Professional Documents

Culture Documents

Plywood Desk For Double Home Office

Uploaded by

Vincent GandoisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plywood Desk For Double Home Office

Uploaded by

Vincent GandoisCopyright:

Available Formats

instructables

Plywood Desk for Double Home Office

by linus strothmann

OK, so here is the problem: My wife and I suddenly Our house is insulated with straw-bales and the inside

have to work from home. This wasn't even an option is plastered with clay. All the corners of the clay

before and with an apartment of ve bedrooms and plastering are rounded. So I measured the radius of

four kids we actually don*t have a room for it. Only these corners and used that as the basis for the

option: our bedroom. With all the chaos that comes design.

with a bunch of kids, we have tried to keep our

bedroom as tidy as possible. The idea that we would Here is a video about the process:

have to turn this room into an o ce was a little

nightmare for me. So I decided: If we put a desk in https://youtu.be/ZkiagzZymEs

there, it should be two things:

Ok, let's get started!

1. It should look really nice and incorporate some

design elements that will make it seem like it was only Supplies:

built for this room.

The desk is made from one sheet (2,5m*1,25m) of

18mm birch plywood. Only other supplies are drawer-

2. Everything that is on the desk while we work needs

slides and a couple of 15mm plywood pieces for the

to go into drawers in the evening, so that the

drawers.

bedroom becomes a bedroom again.

Here is the Link for the CNC:

The solution: this plywood desk with at but very

large drawers and rounded feet that take up a shape

https://easel.inventables.com/projects/IDviEZe4OEplp

already existent in our room.

XLe5ug9wA

https://youtu.be/ZkiagzZymEs

Plywood Desk for Double Home Office: Page 1

Step 1: Cutting the Plywood

Plywood Desk for Double Home Office: Page 2

The rst thing to do is to have a good look at your After that I cut out four pieces of 77+31cm. These are

plywood sheet and decide where your desktop is the pieces that go on the cnc (in my case an x-carve)

going to be cut out. It's the only piece where the and later make up the four legs, leg support plus

surface is visible, everything else will be cut anyway. sides of the desk.

I cut out this piece rst, for my desk it was 70*176cm. Then it's time to cut 2cm strips of plywood for the

Since cutting a whole board on the table saw can be back and the sides.

tricky, I cut it a little oversize rst and later cut the real

dimensions. The dimensions are as follows:

Backpanel: four pieces 2* 136cm (width of the desk so: eight pieces 2*60cm for the drawers, four pieces

minus 40cm) 2*16cm for the centre front.

Front: Last you will need to cut ten pieces 37cm long to

make a panel out of which to cut rounded corners.

the front consist of two drawers 60cm wide and a

centre piece 16cm wide (width of the desk minus Ok, everything cut: let´s use the cnc then.

40cm minus drawers)

Step 2: CNC-Cutting Side and Leg Elements

Plywood Desk for Double Home Office: Page 3

The table has a top 18mm, then four "layers" of 18mm is made form the cutout left after the cnc is nished

all around, so this adds up to 5*18mm= 9cm. I wanted (you can see it on the picture, it needs rounded edges,

the desk to be about 72cm, so I decided to make 38 which I did with a round-over- bit) because otherwise

pieces for each leg, so that I had enough spares. I the small cutout doesn`t t properly). All of these

ended up using 34 pieces, so my desk is a total of pieces I put on four sheets of plywood each 77*31cm.

34*1,8+9=eg need 38 pieces of 18mm, adding up to For each board the x-carve needed 3 hours, so in total

70,2cm. I kept four pieces so that I can still make it it was used for twelve hours. I used this time to do

higher if I want to. other projects and glue up the front and backpanels.

Plus, after the rst one was done, I cleaned the edges

So in total we need four U-shaped pieces for each side and so on...

of the desk, eight in total and 38*4= 152 leg pieces.

Additional the legs need an L-shaped support, which

Step 3: Gluing Up Front and Back Panels

This is a straigth forward job.

Lay out the 2cm wide pieces and glue them together.

I actually cut these longer originally and cut them to nal size after they were glued up. It makes a much cleaner

cut, then trying to get them lined up perfectly.

Also, while the CNC keeps cutting you can sand these really ush.

Plywood Desk for Double Home Office: Page 4

Step 4: Making Drawers

Another thing that can be done while letting the CNC cut out all the leg and side pieces is to make drawers.

I did it in a very simple way and used some 15mm plywood I had lying around and simply glued up the drawers so

that there was enough space for hidden drawer slides at the side. There is a hundred ways to make drawers,

depending on what tools you have. I use my old lamello for this.

Step 5: Gluing the Side Panels

When the CNC is done you can glue up the two sidepanels. It is absolutely crucial to be very precise here, because

otherwise it will be di cult to t in the L-shaped leg support. I found it easier to glue two at a time and then glue

two and two together once the glue was dry (I only have a foto of the rst i did, where I glued all four pieces

together at the same time.)

Plywood Desk for Double Home Office: Page 5

Step 6: Gluing Up All Side, Back and Front Panels

So after you have glued up all the individual panels I layed everything out and attached it with clamps to

it's time to glue it all to the underside of the desk top. make sure everything really t. Then I only took o the

part I was preparing and gluing on, instead of taking

I added four pieces of 15mm plywood that go from everything o and then glueing everything on at

front to back and to which the drawerslides will be once.

attached. again I used lamellos, but you can also use

just glue or even pocket screws (in this case you have I also tested if the drawers t in... just in case.

to be really carefull not to go through to the top of

the desk...would be a shame) Good luck!

Plywood Desk for Double Home Office: Page 6

Plywood Desk for Double Home Office: Page 7

Step 7: Attaching the Leg-support

Once the actual desktop plus sidepanels are done, the screw to attach them to the desktop.

next step is to attach the L-shaped leg supports.

This could be done in a lot of di erent ways. I made

I wanted to be able to take the legs o , so I decided to small round pieces with the cnc in which I hammered

use screws here. small t-nuts and then glued them under the L-shaped

leg support. Then I drilled a hole and sat a small screw

The L-shaped leg support t very snug into the resees in.

in the corners of the sidepanels, so I only used one

Plywood Desk for Double Home Office: Page 8

Plywood Desk for Double Home Office: Page 9

Step 8: Yeah: Making the Legs!

Now this is the step you'll be waiting for: glueing up to press them rmly on to the legsupport.

all those 150 pieces together to make those nice

looking legs. This is a really rewarding job!!

Important: The rst piece should only be glued to the When all four legs are done you can turn the table

legsupport, NOT TO THE SIDEPANEL!! around to get a feeling for it. when I did this I decided

it was a little bit too shaky. So I added two strips of

Otherwise the leg wont' be detachable. 2cm plywood next to the leg support. Make sure to

only glue these to the leg, not to the sidepanel. After

After the rst one is on, it is all straight forward. Put that the table was really stable.

glue on, press on. Sometimes I needed a hammer to

get them tightly down, and very often I used a clamp

Plywood Desk for Double Home Office: Page 10

Step 9: Attaching the Drawers

you could do this step before doing the legs or after, it doesn't really matter. How the drawers are attached

depends entirely on the sliders you use. I can only recommend to use high quality sliders!

Step 10: Adding Rounded Corners to the Legs

This is optional, but I think it makes the table look so much better.

I cut two circles on the cnc and then cut out the leftover of these circles into eight pieces, that I then glued to the

legs. Again be careful not to glue them to the sidepanels, remember those detachable legs!

I started with clamps, but this is a much easier job with good tape.

Plywood Desk for Double Home Office: Page 11

Step 11: Making Things Even More Round

So until now everything is round except your desktop. I cut it rough with a Japanese hand saw and then used a

router with a ush-trim-bit.

Plywood Desk for Double Home Office: Page 12

When that is done it is time to round over all edges. I used a big radius round-over-bit on the top, and a small one

for everything else.

Step 12: Sanding and Finish

Plywood Desk for Double Home Office: Page 13

Time to sand! After everything is really nice, take a cloth and clean

the whole desk.

I used a belt-sander to get everything ush and then

sanded everything, including the top, by hand Then use whatever nish you prefer.

afterwards.

Since it is going into our bedroom I decided to use

I wouldn`t recommend to use anything too rough and just linseed oil. Looks nice, I think.

powerful on the rounded legs, because you`ll never

get it looking so round again, once you've taken o to

much... better by hand.

Step 13: Now: Go to Work!!

Ok, so that was that. I really enjoyed building this and I am super happy about it. I am going to do a couple of

smaller tables for plants in the same style soon....

Now we can both work from home, without ruining our nice bedroom...

If you need any help with the CNC les, let me know.

Plywood Desk for Double Home Office: Page 14

video is finally ready and included in the instructable

Love the curves on the legs and how they match the curve on the walls.

Plywood Desk for Double Home Office: Page 15

This is absolutely beautiful! As said previously, it really takes plywood up many levels. I look

forward to your smaller tables.

thanks!

I'm a big fan of making a feature of ply-edge, but this is next level. Beautiful piece, and I love the

way you make the legs. Thank you for sharing your work, and good luck in the competition :-)

thanks a lot alex! I think the legs can still be optimized, maybe I will do that on the next smaller

piece...

"The legs can still be optimized"

If you didn't think that _everything_ could be optimized then you wouldn't be a maker :-)

Do post the enhancement when you develop it.

Plywood Desk for Double Home Office: Page 16

You might also like

- DIY Tri-Fold Futon BaseDocument27 pagesDIY Tri-Fold Futon BaseJosh Grantmorceau100% (3)

- How To Make Floating Tensegrity Table: Step 1Document9 pagesHow To Make Floating Tensegrity Table: Step 1Januar EmberNo ratings yet

- The Essential "All Purpose" Workbench: Challenging ProjectDocument34 pagesThe Essential "All Purpose" Workbench: Challenging ProjectB. IonutNo ratings yet

- Pallet Wood WorkbenchesDocument10 pagesPallet Wood WorkbenchesRicardo Fernandes GalliNo ratings yet

- Line Table Press Plan PDFDocument26 pagesLine Table Press Plan PDFbongsky167% (3)

- F WW Grooving PlanesDocument5 pagesF WW Grooving PlanesKaren Rathbun100% (1)

- 2x1000 MW - Central Java IPP-RFP FinalDocument174 pages2x1000 MW - Central Java IPP-RFP FinalYin ThoNo ratings yet

- Convertible Plywood Coffee TableDocument9 pagesConvertible Plywood Coffee TableYockobeeko YocNo ratings yet

- Folding Side TableDocument10 pagesFolding Side TableNijaz HadzicNo ratings yet

- Easy DIY Plywood Desk For 40 55Document8 pagesEasy DIY Plywood Desk For 40 55germanNo ratings yet

- Foosball Table DIY!: Step 1: PlanningDocument23 pagesFoosball Table DIY!: Step 1: PlanningManuel TorresNo ratings yet

- Kitchen Helper With Sliding Step and Drawing TableDocument12 pagesKitchen Helper With Sliding Step and Drawing Tablejankels865No ratings yet

- Homemade 3 in 1 Multipurpose Workbench: Table Saw, Router Table and Inverted Jigsaw (Free Plans)Document20 pagesHomemade 3 in 1 Multipurpose Workbench: Table Saw, Router Table and Inverted Jigsaw (Free Plans)jeffNo ratings yet

- Parsons Style Coffee Table: Step 1: Rough Sawn LumberDocument11 pagesParsons Style Coffee Table: Step 1: Rough Sawn LumberrhinorodNo ratings yet

- Making A Mid Century Modern ArmchairDocument7 pagesMaking A Mid Century Modern ArmchairJB WellsNo ratings yet

- Making A Mid Century Modern ArmchairDocument7 pagesMaking A Mid Century Modern ArmchairJB WellsNo ratings yet

- Designing and Building A Computer TableDocument9 pagesDesigning and Building A Computer Tablemaster_codersNo ratings yet

- Hexagon Side Table With Drawer: InstructablesDocument15 pagesHexagon Side Table With Drawer: InstructablesRod HyattNo ratings yet

- Toy Organization Cabinet With A Walnut Bench and DDocument12 pagesToy Organization Cabinet With A Walnut Bench and DJ.D. ShellnutNo ratings yet

- Wooden Bench-Vise 6 InchDocument12 pagesWooden Bench-Vise 6 InchKates SimaduNo ratings yet

- Awesome CNC Table: InstructablesDocument7 pagesAwesome CNC Table: InstructablesNana Obiri Yeboa DarkoNo ratings yet

- Armchair 400 by Aalto?: InstructablesDocument23 pagesArmchair 400 by Aalto?: InstructablesGP JGNo ratings yet

- Wooden Marble Roller Machine: InstructablesDocument20 pagesWooden Marble Roller Machine: InstructablesJair MergNo ratings yet

- The Classic Roubo Style Workbench: Intermediate Level ProjectDocument21 pagesThe Classic Roubo Style Workbench: Intermediate Level ProjectB. IonutNo ratings yet

- Chevron Pattern Plywood Corner Desk MotorizedDocument45 pagesChevron Pattern Plywood Corner Desk MotorizedGabriel Antonio NájeraNo ratings yet

- Build A Raised Garden Bed: InstructablesDocument14 pagesBuild A Raised Garden Bed: InstructablesBryan Abd AzizNo ratings yet

- DIY Editing Desk - PDF (Youtube)Document3 pagesDIY Editing Desk - PDF (Youtube)Jarrett YewNo ratings yet

- Building A Laptop Table (Wheely Desk) Part 1Document5 pagesBuilding A Laptop Table (Wheely Desk) Part 1PayasoTecnoNo ratings yet

- Spanish Chair Made With PlywoodDocument32 pagesSpanish Chair Made With PlywoodJazzy VaaltynNo ratings yet

- How To Build Modern Barstools Like A ProDocument17 pagesHow To Build Modern Barstools Like A Progerman100% (1)

- Picnic Table: Step 1: Layout - CutlistDocument12 pagesPicnic Table: Step 1: Layout - CutlistAntonios MarkogiannakisNo ratings yet

- Leaning Wall Ladder DeskDocument19 pagesLeaning Wall Ladder DeskKenneth M GordonNo ratings yet

- Modern Plywood Desk: InstructablesDocument13 pagesModern Plywood Desk: InstructablesraduNo ratings yet

- Making A Prallel Jaw Bar ClampDocument34 pagesMaking A Prallel Jaw Bar ClampHomayoon GeramifarNo ratings yet

- Adirondack ChairDocument11 pagesAdirondack ChairMoises Martins RochaNo ratings yet

- Corner O Ce Desk: Step 1: PlansDocument28 pagesCorner O Ce Desk: Step 1: Plansarmando.alanisNo ratings yet

- A Carved Tea Box: InstructablesDocument10 pagesA Carved Tea Box: InstructablesVictor Hugo MartinezNo ratings yet

- Step 1 - Gather Your Materials: Click HERE or On The Image Below For The Downloadable Double Chair Bench PlansDocument35 pagesStep 1 - Gather Your Materials: Click HERE or On The Image Below For The Downloadable Double Chair Bench PlansGerardo Silva JassoNo ratings yet

- In Basic Wood Working The Requires Precision and Patience To Produce A Good Quality ProductDocument10 pagesIn Basic Wood Working The Requires Precision and Patience To Produce A Good Quality ProductAngeloLorenzoSalvadorTamayoNo ratings yet

- How To Build An Outdoor Lounge ChairDocument11 pagesHow To Build An Outdoor Lounge ChairJ MartinNo ratings yet

- Work Bench: A Design For Holding The WorkDocument89 pagesWork Bench: A Design For Holding The WorkRalf Homberg100% (1)

- Making High End Furniture From Plywood DIY ModernDocument10 pagesMaking High End Furniture From Plywood DIY ModernVincent GandoisNo ratings yet

- Easy Woodworking ProjectsDocument8 pagesEasy Woodworking Projectstitch1680% (5)

- How To Build A Double Chair Bench With TableDocument27 pagesHow To Build A Double Chair Bench With TablebearyuyuNo ratings yet

- Make A Quoridor Game PDFDocument12 pagesMake A Quoridor Game PDFVedran Mirko100% (1)

- Building The WorkshopDocument10 pagesBuilding The WorkshopDan MacRaeNo ratings yet

- Minas TirithDocument10 pagesMinas TirithHenry MarshallNo ratings yet

- Easy Outdoor Sofa From 2x4s and Two Power ToolsDocument21 pagesEasy Outdoor Sofa From 2x4s and Two Power ToolsDany MounsefNo ratings yet

- Como Adaptar Uma Impressora para CdsDocument11 pagesComo Adaptar Uma Impressora para CdsJosevalMazeNo ratings yet

- Madill - Design FinalDocument9 pagesMadill - Design Finalapi-467570170No ratings yet

- Coat Hanger - MainDocument4 pagesCoat Hanger - MainStephen DudleyNo ratings yet

- Build Your Own Drill Press For FREE!: InstructablesDocument27 pagesBuild Your Own Drill Press For FREE!: InstructablesMynor Fahrenreich100% (1)

- How To Make A SOFA That Turns Into A BEDDocument16 pagesHow To Make A SOFA That Turns Into A BEDKalid Kemal100% (1)

- Neutra Boomerang ChairDocument20 pagesNeutra Boomerang Chairpedro.guzmanNo ratings yet

- Diy Kid'S Nesting TableDocument12 pagesDiy Kid'S Nesting TableJeffrey WittyNo ratings yet

- DIY Book ScannerDocument101 pagesDIY Book Scannerjahanavi pethani100% (1)

- Cherry and Fir BookcaseDocument6 pagesCherry and Fir Bookcasecaballo_blanco_2100% (1)

- Robot Blocs de BoisDocument42 pagesRobot Blocs de BoisLuc PoiretNo ratings yet

- Heirloom Push ToyDocument13 pagesHeirloom Push ToyLinoNo ratings yet

- My New Wooden Garbage Box PDFDocument14 pagesMy New Wooden Garbage Box PDFHogen KoglerNo ratings yet

- Family Handyman Ultimate 1 Day ProjectsFrom EverandFamily Handyman Ultimate 1 Day ProjectsRating: 5 out of 5 stars5/5 (1)

- Secret Compartment Plywood LampDocument20 pagesSecret Compartment Plywood LampVincent GandoisNo ratings yet

- Plan Compas A Verge 30cmDocument1 pagePlan Compas A Verge 30cmVincent GandoisNo ratings yet

- Premeire Edition n07 CarsDocument4 pagesPremeire Edition n07 CarsVincent GandoisNo ratings yet

- Premeire Edition n05 Rain&Thunder, Fire, BubblesDocument1 pagePremeire Edition n05 Rain&Thunder, Fire, BubblesVincent GandoisNo ratings yet

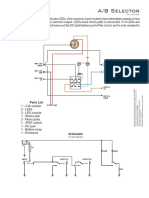

- A-B Switch Box (Passive) Parts Layout and Wiring DiagramDocument1 pageA-B Switch Box (Passive) Parts Layout and Wiring DiagramVincent GandoisNo ratings yet

- A-B Switch Box (Passive) SchematicDocument1 pageA-B Switch Box (Passive) SchematicVincent GandoisNo ratings yet

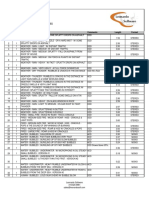

- A-B Switch Box (Passive) Billn of MaterialsDocument1 pageA-B Switch Box (Passive) Billn of MaterialsVincent GandoisNo ratings yet

- A-B SelectorDocument1 pageA-B SelectorVincent GandoisNo ratings yet

- 19msagro074Document15 pages19msagro074Praveen kumar ShuklaNo ratings yet

- PROBLEMSChap 7 SMDocument27 pagesPROBLEMSChap 7 SMVillena Divina VictoriaNo ratings yet

- Cement and Fuel RequirmentDocument2 pagesCement and Fuel RequirmentAbel100% (1)

- Accounting For Non-Current AssetsDocument4 pagesAccounting For Non-Current AssetsPrinceNo ratings yet

- ContractDocument3,272 pagesContractJanet VillarrealNo ratings yet

- Deed of Absolute SaleDocument2 pagesDeed of Absolute SaleAl FloresNo ratings yet

- Corrugated Boxes - 250Document9 pagesCorrugated Boxes - 250Dhruv ChandwaniNo ratings yet

- Ashish BookDocument79 pagesAshish BookDhanush Kumar100% (1)

- Plant Chiller BOQDocument3 pagesPlant Chiller BOQmohammad illiasNo ratings yet

- SHS APPLIED ECONOMICS Module 2 Utility and Application of Applied Economics To Solve Economic Issues and ProblemsDocument17 pagesSHS APPLIED ECONOMICS Module 2 Utility and Application of Applied Economics To Solve Economic Issues and ProblemsJr ParaynoNo ratings yet

- Fibonacci 2Document27 pagesFibonacci 2shahzainkhan100% (1)

- Mathematical Analysis 2019 ASSIGNDocument9 pagesMathematical Analysis 2019 ASSIGNMario Rioux JnrNo ratings yet

- Invoice 17780702440786029961Document2 pagesInvoice 17780702440786029961aravind grandhiNo ratings yet

- BUCKET - M Type Elevator SANWEIDocument3 pagesBUCKET - M Type Elevator SANWEIPurchasing Central TechnicNo ratings yet

- Contemp. Assighnment 2Document2 pagesContemp. Assighnment 2Roberto E. De LeonNo ratings yet

- Rs Aggarwal For Class 9 Math Chapter 12 - Simple InterestDocument35 pagesRs Aggarwal For Class 9 Math Chapter 12 - Simple InterestKarthik PillaiNo ratings yet

- Energy Material 101Document8 pagesEnergy Material 101Dr. Muhammad ImranNo ratings yet

- Tata-Aig General Insurance Company LTD: Policy No. 0238443404 / 0238443469 Claim No.Document3 pagesTata-Aig General Insurance Company LTD: Policy No. 0238443404 / 0238443469 Claim No.Mahendra SinghNo ratings yet

- Index Number (1) B SC III 16-4Document44 pagesIndex Number (1) B SC III 16-4alcinialbob1234No ratings yet

- 2147 Bill OmrDocument1 page2147 Bill Omrofficer lkoNo ratings yet

- PVC Pipe, Hdpe Pipe ManufacuringDocument10 pagesPVC Pipe, Hdpe Pipe ManufacuringDijin MaroliNo ratings yet

- Harmonic Trading - AflDocument3 pagesHarmonic Trading - Aflpg_hardikarNo ratings yet

- Jurnal TOCDocument11 pagesJurnal TOCEndia HergariNo ratings yet

- Indian Immunologicals Ltd.Document10 pagesIndian Immunologicals Ltd.Nani VolsNo ratings yet

- Office of Temporalities: Jerome TenebroDocument2 pagesOffice of Temporalities: Jerome TenebroJerome TenebroNo ratings yet

- Cad JpyDocument7 pagesCad Jpyhung tranNo ratings yet

- Activity #3 (1) GDocument4 pagesActivity #3 (1) GJosé Daniel YucraNo ratings yet

- Paranoia - Forms PackDocument28 pagesParanoia - Forms PackcthuflyNo ratings yet

- Simulation Report PDFDocument12 pagesSimulation Report PDFSweta RanjanNo ratings yet