Professional Documents

Culture Documents

General Notes: Anowara Knit Composite Limited

General Notes: Anowara Knit Composite Limited

Uploaded by

Md SuruzzamanOriginal Title

Copyright

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentGeneral Notes: Anowara Knit Composite Limited

General Notes: Anowara Knit Composite Limited

Uploaded by

Md SuruzzamanGENERAL NOTES 8. LAP LENGTH 17.

CORNER REINFORCEMENT ('CR')

UNLESS OTHERWISE MENTIONED IN THE DRAWINGS, LAP LENGTH CORNER REINFORCEMENT FOR BEAM SUPPORTED 2-WAY SLABS

1. GENERAL

OF BARS SHALL BE :

a) DESIGN METHOD USED IS USD ACCORDING TO BANGLADESH NATIONAL L/5

BUILDING CODE (BNBC) 1993, UBC 1994 AND ACI 318-11.

f y=60000 psi & f'c = 3500 psi

b) ALL THE STRUCTURAL DRAWINGS SHALL BE READ IN CONJUNCTION BAR DIA L = LONGER CLEAR SPAN

(mm) (INCH)

WITH RELEVANT ARCHITECTURAL DRAWINGS. BARS BARS a = TOP BARS

c) FOLLOW BNBC/93 FOR SPECIFICATIONS/STRUCTURAL REQUIREMENTS NOT MENTIONED

10Ø 21 17 12 b = BOTTOM BARS

IN THE DRWAINGS OR IN THIS NOTE SHEET. 26 20

12Ø 15 b a=b

d) ANY DETAILS NOT SHOWN IN THE DRAWING SHOULD BE DONE ACCORDING TO a

L/5

16Ø 34 26 19 SPACING OF CORNER BARS =

ACI DETAILING MANUAL. a

20Ø 43 33 24 b a SPACING OF MAXIMUM POSITIVE BARS

e) BASIC WIND SPEED = 209 km/hr 22Ø 57 45 27 a

f) SEISMIC ZONE - 2 25Ø 65 50 30 b a

g) OTHER LOADS AS PER BNBC 1993 a

b

COLUMN LAPS SHALL BE TENSION LAPS

b

2. FOUNDATION

a) THE BUILDING HAS BEEN DESIGNED FOR TWO STORIED ETP 9. HOOKS OF REBAR

a) FOR ALL RE-BAR : PROVIDE 90° STANDARD HOOKS (L-BENT)

b) FOUNDATION TYPE - FOOTING & SEMI-BASEMENT

IF NOT SHOWN IN THE DRAWINGS. 18. CONCRETE CLEAR COVER FOR REINFORCING BARS

c) DEPTH OF FOUNDATION AS PER FOUNDATION LAYOUT PLAN.

10. SPACER BARS

3. CONCRETE : Member Location/Condition Clear Figure

TO SUPPORT SECOND LAYER BARS IN BEAMS USE 25mm Ø SPACER Cover (inch)

a) TYPE : CONCRETE COMPRESSIVE STRENGTH CONSIDERED AS FOLLOWS :

CONCRETE COMPRESSIVE STRENGTH MINIMUM BARS @ 3' - 0" C/C WHERE REQUIRED.

fc' = 3000 psi FOR ALL FOUNDATION Members in Side, Top

fc' = 3500 psi FOR COLUMNS,PILECAP,GRADE BEAM & FLOOR BEAMS contact & Bottom 3

with earth 3

fc' = 3000 psi FOR SLAB,STAIR & OTHER STRUCTURAL ELEMENTS. 11. CHAIRS

3

WITH STONE CHIPS WHICH ARE TO BE CONFIRMED BY TRIAL MIX DESIGN. USE CHAIRS OF NECESSARY DIMENSION MADE OF 10mmØ BAR * 1.5 1.5

b) MINIMUM CYLINDER STRENGTH : BASED ON CYLINDER TEST OF TO SUPPORT TOP BARS OF MAT @ 3' - 0" C/C. Not in Contact 1.5

Column With Earth 1.5

DIAMETER, D = 6 INCH & HEIGHT, H = 12 INCH

1.5

I) 28TH DAY STRENGTH, f'c = 3000 psi I) 7TH DAY STRENGTH, f'c = 2100 psi

II) 28TH DAY STRENGTH, f'c = 3500 psi II) 7TH DAY STRENGTH, f'c = 2400 psi 12. LAP LOCATION : * 1.5

Wall Not in Contact 1.5 1.5

a) FOR BEAM BOTTOM BAR, LAP NOT TO BE PROVIDED AT MIDDLE With Earth

c) CURING OF R.C.C WORK : THIRD ZONE OF THE SPAN

I) CURING TIME MINIMUM 28 DAYS

b) FOR BEAM TOP BAR, LAP MAY BE PROVIDED AT MIDDLE 1.5

II) METHOD OF CURING :

THIRD ZONE OF THE SPAN ** 1.5 1.5

* HORIZONTAL SURFACE - BY PONDING OF WATER top, side

c) NOT MORE THAN 50% OF THE BARS SHALL BE SPLICED AT Beam

* OTHER SURFACES-BY WRAPPING MOIST JUTE FABRIC AND

SPRINKLING WATER BY HOSE PIPE FREQUENTLY. ONE PLACE

bottom ** 1.5 1.5

d) LAP SPLICES ARE TO BE CONFINED BY HOOPS WITH MAXIMUM

4. CEMENT(Water Protect) 1.5

SPACING OR PITCH OF d/4 OR 100 WHERE d IS THE

ORDINARY PORTRAND CEMENT OR PORTLAND COMPOSITE CEMENT AS MENTIONED EFFECTIVE DEPTH OF THE BEAM.

.75

ITEMWISE CONFORMING TO BDS 232 : 1974/ASTM C150 Slab and stair Top and bottom .75

.75

5. CONCRETE AGGREGATE 13. DEVELOPMENT LENGTH

ALL BEAM AND SLAB REBARS SHOULD BE EXTENDED INTO THE SUPPORT UPTO Exterior 2.5

a) FINE AGGREGATES : SAND OF F.M 2.50 (Min.)

Retaining Wall/ 2.5 1.5

DEVELOPMENT LENGTH.

b) COARSE AGGREGATES : 3/4 in DOWN WELL GRADED STONE Basement Wall

GRADE BEAMS,COLUMNS FLOOR BEAM AND REST OF THE MEMBER OF THE STRUCTURE Interior 1.5

14. ADMIXTURE 1.5 2

APPROVED BY THE DESIGN ENGINEER. Water face 2

6. WATER

2

Water tank

POTABLE WATER TO BE USED IN ALL CONCRETE MIX.

15. WATER STOPPER

1.5

Other face 1.5

7. STEEL REINFORCEMENT 9 inch WIDE PVC WATER STOPPER TO BE USED AT ALL CONSTRUCTION JOINTS

a) COLUMNS, SHEAR WALLS & BEAM REINFORCEMENTS ARE OF 72.5 GRADE BELOW GROUND IN SHALLOW FOUNDATION, RETAING WALL & WATER TANK WALL.

* From tie

b) DEFORMED BAR MADE FROM BILLET STEEL ** From stirrups

16. MAXIMUM BARS IN BEAMS IN SINGLE LAYER

MAXIMUM NUMBER OF BARS AS A SINGLE LAYER IN BEAM 19. MINIMUM BAR SPACING OF COLUMN

c) SLAB, WATER TANK, STAIR, LINTEL ETC. REINFORCEMENTS ARE OF 72.5 GRADE STEM SHALL BE AS PER ACI DETAILING MANUAL. LONGITUDINAL BARS

DEFORMED BAR MADE FROM BILLET STEEL

CLEAR DISTANCE BETWEEN LONGITUDINAL BARS SHALL NOT BE

d) YIELD STRENGTH OF 60 GRADE STEEL f'y = 72500 psi CONFORMED

TO ONE OF THE FOLLOWING SPECIFICATIONS :i) BDS 1313 : 1991, ii) ASTM A615M LESS THAN 1.5 TIMES BAR DIAMETER, 1.5 TIMES OF THE MAXIMUM SIZE OF

e) ASSUME SOIL BEARING CAPACITY: 1.5TSF COARSE AGGREGATE NOR 1.5 inch

CLIENT NAME & ADDRESS CONSULTANT NAME:

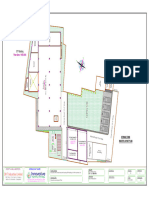

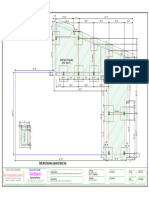

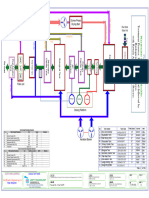

Combined Effluent Treatment Plant for Anowara Knit Composite Limited Engr. M.M Sanjidul Islam - -

Prof. Engr. Ruhul Amin (BUET)

Anowara Knit Composite Limited B.Sc in Civil, MIEB-M/31346

Mulayed, Dhaka - Mymensingh Hwy, Mawna Union

236/5/A, South Pirerbag, 60 Feet, General Information-1 13/02/2022 03

Mirpur, Dhaka-1216. Engr. Md. Suruz Zaman

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Geospace: BHT Industries LimitedDocument1 pageGeospace: BHT Industries LimitedMd SuruzzamanNo ratings yet

- Geospace: BHT Industries LimitedDocument1 pageGeospace: BHT Industries LimitedMd SuruzzamanNo ratings yet

- Property Line 1Document1 pageProperty Line 1Md SuruzzamanNo ratings yet

- SetbackDocument1 pageSetbackMd SuruzzamanNo ratings yet

- Toilet Toilet: Kitchen KitchenDocument1 pageToilet Toilet: Kitchen KitchenMd SuruzzamanNo ratings yet

- 24 TytuDocument1 page24 TytuMd SuruzzamanNo ratings yet

- Tank Layout PlanDocument1 pageTank Layout PlanMd SuruzzamanNo ratings yet

- Earth Work Excavation - 20'-6" From PL: GeospaceDocument1 pageEarth Work Excavation - 20'-6" From PL: GeospaceMd SuruzzamanNo ratings yet

- Biological Tank 15'-0''x13'-0"x15'-0" Equalization Tank 10'-0''x13'-0"x10'-0"Document1 pageBiological Tank 15'-0''x13'-0"x15'-0" Equalization Tank 10'-0''x13'-0"x10'-0"Md SuruzzamanNo ratings yet

- CETP-Combined Effluent Treatment PlantDocument5 pagesCETP-Combined Effluent Treatment PlantMd SuruzzamanNo ratings yet

- Effluent Treatment Plant, Capacity: 8m3/hr. Treatment Process: Bio-Chemical With Return Activated Sludge ProcessDocument1 pageEffluent Treatment Plant, Capacity: 8m3/hr. Treatment Process: Bio-Chemical With Return Activated Sludge ProcessMd SuruzzamanNo ratings yet

- Grid Chamber Oil Separator: Secondary ClarifierDocument1 pageGrid Chamber Oil Separator: Secondary ClarifierMd SuruzzamanNo ratings yet

- 7'-6"x3'-0"x5'-0" 7'-6"x3'-0"x5'-0": Grid Chamber Oil SeparatorDocument1 page7'-6"x3'-0"x5'-0" 7'-6"x3'-0"x5'-0": Grid Chamber Oil SeparatorMd SuruzzamanNo ratings yet

- Treatment Process: Physico-Chemical Followed by Biological Oxidation Process With Return Activated Sludge ProcessDocument1 pageTreatment Process: Physico-Chemical Followed by Biological Oxidation Process With Return Activated Sludge ProcessMd SuruzzamanNo ratings yet

- 7'-6"x3'-0"x5'-0" 7'-6"x3'-0"x5'-0": Grid Chamber Oil SeparatorDocument1 page7'-6"x3'-0"x5'-0" 7'-6"x3'-0"x5'-0": Grid Chamber Oil SeparatorMd SuruzzamanNo ratings yet

- DM Plant DrawingDocument1 pageDM Plant DrawingMd SuruzzamanNo ratings yet

- Roof Top Garden Area: Walk Way RailingDocument1 pageRoof Top Garden Area: Walk Way RailingMd SuruzzamanNo ratings yet

- Concept PresentationDocument5 pagesConcept PresentationMd SuruzzamanNo ratings yet

- 247 SW 28 RD - Tatiana Renginfo-0620-006 - Shop Drawings - 3.0 PDFDocument7 pages247 SW 28 RD - Tatiana Renginfo-0620-006 - Shop Drawings - 3.0 PDFMd SuruzzamanNo ratings yet

- Iron Removal-Softener & Drinking Water Treatment Plant - DrawingDocument1 pageIron Removal-Softener & Drinking Water Treatment Plant - DrawingMd SuruzzamanNo ratings yet

- Existing Ground Floor Plan: Culverted Watercourse Foul SewerDocument1 pageExisting Ground Floor Plan: Culverted Watercourse Foul SewerMd SuruzzamanNo ratings yet

- Figure: Process Flow Diagram of ETPDocument1 pageFigure: Process Flow Diagram of ETPMd SuruzzamanNo ratings yet