Professional Documents

Culture Documents

Ball Throwing Machine Design To Develop Footballers Technical Attributes

Ball Throwing Machine Design To Develop Footballers Technical Attributes

Uploaded by

Pes PorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ball Throwing Machine Design To Develop Footballers Technical Attributes

Ball Throwing Machine Design To Develop Footballers Technical Attributes

Uploaded by

Pes PorCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/350244071

Ball Throwing Machine Design To Develop Footballers’ Technical Attributes

Article in European Mechanical Science · March 2021

DOI: 10.26701/ems.777400

CITATIONS READS

3 2,187

5 authors, including:

Cemile Arslan Gökhan Yalçın

Konya Technical University KONYA TEKNİK ÜNİVERSİTESİ

2 PUBLICATIONS 3 CITATIONS 3 PUBLICATIONS 15 CITATIONS

SEE PROFILE SEE PROFILE

Humar Kahramanli Örnek

Selcuk University

45 PUBLICATIONS 882 CITATIONS

SEE PROFILE

All content following this page was uploaded by Humar Kahramanli Örnek on 03 December 2021.

The user has requested enhancement of the downloaded file.

EUROPEAN

MECHANICAL

SCIENCE Research Paper

e-ISSN: 2587-1110

Ball Throwing Machine Design To Develop Footballers’ Technical

Attributes

Cemile Arslan 1* , Mustafa Arslan 2 , Gökhan Yalçın 3 , Turgut Kaplan 4 ,

Humar Kahramanlı Örnek5

1

Konya Technical University, Vocational School of Technical Sciences, Department of Electronics and Automation, Konya, Turkey

2

Konya Technical University, Vocational School of Technical Sciences, Department of Electricity and Energy, Konya, Turkey

3

Konya Technical University, Vocational School of Technical Sciences, Department of Machinery and Metal Technologies, Konya, Turkey

4

Selcuk University, Faculty of Sport Sciences, Department of Trainer Education, Konya, Turkey

5

Selcuk University, Faculty of Technology Department of Computer Engineering, Konya, Turkey

Abstract

For a football player to perform well in football, it is necessary to improve his technical and tactical skills.

Improving these skills is enabled with the repetition of the same positions that the football player has the ball.

The repetitions of these same positions can be performed with the aid of a machine. In this study, a football

throwing machine design that can provide direction and velocity for the ball in a repeatable and controllable

manner is generated for full educational evaluation. Ball loading canister on the ball throwing machine enabled

to use of many balls. There are a couple of ball throwing wheels both are made of polyurethane material and

have a concave surface. These wheels are mounted on a body for axial rotation on common ground. Each wheel’s

rotation speed can be adjusted individually. To determine the horizontal-vertical direction of movement of the

ball, two linear actuators are used. Ball’s velocity, direction, orbit, and throwing laps are controlled electronically.

All controls concerning ball throwing are carried out via Delta PLC (Programmable Logic Controller) and HMI

(Human Machine Interface) panel. A user interface is developed for controls made via PLC. Owing to the

interface, different training plans are designed by handler or trainer via operator panel, and footballer is provided

to train in various densities. To prevent toppling tripod system, and to carry easily a towing arm is used. The

machine can work with an accumulator or feed directly from the grid circuit.

Keywords: Ball throwing machine, player training, individual training, PLC

1. INTRODUCTION To have a fine technique a footballer is required to control

In our country, football love and participation are at an in- his dominance over the ball in any case of kicking or passing.

disputable extent. Nevertheless, the desired success level has This controlling can be performed with head, chest, and feet

not yet been reached. It can be said that the most important or anywhere the ball hits according to various positions. The

factor to determine a football match’s quality is footballers position to stop the ball can be determined by the ball’s ve-

having high-level technical capacity. A fine technique is a locity, height, direction, and footballer’s technique and hab-

footballer’s performing appropriate movements in the most its. A player’s dominance over the ball and controlling it can

efficient way (Taşkın, 2005). be developed by repeats [2 - 5]. Studies show that repeating

the movements results in the player memorizing them in

Football is a sport played with feet. Football requires some his subconscious. This led to successful results in the match

technical competence like passing, crossing, and free-kick, either technically or visually [5, 6]. There is some test to de-

shoot, dribbling, blocking and cutting the balls, ball controls, termine the technique in football [7, 8]. In some of these

and headers to be performed efficiently. A successful player tests, a training footballer needs another person to pass him

is expected to handle the ball with his feet, throw curveballs, and since it is human passing the ball’s velocity, height and

pass his friends, and kick the ball with his feet inside, out- direction will not be the same all the time [4, 5]. Hence to

side, tip and heel kick. Being capable of these pleases both train the same move again and again a machine will be more

footballer and the audience. reliable. A machine after programmed can perform the

same move several times provided that the environmental

European Mechanical Science (2021), 5(1): 39-43

* Corresponding author doi: https://doi.org/10.26701/ems.777400

Email: carslan@ktun.edu.tr Received: July 3, 2020

Accepted: September 8, 2020

Ball Throwing Machine Design To Develop Footballers’ Technical Attributes

conditions are not changed [2, 9]. Accordingly, a ball throw- the second part of the study parts of the machine are intro-

ing machine can provide a player to train without another duced and their tasks in the system are mentioned. The third

person in his training. part has consisted of results and suggestions.

In our literature review, we encountered some significant

2. DESIGN METHODOLOGY

studies about ball throwing machine design. Terzioğlu and

et al.[10] controlled servomotor by using SCADA in their Ball throwing machine designed in this study consists of th-

study. They used Delta branded PLC, servomotor speed ree parts:

control device, and HMI panel in this control. By determi- • Mechanical parts;

ning the working parameters of the servomotor from the • Electrical-Electronical equipment;

HMI screen, it is ensured to work in the desired way. Ashte-

• Software and control group.

kar and et al.[11] have developed a SCADA system by simu-

lating a real-time industrial process (water level controller). 2.1. Mechanical Parts of the Ball Throwing Machine

They have generated the process control layer of the system

The general view of the ball throwing machine can be seen

by using Delta branded PLC. To control the water level they

in Figure 1, the schematic view, on the other hand, can be

used MODBUS protocol for transmission between PLC

seen in Figure 2. The machine has 2x1, 7x1 m dimensions.

and PC. Gupta and et al.[12] have designed a smart electri-

The body of the machine consists of an iron sheet and beam.

city control system. By using Delta branded PLC and HMI

Iron sheet plates are 1.5 mm thick, main beams consist of

interface they enabled the user to monitor and control all

30x50x3 mm dimensions rectangular beam and 34x3 mm

electrical components’ statuses located inside rooms or offi-

dimensions pipe beam. Considering that this developed ma-

ces. Marhas and et al.[6] have developed a football throwing

chine will be used outside mostly, to have resistance against

concept based on aerodynamic and mechanical principles to

corrosion entire body is painted with synthetic metal paint.

enhance goalkeeper’s and striker’s average attributes. They

Tripod wheeling system to prevent tipping over and towing

designed and developed this concept to repeat different mo-

arm for easy transportation are used. Boxes made of iron

ves, speeds, and orbits consecutively and properly. In their

sheets are designed to protect electrical-electronic equip-

study, Singh and et al.[13] have constructed a bowling ball

ment from impacts and unfavorable weather conditions.

throwing machine for both entertaining and professional

purposes. They aimed the machine to be portable, have a Ball throwing wheels are made of polyurethane which is re-

portable power source in order it to be used in the field and sistant to snapping, tearing, and corrosion. Wheels are de-

they also aimed it to be safe to hold still. Perumalsamy and et signed concave to grip the ball perfectly. The diameters of

al.[14] have designed an automated volleyball throwing ma- the wheels are 260 mm and their thickness is 140 mm. These

chine in their study. Movement and velocity of the ball, pro- wheels are mounted horizontally with a space between them

per and repeatable path following of the ball programmed in order the ball to go through. To prevent errors due to ex-

with Solid Works and AutoCAD software. Mahapatra and

et al.[15] have developed a simulation of the computer-sup-

ported design of cricket ball throwing machine. They have

designed a virtual model ball throwing machine in CATIA

software of CAD/CAE software package to simulate diffe-

rent mechanical subunits of the machine via using ADAMS

software. Saal et al.[16] developed the "Footbonaut" measu-

rement system, in which movement speed can be diagnosed

and trained, and used as a measurement and information

system. It was stated that with this system, the existing talent

identification and talent development structure of football

players can be strengthened. In another study, Saal et al.[17]

evaluated the reliability and validity of a soccer short passing

test using the Footbonaut measurement system. As a result,

they concluded that skilled players are significantly faster in

performing short passes than less-skilled players.

In this study, a football throwing machine is designed for

footballers to develop their personal attributes and perfor-

mances, to train repeatedly, and to have a complete training

assessment. The designed machine enables us to apply vari-

ous training programs along with throwing the ball in differ-

ent directions. That is to say, a footballer can train himself in

various tempos after a trainer determines various plans. In Figure 1. General View of the Ball Throwing Machine

40 European Mechanical Science (2021), 5(1): 39-43

doi: https://doi.org/10.26701/ems.777400

Cemile Arslan, Mustafa Arslan, Gökhan Yalçın, Turgut Kaplan, Humar Kahramanlı Örnek

ternal factors, a covering part is designed for the outer part to throw the ball (Figure 3) and they work independently of

of the wheels. each other. Wheels are mounted as their direction of rota-

tion is opposite so that they can throw the ball. By providing

Considering that the machine will de for individual use, a

various DC voltages to the motor feeds, their rpm (revs per

ball loading canister is developed. This canister has 20 balls

minute) can be changed and this enables the ball to follow

capacity. It is constructed with steel flat with 10 mm thick-

curved or linear orbit as shown in Figure 4.

ness and its outer ring has 785 mm in diameter. The channel

through which the ball will line up is designed with a 6 mm Training can be diversified by locating the machine in differ-

diameter pipe beam, three-level helical steps and it has a to- ent locations inside the pitch.

tal of 820 mm height.

Figure 3. Ball thrower wheels and their motors

1. Chassis

2. Towing arm

3. Battery Cover

4. Motor of ball thrower wheels

5. Ball thrower wheel

6. Motor of horizontal-vertical movement piston

7. Horizontal-vertical movement piston

8. System control board

9. Ball throwing sorting motor

10. Piston cover

11. Ball sorting canister

12. Ball loading canister

13. Open-Close lever Figure 4. The orbit of the curved ball

Figure 2. Schematic View of Ball Throwing Machine

A DC gear motor that can produce high torque at low speed

Between the ball loading canister and ball thrower wheels,

is used to let the ball from the sorting canister. This DC gear

there is a ball sorting canister. An open-close lever is ad-

motor controls the open-close lever (Figure 5).

ded to the ball sorting canister to send the balls towards ball

thrower wheels. One end of this lever is connected to the Two step motors with encoders and Linear Actuator en-

engine and the other end is connected to the sorting canis- abled the ball thrower wheels to move both horizontally

ter. The part which is connected to the loading canister is and vertically (Figure 6). One of the motors provides hori-

designed as a roller bearing so that it can rotate easily. Thus zontal, the other one provides vertical movements. The lin-

and so a ball can be sent to be thrown after the ball thrower ear actuators which are used to enable horizontal-vertical

wheels adjust their positions. movement can be moved as far as desired via the motors

connected to them. This hardware can rotate ball throwing

2.2. Electric-Electronical Equipment of Ball Throwing mechanism 45-degree angle maximum to left and right hor-

Machine izontally. This provides us total 90-degree angle ball throw-

In this machine two permanent magnet DC motors, a DC ing capability in the circular sector horizontally. With this

gear motor, two step motors with encoders, and two linear hardware 45-degree maximum area can be scanned in the

actuators are used. vertical axis, towards positive (Figure 7).

Permanent magnet DC motors provide the desired velocity

European Mechanical Science (2021), 5(1): 39-43 41

doi: https://doi.org/10.26701/ems.777400

Ball Throwing Machine Design To Develop Footballers’ Technical Attributes

a)

Figure 7. The schematic view of the angle is scanned horizontally and

vertically.

A motor drive circuit is used to control permanent magnet

DC motors. This drive circuit is selected to be compatible

with a digital screen to monitor velocity. At digital screen

capacity of the motor is seen between 0-100 percent accor-

ding to amplitude modulation conversion. Motor’s rpm is

measured with a tachometer depending upon working ca-

(b)

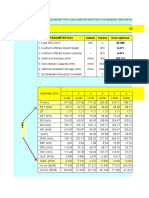

pacity. Measurement results are seen in Table 1.

Figure 5. Open-Close lever (a) Open (b) Closed

Table 1. DC Motor tachometer measurement results

DC Motor Working Capacity DC Motor Rotational Speed

[%] [rpm]

10 175

20 455

30 745

40 1020

50 1280

60 1543

70 2015

80 2120

90 2365

100 2814

2.3. Software and Control Group of the Throwing

Machine

a) A Delta-Cpu-DVP-14SS2 PLC and DVP-08SN addition

module and a Delta DOP-A series operator panel with TFT

LCD screen is used to control the ball throwing machine.

For the software, the control algorithm is generated with

Ladder programming language via interface found in Delta

SS2 PLC device. PLC is programmed with Delta WPLSoft

software and Operator Panel is programmed with DOPSoft

software so that a user can activate and control the system.

The communication between PLC and devices is provided

with MODBUS serial communication protocol. MODBUS

which uses serial communication standards is used with the

RS232 serial communication interface.

With the help of the control board (Figure 8) coordinates

to send the ball to, throwing frequency, repeating number

can be determined and a training program can be saved and

used.

(b)

Figure 6. Horizontal-Vertical movement pistons and motors (a) Horizon-

tal movement (b) Vertical movement

42 European Mechanical Science (2021), 5(1): 39-43

doi: https://doi.org/10.26701/ems.777400

Cemile Arslan, Mustafa Arslan, Gökhan Yalçın, Turgut Kaplan, Humar Kahramanlı Örnek

[4] Rösch, D., Hodgson, R., Peterson, Baumann, L. T. G., Junge, A., Cho-

miak, J., Dvorak, J. (2000). Assessment and Evaluation of Football

Performance. The American Journal of Sports Medicine, 28(5): 29-

39, DOI: 10.1177/28.suppl_5.s-29.

[5] Varhade, A. R., Tiwari, H., Patangrao, P. D. (2013). Cricket Bowling

Machine, International Journal of Engineering Research & Techno-

logy (IJERT), 2(12): 1920-1924.

[6] Marhas, L. S., Kanojia, K. P., Dhapodkar, V., Trivedi, M. G. (2015).

Design and Development of Sport Utility: A Football Launching

Machine. IJSRD - International Journal for Scientific Research & De-

velopment| 2(12): 302-304.

[7] Özkara, A. (2002). Futbolda Testler, 1. Baskı, İlksan Matbaacılık, An-

kara.

[8] Reilly, T., Holmes, M. (1983). A Preliminary Analysis of Selected Soc-

Figure 8. System Control Board

cer Skills. Physical Education Review, 6: 64-71.

3. RESULTS AND SUGGESTIONS [9] Brechbuhl, C., Millet, G., Schmitt, L. (2016). Accuracy and Reliability

of a New Tennis Ball Machine. Journal of Sports Science and Medi-

In this study, a football throwing machine design to provide cine, 15: 263-267.

convenience for footballers in their training is carried out.

[10] Terzioğlu, H., Yalçın, G. & Kısa, M. (2019). Servomotorun SCADA

This machine is developed to throw the ball in the desired ile Kontrolü. European Journal of Science and Technology, (Special

time period, velocity, and position parameters. The ball Issue), 428-435, DOI: 10.31590/ejosat.638394.

loading canister which is mounted on the machine enables

[11] Ashtekar, A. S., Parvat, B. J., Kadu, C. B. (2013). Application of MOD-

to load of 20 balls at a time and this way a footballer can train BUS to Communicate the PLC and Lab VIEW for Real Time Process

individually. Parameters are provided with PLC software. Control. International Journal of Emerging Science and Engineering

Due to the interface created with the software machine be- (IJESE), 1(11): 41-45 .

came controllable via the operator panel. Trainers can pro- [12] Gupta, M. K., Gupta P. K., Rajat Kumar Giri, R. K. & Gupta, A. (2018).

gram the ball throwing machine to cover all parameters by Smart Electric Control System using PLC & HMI, International Jour-

controlling the machine automatically or manually with the nal of Mechanical Engineering and Technology 9(4): 548–555.

operator panel. Studies showed that the ball throwing ma- [13] Singh, A. P., Jain, A. K., Mahajan, P. (2016). Design And Fabrication of

chine has a user-friendly interface. A Ball Projecting Machine. International Journal of Advance Resear-

ch And Innovation, 4(3): 587-590.

This study can be seen as an example of similar motors in

industrial production for suitable positioning purposes. [14] Perumalsamy, S., Ragupathi, P., Rahul, K. R. (2014). Design and De-

velopment of Volley Ball Practice Machine. International Journal of

Moreover, DC and servo motors which are controlled with

Latest Trends in Engineering and Technology (IJLTET), 4(1):144-156

PLC can also be controlled with a microcontroller if desired.

Performances and cost can be compared between both sys- [15] Mahapatra, A., Chatterjee, A., Roy, S. S. (2009). Modeling and Si-

mulation of A Ball Throwing Machine, 14th National Conference

tems.

on Machines and Mechanisms (NaCoMM09). NIT, Durgapur, India,

December 17-18.

4. THANKS

[16] Saal, C., Zinner, J., Büsch, D., Werner, C., Ückert, S. (2013). Der Foot-

This study is supported with project number 17401043 by bonaut als Mess- und Informationssystem zu Erfassung der Agilität

the University of Selcuk, Scientific Researches Projects Co- im Sportspiel Fußball, Zeitschrift für Gesundheit und Sport, Heft1,

ordinatorship. We thank Hüseyin KORKMAZ and Ilkin 53-61

KORKMAZ for their contributions during the design and [17] Saal, C., Zinner, J., Fiedler, H., Lanwehr, R., Krug, J. (2018). Reliability

construction process of the ball throwing machine. and validity of a soccer passing test using the Footbonaut, German

Journal of Exercise and Sport Research 3: 334-340

RERERENCES

[1] Taşkın, H. (2005). Profesyonel Futbolcularda Teknik Parametrelerin

Tespiti Ve Liglere Göre Değerlendirilmesi, Doktora Tezi, T.C. Selçuk

Üniversitesi Sağlık Bilimleri Enstitüsü Beden Eğitimi ve Spor Anabi-

lim Dalı, Konya.

[2] Haaland, E., & Hoff, J. (2003). Non‐dominant leg training impro-

ves the bilateral motor performance of soccer players. Scandina-

vian journal of medicine & science in sports, 13(3), 179-184. DOI:

10.1034/j.1600-0838.2003.00296.x.

[3] Davids, K., Lees, A., Burwitz, L. (2000). Understanding and Measu-

ring Coordination and Control in Kicking Skills in Soccer: Implicati-

ons for Talent Identification and Skill Acquisition. Journal of Sports

Sciences, 18: 703-714, DOI: 10.1080/02640410050120087.

European Mechanical Science (2021), 5(1): 39-43 43

doi: https://doi.org/10.26701/ems.777400

View publication stats

You might also like

- Bomag BPR 50, BPR 50 D, BPR 55, BPR 55 D, BPR 60 D, BPR 65, BPR 65 D Operators and Maintenance ManualDocument89 pagesBomag BPR 50, BPR 50 D, BPR 55, BPR 55 D, BPR 60 D, BPR 65, BPR 65 D Operators and Maintenance ManualSwiduNo ratings yet

- General - Chemistry - Q4 - M1-Entropy and Gibbs' Free EnergyDocument13 pagesGeneral - Chemistry - Q4 - M1-Entropy and Gibbs' Free EnergySteiner0% (1)

- Driving School Monitoring SystemDocument54 pagesDriving School Monitoring SystemtyetstrstrNo ratings yet

- Psychomotor Domain TaxonomyDocument2 pagesPsychomotor Domain TaxonomyRaijū100% (1)

- Zero and Negative Exponents: Quarter 2Document16 pagesZero and Negative Exponents: Quarter 2Carmi Formentera LuchavezNo ratings yet

- Letter of Intent For Promotion HTIIIDocument2 pagesLetter of Intent For Promotion HTIIIMAY BARCELONA93% (14)

- 10 26701-Ems 777400-1228665Document5 pages10 26701-Ems 777400-1228665MDLNo ratings yet

- A Kicking Mechanism For A Soccer Playing RobotDocument8 pagesA Kicking Mechanism For A Soccer Playing RobotTan Tien NguyenNo ratings yet

- Table Tennis Training AutomotionDocument6 pagesTable Tennis Training AutomotionEditor IJTSRDNo ratings yet

- SeminarDocument25 pagesSeminaramishakr0708No ratings yet

- Nadeem ReportDocument19 pagesNadeem ReportNaheeda AfreenNo ratings yet

- MechatronicsDocument13 pagesMechatronicsIsmail LahlouNo ratings yet

- Higher Diploma in Electrical and Electronics EngineeringDocument23 pagesHigher Diploma in Electrical and Electronics Engineeringmohammedifam5No ratings yet

- Modelling of Pilot Decision Making Mechanism by Using Fuzzy LogicDocument15 pagesModelling of Pilot Decision Making Mechanism by Using Fuzzy LogicÖmer Faruk ÇiftçiNo ratings yet

- An-Engineering-Project 1Document40 pagesAn-Engineering-Project 1Rubik Raj RayNo ratings yet

- Ergonomics Assessment of Workstation Design in Automotive IndustryDocument7 pagesErgonomics Assessment of Workstation Design in Automotive IndustryGabriel AboroenceiNo ratings yet

- "Air Traffic Control": Bachelor of Technology IN Computer Science & EngineeringDocument19 pages"Air Traffic Control": Bachelor of Technology IN Computer Science & Engineeringsai shailuNo ratings yet

- Resume AvinashkmDocument3 pagesResume AvinashkmAvinash KMNo ratings yet

- Sarjet 32 55-67Document13 pagesSarjet 32 55-67Mahaling PreethiNo ratings yet

- TM3101 Design Project Report PDFDocument128 pagesTM3101 Design Project Report PDFMd. Mahabubul HassanNo ratings yet

- Eker Bülent Abstract: Technological Advancements Show ThemselvesDocument5 pagesEker Bülent Abstract: Technological Advancements Show ThemselvesashokkdesignNo ratings yet

- Project Student Management System (SMS) 2Document33 pagesProject Student Management System (SMS) 2Rubik Raj RayNo ratings yet

- DEFENCE UNIVERSITY ProposalDocument9 pagesDEFENCE UNIVERSITY ProposalruhamaNo ratings yet

- Project SMSDocument34 pagesProject SMSRubik Raj RayNo ratings yet

- ExconDocument14 pagesExconmed turkiNo ratings yet

- Missile System Design Integrated With System Engineering MethodologyDocument13 pagesMissile System Design Integrated With System Engineering MethodologyPrasanna NaikNo ratings yet

- Wearable Device - Football Player Smart Tracker and AnalyzerDocument16 pagesWearable Device - Football Player Smart Tracker and AnalyzerKavyaNo ratings yet

- Hawkeye TechnologyDocument29 pagesHawkeye TechnologyDevender Raj Hasaji100% (2)

- SERVODocument7 pagesSERVONicole RodriguezNo ratings yet

- 2 BonafideDocument8 pages2 BonafideDerek ChapmanNo ratings yet

- Mechatronic Model-Based Design Applied To An H-Bot RobotDocument18 pagesMechatronic Model-Based Design Applied To An H-Bot RobotMarian VerdeNo ratings yet

- Curriculum VitaeDocument2 pagesCurriculum VitaeArfeen AhmadNo ratings yet

- Skill Court Soccer Ball ReloadDocument7 pagesSkill Court Soccer Ball ReloadPes PorNo ratings yet

- Topic 1. ShuttlecockDocument3 pagesTopic 1. Shuttlecockmacoolet dollenteNo ratings yet

- An Embedded System For Bowling Performance Analysis in CricketDocument5 pagesAn Embedded System For Bowling Performance Analysis in Cricketpravin BalbudheNo ratings yet

- 2!!!!!!!Document8 pages2!!!!!!!Pes PorNo ratings yet

- Diseño de CuadricopteroDocument6 pagesDiseño de Cuadricopterojuan pabloNo ratings yet

- Systems Engineering in AerospaceDocument6 pagesSystems Engineering in Aerospacetareqshahwan9357No ratings yet

- Revan THDocument66 pagesRevan THyynandhivardhanreddyNo ratings yet

- Development of A Special Inertial Measurement Unit For UAV ApplicationsDocument11 pagesDevelopment of A Special Inertial Measurement Unit For UAV ApplicationsmiguelNo ratings yet

- ReportDocument18 pagesReportBalaji PadalaNo ratings yet

- Development and Control of A High Precision Stewart Platform (#273776) - 254873Document9 pagesDevelopment and Control of A High Precision Stewart Platform (#273776) - 254873Redkit ofFootHillNo ratings yet

- Design and Development of One Degree of Freedom Upper Limb ExoskeletonDocument6 pagesDesign and Development of One Degree of Freedom Upper Limb ExoskeletonWarnithaNo ratings yet

- Prototype Auto Badminton Training RobotDocument6 pagesPrototype Auto Badminton Training Robotfarahyusoff96No ratings yet

- A2 Sample1Document28 pagesA2 Sample1DivyaNo ratings yet

- "Hope Center (Donation Based Website) ": Submitted byDocument7 pages"Hope Center (Donation Based Website) ": Submitted byMd Khaled NoorNo ratings yet

- Plant Layout (Hospital) (Operations Management)Document86 pagesPlant Layout (Hospital) (Operations Management)Rifat Rejuan MithunNo ratings yet

- Interior Design of Passenger Coaches Using Fuzzy oDocument9 pagesInterior Design of Passenger Coaches Using Fuzzy oLokesh UnnamNo ratings yet

- AutoRecovery Save of Project Report FormatDocument18 pagesAutoRecovery Save of Project Report FormatPinisetti GovardhanNo ratings yet

- IMST Unit-3 Dip ME 5.1Document19 pagesIMST Unit-3 Dip ME 5.1Kommineni Ravie KumarNo ratings yet

- Automated Guided VehicleDocument5 pagesAutomated Guided VehicleA.Sadish KumarNo ratings yet

- Automated Online Exam Proctor: A Synopsis Report Submitted in Partial Fulfillment of The Requirement For The Degree ofDocument11 pagesAutomated Online Exam Proctor: A Synopsis Report Submitted in Partial Fulfillment of The Requirement For The Degree ofAkhil SinghNo ratings yet

- PLC2Document8 pagesPLC2William BrownNo ratings yet

- Framework of Multi-Microcontroller Evaluation Tool For A Use of Academic EnvironmentDocument6 pagesFramework of Multi-Microcontroller Evaluation Tool For A Use of Academic EnvironmentrajeevNo ratings yet

- Summer Training Me Auto FileDocument7 pagesSummer Training Me Auto FileShraddhaNo ratings yet

- DBMS Lab Manual Jan2024 PDFDocument80 pagesDBMS Lab Manual Jan2024 PDFKamal MNo ratings yet

- Decamber Morphing Concepts by Using A Hybrid Trailing Edge Control SurfaceDocument24 pagesDecamber Morphing Concepts by Using A Hybrid Trailing Edge Control SurfacealvaroNo ratings yet

- Design and Fabrication of Step Feeder Automation MDocument10 pagesDesign and Fabrication of Step Feeder Automation MJesslyne CheniaNo ratings yet

- Volleyball Sport in SchoolsDocument3 pagesVolleyball Sport in SchoolsAcademic JournalNo ratings yet

- Technical Seminar ReportDocument12 pagesTechnical Seminar ReportLipika SltNo ratings yet

- SE Revised FileDocument52 pagesSE Revised FileHarshit RaoNo ratings yet

- IMSS2019 Paper 182 PP 1059-1068Document11 pagesIMSS2019 Paper 182 PP 1059-1068Mohamad MohamadNo ratings yet

- (Lectures 1,2 and 3) : TopicsDocument11 pages(Lectures 1,2 and 3) : TopicsSanthosh SabapathyNo ratings yet

- Rapid Prototyping Software for Avionics Systems: Model-oriented Approaches for Complex Systems CertificationFrom EverandRapid Prototyping Software for Avionics Systems: Model-oriented Approaches for Complex Systems CertificationNo ratings yet

- From Prognostics and Health Systems Management to Predictive Maintenance 2: Knowledge, Reliability and DecisionFrom EverandFrom Prognostics and Health Systems Management to Predictive Maintenance 2: Knowledge, Reliability and DecisionNo ratings yet

- Utilitarianism:: The Road To Greatest HappinessDocument15 pagesUtilitarianism:: The Road To Greatest HappinessKent Clark VillaNo ratings yet

- New Discoveries in ChemistryDocument4 pagesNew Discoveries in ChemistryKritagya XI ANo ratings yet

- Ali Sarfraz Mepco Colony, Khanewal Road, MultanDocument2 pagesAli Sarfraz Mepco Colony, Khanewal Road, MultanEngr Ali Sarfraz SiddiquiNo ratings yet

- The Basic Principles of LogicDocument3 pagesThe Basic Principles of LogicJenny Ruth TubanNo ratings yet

- Cornell-Notetaking-Guide 6Document18 pagesCornell-Notetaking-Guide 6OtavioNo ratings yet

- Maths Revision Notes For DummiesDocument3 pagesMaths Revision Notes For DummiesAnushanNo ratings yet

- 3201 Part B KasaragodDocument242 pages3201 Part B KasaragodKishore Thomas John ms17d020No ratings yet

- Manish Ford CSRDocument4 pagesManish Ford CSRMamta NarulaNo ratings yet

- List of Academic CitationsDocument5 pagesList of Academic CitationsshauryaprabhatinfratechNo ratings yet

- 4 Powerpoint Ethics in ResearchDocument28 pages4 Powerpoint Ethics in ResearchLuis VrioxNo ratings yet

- Significant Digits Worksheet - 2012Document3 pagesSignificant Digits Worksheet - 2012Awadh K SinghNo ratings yet

- Tutorial 5Document2 pagesTutorial 5Irfan KhanNo ratings yet

- PortfolioDocument40 pagesPortfolioJomar MendrosNo ratings yet

- PV45 0 811 405 096 Amplifier Card Bosch Manual - 124527Document8 pagesPV45 0 811 405 096 Amplifier Card Bosch Manual - 124527cesarNo ratings yet

- Which of The Skills Mentioned in The Article Do You Think Is The Most ImportantDocument1 pageWhich of The Skills Mentioned in The Article Do You Think Is The Most ImportantGaby CarvajalNo ratings yet

- EXTRA TITULAR D (Key)Document3 pagesEXTRA TITULAR D (Key)Tani LereleNo ratings yet

- 1.4: Quadratic Equations: Section OutlineDocument4 pages1.4: Quadratic Equations: Section OutlineAHMED ALSHAMMARINo ratings yet

- Lecture 1: Newton Forward and Backward Interpolation: M R Mishra May 9, 2022Document10 pagesLecture 1: Newton Forward and Backward Interpolation: M R Mishra May 9, 2022MANAS RANJAN MISHRANo ratings yet

- Adama Science and Technology University RefeDocument7 pagesAdama Science and Technology University RefeAlamudin sadoNo ratings yet

- Towards Improving Service Delivery in Local Authorities. A Case of Chegutu Municipality in Zimbabwe.Document9 pagesTowards Improving Service Delivery in Local Authorities. A Case of Chegutu Municipality in Zimbabwe.IOSRjournalNo ratings yet

- 9811246513Document221 pages9811246513Antonio Torres PeñaNo ratings yet

- Bag of Words Algorithm: ParagraphDocument3 pagesBag of Words Algorithm: ParagraphVarshitha ReddyNo ratings yet

- Tugas Kalibrasi ModelDocument8 pagesTugas Kalibrasi ModelFajar100% (1)

- A Reflection On Preparedness in Disaster-Prone PhilippinesDocument2 pagesA Reflection On Preparedness in Disaster-Prone PhilippinesJay VinsonNo ratings yet

- Mindset For IELTS 1 Book RoadmapDocument1 pageMindset For IELTS 1 Book RoadmapLân Hoàng NgọcNo ratings yet