Professional Documents

Culture Documents

CBex Manual

Uploaded by

Mohammad TaherOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CBex Manual

Uploaded by

Mohammad TaherCopyright:

Available Formats

POWERMASTER

CONTROLLED BOLTING SOFTWARE

SOLUTIONS FOR EVERY BOLTING APPLICATION

USER

MANUAL

AN EXPRESS WAY FOR EASE OF BOLT LOAD CALCULATION AND DOCUMENTATION.

Contents

Installation Guide

Introduction

Tool Bars

Setting up project, Setting up application

Project application list, Joint Inspector

Information Tab Bars

Manual Input Mode, File Menu

Summary Report

Individual Application Report

CBex Version 6.0 Page 2

Minimum System Requirements:

Operating system: Windows 7 and above

Disk Space: Minimum 1 GB

Processor: Intel dual core or equivalent

Screen Resolution: 1366 x 768

RAM : Minimum 512 MB

Instruction for installation:

First screen informed about copy right, system requirement, and end user license

agreement. Press NEXT button.

Press browse button, select the drive other drive if limited permission available for

default location in ‘C’ drive. Press NEXT button.

Press NEXT button.

Click on create desktop shortcut. Press NEXT

Click on install button.

Select full installation (for Sqlite). Click on NEXT.

Select checkbox for “Generate native images for the assemblies & install them into native

image cache” also select the checkbox for “Install the assemblies into the global

assembly cache”. (This is very important as Sqlite has to be in GAC (Global Assembly

Cache) to run this software)

Click NEXT.

Click NEXT.

Finish.

CBex Version 6.0 Page 3

Introduction

Powermaster Bolting Software "CBex” helps users to calculate bolt tensioner pressures for

specific bolt joint application and to prepare documentation for the same. User need to feed the

minimum essential data to get the necessary details for application using specific tool from

Powermaster. It helps to create Job sheet for a specific application as well as summery Sheet /

Job Register for multiple jobs of a specific project. The software contains data for the following

standard bolted flanges.

ANSI B16.5

ANSI B16.47

API 6A

Notes:

It contains data for the Subsea TSS Series & Topside PST Series of Powermaster Bolt

Tensioning Tools. The software has been developed completely in-house by Powermaster and as

such we have the ability to implement changes and add additional features.

We would hope that our partners that use the software help us by making suggestions and

reporting any problems they encounter with the software.

Caution: The recommended values are based on the experience and are used without any

guarantee or liability to Powermaster. The recommended bolt stress values assume that flange

material yield strength is equal to or greater than 247N/mm2 (35840lbs/In2).

DO NOT USE THE RECOMMENDED ANSI B16.5 BOLT STRESS VALUES FOR FLANGES

MANUFACTURED WITH MATERIAL YIELD STRENGTH LESS THAN 247N/mm2 (35840lbs/In2)

The following flange materials or equivalents are suitable for the recommended bolt stresses

ASTM A105

ASTM A182 Grades -F65, - F60, -F52 & -F51

ASTM A350 Grade -LF2& -LF3

ASTM A694 Grade F52, 60 & -F65

Flange Service Temperature range for the recommended bolt stress values are -101ºc to +200ºc.

or as limited by the piping class specifications or the bolt minimum or maximum temperature

specification. Do not use the recommended bolt stress values outside of this range

This software helps user to create a project with multiple joint application.

Basic working on software is to first create a Project. Then add multiple applications as

applicable.

CBex Version 6.0 Page 4

Toolbars

Project Toolbar:

Refer below project bar for setting up a new project and working on it.

1. To add a New Project 4. To save the Project

To Open an Existing

2. 5. To close the Project

Project

To edit an open existing

3. 6. To delete the project

project

Application Toolbar:

Using Application data sheet, applications are added to a project, using below application bar.

1. Save application as New 4. View application details

Save or Over write View applications in Grid

2. application

5. form of an project.

View application and Joint

3. Delete application 6. Summary sheet/ Report.

CBex Version 6.0 Page 5

Setting up a project:

Click on icon" ", and enter project details.

Close it by clicking on "OK"

CBex Version 6.0 Page 6

Setting up your first application:

Provide an identification no. / serial no in ‘’Joint ID’’.

Enter any comment if required.

Select Flange specification.

Select flange w.r.t. to its size and rating.

Check for bolt specification in bolt thread, change if required.

Select Tool to be used for the application.

Confirm Flange-1 configuration & then select gasket.

Select Flange -2 configuration .Add spacer details if applicable.

Select bolt material from dropdown list and change Residual stress if required.

Select Application Method i.e. 25%, 50%, 100% or Torque application.

Select De-tensioning if required and enter the percentage above residual load it need to be

set.

Save this application using icon " ".

Add as many as applicable applications for the project. To edit an application use

icon " . ".

CBex Version 6.0 Page 7

Project Application List

All applications related to project are displayed in this area. An application can be selected and

edited from here.

Joint Information & Calculation Data.

This area is where the current bolted joint information is with load application data is displayed.

CBex Version 6.0 Page 8

Information Tab Bar

The information tab bar consists of 5 Tabs,

Bolt Stress

Torque

Graph

Bolt

Sequence

Bolt Stress Tab:

Displays Bolt Stress, Bolt Load and %

Bolt Yield over a 3 stage time period.

CBex Version 6.0 Page 9

Torque Tab:

This tab displays the torque value to

achieve the residual bolt load based on the

displayed coefficients of friction.

The global coefficient of friction value can

be edited in the project definition window.

Stress Graph Tap:

This tab displays the predicted bolt stress path

over a 3 point time period.

T0 = Unstressed bolt

T1 = Initial bolt stress A pressure

T1 = Initial bolt stress B pressure

T2 = Final residual bolt stress

The Red line indicates the yield strength of

the bolt

The orange line indicates the maximum

detensioning stress.

Bolt Details Tab:

This tab displays the bolt detail

Tightening Sequence Tab:

This tab displays the recommended

torque application sequence.

Final Torque Value is displayed in Both

ft lbs & Nm

CBex Version 6.0 Page 10

Manual Input Mode

Manual Input mode can be chosen from

the Specification menu.

Manual input mode is used application

having non standard joints.

In this mode below values are to be

entered manually :-

o Flange 1 data

o Flange 2 data

o Bolt Size / thread

o Number of bolts

o Residual Stress

All the 5 orange coloured fields in the

application definition area are to be filled

first before the joint inspector displays the

result.

It is recommended to select values in

sequence .

Once the thread is selected the software

will suggest tensioning tools in the

tensioning tool menu

The Tensioning Tool menu will display

the tools for the selected bolt thread size.

The tools include the special tool created

by the user along with the standard tool

range.

The special tool can be created by the user

in the file menu/special tool library.

CBex Version 6.0 Page 11

Summary Report

To view summary report of project select on icon " "

Application List

To view all application details in the project select on icon " "

CBex Version 6.0 Page 12

Individual Application Report

To view individual application report click on icon" "

CBex Version 6.0 Page 13

POWERMASTER ENGINEERS PVT. LTD.

A-701-702, T.T.C. Industrial Area, Mahape-Turbhe Road, M.I.D.C., Khairne,

Navi Mumbai - 400 705, INDIA.

Phone: +91.22.6761 9100

Website: www.powermaster.in email: sales@powermaster.in

You might also like

- Hacks To Crush Plc Program Fast & Efficiently Everytime... : Coding, Simulating & Testing Programmable Logic Controller With ExamplesFrom EverandHacks To Crush Plc Program Fast & Efficiently Everytime... : Coding, Simulating & Testing Programmable Logic Controller With ExamplesRating: 5 out of 5 stars5/5 (1)

- Certified Solidworks Professional Advanced Weldments Exam PreparationFrom EverandCertified Solidworks Professional Advanced Weldments Exam PreparationRating: 5 out of 5 stars5/5 (1)

- Piping & Instrumentation Diagrams Fundamentals Catia - 001Document30 pagesPiping & Instrumentation Diagrams Fundamentals Catia - 001rvsingh70No ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Certified Solidworks Professional Advanced Sheet Metal Exam PreparationFrom EverandCertified Solidworks Professional Advanced Sheet Metal Exam PreparationRating: 5 out of 5 stars5/5 (4)

- Introduction to the simulation of power plants for EBSILON®Professional Version 15From EverandIntroduction to the simulation of power plants for EBSILON®Professional Version 15No ratings yet

- SAP Variant Configuration: Your Successful Guide to ModelingFrom EverandSAP Variant Configuration: Your Successful Guide to ModelingRating: 5 out of 5 stars5/5 (2)

- C Programming for the Pc the Mac and the Arduino Microcontroller SystemFrom EverandC Programming for the Pc the Mac and the Arduino Microcontroller SystemNo ratings yet

- Integrated Finite Elements Analysis and Design of StructuresDocument50 pagesIntegrated Finite Elements Analysis and Design of Structuresaeiou321No ratings yet

- PIC Projects and Applications using C: A Project-based ApproachFrom EverandPIC Projects and Applications using C: A Project-based ApproachRating: 4 out of 5 stars4/5 (2)

- Projects With Microcontrollers And PICCFrom EverandProjects With Microcontrollers And PICCRating: 5 out of 5 stars5/5 (1)

- Control M Prerequisite ConditionsDocument7 pagesControl M Prerequisite Conditionsnaveenr3No ratings yet

- Secrets of MS Excel VBA Macros for Beginners !: Save Your Time With Visual Basic Macros!From EverandSecrets of MS Excel VBA Macros for Beginners !: Save Your Time With Visual Basic Macros!Rating: 4 out of 5 stars4/5 (1)

- It Application Tools in BusinessDocument35 pagesIt Application Tools in BusinessKrisha SaltaNo ratings yet

- PowerPC Microprocessor Common Hardware Reference Platform: A System ArchitectureFrom EverandPowerPC Microprocessor Common Hardware Reference Platform: A System ArchitectureRating: 4 out of 5 stars4/5 (1)

- Voided Slab ExampleDocument58 pagesVoided Slab ExampleRegina Miller100% (2)

- Save Your Time with VBA!: 5 Quality VBA Books In One Package!From EverandSave Your Time with VBA!: 5 Quality VBA Books In One Package!No ratings yet

- ETAP User Guide 16.0. - Part54 PDFDocument100 pagesETAP User Guide 16.0. - Part54 PDFdardakNo ratings yet

- Selec PLC Programing ManualDocument104 pagesSelec PLC Programing ManualNILESH75% (4)

- Dietrich Product Selector General InstructionsDocument4 pagesDietrich Product Selector General Instructionsjbatista_njg4152No ratings yet

- VAFCP Application: Bangalore Integrated System Solutions (P) LTDDocument43 pagesVAFCP Application: Bangalore Integrated System Solutions (P) LTDAnton GoobinNo ratings yet

- Whats New in Pvelite 2017Document5 pagesWhats New in Pvelite 2017vikramNo ratings yet

- Enhanced Intelligent Drafting System (IDS) : User Guide For Version 9.0 (Rev. F)Document58 pagesEnhanced Intelligent Drafting System (IDS) : User Guide For Version 9.0 (Rev. F)ka lung KongNo ratings yet

- Caesar-II 5.2 Version NotesDocument19 pagesCaesar-II 5.2 Version Notesmsvikhas032No ratings yet

- TDSdescriptionDocument236 pagesTDSdescriptionapi-26946645100% (1)

- A Write Up On The Computer Programs For Curve Realignment Developed by Shri M.S. Ekbote, Addl. Member (CE) (Retired)Document32 pagesA Write Up On The Computer Programs For Curve Realignment Developed by Shri M.S. Ekbote, Addl. Member (CE) (Retired)Lakshya YadavNo ratings yet

- B DEMOdddddddhDocument16 pagesB DEMOdddddddhPabloDoisenbantNo ratings yet

- Experiment No.7: Aim: Design Differential Amplifier Software Used: AWR Design Environment 10 TheoryDocument12 pagesExperiment No.7: Aim: Design Differential Amplifier Software Used: AWR Design Environment 10 TheorySaurabh ChardeNo ratings yet

- Segment Checker ManualDocument32 pagesSegment Checker ManualCarlos VidelaNo ratings yet

- Unisoft Prontotest-Fixture Quick Start Tutorial ManualDocument31 pagesUnisoft Prontotest-Fixture Quick Start Tutorial ManualA2 TEAMNo ratings yet

- Example 4: Steel Beam of 2 Spans: 1) Starting A New StructureDocument16 pagesExample 4: Steel Beam of 2 Spans: 1) Starting A New StructureJosuu :vNo ratings yet

- EB Tester Software User Manual V1.8.5Document16 pagesEB Tester Software User Manual V1.8.5Roel GloriosoNo ratings yet

- Chapter 1: Measurement and Extraction of BSIM4 Model ParametersDocument66 pagesChapter 1: Measurement and Extraction of BSIM4 Model ParametersShreyash SillNo ratings yet

- Polyflow Extrusion WS06 Inverse ExtrusionDocument26 pagesPolyflow Extrusion WS06 Inverse ExtrusionTheerapat TaweebraksaNo ratings yet

- CLM M3 Programming ManualDocument249 pagesCLM M3 Programming Manualelmer jpnsonNo ratings yet

- Easy 8 Quick Start Guide BDocument19 pagesEasy 8 Quick Start Guide BAraik AmbartsumyanNo ratings yet

- Curve RealignmentDocument23 pagesCurve RealignmentSuryakantNo ratings yet

- MIT16 07F09 Lec03Document32 pagesMIT16 07F09 Lec03Никола ИвановNo ratings yet

- Release Notes - READDocument3 pagesRelease Notes - READHari KurniadiNo ratings yet

- Allegro Current Sensor Ltspice ModelsDocument11 pagesAllegro Current Sensor Ltspice ModelshajaNo ratings yet

- Quickguide ProteusDocument7 pagesQuickguide ProteusdavidemirraNo ratings yet

- Integrated Finite Elements Analysis and Design of StructuresDocument50 pagesIntegrated Finite Elements Analysis and Design of StructuresjustakeNo ratings yet

- Sap TutorDocument50 pagesSap Tutoraaa8165No ratings yet

- Genie Um Vol4Document18 pagesGenie Um Vol4Wais GaiNo ratings yet

- Manual Axon Test - Manual At-001.r1.1 - v1 - enDocument18 pagesManual Axon Test - Manual At-001.r1.1 - v1 - enCarlos Carrera CamiloNo ratings yet

- Creating A Function Block Using The Structured Text Editor - LAB1 - 2Document8 pagesCreating A Function Block Using The Structured Text Editor - LAB1 - 2Anandhu KumarNo ratings yet

- ADINA System 9.0Document56 pagesADINA System 9.0hamidNo ratings yet

- PCB Artist User Tips GuideDocument10 pagesPCB Artist User Tips GuideSampa_DudaNo ratings yet

- ADS Tutorial: A Beginners Tutorial: Modes of OperationDocument22 pagesADS Tutorial: A Beginners Tutorial: Modes of OperationFredCamoneNo ratings yet

- Rah 926 AaDocument11 pagesRah 926 AaJosé FariaNo ratings yet

- Express PCB Tutorial: Entering The Schematic Into ExpressschDocument35 pagesExpress PCB Tutorial: Entering The Schematic Into Expressschgyuvaraj10100% (1)

- NX 9 for Beginners - Part 1 (Getting Started with NX and Sketch Techniques)From EverandNX 9 for Beginners - Part 1 (Getting Started with NX and Sketch Techniques)Rating: 3.5 out of 5 stars3.5/5 (8)

- NX 9 for Beginners - Part 3 (Additional Features and Multibody Parts, Modifying Parts)From EverandNX 9 for Beginners - Part 3 (Additional Features and Multibody Parts, Modifying Parts)No ratings yet

- Intermediate C Programming for the PIC Microcontroller: Simplifying Embedded ProgrammingFrom EverandIntermediate C Programming for the PIC Microcontroller: Simplifying Embedded ProgrammingNo ratings yet

- MICROSOFT AZURE ADMINISTRATOR EXAM PREP(AZ-104) Part-4: AZ 104 EXAM STUDY GUIDEFrom EverandMICROSOFT AZURE ADMINISTRATOR EXAM PREP(AZ-104) Part-4: AZ 104 EXAM STUDY GUIDENo ratings yet

- NSF 61-2002e ANSIDocument160 pagesNSF 61-2002e ANSIMohammad TaherNo ratings yet

- Pipe Drafting and DesignDocument38 pagesPipe Drafting and DesignMohammad TaherNo ratings yet

- CECO Emtrol Buell FCCDocument5 pagesCECO Emtrol Buell FCCMohammad TaherNo ratings yet

- SB-619 - ASME BPVC 2021 Sección II Part BDocument8 pagesSB-619 - ASME BPVC 2021 Sección II Part BMohammad TaherNo ratings yet

- ft4x View DatasheetDocument3 pagesft4x View DatasheetMohammad TaherNo ratings yet

- BS 4368-4 1984Document9 pagesBS 4368-4 1984Mohammad TaherNo ratings yet

- Typical Set of Wire Mesh Dimensions Pages From Ken Sutherland - Filters and Filtration Handbook (2008, Elsevier Science) - 2Document2 pagesTypical Set of Wire Mesh Dimensions Pages From Ken Sutherland - Filters and Filtration Handbook (2008, Elsevier Science) - 2Mohammad TaherNo ratings yet

- SA-105 - ASME BPVC 2021 Sección II Parte A-1Document8 pagesSA-105 - ASME BPVC 2021 Sección II Parte A-1Mohammad TaherNo ratings yet

- Differential Pressure Flow Element - Case 2-24in - 50000Document3 pagesDifferential Pressure Flow Element - Case 2-24in - 50000Mohammad TaherNo ratings yet

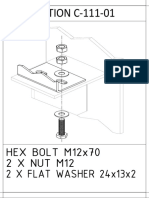

- CONNECTION C-111-01: HEX BOLT M12x70 2 X Nut M12 2 X FLAT WASHER 24x13x2Document1 pageCONNECTION C-111-01: HEX BOLT M12x70 2 X Nut M12 2 X FLAT WASHER 24x13x2Mohammad TaherNo ratings yet

- CONNECTION C-112-01: HEX BOLT M10x25 Nut M10 FLAT WASHER 35x11x2Document1 pageCONNECTION C-112-01: HEX BOLT M10x25 Nut M10 FLAT WASHER 35x11x2Mohammad TaherNo ratings yet

- Ar 207Document54 pagesAr 207Mohammad TaherNo ratings yet

- Connection C-207: Stud Bolt M10X40 2 X Nut M10 Seal Plate 50x20 Thk.2 Clamp M01Document1 pageConnection C-207: Stud Bolt M10X40 2 X Nut M10 Seal Plate 50x20 Thk.2 Clamp M01Mohammad TaherNo ratings yet

- DS MTE DemistersDocument2 pagesDS MTE DemistersMohammad TaherNo ratings yet

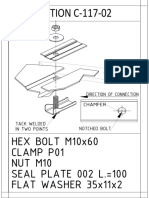

- CONNECTION C-117-02: Clamp P01 Nut M10 SEAL PLATE 002 L. 100 FLAT WASHER 35x11x2 HEX BOLT M10x60Document1 pageCONNECTION C-117-02: Clamp P01 Nut M10 SEAL PLATE 002 L. 100 FLAT WASHER 35x11x2 HEX BOLT M10x60Mohammad TaherNo ratings yet

- Catalytic Products Bro WebDocument4 pagesCatalytic Products Bro WebMohammad TaherNo ratings yet

- Structure Packing TypesDocument2 pagesStructure Packing TypesMohammad TaherNo ratings yet

- Lobry 6189Document15 pagesLobry 6189Mohammad TaherNo ratings yet

- 25mm PolypropyleneDocument1 page25mm PolypropyleneMohammad TaherNo ratings yet

- Book 1Document10 pagesBook 1Mohammad TaherNo ratings yet

- Spiral Wound Gasket 1Document9 pagesSpiral Wound Gasket 1Mohammad TaherNo ratings yet

- Book 1Document33 pagesBook 1Mohammad TaherNo ratings yet

- Book 1Document200 pagesBook 1Mohammad TaherNo ratings yet

- Introduction To Computing Exit Exam Model QuestionsDocument28 pagesIntroduction To Computing Exit Exam Model QuestionsAbdulaziz TilahunNo ratings yet

- W IPRODocument26 pagesW IPROSamad Bilgi50% (2)

- Bab-2 Linear Algebraic EquationsDocument51 pagesBab-2 Linear Algebraic EquationsNata CorpNo ratings yet

- Activity 2.2.2 Karnaugh Mapping POS Solutions: Name: Date: PeriodDocument5 pagesActivity 2.2.2 Karnaugh Mapping POS Solutions: Name: Date: PeriodDulce MelendezNo ratings yet

- Caris Hips and Sips Vessel EditorDocument41 pagesCaris Hips and Sips Vessel Editorlatni el mehdiNo ratings yet

- 03 Algorithm AnalysisDocument27 pages03 Algorithm AnalysisAshraf Uzzaman SalehNo ratings yet

- English Electricity Tariff 2024Document60 pagesEnglish Electricity Tariff 2024UNNI KUTTANNo ratings yet

- Estudio de IoT en El Proceso de Transformaci N Digital 1578106801Document78 pagesEstudio de IoT en El Proceso de Transformaci N Digital 1578106801wmedina1No ratings yet

- Types of Clash DetectionDocument8 pagesTypes of Clash DetectionAlireza ArefiNo ratings yet

- Note Taking Web AppDocument9 pagesNote Taking Web AppsathwickNo ratings yet

- Object Tracking in Crowd Environment Using Deep LearningDocument8 pagesObject Tracking in Crowd Environment Using Deep LearningIJRASETPublicationsNo ratings yet

- Application of Python and Data Analytics in Oil and GAs-1Document40 pagesApplication of Python and Data Analytics in Oil and GAs-1godfreyNo ratings yet

- 5G Progress in The Digital DecadeDocument11 pages5G Progress in The Digital DecadeMiguel Ladron de CegamaNo ratings yet

- CV and Certificates Single PDF (12-3-23) - 8-36-6-29Document24 pagesCV and Certificates Single PDF (12-3-23) - 8-36-6-29BaraneedharanNo ratings yet

- CSS Calibration HarvestingDocument12 pagesCSS Calibration HarvestingChristopher OlayaNo ratings yet

- Intel Annual Report 2021: Form 10-K (NASDAQ:INTC)Document10 pagesIntel Annual Report 2021: Form 10-K (NASDAQ:INTC)WigglepikeNo ratings yet

- Fortinet Security Fabric: Tomislav TucibatDocument31 pagesFortinet Security Fabric: Tomislav TucibatimperiaNo ratings yet

- Grade 5 Computer Week 5 Notes and AssignmentsDocument4 pagesGrade 5 Computer Week 5 Notes and Assignmentshabiba buttNo ratings yet

- Hold em Bot User ManualDocument105 pagesHold em Bot User ManualRio DingoeNo ratings yet

- QuadraticsDocument37 pagesQuadraticsalya farahiyahNo ratings yet

- AIX5L StudentGuide PDFDocument610 pagesAIX5L StudentGuide PDFRobin LiNo ratings yet

- CCNA Training Hot Standby Router Protocol HSRP TutorialDocument4 pagesCCNA Training Hot Standby Router Protocol HSRP Tutorialokotete evidenceNo ratings yet

- Teste Wager NovoDocument6 pagesTeste Wager NovogaleriecezanneNo ratings yet

- Four Metaphors We Need To Understand Assessment: Robert J. MislevyDocument36 pagesFour Metaphors We Need To Understand Assessment: Robert J. MislevyErven Jay EscobilloNo ratings yet

- Shneider Manuela M221 PersonaDocument296 pagesShneider Manuela M221 PersonaRicardo G. MartinezNo ratings yet

- Microsoft CSR Report AnalysisDocument9 pagesMicrosoft CSR Report AnalysisDaniela GudumacNo ratings yet

- WhatsApp Chat With Ritik Chauhan NIUDocument1 pageWhatsApp Chat With Ritik Chauhan NIUkp6649117No ratings yet

- 1 s2.0 S187705091931381X MainDocument8 pages1 s2.0 S187705091931381X MainVu Hoang AnhNo ratings yet