Professional Documents

Culture Documents

DS MTE Demisters

Uploaded by

Mohammad TaherOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DS MTE Demisters

Uploaded by

Mohammad TaherCopyright:

Available Formats

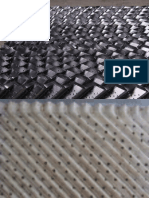

Demister pads

MTE Process technology

Demister pads provide effective mist elimination

compatible with normal packed column

operation. For high gas velocities or low pressure

drop requirements, we also supply vane type

demisters.

The pressure drop of the demister pad is very low

due to the large free volumes, even at higher

velocities. It rises almost proportional with the

thickness of the package and acts nearly

proportional to its density (with the same wire

diameter and knitted wire mesh specification).

Liquid load, viscosity, wetting behaviour of the

liquid, as well as the contamination level of the

gas stream (solid particles) have a strong

influence on the pressure drop.

Applications Benefits

» Scrubbers, absorbers High separation efficiency

» Distillation and rectification columns Low pressure drop

» Evaporation and pressure reducing Easy installation and low in maintenance

plants, knock-out drums High resistance to fouling

» Vacuum and compressed air

systems

» Sea water desalination plants

» Oil and emulsion mist separators

Divisions sales@mte-bv.com

MTE Catalyst Support +31 10 231 0 260

OPTIMIZING MASS TRANSFER MTE Process Technology

MTE Integrated Turnaround Solutions www.mte-process.com

Boezemweg 5, 3255 MC Oude-Tonge, The Netherlands Page 1 of 2

Demister pads

MTE Process technology

Specifications metal wire mesh demisters Available materials

Surface » SS304L

Type Density Voidage

area » SS316L

kg/m 3

m /m

2 3

% » SS904L

MTE-80-SS-0.28 80 145 99.0 » SS321

MTE-110-SS-0.28 110 200 98.6 » SS310

MTE-130-SS-0.28 130 236 98.3 » SS410

MTE-145-SS-0.28 145 265 98.1

» Ni

MTE-175-SS-0.28 175 320 97.8

» Ti Gr.2 & Gr.7

MTE-192-SS-0.28 192 350 97.5

» Cu

MTE-240-SS-0.28 240 435 97.0

» PP

MTE-240-SS-0.14 240 868 97.0

MTE-240-SS-0.12 432 1835 94.5 » EFTE

» PDVF

» Other materials

Specifications plastic wire mesh demisters on request

Surface

Type Density Voidage

area

kg/m3 m2/m3 %

MTE-50-PP-0.40 50 550 94.5

MTE-80-PP-0.40 80 770 92.3

MTE-100-PP-0.40 100 1100 89.0

MTE-100-PP-0.22 100 2200 89.0

MTE-80-PVDF-0.27 80 665 95.5

MTE-100-ETFE-0.27 100 870 94.2

MTE has the knowledge to design, debottleneck and optimize vapor liquid seperators alias

flash drums with a combination of knock-out equipment like baffles, half open feed pipes or

vane inlet devices in combination with demister pads for more efficient removal of droplets.

For additional information, support or (special) requests,

please contact our sales department.

Divisions sales@mte-bv.com

MTE Catalyst Support +31 10 231 0 260

OPTIMIZING MASS TRANSFER MTE Process Technology

MTE Integrated Turnaround Solutions www.mte-process.com

Boezemweg 5, 3255 MC Oude-Tonge, The Netherlands Page 2 of 2

You might also like

- DS MTE DemistersDocument2 pagesDS MTE DemistersJim Barrón GarcíaNo ratings yet

- DS MTE Pall RingsDocument6 pagesDS MTE Pall RingsD9 The GamerNo ratings yet

- M2T - MegaFlex - Hose GATESDocument4 pagesM2T - MegaFlex - Hose GATESDaniel MarNo ratings yet

- The Complete Rail System For Standard Applications: Advantages/Benefits Applications PropertiesDocument2 pagesThe Complete Rail System For Standard Applications: Advantages/Benefits Applications PropertiesilieoniciucNo ratings yet

- Manguera C-Inc. Nitrilo Acop. Br. de 30MTS 300psi 5elem UlDocument1 pageManguera C-Inc. Nitrilo Acop. Br. de 30MTS 300psi 5elem UlComercial FirenoNo ratings yet

- 9851 3586 01 COP MD20 BrochureDocument4 pages9851 3586 01 COP MD20 BrochureEduardo MassainiNo ratings yet

- 9851 3586 01 - Cop MD20Document4 pages9851 3586 01 - Cop MD20Guifo salvadorNo ratings yet

- Tensar SS Geogrids Product Specifications: Sales@Tcs-Geotechnics - Co.Uk 01942 218597 WWW - Tcs-Geotechnics - Co.UkDocument2 pagesTensar SS Geogrids Product Specifications: Sales@Tcs-Geotechnics - Co.Uk 01942 218597 WWW - Tcs-Geotechnics - Co.UkAshraf KadabaNo ratings yet

- Dta, GB 2Document1 pageDta, GB 2Sandeep YadavNo ratings yet

- Precint 1 Sewerage Schedule (20!6!18)Document1 pagePrecint 1 Sewerage Schedule (20!6!18)hasbulrahmanNo ratings yet

- Fisa Tehnica RG40Document2 pagesFisa Tehnica RG40Andrei TeoNo ratings yet

- Subm Motor Accessories Catalog enDocument13 pagesSubm Motor Accessories Catalog enmijael104No ratings yet

- Mo Slurry Hose Systems - Brochure en 4868 03 23 en MNGDocument27 pagesMo Slurry Hose Systems - Brochure en 4868 03 23 en MNGIgnacio Moratinos CastañedaNo ratings yet

- 9865 0049 01a COP MD20 BrochureDocument4 pages9865 0049 01a COP MD20 Brochurewaldycotrina105No ratings yet

- Cop Md20Document4 pagesCop Md20Isaac AliagaNo ratings yet

- Leichtmetall Data Sheet EN AW 6082T6Document1 pageLeichtmetall Data Sheet EN AW 6082T6Satendra ThakurNo ratings yet

- Wedge Wire Screens - Techincal Info - Screen SystemsDocument5 pagesWedge Wire Screens - Techincal Info - Screen SystemsChris HdezNo ratings yet

- IMI CCI Product MSDlll-actuator AW DigDocument6 pagesIMI CCI Product MSDlll-actuator AW DigpanametshNo ratings yet

- ESAB ExtractPage20-21cDocument8 pagesESAB ExtractPage20-21cDries VandezandeNo ratings yet

- Trellex Hose Flanges GasketsDocument6 pagesTrellex Hose Flanges GasketsHassan ShirivandNo ratings yet

- Brosur Pt. Srirejeki Perdana Steel-1Document16 pagesBrosur Pt. Srirejeki Perdana Steel-1Agus SofiansyahNo ratings yet

- Hydraulic Bolt Tensioners EnerpacDocument2 pagesHydraulic Bolt Tensioners EnerpacGurdeep Sungh AroraNo ratings yet

- Valqua No. 6500 Product Name General Use Compressed Non-Asbestos Fiber SheetDocument5 pagesValqua No. 6500 Product Name General Use Compressed Non-Asbestos Fiber SheetDocholosoNo ratings yet

- Accessories ESAB Gas Equipment Accessories: Spark LightersDocument4 pagesAccessories ESAB Gas Equipment Accessories: Spark LightersDries VandezandeNo ratings yet

- Data Sheet: Valid From: 1/6/20Document3 pagesData Sheet: Valid From: 1/6/20David AldanaNo ratings yet

- TORAY Membrane EuropeDocument25 pagesTORAY Membrane EuropemelpomenneNo ratings yet

- 9630 20 TSM HBQ 8439.autoDocument1 page9630 20 TSM HBQ 8439.autoIvan QuezadaNo ratings yet

- Atlas 9851 3497 01 - LDocument4 pagesAtlas 9851 3497 01 - LYiğit ErpakNo ratings yet

- 387 / 387TC / 387ST Hose: Delivering Value and Performance For High-Pressure SystemsDocument1 page387 / 387TC / 387ST Hose: Delivering Value and Performance For High-Pressure SystemsNgô Mạnh TiếnNo ratings yet

- Accessories ESAB Gas Equipment Accessories: Spark LightersDocument2 pagesAccessories ESAB Gas Equipment Accessories: Spark LightersDries VandezandeNo ratings yet

- Technical Specifications: ©envirobuild 2017Document4 pagesTechnical Specifications: ©envirobuild 2017Gonzalo Agulló FernándezNo ratings yet

- 2.halambiyo Distribution Pipe Quantity: 3 Supply and Installation of Distribution Fittings and AccessoriesDocument5 pages2.halambiyo Distribution Pipe Quantity: 3 Supply and Installation of Distribution Fittings and AccessoriesAbi DemeNo ratings yet

- Calculo Cables Coke2Document3 pagesCalculo Cables Coke2Jose Antonio Salazar HidalgoNo ratings yet

- Sefar Spécification: SEFAR TETEX MONO 03-1010-K 050 225 CM Numéro D' Article: 3B03-0420-225-00Document1 pageSefar Spécification: SEFAR TETEX MONO 03-1010-K 050 225 CM Numéro D' Article: 3B03-0420-225-00Bkiri AbderrahimNo ratings yet

- Portable Cutting Machine VCM 200 Portable Cutting Machine: Type 101 One Piece Acetylene NozzleDocument1 pagePortable Cutting Machine VCM 200 Portable Cutting Machine: Type 101 One Piece Acetylene NozzleDries VandezandeNo ratings yet

- VicWest Deck tableRD938-M - Load - Table - PDFDocument1 pageVicWest Deck tableRD938-M - Load - Table - PDFDarren Mitchell100% (1)

- Webergrout Fine - Product Sheet (2020 - 09)Document4 pagesWebergrout Fine - Product Sheet (2020 - 09)CHI KEUNG LINo ratings yet

- Torque Information - Fuller FastenersDocument3 pagesTorque Information - Fuller FastenersdangmiuNo ratings yet

- P E W Debabrata Chakraborty (Marketing Manager)Document1 pageP E W Debabrata Chakraborty (Marketing Manager)kumaran babaNo ratings yet

- 000 RA 3 Additanalservice ReportDocument1 page000 RA 3 Additanalservice Reportajay singhNo ratings yet

- 10 - Tech Manual Flat Face CouplersDocument4 pages10 - Tech Manual Flat Face Couplerschristian vergaray gonzalesNo ratings yet

- Chiyoda Welding Products: Combination Welding and Cutting TorchesDocument13 pagesChiyoda Welding Products: Combination Welding and Cutting Torchesandi permanaNo ratings yet

- Hikelok Tubing and PipeDocument6 pagesHikelok Tubing and Pipecesar floresNo ratings yet

- Portable Cutting Machine VCM 200 Portable Cutting Machine: Type 101 One Piece Acetylene NozzleDocument2 pagesPortable Cutting Machine VCM 200 Portable Cutting Machine: Type 101 One Piece Acetylene NozzleDries VandezandeNo ratings yet

- Sinhoo-SMTSO2530MTJ C2916380Document3 pagesSinhoo-SMTSO2530MTJ C2916380Mirosław MirekNo ratings yet

- Tenax-Htt N-Tscgewoeu 6-10 KVDocument2 pagesTenax-Htt N-Tscgewoeu 6-10 KVbeycanNo ratings yet

- Pot Bearing - Guided Bearing DesignDocument2 pagesPot Bearing - Guided Bearing Designtrichandra maharjanNo ratings yet

- Torayca Carbon T1100G-Technical-Data-Sheet-1 PDFDocument2 pagesTorayca Carbon T1100G-Technical-Data-Sheet-1 PDFd25932373No ratings yet

- RA4 Series: Reverse-Acting Metal Rupture DisksDocument2 pagesRA4 Series: Reverse-Acting Metal Rupture DisksNavneet SumanNo ratings yet

- Entech TPE Resin Datasheet 1Document4 pagesEntech TPE Resin Datasheet 1Ermin CisicNo ratings yet

- TN SSspecDocument1 pageTN SSspecDr Rami BakrNo ratings yet

- Pipa Baja Gelombang NF (Gorong Gorong Besi Corrugated Pipe)Document1 pagePipa Baja Gelombang NF (Gorong Gorong Besi Corrugated Pipe)Helori Grahasarana, PTNo ratings yet

- PTI - Sheave SPADocument5 pagesPTI - Sheave SPAvilash kumar sNo ratings yet

- Dosing Pump Milton Roy P Series PDFDocument2 pagesDosing Pump Milton Roy P Series PDFPT Purione MegatamaNo ratings yet

- Piling Systems: Ductile Iron SolutionsDocument16 pagesPiling Systems: Ductile Iron SolutionsDaniel MarínNo ratings yet

- 420118-Hydraulic Pump SettimaDocument9 pages420118-Hydraulic Pump SettimaAndreyOsyaninNo ratings yet

- Typical Set of Wire Mesh Dimensions Pages From Ken Sutherland - Filters and Filtration Handbook (2008, Elsevier Science) - 2Document2 pagesTypical Set of Wire Mesh Dimensions Pages From Ken Sutherland - Filters and Filtration Handbook (2008, Elsevier Science) - 2Mohammad TaherNo ratings yet

- NSF 61-2002e ANSIDocument160 pagesNSF 61-2002e ANSIMohammad TaherNo ratings yet

- BS 4368-4 1984Document9 pagesBS 4368-4 1984Mohammad TaherNo ratings yet

- SB-619 - ASME BPVC 2021 Sección II Part BDocument8 pagesSB-619 - ASME BPVC 2021 Sección II Part BMohammad TaherNo ratings yet

- Pipe Drafting and DesignDocument38 pagesPipe Drafting and DesignMohammad TaherNo ratings yet

- ft4x View DatasheetDocument3 pagesft4x View DatasheetMohammad TaherNo ratings yet

- CONNECTION C-112-01: HEX BOLT M10x25 Nut M10 FLAT WASHER 35x11x2Document1 pageCONNECTION C-112-01: HEX BOLT M10x25 Nut M10 FLAT WASHER 35x11x2Mohammad TaherNo ratings yet

- CECO Emtrol Buell FCCDocument5 pagesCECO Emtrol Buell FCCMohammad TaherNo ratings yet

- SA-105 - ASME BPVC 2021 Sección II Parte A-1Document8 pagesSA-105 - ASME BPVC 2021 Sección II Parte A-1Mohammad TaherNo ratings yet

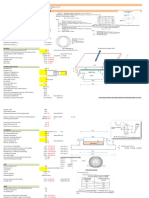

- Differential Pressure Flow Element - Case 2-24in - 50000Document3 pagesDifferential Pressure Flow Element - Case 2-24in - 50000Mohammad TaherNo ratings yet

- CONNECTION C-111-01: HEX BOLT M12x70 2 X Nut M12 2 X FLAT WASHER 24x13x2Document1 pageCONNECTION C-111-01: HEX BOLT M12x70 2 X Nut M12 2 X FLAT WASHER 24x13x2Mohammad TaherNo ratings yet

- Book 1Document200 pagesBook 1Mohammad TaherNo ratings yet

- 25mm PolypropyleneDocument1 page25mm PolypropyleneMohammad TaherNo ratings yet

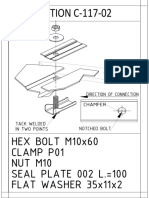

- CONNECTION C-117-02: Clamp P01 Nut M10 SEAL PLATE 002 L. 100 FLAT WASHER 35x11x2 HEX BOLT M10x60Document1 pageCONNECTION C-117-02: Clamp P01 Nut M10 SEAL PLATE 002 L. 100 FLAT WASHER 35x11x2 HEX BOLT M10x60Mohammad TaherNo ratings yet

- Connection C-207: Stud Bolt M10X40 2 X Nut M10 Seal Plate 50x20 Thk.2 Clamp M01Document1 pageConnection C-207: Stud Bolt M10X40 2 X Nut M10 Seal Plate 50x20 Thk.2 Clamp M01Mohammad TaherNo ratings yet

- Ar 207Document54 pagesAr 207Mohammad TaherNo ratings yet

- Lobry 6189Document15 pagesLobry 6189Mohammad TaherNo ratings yet

- Spiral Wound Gasket 1Document9 pagesSpiral Wound Gasket 1Mohammad TaherNo ratings yet

- Catalytic Products Bro WebDocument4 pagesCatalytic Products Bro WebMohammad TaherNo ratings yet

- Book 1Document33 pagesBook 1Mohammad TaherNo ratings yet

- Structure Packing TypesDocument2 pagesStructure Packing TypesMohammad TaherNo ratings yet

- Book 1Document10 pagesBook 1Mohammad TaherNo ratings yet