple Cancer TypesXavierNo ratings yet

- GeneMANIA - ERK Signaling ReportDocument22 pagesGeneMANIA - ERK Signaling ReportXavierNo ratings yet

- GeneMANIA - Networks Report (Core and SP Genes)Document12 pagesGeneMANIA - Networks Report (Core and SP Genes)XavierNo ratings yet

- (2018) Sex and Gender Differences Research Design For Basic, Clinical, and Population Studies - Essentials For InvestigatorsDocument16 pages(2018) Sex and Gender Differences Research Design For Basic, Clinical, and Population Studies - Essentials For InvestigatorsXavierNo ratings yet