Professional Documents

Culture Documents

Ultrahigh-Performance Concrete For Posttensioned Precast Bridge Piers For Seismic Resilience

Uploaded by

Aristotle MedinaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ultrahigh-Performance Concrete For Posttensioned Precast Bridge Piers For Seismic Resilience

Uploaded by

Aristotle MedinaCopyright:

Available Formats

Ultrahigh-Performance Concrete for Posttensioned

Precast Bridge Piers for Seismic Resilience

Cancan Yang, S.M.ASCE 1; and Pinar Okumus, Ph.D., A.M.ASCE 2

Downloaded from ascelibrary.org by Nanyang Technological University- Library on 09/24/17. Copyright ASCE. For personal use only; all rights reserved.

Abstract: Precast concrete bridge substructures accelerate construction. Precast concrete piers can also limit residual displacements after

earthquakes when used with nonemulative connections. This paper investigates the use of ultrahigh-performance concrete (UHPC) to elimi-

nate damage under moderate to high seismic activity for posttensioned self-centering precast piers. Large-scale laboratory testing was used to

assess damage in pier specimens. Specimens were constructed in segments, where the column segment above the foundation had varying

details: conventional concrete with mild steel reinforcing bars, UHPC with mild steel reinforcing bars, and UHPC without mild steel reinforc-

ing bars. Specimens were subjected to quasi-static cyclic lateral loading, allowing and disallowing shear slip. The use of UHPC led to minimal

damage at displacements much larger than the seismic demand. The difference in damage of UHPC segments with and without mild steel

reinforcement was negligible. A comparison of hysteretic responses of different specimens revealed that strength, stiffness, and energy

dissipation depended on shear slip more than the material type when shear slip was allowed. For tests without shear slip, specimens with

UHPC had higher strength and stiffness. DOI: 10.1061/(ASCE)ST.1943-541X.0001906. © 2017 American Society of Civil Engineers.

Author keywords: Advanced materials; Self-centering; Rocking; Low damage; Nonemulative connections; Accelerated bridge construc-

tion; Posttension; Seismic response; Seismic effects.

Introduction ECC, or rubber and steel elastomeric pads (Cruz Noguez and Saiidi

2012), or a combination of Cu-Al-Mn SMA and ECC (Hosseini

Precast concrete bridge construction accelerates construction and et al. 2015). For these systems, minimal plastic-hinge damage was

improves quality by moving critical construction activities to pre- reported as a result of the additional ductility and improved crack

fabrication plants. Emulative and nonemulative precast concrete distribution of ECC and large strain recovery of superelastic SMAs.

substructure systems have been developed to take advantage of Alternatively, seismic damage can be controlled and contained

precast concrete systems in seismic regions. Emulative precast con- using nonemulative precast concrete systems. Nonemulative sys-

crete systems mimic cast-in-place construction by using socket, tems (precast systems that do not emulate cast-in-place behavior)

grouted-duct, mechanically spliced column–footing connections, develop nonlinear elasticity through a joint opening (Priestley

or similar (Marsh et al. 2011). Precast concrete bridge pier systems, et al. 1999). These systems are typically accompanied by unbonded

developed to emulate monolithic concrete behavior, were proven to posttensioning to achieve self-centering and limited residual dis-

have acceptable seismic response (Marsh et al. 2011), but suffer ir- placements (Hewes and Priestley 2002; Mander and Cheng 1997;

recoverable damage stemming from the formation of plastic hinges. Yamashita and Sanders 2009). Energy dissipation can be provided

Substantial seismic damage to bridges, particularly to the ones that by internal energy-dissipating bars (Lee et al. 2007; Ou et al. 2007;

connect lifelines, can lead to long downtimes, disruption of civilian Palermo et al. 2007), replaceable yielding dampers (Chou and Chen

life, and may require costly repairs or reconstruction. 2006; ElGawady and Sha’lan 2011; Guerrini et al. 2014; Marriott

Large socioeconomic losses caused by earthquakes can be mi- et al. 2009; Mashal and Palermo 2015; Solberg et al. 2009), friction

tigated by controlling seismic damage and maintaining functional- dampers (Morgen and Kurama 2004), or allowing shear slip be-

ity of essential structures. Several strategies exist for controlling tween precast segments (Sideris et al. 2014b).

damage. For emulative precast concrete systems, advanced mate- Although nonemulative systems can tolerate global damage bet-

rials have been used in the plastic-hinge regions of piers. These ter than emulative systems, joint opening and closing in nonemu-

materials include a combination of engineered cementitious compo- lative systems cause local damage in the form of concrete cracking,

sites (ECC), nickel-titanium (Ni-Ti) shape-memory alloys (SMA), spalling, or crushing near rocking interfaces. Attempts to mitigate

and ultrahigh-performance concrete (UHPC) connector fillers this damage have included encasing part of the column or the entire

(Tazarv and Saiid Saiidi 2015a), a combination of Ni-Ti SMA and column in fiber reinforced polymer (FRP) or steel jackets (Chou

and Chen 2006; ElGawady and Sha’lan 2011; Guerrini et al.

1

Graduate Student, Dept. of Civil, Structural, and Environmental 2014; Hewes and Priestley 2002; Zhu et al. 2006), using steel plates

Engineering, Univ. at Buffalo, Buffalo, NY 14260 (corresponding author). as armor at rocking interfaces (Marriott et al. 2009; Solberg et al.

ORCID: https://orcid.org/0000-0001-8596-2265. E-mail: cancanya@ 2009), and reducing seismic demand by elastomeric pads used as

buffalo.edu built-in isolators (ElGawady and Sha’lan 2011). High-performance

2

Assistant Professor, Dept. of Civil, Structural, and Environmental materials such as ECC (Billington and Yoon 2004), steel fiber–

Engineering, Univ. at Buffalo, Buffalo, NY 14260. E-mail: pinaroku@

reinforced concrete with mild reinforcing bars (Trono et al.

buffalo.edu

Note. This manuscript was submitted on May 6, 2016; approved on 2014), or analytical investigations of Ni-Ti SMA bars (Roh and

June 5, 2017; published online on September 23, 2017. Discussion per- Reinhorn 2010) have shown to reduce damage when used with

iod open until February 23, 2018; separate discussions must be submitted rocking systems.

for individual papers. This paper is part of the Journal of Structural This paper presents the results of an experimental investigation

Engineering, © ASCE, ISSN 0733-9445. of a low-damage, nonemulative precast concrete segmental bridge

© ASCE 04017161-1 J. Struct. Eng.

J. Struct. Eng., 2017, 143(12): 04017161

pier that used UHPC for damage control and unbonded posttension demonstrated. Sources of energy dissipation, residual displace-

for self-centering. The pier was prefabricated for accelerated bridge ments, and stiffness and strength degradation, as well as their rela-

construction and composed of a precast foundation, column seg- tionship to seismic damage, were identified. Impacts of reinforced

ments, and a pier cap. Bridge piers with hollow cross sections, and unreinforced UHPC on performance has also been evaluated in

which are reported to have consistently poor hysteretic behavior piers where segmental shear slip can provide additional energy dis-

(Calvi et al. 2005; Pinto et al. 2003) in cast-in-place applications, sipation. The paper presents unique test data and conclusions, which

may also benefit from UHPC to improve performance. can guide engineers and researchers in selecting low-damage mate-

UHPC is a cementitious self-consolidating material typically rials for seismic applications for bridge columns.

enhanced with discontinuous steel-fiber reinforcement and has con-

siderably higher compressive strength, sustained postcracking ten-

sile strength, and improved toughness compared with conventional

Downloaded from ascelibrary.org by Nanyang Technological University- Library on 09/24/17. Copyright ASCE. For personal use only; all rights reserved.

Experimental Protocol

concrete. The U.S. Federal Highway Administration (FHWA) has

worked with multiple state departments of transportations to imple-

Specimens

ment UHPC for various bridge elements since 2002 (Russell and

Graybeal 2013). Previous uses of UHPC for bridge columns have Bridge pier specimens consist of a capacity-protected precast con-

been mostly limited to monolithic or emulative applications. Tazarv crete foundation element, a capacity-protected precast concrete cap

and Saiidi (2015b) showed that UHPC-filled duct connections of beam, and five precast concrete hollow column segments. Three

precast concrete emulated cast-in-place concrete. Ichikawa et al. specimens were tested. The difference between the three speci-

(2016) concluded that a reinforced concrete core encased in a mens was the material of the bottom column segment. Specimen I

UHPC jacket was superior to conventionally reinforced concrete in had conventional 34.5-MPa (5-ksi) compressive design strength

terms of damage control. On the other hand, a precast posttensioned concrete for all column segments. Specimen II had an UHPC

segmental concrete column with UHPC hollow core in the plastic- bottom column segment with the same mild reinforcing bars as

hinge region suffered significant torsion and failed when the UHPC Specimen I, and four 34.5-MPa (5-ksi) compressive-strength con-

was crushed at the bottom segment (Ichikawa et al. 2016). Cover crete upper column segments. Specimen III had an UHPC bot-

spalling or crushing typically seen in conventional concrete was tom column segment without any mild reinforcing bars and four

avoided by replacing concrete with reinforced UHPC in the plastic- 34.5-MPa (5-ksi) compressive-strength concrete upper column seg-

hinge region. Using UHPC in the plastic-hinge region of a mono- ments. Specimen III was designed to demonstrate if there is a need

lithic bridge pier confined with FRP significantly increased both for mild reinforcement for UHPC specimens. All other column

strength and stiffness compared with normal concrete (Zohrevand segments had the same reinforcing bar amount and layout. An

and Mirmiran 2012). Although lifecycle costs of structures incor- elevation view, segment cross section, and mild steel reinforcement

porating UHPC are anticipated to be low because of enhanced layout of specimens are provided in Fig. 1.

durability, the initial cost of UHPC is much higher than that of UHPC was the Ductal JS1000 (Paris, France) mix (Lafarge

conventional concrete. Canada 2009) of LafargeHolcim with mean characteristic compres-

To offset the higher initial cost of UHPC, this paper limited the sive and tensile design strength of 138 MPa (20 ksi) and 8 MPa

use of UHPC to the seismic damage–prone regions of precast col- (1.2 ksi), respectively, and a modulus of elasticity of 50 GPa

umns, namely, the bottom column segment right above the founda- (7,200 ksi). The mix has high tensile–strength steel fibers that are

tion where rocking takes place. This segment was built with UHPC to 0.2 mm (0.008 in.) in diameter and 12.7 mm (0.5 in.) in length.

control seismic damage. In order to further reduce the cost and ac- The premix (silica fume, ground quartz, sand, and cement), steel

celerate construction, the feasibility of removing mild reinforcement fibers, and admixture (water reducer) were provided by the

bars entirely from the UHPC bottom segment was also explored. manufacturer. This mix is typically used for field-cast joints of

Large-scale quasi-static testing was used to investigate the im- precast concrete bridge deck panels, developing characteristic

pact of UHPC and lack of steel reinforcement bars on seismic dam- strength in 96 h after casting.

age in precast rocking bridge piers. Damage control with UHPC The tests were conducted at a 1–2.4 length-scale. Material prop-

was implemented on a precast concrete system developed by erties were not scaled. From a similitude analysis, this translates to

Sideris et al. (2014b), where column segments did not have shear 2.4 for time and period scale and 0.42 for acceleration scale

keys. Shear slip, hence, was allowed in cases where friction was (Anagnostopoulou 2009). Scaling was performed following the

overcome by the externally applied lateral force. The hysteretic gravity forces neglected prototype material method (Harris and

response of each specimen to cyclic loading was compared to under- Sabnis 1999). This method is applicable where stresses attributable

stand the impact of UHPC. Damage with and without UHPC was to gravity are small and the same materials are used in both model

compared visually and quantified by evaluating the dynamic proper- and prototype structures. The design of the pier specimens followed

ties of specimens measured before and after testing. Sources of en- the design by Sideris (2012) but was modified for UHPC and for

ergy dissipation, residual displacements, and stiffness and strength the constraints of the test setup used in this paper. The foundation,

degradation, and their relationship to damage were identified. column segments, and cap beam were connected to each other with

eight unbonded posttension strands. Posttensioning strands were

7-wire, 15.2-mm (0.6-in.) diameter low-relaxation strands, with

Research Significance 1,862 MPa (270 ksi) ultimate strength. Each unbonded strand

had 89 kN (20 kips) of posttension force, which was selected so that

This paper demonstrates the role UHPC can play in controlling strands were efficiently used without allowing them to yield at maxi-

seismic damage to segmental self-centering precast piers at the mum considered earthquake (MCE) levels. The posttension strands

rocking plane. Damage in the form of concrete spalling, cracking, were fitted into ungrouted flexible PVC corrugated ducts with an

and posttension loss was documented by measuring the dynamic interior diameter of at least 22.9 mm (0.9 in.). There were no shear

properties of specimens before and after testing and by visual in- keys between segments. A layer of silicone was applied between

spections. In addition, the efficacy of mild steel longitudinal and each segment to reduce friction between concrete surfaces and

confinement reinforcement within UHPC in resisting damage was facilitate shear slip. Fresh silicone, a material with a low friction

© ASCE 04017161-2 J. Struct. Eng.

J. Struct. Eng., 2017, 143(12): 04017161

25 25

Actuator bolt holes 635 Ducts for PT tendons

Duct for gravity tendons

419

64

Cap beam

Joint 5

177

254

886

635

Column segment 5

Joint 4

254

Column segment 4

64

Joint 3

127 381 127

Downloaded from ascelibrary.org by Nanyang Technological University- Library on 09/24/17. Copyright ASCE. For personal use only; all rights reserved.

3048

Column segment 3

Joint 2

Gravity tendon

(b)

Column segment 2

Joint 1

Column segment 1

(with varying materials and design details) Joint 0

Bar size: #3

737

Foundation

Spacing: 76.2 mm

Duct for tie-down bars Anchorage end Bar size: #3

2743 Spacing: 63.5 mm

(a) (c)

Fig. 1. Specimen details: (a) elevation; (b) column cross-section views; (c) reinforcement layout (unit: millimeters)

coefficient, aims at allowing shear slip to add energy dissipation Impact-hammer tests were performed to measure the change in

through friction (Sideris et al. 2014b; Yang and Okumus 2017). dynamic properties (i.e., fundamental frequency and damping ratio)

of all specimens resulting from Test Protocols I and II. This test was

performed by creating a free vibration in longitudinal and trans-

Test Matrix verse bridge directions using an impact hammer instrumented with

Each specimen was tested under a quasi-static rate of loading an accelerometer.

and at dynamic rates of loading. The spectral displacement and

velocity were calculated using the fundamental frequency obtained

Loading Protocols

through tests by Sideris et al. (2014a) and the response spectra es-

tablished by Anagnostopoulou (2009). The response spectra for de- Test Protocols I and II had quasi-static cyclic loading at an average

sign earthquake (DE) and MCE hazard levels were created for a velocity of 0.25–1.27 mm=s (0.01–0.05 in:=s), applied using dis-

prototype bridge located near the City of Los Angeles, California, placement control. Loading paths for the two protocols are shown

and scaled to the testing model using 0.42 for acceleration scale and in Fig. 2. In Test Protocol I, all specimens were tested to a peak

2.4 for period scale (Anagnostopoulou 2009). In addition to cyclic displacement amplitude of 31.2 mm (1.23 in.) (0.9% drift ratio),

testing, impact-hammer testing was performed to identify modal corresponding to the response spectra displacement of the DE

properties of the specimens. (RSD-DE). An exception to this was Specimen I, which had a

Two quasi-static cyclic tests were conducted on each specimen. larger peak lateral displacement [69.9 mm (2.75 in.) or 2.1% lateral

The first quasi-static test, conducted using Test Protocol I, was per- drift ratio]. At this larger peak displacement, Specimen I had con-

formed on specimens that had fresh silicone between segments, crete cross-section and posttension losses. In order to be able to

allowing shear slip. The second quasi-static cyclic test, conducted reuse specimens for other tests, Specimens II and III were tested

using Test Protocol II, was performed on specimens which were to a peak displacement of 31.2 mm. (1.23 in.). Specimen I was re-

previously tested but not damaged, and which had deteriorated built before Test Protocol II.

silicone between segments. Test Protocol II was preceded by Test In Test Protocol II, all specimens were loaded until the maxi-

Protocol I and testing performed under dynamic rates of loading. mum stroke of the actuator was reached or until specimens failed.

Impact-hammer testing before Test Protocol II ensured no perma- Failure was defined by excessive loss of posttension, risking the

nent damage occurred during tests prior to Test Protocol II. If stability of the specimen.

damage was evident by impact-hammer tests, specimens were

rebuilt before being tested under Test Protocol II. Rebuilding

Instrumentation

involved disassembling specimens, removing damaged segments

(if any), replacing the damaged segments with new segments, or Load on each posttension strand was measured using load cells.

moving segments with minor damage to the top of the pier, and Eight accelerometers, representing degrees of freedom of an ideal-

re-posttensioning. This ensured that specimens did not have accu- ized structural model, measured accelerations in transverse and

mulated damage before any test. This paper discusses the results of longitudinal bridge directions for impact-hammer testing. Gap

the quasi-static testing and impact testing only. The results of the openings and shear slip at joints were measured using a string

dynamic tests are out of the scope of this paper. potentiometer and LVDT, respectively. Global displacements of

© ASCE 04017161-3 J. Struct. Eng.

J. Struct. Eng., 2017, 143(12): 04017161

(a) (b)

Downloaded from ascelibrary.org by Nanyang Technological University- Library on 09/24/17. Copyright ASCE. For personal use only; all rights reserved.

Fig. 2. Loading time history for (a) Loading Protocol I; (b) Loading Protocol II

segments were also measured by string pots and a camera triangu- force-displacement hysteretic response of all specimens are com-

lation system. pared in Fig. 5, for up to 31.2 mm (1.23 in.) peak displacement

amplitude (0.9% drift ratio), corresponding to RSD-DE. All spec-

imens had a large area under the load-displacement curves and

Test Setup

therefore had large energy dissipation. On the other hand, all spec-

Cyclic loading was quasi-statically applied through one MTS imens had residual displacements upon removal of the load because

(MTS System Corporation, Eden Prairie, Minnesota) 978-kN of shear slip and therefore had limited self-centering capability.

(220-kips) capacity hydraulic actuator with a 1,016-mm (40-in.) What can traditionally be interpreted as the deterioration of stiff-

stroke. The actuator was mounted to the specimens at the ness in the hysteretic response resulted from rocking and shear slip,

midspan of the pier cap. Because the superstructure was excluded not from damage to the specimens. The narrowing of the hysteretic

from the test setup, the weight of the superstructure was simulated loop at large displacements, more evident in Fig. 4 because of the

using two posttension strands, which were placed on each side of larger peak displacement, is attributed to the reversal of only rock-

the cap beam and posttensioned to 91 kN (20.5 kips). These gravity ing displacements upon unloading.

strands provided axial load corresponding to 2.5% of the column

axial-load capacity. The ratio of axial load including the internal Posttension Force

posttension force to the axial capacity was 12.3%.

Two steel bracings restrained the transverse movement of the Fig. 6 shows the average posttension force of all strands against

specimens during testing. A small gap and Teflon (Curbell Plastics, lateral displacement for all specimens. The posttension loss was

Orchard Park, New York) polytetrafluorethylene plates were used 4.0, 4.2, and 7.6% of the initial posttension force at the end of the

between the bracings and the cap beam to allow free movement in cycle at RSD-DE for Specimens I, II, and III, respectively. The

the direction of loading. The foundation block was tied to the force at which strands yield was calculated as 235 kN (52.7 kips),

strong floor using tie-down bars. The experimental setup is shown which is 90% of the ultimate capacity for 15.2-mm (0.6-in.) diam-

in Fig. 3. eter strands. Posttension force remained below the nominal mini-

mum yield force in all strands. Therefore, material inelasticity did

not play a role in the posttension loss. The maximum axial stress

Results of Tests Performed with Test Protocol I change caused by the variation of the forces in gravity strands was

within 1.0% of total axial stress at RSD-DE.

Global Response

Displacement Source

The lateral force-displacement hysteretic response of Specimen I

up to peak displacement of 69.9 mm (2.75 in.) (2.1% drift ratio) Precast piers did not have shear keys or longitudinal reinforcement

is shown in Fig. 4, separately from the other specimens. The lateral between segments. Therefore, lateral displacement resulted from

shear slip, gap opening, or both, depending on loading and segment

Bolted threaded rods Sandwich plate

Actuator

Teflon plate

Strong wall

Gravity strands

Lateral restraint system

Tie-down bars

Fig. 4. Hysteretic response of Specimen I under Test Protocol I up to

Fig. 3. Experimental setup 2.1% drift ratio

© ASCE 04017161-4 J. Struct. Eng.

J. Struct. Eng., 2017, 143(12): 04017161

Downloaded from ascelibrary.org by Nanyang Technological University- Library on 09/24/17. Copyright ASCE. For personal use only; all rights reserved.

(a) (b) (c)

Fig. 5. Hysteretic response of (a) Specimen I; (b) Specimen II; (c) Specimen III under Test Protocol I up to 0.9% drift ratio

(a) (b) (c)

Fig. 6. Average posttension force versus lateral displacement under Test Protocol I for (a) Specimen I; (b) Specimen II; (c) Specimen III

surface conditions. Under Test Protocol I, all specimens had larger many factors, including surface characteristics, contact area, and

shear slip than gap openings. Joint shear is plotted against shear slip normal force, and was observed to occur in a random joint order

at each joint for all specimens in Fig. 7 for up to the cycle at RSD- even though shear force was expected to be the same at each joint.

DE. Results from joints where virtually no shear slip was measured Although shear slip was asymmetric at individual joints because of

were omitted from this figure. The force required to activate shear segment twisting in Specimens II and III, the global response

slip was lower than 44 kN (10 kips) for all specimens. This force (Fig. 5) was symmetric because of symmetry in cumulative shear

is lower than the rocking force and therefore shear slip takes place slip of all joints.

before rocking. The stiffening at large shear-slip amplitudes is Joint openings concentrated in the first three column segment

attributable to strands bearing against ducts and a nonproportional joints from the bottom for all specimens and were smaller than

increase in rocking compared to shear slip. Fig. 7 shows that the shear slip displacements. The joint opening affected the shear-

large energy dissipation and low self-centering capability observed slip response by changing segment contact area and posttension

in Fig. 5 mainly resulted from shear slip. Shear slip depends on force.

(a) (b) (c)

Fig. 7. Shear force versus joint shear slip under Test Protocol I for (a) Specimen I; (b) Specimen II; (c) Specimen III

© ASCE 04017161-5 J. Struct. Eng.

J. Struct. Eng., 2017, 143(12): 04017161

Downloaded from ascelibrary.org by Nanyang Technological University- Library on 09/24/17. Copyright ASCE. For personal use only; all rights reserved.

(a) (b) (c)

Fig. 8. Hysteretic response of (a) Specimen I; (b) Specimen II; (c) Specimen III under Test Protocol II up to failure displacement

Results of Tests Performed with Test Protocol II history of force in each posttension strand revealed that the sudden

drops of posttension force were concurrent with the degradations of

Global Response lateral strength shown in Fig. 8. The slopes (or increase) of post-

tension force in Fig. 9 for Specimens II and III (denoted K PT-II and

The lateral-force versus lateral-displacement hysteretic response of K PT-III , respectively) were higher and correspond to larger strand

specimens to Test Protocol II is shown in Fig. 8. The displacement elongations than the one for Specimen I (denoted K PT-I ). This dif-

amplitude of the eighth set of loading cycles was 51 mm (2 in.), ference was caused by the differences of conventional concrete and

which is the closest amplitude to RSD-MCE [47 mm (1.85 in.)]. UHPC to resist damage. Specimen I, with a normal concrete bottom

For all specimens, the bilinear hysteretic curves virtually overlapped segment, had more damage at the rocking edge, causing a shift in

with each other for the first four cycles of Specimen I, eight cycles of the pivot point of rocking. On the contrary, for specimens with

Specimen II, and nine cycles of Specimen III, resulting in self- UHPC, the pivot point of rocking remained at the column bottom

centering but low energy dissipation. Rocking did not initiate until edge, causing a larger gap opening at the segment–foundation joint.

12.7 mm (0.5 in.) of lateral displacement for any of the specimens. Larger inelastic strand strains and larger wedge seating caused a

Several abrupt degradations in strength were observed and attributed larger posttension loss (more than 90%) in Specimens II and III

to random and sudden shear slip at large displacements. As a re- than they did for Specimen I (68%) at failure. The maximum axial

sult, the area under the hysteretic loops grew larger, indicating en- stress change caused by the variation in forces in gravity strands

ergy dissipation and partial loss of recentering capability. Shear slip

was within 3.5 and 17.0% of total axial stress at RSD-MCE and

was offset by a decrease in gap opening, leading to a sudden de-

maximum drift ratios, respectively.

crease of posttension force. All specimens, however, maintained

their strength, stiffness, and self-centering capability throughout the

test, even when the actuator reached its displacement-loading capac- Displacement Source

ity of 488 mm (19.2 in.). This displacement corresponds to 14.6%

lateral-drift ratio, which is much larger than the ones expected at DE Gap opening controlled the overall performance during Test

or MCE hazard levels. The lateral strength plateaued at larger dis- Protocol II. Shear slip in all specimens was small, particularly when

placements because of the yielding of strands. compared to gap opening, and is not shown in this paper. Shear

slip did not exceed 16, 7, and 12% of the total displacement for

Specimens I, II, and III, respectively. Joint-slip time history con-

Posttension Force firmed that small random shear slip coincided with the sudden de-

The average posttension force of strands is plotted against the crease of joint rotation, resulting in the momentary decrease of

global lateral displacement for each specimen in Fig. 9. The time posttension force and global lateral strength.

KPT-SPI KPT-II KPT-SPIII

(a) (b) (c)

Fig. 9. Average posttension force versus lateral displacement for Test Protocol II for (a) Specimen I; (b) Specimen II; (c) Specimen III

© ASCE 04017161-6 J. Struct. Eng.

J. Struct. Eng., 2017, 143(12): 04017161

Downloaded from ascelibrary.org by Nanyang Technological University- Library on 09/24/17. Copyright ASCE. For personal use only; all rights reserved.

(a) (b) (c)

Fig. 10. Moment versus joint opening at Joint 0 under Test Protocol II for (a) Specimen I; (b) Specimen II; (c) Specimen III

Gap opening controlled the overall performance during Test calculated as the average of values in the positive and negative

Protocol II. At small lateral displacements of less than 25.4 mm directions. For specimens under Test Protocol I, the stiffness of

(1 in.), gap opening was comparable at each joint for each speci- specimens depended on shear slip. Specimen III, for which shear

men. At the prerocking stage, where the response is similar to that slip was the most significant among all specimens, had a lower

of a monolithic column with a constant increase in curvature along lateral stiffness than the other specimens. Use of UHPC did not

the height, this response was expected. With the increase of lateral change stiffness or strength for specimens where shear slip was

displacement, gap opening concentrated at the bottom column allowed. During Test Protocol II, shear slip was prevented as a re-

joint, causing the pier to rotate similarly to a rigid body for all spec- sult of degradation in the silicone layer between segments. Table 2

imens. The relationship between moment and rotation at the bottom indicates that Specimen II and III had higher stiffness and strength

column segment–foundation joint is displayed for each specimen in at larger displacements than Specimen I. Concrete spalling in

Fig. 10. Moment-rotation curves demonstrated high self-centering Specimen I led to stiffness and strength loss, even though postten-

capability for all specimens. At large displacements, yielding of sion loss in Specimen I was smaller because of the shift in rocking

posttension strands in Specimens II and III was more evident than pivot point. Specimens II and III, with negligible concrete spalling,

in Specimen I. The force needed to initiate rocking decreased with had minor differences in stiffness and strength.

larger displacements, primarily because of the posttension loss, and

secondarily because of loss of concrete cover.

Energy Dissipation and Self-Centering Capability

The hysteretic energy dissipation of the specimens is quantified by

Impact of UHPC on Seismic Response using an equivalent viscous damping ratio (Chopra 2007). A higher

ratio value indicates higher energy-dissipation capacity. Energy dis-

The response of the three specimens was compared to understand

sipation for a given cycle is computed by calculating the area under

the enhancement of seismic response and damage control because

the hysteresis loop. The equivalent stiffness was taken as the secant

of UHPC and to understand whether mild steel reinforcing bars are

stiffness of a given loop. Figs. 11(a and b) present a comparison of

necessary for UHPC column segments. Strength, stiffness, energy

the viscous damping ratio of all specimens under Test Protocols I

dissipation, self-centering, and damage were compared for all spec-

and II, respectively.

imens for Test Protocols I and II. Damage was also quantitatively

The self-centering capacity was quantified using a residual

assessed by impact-hammer testing.

displacement ratio, which was calculated as the ratio of the total

Strength and Stiffness

Tables 1 and 2 present the peak lateral displacement and force Table 2. Peak Lateral Displacement and Force at Each Loading Cycle of

at each loading cycle for specimens under Test Protocols I and II, Test Protocol II

respectively. The lateral-force and displacement amplitudes were Peak lateral Peak lateral Peak lateral force (kN)

displacement drift ratio

(mm) (%) Specimen I Specimen II Specimen III

Table 1. Peak Lateral Displacement and Force at Each Loading Cycle of 2.5 0.1 23.6 26.7 22.2

Test Protocol I 5.1 0.2 41.8 48.0 39.6

10.2 0.3 65.8 72.9 64.1

Peak lateral Peak lateral Peak lateral force (kN)

15.2 0.5 78.7 83.6 73.4

displacement drift ratio

20.3 0.6 85.0 90.3 78.3

(mm) (%) Specimen I Specimen II Specimen III

25.4 0.8 90.3 96.5 83.2

2.5 0.1 23.1 21.8 20.0 50.8 1.5 108.5 118.8 104.1

5.1 0.2 38.7 35.6 32.0 101.6 3.0 127.7 151.7 135.2

10.2 0.3 53.8 52.0 43.6 177.8 5.3 152.6 185.0 170.8

15.2 0.5 61.4 59.2 49.4 254.0 7.6 167.7 199.7 193.5

20.3 0.6 68.9 63.2 53.8 342.9 10.2 180.1 206.8 206.8

25.4 0.8 74.3 68.9 57.8 431.8 12.9 179.3 208.6 210.8

31.2 0.9 77.4 78.7 63.6 487.7 14.6 178.8 196.6 211.7

© ASCE 04017161-7 J. Struct. Eng.

J. Struct. Eng., 2017, 143(12): 04017161

Lateral Drift Ratio (%)

Eq. Damping Ratio

Downloaded from ascelibrary.org by Nanyang Technological University- Library on 09/24/17. Copyright ASCE. For personal use only; all rights reserved.

Peak Displacement at the Corresponding Cycle (mm)

(a) (b)

Fig. 11. Comparison of equivalent viscous damping ratios of specimens under (a) Test Protocol I; (b) Test Protocol II

Lateral Drift Ratio (%)

Residual Displacement Ratio

Peak Displacement at the Corresponding Cycle (mm)

(a) (b)

Fig. 12. Comparison of residual displacement ratios of specimens under (a) Test Protocol I; (b) Test Protocol II

residual displacement at the end of each cycle to the total peak strains. Because viscous damping and self-centering ratios are unit-

displacement at that cycle. Displacements were calculated as the less, similar ratios can be expected at full scale.

sum of displacements in positive and negative directions for each

cycle. Lower values of the residual displacement ratio indicate

higher self-centering capabilities. Figs. 12(a and b) provide a com- Damage Assessment

parison of residual displacement ratio for all specimens under Test

Protocols I and II, respectively. Inspection of Posttension Loss

For all specimens under Test Protocol I, the viscous damping For Test Protocol I, the posttension loss was proportional to the

ratio increased as the displacement amplitude increased. This trend shear slip amount for all specimens. Small posttension losses in

is caused by the increasing contribution of shear slip to lateral dis- Test Protocol II, for which shear slip was prevented at similar dis-

placement. Similarly, for all specimens under Test Protocol I, placement amplitudes as in Test Protocol I, confirm this conclusion.

residual displacements increased with increasing displacement am- Use of UHPC, therefore, did not affect the posttension loss under

plitudes. Figs. 11(a) and 12(a) show that Specimens II and III had Test Protocol I caused by shear slip.

better energy dissipation than Specimen I, but at the expense of Other factors, including use of UHPC, controlled the postten-

residual displacements. Similar to the stiffness, the differences be- sion loss for Test Protocol II. Fig. 13 examines these factors, start-

tween the equivalent viscous damping ratio and residual displace- ing at the cycle of 51 mm (2 in.) displacement because losses before

ment ratio stemmed from shear slip and not from material type this displacement were negligible. Fig. 13(a) shows the slope of

under Test Protocol I. Use of UHPC, therefore, did not alter energy posttension force with displacement (denoted K PT and shown in

dissipation or self-centering. Fig. 9) as a function of lateral displacement amplitude at each load-

Figs. 11(b) and 12(b) indicate that in the absence of shear slip ing cycle. The slope of posttension force, or increase in posttension

under Test Protocol II, specimens have small and similar equivalent force, in Specimen I was smaller, which is attributable to the shift

viscous damping ratios (less than 0.1), and residual displacement of rocking pivot point toward the cross-section centerline caused

ratios (less than 0.3). As expected, UHPC or reinforcing bars in by cover concrete spalling and crushing. The strands yielded at a

UHPC did not contribute to energy dissipation because the bottom larger displacement amplitude of 178 mm (7 in.) for Specimen I,

column segment acted as a rigid body with localized compressive compared with the displacement amplitude of 254 mm (10 in.) for

strains at the rocking edge, as opposed to well-distributed bending Specimens II and III. Fig. 13(b) compares posttension loss ratio at

© ASCE 04017161-8 J. Struct. Eng.

J. Struct. Eng., 2017, 143(12): 04017161

Lateral Drift Ratio (%)

PT Loss Ratio (%)

KPT (KN/mm)

Downloaded from ascelibrary.org by Nanyang Technological University- Library on 09/24/17. Copyright ASCE. For personal use only; all rights reserved.

Peak Displacement at the Corresponding Cycle (mm)

(a) (b)

Fig. 13. Comparison of (a) posttension force increase; (b) posttension loss for specimens under Test Protocol II

the end of each loading cycle for specimens. Specimens II and III Inspection of Changes in Dynamic Properties

had larger posttension losses. For Specimens II and III, the column The damage to specimens in Test Protocols I and II was assessed

rotated around the column bottom edge, increasing forces in post- by measuring dynamic properties of specimens before and after

tension strands. Higher posttension forces caused larger inelastic testing. The natural frequency and damping ratios of specimens

strains and anchorage wedge seating, leading to higher posttension were obtained by impact-hammer testing. The fundamental fre-

losses in UHPC specimens. quency was identified where Fourier amplitude spectra accelera-

tions peaked for the cap beam and Column Segments 5 and 3.

Inspection of Changes in Stiffness In order to identify the free-vibration part of the motion, a band-

Damage to specimens was assessed by comparing the change pass zero-phase filter with a frequency range suitable to filter the

in stiffness of specimens caused by testing. For Test Protocol I, acceleration time-history response from other modes and noise was

Figs. 5–7 indicate that the differences of secant stiffness for each used. The acceleration time-history response was fitted to the free-

specimen is highly depended on shear slip, rather than specimen vibration expression of a single-degree-of-freedom system with

material type, for specimens with comparable posttension forces. classical damping (Chopra 2007). Coefficient of determination (R2 )

Under Test Protocol II, as displacements increased, all speci- was also calculated to judge the fit. In addition, the fundamental

mens went through a decompression stage, a rocking or joint- frequency obtained from this method was compared with frequen-

opening stage, and a stage where strands yielded, before failure cies at which the Fourier amplitude spectra accelerations peaked.

was reached. Only the stiffness change at the last stage is related The results from the two methods matched well.

to damage in the form of strand yielding. To investigate accumu- Figs. 15(a and b) presents natural frequency and damping ratio

lated damage, Figs. 14(a and b) present the stiffness (K initial ) and of each specimen in the direction of loading before and after each

posttension force (PT initial ) at the beginning of each cycle, respec- test. Impact test data for Specimen II before Test Protocol II were

tively. Specimen I had the largest degradation of initial stiffness not available, and are shown as N/A in Figs. 15(a and b). The re-

after each cycle among all specimens, even though it had higher sults of damping ratio calculations with R2 values lower than 0.9,

posttension force at the beginning of each cycle. The main source indicating a poor fit to the theoretical free-vibration expression, are

of this degradation was concrete spalling. Loss of posttension force also omitted and shown by their respective R2 values in Fig. 15(b).

had a secondary effect on initial stiffness compared with concrete The posttension force on specimens affects their stiffness and

spalling. Concrete spalling and posttension loss were not signifi- dynamic properties. Hence, the average posttension force of inter-

cant enough to cause large residual displacements, even at large nal and gravity strands is also given in Fig. 15(c) before and after

displacements, for Specimen I. each test. The target posttension force was 89 kN (20 kips) per

Lateral Drift Ratio (%)

Normalized PTinitial

Normalized Kinitial

Peak Displacement at the Corresponding Cycle (mm)

(a) (b)

Fig. 14. Comparison of (a) normalized initial stiffness; (b) normalized posttension force for specimens under Test Protocol II

© ASCE 04017161-9 J. Struct. Eng.

J. Struct. Eng., 2017, 143(12): 04017161

7%

Fundamental Frequency

6%

Damping Ratio (%)

5%

4%

(Hz)

3%

R2 = 0.81

R2 = 0.64

2%

N/A

N/A

1%

0%

SP I SP II SP III SP I SP II SP III SP I SP II SP III SP I SP II SP III

Test Protocol I Test Protocol II Test Protocol I Test Protocol II

Downloaded from ascelibrary.org by Nanyang Technological University- Library on 09/24/17. Copyright ASCE. For personal use only; all rights reserved.

(a) (b)

120

Average PT Force (kN)

Target PT force = 89 kN : Before test

100

: After test

80

60

40

20

0

SP I SP II SP III SP I SP II SP III

Test Protocol I Test Protocol II

(c)

Fig. 15. Variations in (a) fundamental frequency; (b) damping ratio; (c) average posttension force for specimens before and after Test

Protocols I and II

internal strand. Variations from the target posttension force were cameras during all tests. Each specimen was inspected in detail

small (less than 15%) and were caused by limitations of manual for damage on the exterior concrete surfaces after each test. Visible

posttensioning. The small difference between the posttension forces damage to strands, ducts, and interior concrete surfaces were doc-

in Fig. 15(c) and Figs. 6 and 9 are attributable to the weight of the umented by disassembling specimens after Test Protocol II.

actuator and inclusion of gravity strands. During Test Protocol I, all specimens had repairable damage. It

All specimens had similar fundamental frequencies of ap- should be recalled that Specimen I had twice the displacement of

proximately 10 Hz before Test Protocol I, similar to ones identified the other specimens under Test Protocol I. In all specimens, column

elsewhere (Sideris 2012) for similar specimens. This indicates segments were misaligned as a result of asymmetric and irrecov-

that replacing the bottom segment of piers with UHPC with or erable shear slip. Shear slip also caused silicone, placed to develop

without mild reinforcement does not considerably change seismic shear slip, to be pressed out of the joint interfaces. Damage to the

demand at small displacements. The initial damping ratios of all bottom column segment of specimens with varying concrete types

specimens were also similar, between 1.3 and 1.4%. In order to is shown on the faces perpendicular to the loading direction in

restore the stiffness after Test Protocol I, specimens were either Fig. 16. For Specimen I with normal concrete, concrete cracking

re-posttensioned (Specimen II and III) or rebuilt (Specimen I). initiated on top of the bottom segment and propagated downward

Specimens were rebuilt if a difference of more than 20% in funda- for 254 mm (10 in.). Concrete in one corner of the bottom segment

mental frequency was measured after testing. Specimen initial fun- spalled off along the full segment height. The first concrete spalling

damental frequencies were within 10 and 20% of each other for occurred at 25.4-mm (1-in.) displacement or a 0.7% drift ratio.

Test Protocols I and II, respectively. Recall that Test Protocol I on Damage was triggered by friction between segments and by bearing

Specimen I had twice the peak displacement amplitude of the other of strands against ducts. Specimens II and III with UHPC had no

specimens. visible damage at RSD-DE of 31.2 mm (1.23 in.) or 0.9% drift

For all specimens, the most significant loss in stiffness (decrease ratio.

in fundamental frequency) was found for Test Protocol II. Despite Under Test Protocol II, all specimens remained in a low-damage

the fact that the remaining posttension force in Specimen I after state where the confined core remained intact. Some concrete spall-

Test Protocol II was approximately four times that for other spec- ing occurred at upper column segments because of sudden shear

imens, the three specimens had similar fundamental frequencies slip at upper column joints. Fig. 17 shows damage to the bottom

after Test Protocol II. This is a quantitative indicator of severe con- column segment on the faces perpendicular to the loading direction at

crete damage in Specimen I. This damage did not occur in other the end of Test Protocol II. UHPC specimens had minor damage (edge

specimens. Damage to Specimen I was also evident from the high crushing) even at large displacements. The damage was confined to an

damping-ratio change (from 1.1 to 6.1%) of Specimen I under Test area smaller than 25.4 mm (1 in.) wide near the rocking edges and was

Protocol II. Evaluation of stiffness and damping ratios indicates in the form of the steel fibers breaking. The fibers breaking was

that both posttension loss and concrete damage degrade stiffness. audible at large displacements but fibers were able to hold concrete

together, preventing spalling. The comparison of damage in

Inspection of Visible Damage Specimens II and III showed that reinforcement bars in Specimen II

Visible damage, i.e., cracking, spalling, and crushing of concrete, did not contribute to damage protection. For Specimen I, concrete

as well as permanent shear slip, were monitored using video cover was lost, confinement reinforcement was exposed, and the

© ASCE 04017161-10 J. Struct. Eng.

J. Struct. Eng., 2017, 143(12): 04017161

Downloaded from ascelibrary.org by Nanyang Technological University- Library on 09/24/17. Copyright ASCE. For personal use only; all rights reserved.

(a) (b) (c)

Fig. 16. Comparisons of bottom segment damage after Test Protocol I

(a) (b) (c)

Fig. 17. Comparison of bottom segment damage after Test Protocol II

rocking edges were entirely crushed. Spalling damage was spread expected as maximum posttension force was measured to be

to an area 254 mm (10 in.) wide. The displacements at which 261 kN (58.6 kips), larger than the yield capacity.

specimens failed under Test Protocol II, 15%, were well above

the displacements expected even during maximum-level

earthquakes. UHPC specimens had minor damage even at this Summary and Conclusions

very large displacement level.

Upon disassembly of the specimens after Test Protocol II, it was This paper presented an experimental investigation of the response

revealed that elongations in strands towards the edge of col- of large-scale precast posttensioned concrete segmental column

umn cross section were visible, implying yield. None of the post- specimens with UHPC to quasi-static cyclic lateral loading. UHPC

tension strands fractured, except a single wire broken in one strand was used in the system to eliminate damage near the rocking

located eccentrically in Specimen III. Localized bending of strands planes of segmental columns. In addition, to offset the high

was observed near segment joints resulting from shear slip. Several cost of UHPC, elimination of mild steel reinforcement bars, includ-

cracks were detected in the anchorage chucks. Strand yield was ing confinement reinforcement, in UHPC was also investigated.

© ASCE 04017161-11 J. Struct. Eng.

J. Struct. Eng., 2017, 143(12): 04017161

Table 3. Summary of the Improvement from Using UHPC

Shear slip Gap opening Stiffness and strength Energy dissipation Self-centering Damage control

Allowed Allowed Insignificant Insignificant Insignificant Moderate

Disallowed Disallowed Significant Insignificant Moderate Significant

The contribution of UHPC to damage tolerance was assessed by displacements. Re-posttensioning specimens that did not have vis-

comparing the response of columns with UHPC to a reference ible signs of damage was sufficient to restore initial stiffness.

conventional concrete column. Similarly, the contribution of mild Approximately 50% loss in fundamental frequency was iden-

reinforcing bars to damage control was evaluated by comparing the tified for all specimens after Test Protocol II. Specimen with con-

Downloaded from ascelibrary.org by Nanyang Technological University- Library on 09/24/17. Copyright ASCE. For personal use only; all rights reserved.

response of UHPC columns with and without mild reinforcement ventional concrete, despite retaining a larger posttension force, had

bars. To control the cost of the system, UHPC was used for only the a smaller fundamental frequency and higher damping ratio com-

bottom column segment of the segmental pier. Specimens were pared with UHPC specimens, quantifying damage in conventional

displaced to RSD-DE, RSD-MCE, and failure under two testing concrete.

protocols called Test Protocols I and II. In Test Protocol I, specimens All specimens, regardless of the bottom segment type, had

had fresh silicone between segments and were tested to a peak acceptable damage at DE and MCE. Acceptable damage is defined

displacement amplitude of 31.2 mm (1.23 in.). In Test Protocol as reparable damage where confined concrete remains undamaged.

II, specimens had deteriorated silicone between segments and were UHPC specimens even without mild reinforcement had no visible

tested to a peak displacement amplitude of 487.7 mm (19.2 in.). damage, indicating no repairs would be necessary after a major

During Test Protocol I, the impact of UHPC on stiffness, earthquake. At a failure displacement much beyond the seismic

strength, and energy dissipation was minor because these were pri- demand, damage to UHPC segments was confined to 4% of the

marily affected by shear slip. Specimens displayed high energy dis- segment height near the rocking edges. Although the edges were

sipation but low self-centering capability because of shear slip. The crushed, no spalling or section loss occurred. At this displacement,

equivalent damping ratios and residual displacement ratios were the conventional concrete segment suffered severe concrete spall-

larger than 15 and 35%, respectively, at the RSD-DE cycle. ing, with edge concrete crushing propagating to 40% the column

Posttension loss was small and less than 10% in all specimens segment height and exposing reinforcement. The difference in dam-

at RSD-DE (0.9% lateral drift ratio). age to the UHPC segments with and without mild steel reinforce-

At RSD-DE, UHPC was effective in preventing damage. The ment was negligible, indicating that steel reinforcement, including

conventional concrete specimen had cover spalling and cracking at the confinement reinforcement, can be eliminated with UHPC to

RSD-DE in the bottom segment caused by Test Protocol I. Damage further accelerate construction and reduce cost. The reduction in

to this specimen was related to shear slip and friction between seg- initial cost is particularly beneficial given the higher initial material

ments. At the same displacement, there was no visible cracking, cost of UHPC.

spalling, or crushing in the UHPC specimens. The UHPC specimen Because segmental shear slip can be a source of energy dissipa-

without reinforcing bars had identical damage to the one with tion, UHPC was evaluated on specimens with and without shear

reinforcing bars, indicating longitudinal or confinement reinforcing slip. The contribution of UHPC to stiffness, strength, energy dissi-

are not needed when UHPC is used for DE-level designs. pation, self-centering, and damage control is summarized in Table 3

The impact of UHPC on strength and stiffness was evident when for cases with and without shear slip. The impact of UHPC on dam-

shear slip was limited in Test Protocol II. The responses of all spec- age protection was more pronounced for cases without shear slip,

imens were governed by a gap opening at the column–foundation partially a reflection of higher maximum drift ratios. In both cases,

joint. The stiffness and strength of UHPC specimens were higher the UHPC segments were successful in eliminating damage.

than those of conventional concrete because of elimination of dam-

age to concrete, particularly at large displacements. In all speci-

Acknowledgments

mens, the residual displacements remained smaller than 10 and

20% of the total displacement amplitude at MCE and failure level The authors gratefully acknowledge the financial support pro-

displacements, respectively. Energy dissipation, mainly caused by vided by Federal Highway Administration (FHWA) through the

strand yielding, was minimal. The equivalent damping ratio was Multidisciplinary Center for Earthquake Engineering Research

below 20% for all specimens. (MCEER) of University at Buffalo. Donation of labor and materials

The accumulation of damage was evident in the conventional by LafargeHolcim for the construction of the specimens is also ac-

concrete specimen from the decrease of the stiffness at the begin- knowledged. The results, conclusions, and opinions given in this

ning of each cycle. The accumulated damage was in the form of paper are the ones of the authors and do not necessarily reflect the

concrete section loss and posttension loss. Posttension loss was views of the funding agencies and the parties acknowledged.

higher in UHPC specimens than in conventional concrete because

the pivot point of rocking shifted inside the cross section in conven-

tional concrete because of section loss. Specimens with UHPC, de- References

spite having higher posttension losses, had smaller reductions in

initial stiffness, indicating better damage control. This was related Anagnostopoulou, M. (2009). “Seismic design and analysis of precast seg-

to the smaller cross-section loss in UHPC than in conventional mental concrete bridge superstructure.” M.Sc. thesis, Univ. of Pavia,

Pavia, Italy.

concrete.

Billington, S., and Yoon, J. (2004). “Cyclic response of unbonded post-

Impact-hammer tests showed that all specimens with com- tensioned precast columns with ductile fiber-reinforced concrete.”

parable posttension force had similar stiffness before testing. Re- J. Bridge Eng., 10.1061/(ASCE)1084-0702(2004)9:4(353), 353–363.

placing one segment of the column with UHPC with or without Calvi, G. M., Pavese, A., Rasulo, A., and Bolognini, D. (2005). “Exper-

reinforcement did not change the initial stiffness considerably, in- imental and numerical studies on the seismic response of R.C. hollow

dicating UHPC will not increase seismic demand at small bridge piers.” Bull. Earthquake Eng., 3(3), 267–297.

© ASCE 04017161-12 J. Struct. Eng.

J. Struct. Eng., 2017, 143(12): 04017161

Chopra, A. K. (2007). Dynamics of structures: Theory and applications to Palermo, A., Pampanin, S., and Marriott, D. (2007). “Design, modeling,

earthquake engineering, Prentice-Hall, New Delhi, India. and experimental response of seismic resistant bridge piers with post-

Chou, C.-C., and Chen, Y.-C. (2006). “Cyclic tests of post-tensioned tensioned dissipating connections.” J. Struct. Eng., 10.1061/(ASCE)

precast CFT segmental bridge columns with un-bonded strands.” 0733-9445(2007)133:11(1648), 1648–1661.

Earthquake Eng. Struct. Dyn., 35(2), 159–175. Pinto, A., Molina, J., and Tsionis, G. (2003). “Cyclic tests on large-scale

Cruz Noguez, C., and Saiidi, M. (2012). “Shake-table studies of a four-span models of existing bridge piers with rectangular hollow cross-section.”

bridge model with advanced materials.” J. Struct. Eng., 10.1061 Earthquake Eng. Struct. Dyn., 32(13), 1995–2012.

/(ASCE)ST.1943-541X.0000457, 183–192. Priestley, M., Sritharan, S., Conley, J. R., and Pampanin, S. (1999). “Pre-

ElGawady, M., and Sha’lan, A. (2011). “Seismic behavior of self-centering liminary results and conclusions from the PRESSS five-storey precast

precast segmental bridge bents.” J. Bridge Eng., 10.1061/(ASCE)BE concrete test building.” PCI J., 44(6), 42–67.

.1943-5592.0000174, 328–339. Roh, H., and Reinhorn, A. M. (2010). “Hysteretic behavior of precast

Guerrini, G., Restrepo, J., Massari, M., and Vervelidis, A. (2014).

Downloaded from ascelibrary.org by Nanyang Technological University- Library on 09/24/17. Copyright ASCE. For personal use only; all rights reserved.

segmental bridge piers with superelastic shape memory alloy bars.”

“Seismic behavior of posttensioned self-centering precast concrete Eng. Struct., 32(10), 3394–3403.

dual-shell steel columns.” J. Struct. Eng., 10.1061/(ASCE)ST.1943 Russell, H. G., and Graybeal, B. A. (2013). “Ultra-high performance con-

-541X.0001054, 04014115. crete: A state-of-the-art report for the bridge community.” Rep. No.

Harris, G. H., and Sabnis, G. (1999). Structural modeling and experimental FHWA-HRT-13-060, Federal Highway Administration, Washington,

techniques, 2nd Ed., CRC, Boca Raton, FL. DC.

Hewes, J. T., and Priestley, M. J. N. (2002). “Seismic design and Sideris, P. (2012). “Seismic analysis and design of precast concrete seg-

performance of precast concrete segmental bridge columns.” Rep. No. mental bridges.” Ph.D. dissertation, Univ. at Buffalo, Buffalo, NY.

SSRP-2001/25, Univ. of California, San Diego. Sideris, P., Aref, A., and Filiatrault, A. (2014a). “Large-scale seismic test-

Hosseini, F., Gencturk, B., Lahpour, S., and Gil, D. I. (2015). “An exper- ing of a hybrid sliding-rocking posttensioned segmental bridge system.”

imental investigation of innovative bridge columns with engineered J. Struct. Eng., 10.1061/(ASCE)ST.1943-541X.0000961, 04014025.

cementitious composites and Cu-Al–Mn super-elastic alloys.” Smart

Sideris, P., Aref, A., and Filiatrault, A. (2014b). “Quasi-static cyclic testing

Mater. Struct., 24(8), 085029.

of a large-scale hybrid sliding-rocking segmental column with slip-

Ichikawa, S., Matsuzaki, H., Moustafa, A., ElGawady, M., and Kawashima,

dominant joints.” J. Bridge Eng., 10.1061/(ASCE)BE.1943-5592

K. (2016). “Seismic-resistant bridge columns with ultrahigh-

.0000605, 04014036.

performance concrete segments.” J. Bridge Eng., 10.1061/(ASCE)BE

Solberg, K., Mashiko, N., Mander, J., and Dhakal, R. (2009). “Performance

.1943-5592.0000898, 04016049.

of a damage-protected highway bridge pier subjected to bidirectional

Lafarge Canada. (2009). “Product data sheet: JS 1000.” 〈http://www.ductal

earthquake attack.” J. Struct. Eng., 10.1061/(ASCE)0733-9445(2009)

.com/JS1000_2009.pdf〉 (Jan. 15, 2015).

135:5(469), 469–478.

Lee, W., Jeong, H., Billington, S., Mahin, S., and Sakai, J. (2007).

“Post-tensioned structural concrete bridge piers with self-centering Tazarv, M., and Saiid Saiidi, M. (2015a). “Low-damage precast columns

characteristics.” Structural Engineering Research Frontiers, Proc., Re- for accelerated bridge construction in high seismic zones.” J. Bridge

search Frontiers Sessions of the 2007 Structures Congress, Long Eng., 10.1061/(ASCE)BE.1943-5592.0000806, 04015056.

Beach, CA, 1–15. Tazarv, M., and Saiidi, M. S. (2015b). “UHPC-filled duct connections for

Mander, J. B., and Cheng, C.-T. (1997). “Seismic resistance of bridge piers accelerated bridge construction of RC columns in high seismic zones.”

based on damage avoidance design.” Technical Rep. No. NCEER-97- Eng. Struct., 99(3), 413–422.

0014, Univ. at Buffalo, Buffalo, NY. Trono, W., Jen, G., Panagiotou, M., Schoettler, M., and Ostertag, C. (2014).

Marriott, D., Pampanin, S., and Palermo, A. (2009). “Quasi-static and “Seismic response of a damage-resistant recentering posttensioned-

pseudo-dynamic testing of unbonded post-tensioned rocking bridge HYFRC bridge column.” J. Bridge Eng., 10.1061/(ASCE)BE.1943

piers with external replaceable dissipaters.” Earthquake Eng. Struct. -5592.0000692, 04014096.

Dyn., 38(3), 331–354. Yamashita, R., and Sanders, D. H. (2009). “Seismic performance of

Marsh, L. M., Wernli, M., Garrett, B. E., Stanton, J. F., Eberhard, M. O., precast unbonded prestressed concrete columns.” ACI Struc. J.,

and Weinert, M. D. (2011). “Application of accelerated bridge con- 106(6), 821–830.

struction connections in moderate-to-high seismic regions.” Rep. 698, Yang, C., and Okumus, P. (2017). “The influence of segment interface char-

Transportation Research Board, Washington, DC. acteristics on seismic performance of post-tensioned precast segmental

Mashal, M., and Palermo, A. (2015). “High-damage and low-damage seis- bridge piers.” PCI Convention and National Bridge Conf., Precast/

mic design technologies for accelerated bridge construction.” Structures Prestressed Concrete Institute, Chicago.

Congress 2015, ASCE, Reston, VA, 549–560. Zhu, Z., Ahmad, I., and Mirmiran, A. (2006). “Seismic performance of

Morgen, B., and Kurama, Y. (2004). “A friction damper for post-tensioned concrete-filled FRP tube columns for bridge substructure.” J. Bridge

precast concrete beam-to-column joints.” PCI J., 49(4), 112–133. Eng., 10.1061/(ASCE)1084-0702(2006)11:3(359), 359–370.

Ou, Y., Chiewanichakorn, M., Aref, A., and Lee, G. (2007). “Seismic Zohrevand, P., and Mirmiran, A. (2012). “Cyclic behaviour of hybrid

performance of segmental precast unbonded posttensioned concrete columns made of ultra high performance concrete and fiber rein-

bridge columns.” J. Struct. Eng., 10.1061/(ASCE)0733-9445(2007)133: forced polymers.” J. Compos. Constr., 10.1061/(ASCE)CC.1943-5614

11(1636), 1636–1647. .0000234, 91–99.

© ASCE 04017161-13 J. Struct. Eng.

J. Struct. Eng., 2017, 143(12): 04017161

You might also like

- Seismic Performance of Axially Restrained Reinforced Concrete Frame BeamsDocument12 pagesSeismic Performance of Axially Restrained Reinforced Concrete Frame BeamsAristotle MedinaNo ratings yet

- Effect of Seismic Load History On Deformation Limit States For Longitudinal Bar Buckling in RC Circular ColumnsDocument13 pagesEffect of Seismic Load History On Deformation Limit States For Longitudinal Bar Buckling in RC Circular ColumnsAristotle MedinaNo ratings yet

- Column Base Connections For Hollow Steel Sections Seismic Performance and Strength ModelsDocument13 pagesColumn Base Connections For Hollow Steel Sections Seismic Performance and Strength ModelsAristotle MedinaNo ratings yet

- Variability in Seismic Collapse Probabilities of Solid - and Coupled-Wall BuildingsDocument17 pagesVariability in Seismic Collapse Probabilities of Solid - and Coupled-Wall BuildingsAristotle MedinaNo ratings yet

- Finite Element Simulation of Concrete-Filled Double-Skin Tube Columns Subjected To Postearthquake FiresDocument15 pagesFinite Element Simulation of Concrete-Filled Double-Skin Tube Columns Subjected To Postearthquake FiresAristotle MedinaNo ratings yet

- Sustainability Metrics For Performance Based Seismic Bridge ResponseDocument12 pagesSustainability Metrics For Performance Based Seismic Bridge ResponseAristotle MedinaNo ratings yet

- Reference #03 - JR-403 Sandwich Wall PanelsDocument61 pagesReference #03 - JR-403 Sandwich Wall PanelsAristotle MedinaNo ratings yet

- How A Bolt WorksDocument6 pagesHow A Bolt WorksAristotle MedinaNo ratings yet

- Guide To Accelerated Conditioning Protocols For Durability Assessment of Internal and External Fiber-Reinforced Polymer (FRP) ReinforcementDocument16 pagesGuide To Accelerated Conditioning Protocols For Durability Assessment of Internal and External Fiber-Reinforced Polymer (FRP) ReinforcementAristotle Medina100% (1)

- Connections and Fatigue Behaviour of Precast Insulated PanelDocument169 pagesConnections and Fatigue Behaviour of Precast Insulated PanelAristotle MedinaNo ratings yet

- Unequal Angles To en 10056-1 - 1998Document3 pagesUnequal Angles To en 10056-1 - 1998Aristotle MedinaNo ratings yet

- An Engineering Application of Earthquake Early Warning ePAD-Based Decision Framework For Elevator ControlDocument10 pagesAn Engineering Application of Earthquake Early Warning ePAD-Based Decision Framework For Elevator ControlAristotle MedinaNo ratings yet

- Finite Element Analysis of Thin Precast Concrete Sandwich PanelsDocument6 pagesFinite Element Analysis of Thin Precast Concrete Sandwich PanelsAristotle MedinaNo ratings yet

- British Steel SectionsDocument6 pagesBritish Steel SectionsAristotle MedinaNo ratings yet

- The Yielding of Fasteners Duirng Tightening PDFDocument2 pagesThe Yielding of Fasteners Duirng Tightening PDFAristotle MedinaNo ratings yet

- Universal Beams To BS4 Part 1 - 1993Document3 pagesUniversal Beams To BS4 Part 1 - 1993Aristotle MedinaNo ratings yet

- UpeDocument1 pageUpeAristotle Medina100% (1)

- Chemical and Mechanical PropertiesDocument5 pagesChemical and Mechanical PropertiesAristotle MedinaNo ratings yet

- IpeDocument2 pagesIpeAristotle MedinaNo ratings yet

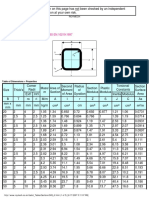

- Square Hollow Sections - Cold FormedDocument5 pagesSquare Hollow Sections - Cold FormedAristotle MedinaNo ratings yet

- Square Hollow Sections - Hot FormedDocument5 pagesSquare Hollow Sections - Hot FormedAristotle MedinaNo ratings yet

- Universal Beams To BS4 Part 1 - 1993Document3 pagesUniversal Beams To BS4 Part 1 - 1993Aristotle MedinaNo ratings yet

- Channels DimensionsDocument2 pagesChannels DimensionsAristotle MedinaNo ratings yet

- Rectangular Hollow Sections - Hot FormedDocument5 pagesRectangular Hollow Sections - Hot FormedAristotle MedinaNo ratings yet

- Joist (BS4 Part 1@1993 Dimensions PropertiesDocument2 pagesJoist (BS4 Part 1@1993 Dimensions PropertiesAristotle MedinaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)