ISO 27001 Clause 8.3 Overview

Uploaded by

Vasant bhoknalISO 27001 Clause 8.3 Overview

Uploaded by

Vasant bhoknalEnjoy this site? Gift the author a WordPress.com plan.

Gift

EN

PRETESH BISWAS

Your Partner in ISO Standard compliance

Steps for ISO Certification ISO 9001:2015 ISO 14001:2015 ISO 45001:2018 ISO 27001:2022 About Pretesh Biswas

Example of documentation

Please choose your preferred

template for process of Control Language

of Documents

EN

Pretesh Biswas IATF 16949:2016 July 2, 2023 3 Minutes

ISO 9001:2015 Quality Management System

ISO 14001:2015 Environment Management

Listen

System

ISO 45001:2018 OH& S management

The following document templates (tool kits) are provided totally complimentary, free of system

charge to use as a starting point for Process of Control of Documents in IATF. As each business ISO 27001:2022 Information Security

is different, additional documents or revisions would be required to meet your organization’s Management System

specific needs, requirements, context, risk profile, etc. If after reading through all of these IATF 16949:2016 Automotive Quality

Management System

documents, you feel like you still need a consulting partner to help you develop your new

ISO 31000:2018 Risk Management

documents – Contact Us. We’re always looking for interesting new clients and projects. Guidelines

ISO 29001:2020 Petroleum,Petrochemical

1.0 Process Approach of Process of Control of Document

and Natural gas industries Sector specific

Quality Management System

API Q1 4 Quality Management System

Requirements

ISO 19011:2018 Guidelines for auditing

management systems

What is Six Sigma?

What is Project Management?

IATF 16946:2016

IATF 16949:2016 Automotive Quality

Management System

Example of IATF 16949:2016 Quality

Manual

IATF 16949:2016 Internal audit checklist

Example of IATF Manufacturing Process

Audit Checklist

Example of IATF Process IA checklist

IATF 16949:2016 Clause 4.3.1 Determining

the Scope of the Quality Management System

and Clause 4.3.2 Customer specific

requirements

IATF 16949:2016 Clause 4.4.1.1

Conformance of products and processes

IATF 16949:2016 Clause 4.4.1.2 Product

safety

IATF 16949:2016 Clause 5.1.1.1 Corporate

responsibility

IATF 16949:2016 Clause 5.1.1.2 Process

effectiveness and efficiency

IATF 16949:2016 Clause 5.1.1.3 Process

owners

IATF 16949:2016 clause 5.3.1

Organizational roles responsibilities and

authorities and 5.3.2 Responsibility and

authority for product requirements and

corrective actions

IATF 16949:2016 6.1.2.1 Risk analysis

IATF 16949:2016 Clause 6.1.2.2 Preventive

Action

IATF 16949:2016 clause 6.1.2.3

Contingency plans

IATF 16949:2016 Clause 6.2.2.1 Quality

objectives and planning to achieve them

IATF 16949:2016 Clause 7.1.3.1 Plant,

facility, and equipment planning

IATF 16949:2016 Clause 7.1.4.1

Environment for the operation of processes

IATF 16949:2016 Clause 7.1.5.1.1

Measurement systems analysis

IATF 16949:2016 Clause 7.1.5.2.1

Calibration/verification records

IATF 16949:2016 Clause 7.1.5.3 Laboratory

requirements

IATF 16949:2016 Clause 7.2.1 Competence

IATF 16949:2016 Clause 7.2.2 Competence

— on-the-job training

IATF 16949:2016 Clause 7.2.3 Internal

auditor competency

IATF 16949:2016 Clause 7.2.4 Second-party

auditor competency

IATF 16949:2016 Clause 7.3.1 Awareness

IATF 16949:2016 Clause 7.3.2 Employee

motivation and empowerment

IATF 16949:2016 Clause 7.5.1.1 Quality

management system documentation

IATF 16949:2016 Clause 7.5.3.2.1 Record

retention

IATF 16949:2016 Clause

7.5.3.2.2 Engineering specifications

IATF 16949:2016 Clause 8.1.1 Operational

planning and control

IATF 16949:2016 Clause 8.1.2

Confidentiality

IATF 16949:2016 Clause 8.2.1.1 Customer

communication

IATF 16949:2016 Clause 8.2.2.1

Determining the requirements for products

and services

IATF 16949:2016 Clause 8.2.3.1.1 Review

of the requirements for products and services

IATF 16949:2016 Clause 8.2.3.1.2

2.0 Turtle Diagram of Process of Control of Document Customer-designated special characteristics

IATF 16949:2016 Clause

8.2.3.1.3 Organization manufacturing

feasibility

IATF 16949:2016 Clause 8.3.1.1 Design and

development of products and services

IATF 16949:2016 Clause 8.3.2.1 Design and

development planning

IATF 16949:2016 Clause 8.3.2.2 Product

design skills

IATF 16949:2016 Clause 8.3.2.3

Development of products with embedded

software

IATF 16949:2016 Clause 8.3.3.1 Product

design input

IATF 16949:2016 Clause 8.3.3.2

Manufacturing process design input

IATF 16949:2016 Clause 8.3.3.3 Special

characteristics

IATF 16949:2016 Clause 8.3.4.1

Monitoring

IATF 16949:2016 Clause 8.3.4.2 Design and

3.0 Work Instruction of Document Numbering development validation

IATF 16949:2016 Clause 8.3.4.3 Prototype

programme

IATF 16949:2016 Clause 8.3.4.4 Product

approval process

IATF 16949:2016 Clause 8.3.5.1 Design and

development outputs

IATF 16949:2016 Clause 8.3.5.2

Manufacturing process design output

IATF 16949:2016 Clause 8.3.6.1 Design and

development changes

IATF 16949:2016 Clause 8.4.1.1 Control of

externally provided processes, products and

services-General

IATF 16949:2016 Clause 8.4.1.2 Supplier

selection process

IATF 16949:2016 Clause 8.4.1.3 Customer-

directed sources (also known as “Directed–

Buy”)

IATF 16949:2016 Clause 8.4.2.1 Type and

extent of control

IATF 16949:2016 Clause 8.4.2.2 Statutory

and regulatory requirements

IATF 16949:2016 8.4.2.3 Supplier quality

management system development

IATF 16949:2016 Clause 8.4.2.3.1

Automotive product-related software or

automotive products with embedded software

IATF 16949:2016 Clause 8.4.2.4 Supplier

monitoring

IATF 16949:2016 Clause 8.4.2.4.1 Second-

party audits

IATF 16949:2016 Clause 8.4.2.5 Supplier

development

IATF 16949:2016 Clause 8.4.3.1 Information

for external providers

IATF 16949:2016 Clause 8.5.1.1 Control

plan

IATF 16949:2016 Clause 8.5.1.2

Standardised work — operator instructions

and visual standards

IATF 16949:2016 Clause 8.5.1.3 Verification

of job set-ups and 8.5.1.4 Verification after

shutdown

IATF 16949:2016 Clause 8.5.1.5 Total

productive maintenance

IATF 16949:2016 Clause 8.5.1.6

Management of production tooling and

manufacturing, test, inspection tooling and

equipment

IATF 16949:2016 clause 8.5.1.7 Production

scheduling

IATF 16949:2016 Clause 8.5.2.1

Identification and traceability

IATF 16949:2016 Clause 8.5.4.1

Preservation

IATF 16949:2016 Clause 8.5.5.1 Feedback

of information from service

IATF 16949:2016 Clause 8.5.5.2 Service

agreement with customer

IATF 16949:2016 Clause 8.5.6.1 Control of

changes

IATF 16949:2016 Clause 8.5.6.1.1

Temporary change of process controls

IATF 16949:2016 Clause 8.6.1 Release of

products and services

IATF 16949:2016 Clause 8.6.2 Layout

inspection and functional testing

IATF 16949:2016 Clause 8.6.3 Appearance

items

IATF 16949:2016 Clause 8.6.4 Verification

and acceptance of conformity of externally

provided products and services

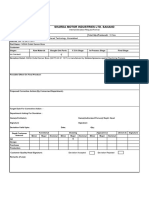

4.0 Document Change Request IATF 16949:2016 Clause 8.6.5 Statutory and

regulatory conformity

Change Request No: IATF 16949:2016 Clause 8.6.6 Acceptance

criteria

Date:

IATF 16949:2016 Clause 8.7.1.1 Customer

authorization for concession

Document Ref.: Function /Area:

IATF 16949:2016 Clause 8.7.1.2 Control of

Detail(s) of Change : nonconforming product — customer-

specified process and Clause 8.7.1.6

Customer notification

Reason for Change :

IATF 16949:2016 Clause 8.7.1.3 Control of

suspect product

REQUESTED BY : (NAME & INITIALS) REVIEWED BY HOD Requesting Dept

IATF 16949:2016 Clause 8.7.1.4 Control of

MODIFICATION NOTE: (FOR M.R OFFICE USE ONLY) reworked product

IATF 16949:2016 Clause 8.7.1.5 Control of

repaired product

IATF 16949 Clause 8.7.1.7 Nonconforming

a) Cost product disposition

IATF 16949:2016 Clause 9.1.1.1 Monitoring

b) Quality/Productivity and measurement of manufacturing processes

Impact on :

IATF 16949:2016 Clause

c) QMS system

9.1.1.2 Identification of statistical tools and

Clause 9.1.1.3 Application of statistical

d) Any other Process concepts

IATF 16949:2016 Clause 9.1.2.1 Customer

Management Representative’s Remarks: satisfaction

IATF 16949:2016 Clause 9.1.3.1

Approved Not Approved If not approved, attach reasons for the same

Prioritization

Concerned approving authority of original document

IATF 16949:2016 Clause 9.2.2.1 Internal

audit programme

Implementation Date:

IATF 16949:2016 Clause 9.2.2.2 Quality

management system audit

Revision No.:

IATF 16949:2016 Clause 9.2.2.3

Manufacturing process audit

IATF 16949:2016 Clause 9.2.2.4 Product

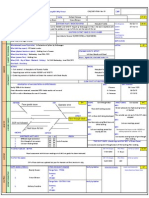

5.0 MASTER LIST OF DOCUMENTS (INTERNAL) audit

IATF 16949:2016 clause 9.3.1.1

Document Document Retention Rev Rev

Distribution Management review, Clause 9.3.2.1

Sr.No Description No. Period No date Management review inputs and Clause

9.3.3.1 Management review outputs

IATF 16949:2016 Clause 10.2.3 Problem

solving

IATF 16949:2016 Clause 10.2.4 Error-

proofing

IATF 16949:2016 Clause 10.2.5 Warranty

management systems

IATF 16949:2016 clause 10.2.6 Customer

complaints and field failure test analysis

IATF 16949:2016 Clause 10.3.1 Continual

improvement

Example of documentation template for HR

process in IATF

Example of documentation template for

process of Dispatch of Finished products in

IATF

Example of documentation template for

process of customer complaint handling in

IATF

Example of documentation template for

process of Contract Review in IATF

Example of documentation template for

Customer Satisfaction Measurement Process

in IATF

Example of documentation template for

Advanced Product Quality Planning (APQP)

in IATF

Example of documentation template for

Control of drawing including ECN and ECR

in IATF

PREPARED BY: APPROVED BY: Example of documentation template for

Production Part approval Process (PPAP) in

IATF

6.0 Master List of Documents (External) Example of documentation template for

Process of Identification of special

characteristics in IATF

Sr.No Document No Document Description Issue No Distribution

Example of documentation template for

Process of Product Safety in IATF

Example of documentation template for

Process of Facility Planning & Deployment

in IATF

You might also like

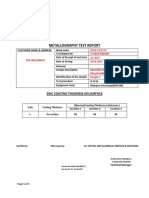

- Metallography Test Report: Zinc Coating Thickness On SurfaceNo ratings yetMetallography Test Report: Zinc Coating Thickness On Surface1 page

- Determination of Transfer Efficiency Under General Production Conditions For Spray Application of PaintsNo ratings yetDetermination of Transfer Efficiency Under General Production Conditions For Spray Application of Paints5 pages

- Effective Management Review Training (For Sharing)No ratings yetEffective Management Review Training (For Sharing)11 pages

- Supplier Quality Development - A Review of Literature and Industry PracticesNo ratings yetSupplier Quality Development - A Review of Literature and Industry Practices24 pages

- Circumferential Welding Procedures for Gas Pipelines100% (1)Circumferential Welding Procedures for Gas Pipelines11 pages

- Innovative Approach To FMEA Facilitation: Govind Ramu100% (1)Innovative Approach To FMEA Facilitation: Govind Ramu34 pages

- IATF 16949:2016 vs. ISO/TS 16949:2009 Matrix50% (2)IATF 16949:2016 vs. ISO/TS 16949:2009 Matrix26 pages

- CPRE Flowchart for Transport OperationsNo ratings yetCPRE Flowchart for Transport Operations69 pages

- Indian Standard On Hex Bolts - IS 1363 Part 2No ratings yetIndian Standard On Hex Bolts - IS 1363 Part 212 pages

- Cost of Quality Worksheet / Grinding Variation Rework CostsNo ratings yetCost of Quality Worksheet / Grinding Variation Rework Costs2 pages

- Q.R.Q.C Quick Response Quality Control: M Davies - Aug 2009No ratings yetQ.R.Q.C Quick Response Quality Control: M Davies - Aug 200910 pages

- IATF 16949:2016 Information: ISO/TS 16949 OverviewNo ratings yetIATF 16949:2016 Information: ISO/TS 16949 Overview3 pages

- The Role of Variation, Error, and Complexity in Manufacturing Defects"No ratings yetThe Role of Variation, Error, and Complexity in Manufacturing Defects"28 pages

- Measurement System Analysis at Bosch RexrothNo ratings yetMeasurement System Analysis at Bosch Rexroth124 pages

- Statistical Test Methods For Hypothesis TestingNo ratings yetStatistical Test Methods For Hypothesis Testing6 pages

- ANSI B92!1!1996 Involute Splines and Inspection75% (4)ANSI B92!1!1996 Involute Splines and Inspection163 pages

- CP, CPK, PP, and PPK - A Guide To Process Capability and Capability IndicesNo ratings yetCP, CPK, PP, and PPK - A Guide To Process Capability and Capability Indices13 pages

- Simplifying Six Sigma Methodology Using Shainin D.O.ENo ratings yetSimplifying Six Sigma Methodology Using Shainin D.O.E6 pages

- Panasonic TX-l55et60e TX-l55dtw60 Chassis La42 Pcz1303078ceNo ratings yetPanasonic TX-l55et60e TX-l55dtw60 Chassis La42 Pcz1303078ce98 pages

- Concepts in Engineering Design - Mechanical Engineering Second Year Notes, Books, Ebook PDF Download100% (1)Concepts in Engineering Design - Mechanical Engineering Second Year Notes, Books, Ebook PDF Download149 pages

- DMP900: Advanced Video Delivery SolutionNo ratings yetDMP900: Advanced Video Delivery Solution4 pages

- Business Objectives & Constraints in TelecomNo ratings yetBusiness Objectives & Constraints in Telecom2 pages

- 024-2019-CRYPTO-New Results On Modular Inversion Hidden Number ProblemNo ratings yet024-2019-CRYPTO-New Results On Modular Inversion Hidden Number Problem25 pages

- Measuring Turbulence with Hot-Wire AnemometersNo ratings yetMeasuring Turbulence with Hot-Wire Anemometers56 pages

- Basic Service Purchase Order Process Withholding - Service Management - Localization Latin America - SCN Wiki100% (1)Basic Service Purchase Order Process Withholding - Service Management - Localization Latin America - SCN Wiki10 pages

- W322 Cellular Router for M2M ConnectivityNo ratings yetW322 Cellular Router for M2M Connectivity2 pages

- Anycubic Kobra 2 Max Bed Level First Layer Calibration Squares Aligned With Bed Screws and Brim TestNo ratings yetAnycubic Kobra 2 Max Bed Level First Layer Calibration Squares Aligned With Bed Screws and Brim Test7 pages