Professional Documents

Culture Documents

Effluent Treatment Plant, Capacity: 8m3/hr. Treatment Process: Bio-Chemical With Return Activated Sludge Process

Effluent Treatment Plant, Capacity: 8m3/hr. Treatment Process: Bio-Chemical With Return Activated Sludge Process

Uploaded by

Md SuruzzamanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effluent Treatment Plant, Capacity: 8m3/hr. Treatment Process: Bio-Chemical With Return Activated Sludge Process

Effluent Treatment Plant, Capacity: 8m3/hr. Treatment Process: Bio-Chemical With Return Activated Sludge Process

Uploaded by

Md SuruzzamanCopyright:

Available Formats

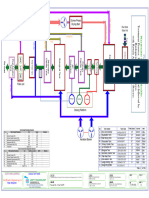

SN Tank Name Tank Size Free Board Volume HRT

01 Oil & Grid Chamber 7'-6"x3'-0"x7'-0" 12" 8.0m3 1hr.

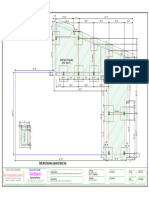

Hydraulic Process Flow Drawing for ETP 02 Equalization Tank 14'-8"x13'-4"x13'-0" 12" 64.0m3 8hr.

03 Flash Mixing Tank 4'-6"x4'-0"x5'-0" 6" 2.5m3 20min

Plant Details: 04 Flocculation Tank 4'-6"x4'-0"x5'-0" 6" 2.5m3 20min

Effluent Treatment Plant, Capacity: 8m3/hr. 05 Primary Clarifier Tank 10'-0"x11'-0"x17'-0" 6" 40m3 5.0hr.

06 pH Correction Pit 1.15m3 8min

Treatment Process: Bio-Chemical 3'-0"x3'-0"x5'-0" 12"

07 Biological Tank 20'-0"x25'-0"x16'-0" 12" 208m3 26hr.

with Return Activated Sludge Process 08 Secondary Clarifier Tank 10'-0"x11'-0"x15'-0" 6" 40m3 5hr.

09 Filter Feed Tank 10'-0"x4'-0"x13'-0" 12" 12m3 1.5hr.

10 Post Aeration Tank 10'-0"x8'-0"x13'-0" 12" 24m3 3.0hr.

11 Sludge Holding Tank 11'-0"x4'-0"x9'-0" 12" 8m3 1.0hr.

Temp. DO, pH & TDS Meter Inlet & Outlet 12 Sludge Drying Bed 5'-0"x3'-0"x5'-0"

Water Flow Meter Total = 51.5hr.

Sludge Holding Tank

Chemical Dosing Unit Water Line

Air Li ne

Sludge Store

Treated Water

Storage Tank

BIO-101 Poly Acid

(De-watering)

Optional

Flash Mixing Tank

Flocculation Tank To Equalization Tank

Primary Clarifier Tank Aeration Line

Agitator Agitator

20-35RPM

70-90RPM Neutralization Tank

pH Controller

Secondary Clarifier Tank

Recycle Activated Sludge (RAS) V-Notch

Over Flow Drain

Water Inlet Pipe

Floor & Parking Wash

66.0831

Control Panel Board Roots Air Blower

MULTIGRADE SAND FILTER ACTIVATED CARBON & MF FILTER

To Sludge Top Manhole Top Manhole

Holding Tank

Spry Header

Bar Screen

Flow Meter

G.L

Drain Line Drain Line G.L

66.0831

Waste Water Inlet

Q : 8m3/hr.

Toilet/Wash

Effluent

Disinfection

To Re-Used & Drain

1380.66

Sludge Transfer Pump

Oil Separator & Grid Chamber DO Meter Garden

Influent Lifting Pump Aeration System Primary Clarifier RAS Pump Filter Feed Tank Post Aeration Tank

Biological Tank

Influent Feeding Pump Equalization Tank RAS Tank

Aeration System

Equalizing of Water & Increase of Aeration/Oxidizing System Secondary Sedimentation System Advanced & RO System Reduce

Chemical &Sedimentation System

Dissolved Oxygen in Water Reduce with Control of BOD, COD & Nitrogen Reduce High TSS & Recycling of TDS, Chloride, Nitrate , Sodium &

is All ways Reduce High TSS

Sludge in Oxidizing Tank Coliforms Bacteria.

Irrigation /Land

CLIENT NAME & ADDRESS CONSULTANT NAME:

Effluent Treatment Plant for "M/S Aunjali Vander Auto Rice Mill", Capacity: 8m3/hr. Engr. M.M Sanjidul Islam Engr. Md. Suruz Zaman - -

M/S Aunjali Vander Auto Rice Mill MIEB-M/31346 (BSc in Civil)

Uttar Gosaipur, Sadar, Dinajpur, Bangladesh.

Arif Complex, Radio Colony Bus Stand, Savar, Dhaka. Engr. Naimatun Jannat Engr. Md. Anisur Rahman 12/08/2023

Mail: ietbd.office@gmail.com, Mob: 01723-576336

Hydraulic Process Flow Drawing for ETP (BSc in Civil) (BSc in Environment) 05

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Geospace: BHT Industries LimitedDocument1 pageGeospace: BHT Industries LimitedMd SuruzzamanNo ratings yet

- Property Line 1Document1 pageProperty Line 1Md SuruzzamanNo ratings yet

- Tank Layout PlanDocument1 pageTank Layout PlanMd SuruzzamanNo ratings yet

- Earth Work Excavation - 20'-6" From PL: GeospaceDocument1 pageEarth Work Excavation - 20'-6" From PL: GeospaceMd SuruzzamanNo ratings yet

- Toilet Toilet: Kitchen KitchenDocument1 pageToilet Toilet: Kitchen KitchenMd SuruzzamanNo ratings yet

- SetbackDocument1 pageSetbackMd SuruzzamanNo ratings yet

- Geospace: BHT Industries LimitedDocument1 pageGeospace: BHT Industries LimitedMd SuruzzamanNo ratings yet

- 7'-6"x3'-0"x5'-0" 7'-6"x3'-0"x5'-0": Grid Chamber Oil SeparatorDocument1 page7'-6"x3'-0"x5'-0" 7'-6"x3'-0"x5'-0": Grid Chamber Oil SeparatorMd SuruzzamanNo ratings yet

- 7'-6"x3'-0"x5'-0" 7'-6"x3'-0"x5'-0": Grid Chamber Oil SeparatorDocument1 page7'-6"x3'-0"x5'-0" 7'-6"x3'-0"x5'-0": Grid Chamber Oil SeparatorMd SuruzzamanNo ratings yet

- General Notes: Anowara Knit Composite LimitedDocument1 pageGeneral Notes: Anowara Knit Composite LimitedMd SuruzzamanNo ratings yet

- 24 TytuDocument1 page24 TytuMd SuruzzamanNo ratings yet

- CETP-Combined Effluent Treatment PlantDocument5 pagesCETP-Combined Effluent Treatment PlantMd SuruzzamanNo ratings yet

- Roof Top Garden Area: Walk Way RailingDocument1 pageRoof Top Garden Area: Walk Way RailingMd SuruzzamanNo ratings yet

- Treatment Process: Physico-Chemical Followed by Biological Oxidation Process With Return Activated Sludge ProcessDocument1 pageTreatment Process: Physico-Chemical Followed by Biological Oxidation Process With Return Activated Sludge ProcessMd SuruzzamanNo ratings yet

- Grid Chamber Oil Separator: Secondary ClarifierDocument1 pageGrid Chamber Oil Separator: Secondary ClarifierMd SuruzzamanNo ratings yet

- Biological Tank 15'-0''x13'-0"x15'-0" Equalization Tank 10'-0''x13'-0"x10'-0"Document1 pageBiological Tank 15'-0''x13'-0"x15'-0" Equalization Tank 10'-0''x13'-0"x10'-0"Md SuruzzamanNo ratings yet

- DM Plant DrawingDocument1 pageDM Plant DrawingMd SuruzzamanNo ratings yet

- Concept PresentationDocument5 pagesConcept PresentationMd SuruzzamanNo ratings yet

- 247 SW 28 RD - Tatiana Renginfo-0620-006 - Shop Drawings - 3.0 PDFDocument7 pages247 SW 28 RD - Tatiana Renginfo-0620-006 - Shop Drawings - 3.0 PDFMd SuruzzamanNo ratings yet

- Iron Removal-Softener & Drinking Water Treatment Plant - DrawingDocument1 pageIron Removal-Softener & Drinking Water Treatment Plant - DrawingMd SuruzzamanNo ratings yet

- Existing Ground Floor Plan: Culverted Watercourse Foul SewerDocument1 pageExisting Ground Floor Plan: Culverted Watercourse Foul SewerMd SuruzzamanNo ratings yet

- Figure: Process Flow Diagram of ETPDocument1 pageFigure: Process Flow Diagram of ETPMd SuruzzamanNo ratings yet