Professional Documents

Culture Documents

Type-ZHLA-Flexible Conduit - Electri-Flex

Uploaded by

AE ENERGY Jefe de ProyectosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Type-ZHLA-Flexible Conduit - Electri-Flex

Uploaded by

AE ENERGY Jefe de ProyectosCopyright:

Available Formats

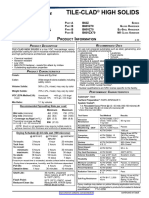

Type ZHLA

Part of the Zero-Halogen Flexible Conduit Family.

Non-halogen, low smoke and low ame spread make Type ZHLA a proven choice for

applications where limiting toxic materials of combustion are an important issue. Since ZHLA

is also UL listed and CSA Certi ed for “Heavy-Duty” applications, it is ideal for eld installation

All Products Proudly Made in the USA

in con ned, public areas such as subways, tunnels, etc.

Construction: Product

Information

Inner Core:

CERTIFICATIONS &

• Hot Dipped Galvanized Steel

• 3/8” – 1-1/4” Squarelock Pro le with continuous bonding strip

COMPLIANCE

• 1-1/2” – 4” Fully Interlocked Pro le Listed File # E29278. Conforms to

Underwriters Laboratories

Liquidtight Jacket: Standard ANSI/UL-360 for

Liquidtight Flexible Steel conduit.

• Zero-Halogen Polyurethane

Certi ed File #LL18858. Conforms

• Resistant to Ozone, Hydrocarbons, Chemicals and Oils to CSA Standard C22.2 No 56-17.

• Flame Retardant Conforms to Annex A “Heavy-

• Low Smoke Duty” in sizes 1/2″ or larger. FT1

• Low Toxicity

WEEE and RoHS Compliant

• Sunlight Resistant (UV)

• Marked HD for “Heavy-Duty” BS EN IEC 61386 Classi cation

Code 445240650414 CE

Application: Declaration

ARRA: For ARRA Certi cation

• Meets the requirements of Bombardier SMP 800-C for Toxic Gas Generation.

Letter, please click here.

• Meets the requirements of both ASTM E162 for Flame Spread and ASTM E662 for Smoke

Generation.

Buy America: For Buy America

Certi cation Letter, please click

This conduit is intended for installation in accordance with Article 350 of the NEC

here.

(ANSI/NFPA-70) and in section 14.5.4 of the ANSI/NFPA-79 Standard for Industrial Machinery:

STANDARD COLORS

• Listed and marked for Direct Burial and in Poured Concrete

Black. Other colors available upon

• For containment of 1000 volt and lower potential circuits

request.

• Suitable as a grounding conductor when used for circuits rated up to 20A for the 3/8 &

1/2 inch trade sizes and 60A for the 3/4 through 1-1/4 inch trade sizes in lengths six feet

or less per NEC Article 250.118(6). Larger sizes require separate grounding conductor.

• Installations in hazardous (classi ed) locations:

• Class I Div. 2: Article 501.10 (B)(2) & 501.30 (B) WORKING

• Class II Div. 1: Article 502.10 (A)(2) & 502.30 (B) Div. 2: 502.10 (B)(2) TEMPERATURES

• Class III Div. 1: Article 503.10 (A)(3) & 503.30 (B) Div. 2: 503.10 (B) UL: -40°C to 80°C Air / 60°C Wet / 70°C

• Installed under raised oors in Data Processing Areas Articles 645.5 (E) Oil

• Electric Signs and Outline Lighting over 1000 volts Articles 600.7/600.32(A)(1) CSA: -40°C to 60°C Dry / 60°C Oil

• Permitted for Service Entrance wiring to six feet Article 230.43

• Used as Feeders and Services at Marinas and Boatyards Article 553.7(B).

• Wiring on Building Article 225.10

• Conductor Enclosures Adjacent to Motors over 1000 V Article 430.223

• Underground Service, Feeder, Branch Circuit, and Recreational Vehicle Site Feeder Circuit

Conductors Article 551.80

• Elevators and Hoistways Article 620.21

• Pools and Fountains Article 680

• Bodies of water. Article 682

• Fire Pumps. Article 695

This conduit is intended for use according to the Canadian Electrical Code (CEC CSA 22.1-

18) as described in clause 12-1300 for dry, damp or wet locations.

• Conforms to CSA C22.2 No. 56-17 Annex A “Heavy Duty”

Hazardous Locations areas where exibility is necessary:

• Class I Div 2: CSA 22.1 J18-152 (1) (i)

• Class II Div 1: CSA 22.1 J18-204 (4) (b)

• Class II Div 2: CSA 22.1 J18-254 (1) (h)

• Class III Div 1: CSA 22.1 J18-304 (1) (f)

• Class III Div 2: CSA 22.1 J18-354 (h)

• Zone 2: CSA 22.1 18-152 (1) (h)

• Zone 20: CSA 22.1 18-192 (3) (a)

• Zone 21: CSA 22.1 18-202 (4) (a)

• Zone 22: CSA 22.1 18-252 (1) (h)

Combustion & Flammability

Properties

COMBUSTION & FLAMMABILITY TEST VALUE

Vertical Burn (Material) UL94 V-0 Rating; No Flaming Drips

Vertical Burn (Conduit) UL360 Pass; No Flaming Drips

Oxygen Index % D2863 28.5

Flame Spread Index ASTM E162 25; No Flaming Drips

Smoke Generation (Flaming) ASTM E662 (NFPA 258) Ds 41@1.5 Min/Ds 113@4.0 Min

Smoke Generation (Non-Flaming) ASTM E662 (NFPA 258) Ds 4@1.5 Min/Ds 19@4.0 Min

Toxic Gas Generation BOMBARDIER SMP 800-C Pass

Toxicity Index NES 713 3.9

* Test data is based on controlled laboratory conditions and does not necessarily re ect

performance in actual re conditions. Additional product information available upon request.

Markets:

Construction, Data Centers, Defense, Healthcare, Mining, Oil & Gas Re neries, Power

Plants, Rail/Transit, Renewable Energy, Security, Ship Building, Steel

Mills, Telecommunications, Utilities

Product Table

US Trade Size 3/8" 1/2" 3/4" 1" 1 1/4" 1 1/2" 2" 2 1/2" 3" 3 1/2" 4"

ISO (MM) 16 20 25 32 40 50 63 70 80 90 100

CSA (MM) 12 16 21 27 35 41 53 63 78 91 103

Type ZHLA-10 ZHLA-11 ZHLA-12 ZHLA-13 ZHLA-14 ZHLA-15 ZHLA-16 ZHLA-17 ZHLA-18 ZHLA-350 ZHLA-19

Min (IN.) 0.484 0.622 0.820 1.041 1.380 1.575 2.020 2.480 3.070 3.500 4.000

Internal Diameter

Max (IN.) 0.504 0.642 0.840 1.066 1.410 1.600 2.045 2.505 3.100 3.540 4.040

Min (IN.) 0.690 0.820 1.030 1.290 1.630 1.865 2.340 2.840 3.460 3.960 4.460

Outer Diameter

Max (IN.) 0.710 0.840 1.050 1.315 1.660 1.900 2.375 2.875 3.500 4.000 4.500

Inside Bend Radius Static (IN.) 2.0 3.0 4.2 5.5 7.0 4.5 6.0 8.0 10.0 11.0 12.0

Weight Lbs. per 100 Ft 29 32 53 82 102 124 145 192 252 308 350

Carton (Ft.) 100 100 100 100 50 50 50 25 25 25 25

Part # (Black) 88101 88111 88121 88132 88142 88152 88162 88172 88182 88187 88192

Reel (Ft) 500 500 500 400 200 150 100

Standard Length

Part # (Black) 88103 88113 88124 88134 88144 88154 88164

Reel (Ft) 1000 1000 1000

Part # (Black) 88104 88114 88125

related products

You might also like

- Extintores Amerex Product CatalogDocument20 pagesExtintores Amerex Product CatalogGilberto GarciaNo ratings yet

- ABB T B Liquidtight System - Series 5300SST6 LT FITTINGSDocument2 pagesABB T B Liquidtight System - Series 5300SST6 LT FITTINGSJohan ValdiviaNo ratings yet

- TECK90: XLPE/PVC/AIA/PVC, Control, Armored 600 V, CSA TECK90, Multi-Conductor, 14 AWGDocument10 pagesTECK90: XLPE/PVC/AIA/PVC, Control, Armored 600 V, CSA TECK90, Multi-Conductor, 14 AWGjonathan cuba mejiaNo ratings yet

- PXLWDocument10 pagesPXLWEsteban Escobar ValenciaNo ratings yet

- Amerex UL Portable ExtinguishersDocument20 pagesAmerex UL Portable ExtinguishersPati GeniNo ratings yet

- VDRH Series: Vishay BccomponentsDocument25 pagesVDRH Series: Vishay BccomponentsAmir SoleimanyNo ratings yet

- Switch C. I D. I EDS2129 CooperDocument2 pagesSwitch C. I D. I EDS2129 CooperJosabeth González RuízNo ratings yet

- Leroy Somer Lsa 49,1 123Document28 pagesLeroy Somer Lsa 49,1 123Elinton De Jesus SarmientoNo ratings yet

- Description: Liquid Float Level SwitchesDocument4 pagesDescription: Liquid Float Level SwitchesMichaelNo ratings yet

- IndustrialCatalog PDocument1 pageIndustrialCatalog PEnekoNo ratings yet

- EATONS CROUSE-HINDS BUSINESS Vaporgard LED V2LM2CA1-UNV1 PDFDocument4 pagesEATONS CROUSE-HINDS BUSINESS Vaporgard LED V2LM2CA1-UNV1 PDFLeonardo CAMARGO CAMARGONo ratings yet

- Catalog Code - Master Led Factory Sealed Luminaires Appleton en Us 7436896Document15 pagesCatalog Code - Master Led Factory Sealed Luminaires Appleton en Us 7436896Samuel VelizNo ratings yet

- Transformers (Level-1 & 2)Document45 pagesTransformers (Level-1 & 2)SAGARNo ratings yet

- PXLW - Petrolux LedDocument9 pagesPXLW - Petrolux LedAndres martinez callanNo ratings yet

- P7. - Interruptor SeguridadDocument4 pagesP7. - Interruptor SeguridadJimmy GUZMAN HERNANDEZNo ratings yet

- HexfDocument3 pagesHexfpostesdelbajioNo ratings yet

- Brook MotorsDocument16 pagesBrook Motorsreza100% (1)

- Eddythread Sprinkler Pipe Submittal Data Sheet: Approvals and Specifications Finishes and CoatingsDocument1 pageEddythread Sprinkler Pipe Submittal Data Sheet: Approvals and Specifications Finishes and CoatingsDavid TjNo ratings yet

- Amerex Wet Chemical-Portable Fire ExtinguisherDocument1 pageAmerex Wet Chemical-Portable Fire ExtinguisherXuat NguyenNo ratings yet

- Champ Pro PVM Luminaires 1Document4 pagesChamp Pro PVM Luminaires 1DELMAR QUIROGA CALDERONNo ratings yet

- Crouse Hinds Hazard Gard Evll Led Catalog PageDocument4 pagesCrouse Hinds Hazard Gard Evll Led Catalog Pageworawan nuanpleanNo ratings yet

- Specseal LC Endothermic Firestop Sealant: ApplicationsDocument2 pagesSpecseal LC Endothermic Firestop Sealant: ApplicationsKarim TarekNo ratings yet

- Exane 125 Type P-2013 PDFDocument20 pagesExane 125 Type P-2013 PDFAlejandro ZanellaNo ratings yet

- Industrial Applications Standard Glands with Thread PolyamideDocument4 pagesIndustrial Applications Standard Glands with Thread PolyamideMajdi BelguithNo ratings yet

- Code - Master 2 HID Factory Sealed Floodlights: Marine (Outside Type) - ExplosionproofDocument8 pagesCode - Master 2 HID Factory Sealed Floodlights: Marine (Outside Type) - ExplosionproofLuis Guillermo BenitezNo ratings yet

- TECK90: XLPE/PVC/AIA/PVC, Control and Power, Armored 1000 V, CSA TECK90, Three ConductorDocument2 pagesTECK90: XLPE/PVC/AIA/PVC, Control and Power, Armored 1000 V, CSA TECK90, Three ConductorjxvichoNo ratings yet

- PXLHDocument10 pagesPXLHEsteban Escobar ValenciaNo ratings yet

- EVLP Low Profile Hazard - Gard (H.I.D.) Luminaires 4L: Medium and Mogul BaseDocument11 pagesEVLP Low Profile Hazard - Gard (H.I.D.) Luminaires 4L: Medium and Mogul BaseJuan Carlos Bacca RomeroNo ratings yet

- 006 Amlh FR 2023Document20 pages006 Amlh FR 2023sebicapilneanNo ratings yet

- CVTC VFD - Flexible Motor Supply Cable: XLPE/PVC, Low-Voltage Power, Al/Polyester/AI + TC Braid ShieldedDocument2 pagesCVTC VFD - Flexible Motor Supply Cable: XLPE/PVC, Low-Voltage Power, Al/Polyester/AI + TC Braid ShieldedIbrahim ElkhatibNo ratings yet

- 9 Ul Liquidtight Flexible Steel Conduit Type LFMCDocument4 pages9 Ul Liquidtight Flexible Steel Conduit Type LFMCDiana EncarnaciónNo ratings yet

- Factory Sealed: FeaturesDocument3 pagesFactory Sealed: FeaturesJay ValdezNo ratings yet

- Catalogo Appleton 1Document4 pagesCatalogo Appleton 1Comassur SA de CVNo ratings yet

- 7TKK001067 - Rigid Fittings Catalog Updates - DGTDocument152 pages7TKK001067 - Rigid Fittings Catalog Updates - DGTEduardo EspinetNo ratings yet

- 44a0111-20-0 44a0111-20-9 44a0111-22-0 44a0111-22-9 44a0111-24-9 44a1121-22-0/9-9 44a0111-18-0 44a0111-26-2Document6 pages44a0111-20-0 44a0111-20-9 44a0111-22-0 44a0111-22-9 44a0111-24-9 44a1121-22-0/9-9 44a0111-18-0 44a0111-26-2عبدالغني القباطيNo ratings yet

- Gexol - 331HF Fire Resistant Multi-Conductor Power Cable - Low Smoke Halogen-FreeDocument1 pageGexol - 331HF Fire Resistant Multi-Conductor Power Cable - Low Smoke Halogen-Freecmrig74No ratings yet

- Temperature ControllingDocument8 pagesTemperature ControllingSyaf HudaNo ratings yet

- Part Number: Status: Overview: Description:: DocumentsDocument2 pagesPart Number: Status: Overview: Description:: Documentsdilnair99No ratings yet

- LUMINARIADocument4 pagesLUMINARIAEduardo García OrtegaNo ratings yet

- Pintura Epoxica Sherwin Willians Hoja SeguridadDocument4 pagesPintura Epoxica Sherwin Willians Hoja Seguridad1No ratings yet

- Catalog Appleton WSR Interlocked Receptacle Cover en Us 178392Document3 pagesCatalog Appleton WSR Interlocked Receptacle Cover en Us 178392Eecol phone ParedesNo ratings yet

- Ideal For Direct Immersion Heating of Liquids: Features and Benefits Performance CapabilitiesDocument3 pagesIdeal For Direct Immersion Heating of Liquids: Features and Benefits Performance CapabilitiesTayfunwNo ratings yet

- Catalog Pages Appleton Areamaster Generation 2 Led Luminaires en Us 187486Document33 pagesCatalog Pages Appleton Areamaster Generation 2 Led Luminaires en Us 187486Yesenia Jaime RoaNo ratings yet

- Appleton Electric Amlgl7cg6buDocument15 pagesAppleton Electric Amlgl7cg6bumanwar3399No ratings yet

- HD25 DS1205Document4 pagesHD25 DS1205Kleiber FerreiraNo ratings yet

- Cooper MEDC LD15DMDCYWBDR Sinalizador de Advertencia Ficha Tecnica Catalogo DatasheetDocument2 pagesCooper MEDC LD15DMDCYWBDR Sinalizador de Advertencia Ficha Tecnica Catalogo DatasheetPeter PenhaNo ratings yet

- Marine Power Cable and ControlDocument9 pagesMarine Power Cable and ControlagusNo ratings yet

- Asco 362 - 562 Series Solenoid ValvesDocument31 pagesAsco 362 - 562 Series Solenoid ValvesYonis Cordoba0% (1)

- IMT_Aquarius_Perimeter_Light_ELPZ5AP0E243_Catalogo_DatasheetDocument4 pagesIMT_Aquarius_Perimeter_Light_ELPZ5AP0E243_Catalogo_Datasheetshahrol effendy rodziNo ratings yet

- Ultraviolet Flame Detector: Omniguard Model 660Document2 pagesUltraviolet Flame Detector: Omniguard Model 660carlosNo ratings yet

- Brosure IEC MotorDocument4 pagesBrosure IEC Motorafie pio pioNo ratings yet

- ArmaSoundRD 240 ESDocument4 pagesArmaSoundRD 240 ESSuthi Sae DanNo ratings yet

- Crouse Hinds Fmva Led Catalog PageDocument4 pagesCrouse Hinds Fmva Led Catalog Pagerodolfo gonzalezNo ratings yet

- Zerax Cat GB Mu15817 0918 PDFDocument32 pagesZerax Cat GB Mu15817 0918 PDFVenkatesh NaiduNo ratings yet

- CG Three Phase CatalogueDocument6 pagesCG Three Phase CatalogueJim MorrisonNo ratings yet

- 400Y Torrent Engineering - v27 PDFDocument16 pages400Y Torrent Engineering - v27 PDFKrishna N HNo ratings yet

- Optiswitch 5300 - The Switch For Hot and ColdDocument2 pagesOptiswitch 5300 - The Switch For Hot and ColdOmar SaeedNo ratings yet

- Halogen-free security cable technical dataDocument2 pagesHalogen-free security cable technical dataShoaib-Ur -RehmanNo ratings yet

- Cooper MEDC CU1SEM024506RDI1MR Conjunto Sinalizador e Sirene Inmetro Ficha Tecnica Catalogo DatasheetDocument2 pagesCooper MEDC CU1SEM024506RDI1MR Conjunto Sinalizador e Sirene Inmetro Ficha Tecnica Catalogo DatasheetPeter PenhaNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)