PlantPAx 5.

0 Demo Script

REV. 3.0

ROBERT MUNK

�Table of Contents

Login ....................................................................................................................................................... 2

Windows Login .................................................................................................................................... 2

FactoryTalk Login ................................................................................................................................. 2

ACD Controller File .................................................................................................................................. 2

HMI Server .............................................................................................................................................. 4

Communication Setup ......................................................................................................................... 5

Quick Start .............................................................................................................................................. 5

Slurry Area Startup .............................................................................................................................. 5

PlantPAx Library Area ........................................................................................................................ 10

PlantPAx Process Library ....................................................................................................................... 11

Logix Designer PlantPAx 5.0 Firmware Instructions ............................................................................ 12

SAMA Diagrams ..................................................................................................................................... 12

PlantPAx Tasking Model ........................................................................................................................ 14

Instruction Counter ............................................................................................................................... 15

ISA 101 Framework ............................................................................................................................... 16

System Diagnostics ................................................................................................................................ 18

Security ................................................................................................................................................. 19

Prebuilt Faceplates ................................................................................................................................ 21

Faceplate Navigation ......................................................................................................................... 21

Interlocks .......................................................................................................................................... 22

Logic Block ..................................................................................................................................... 24

Motor Runtime .................................................................................................................................. 27

Valve Statistics................................................................................................................................... 29

Instruction Help ................................................................................................................................. 31

Logix Instruction Help .................................................................................................................... 31

HMI Instruction Help...................................................................................................................... 32

Detection / Troubleshooting .................................................................................................................. 33

Alarming................................................................................................................................................ 33

Alarm Rollups ................................................................................................................................ 33

Alarm Summary ............................................................................................................................. 37

Maintenance ......................................................................................................................................... 39

Substitute Values ........................................................................................................................... 39

1

� Bypass Interlocks ........................................................................................................................... 40

Highly Integrated HART ......................................................................................................................... 45

SSRS Reports ......................................................................................................................................... 48

PlantPAx 5.0 Demo Script

This guide will walk you through demonstration examples for many of the common

PlantPAx features available within the PlantPAx 5.0 Demo.

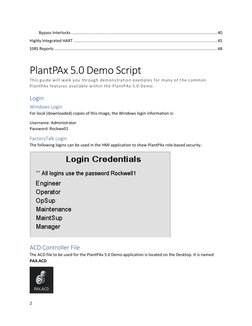

Login

Windows Login

For local (downloaded) copies of this image, the Windows login information is:

Username: Administrator

Password: Rockwell1

FactoryTalk Login

The following logins can be used in the HMI application to show PlantPAx role-based security.

ACD Controller File

The ACD file to be used for the PlantPAx 5.0 Demo application is located on the Desktop. It is named

[Link]

2

�The controller is organized according to the PlantPAx tasking model provided in v33 of Logix. This

application consists of routines for both a continuous process area as well as a Library area for showing

the various HMI and Library objects that are available. The Normal and Slow tasks contain the routines

for the continuous process area. The System (1s) task contains the routines used in the Library area, as

well as three routines, SystemProgram, Org, and Simulation used in the continuous application area.

3

�HMI Server

Open the PlantPAx HMI Application

New to FactoryTalk View 12 is the ability to create subfolders for Display files. The displays used in this

application are contained in four of the folders.

• Area 100 Slurry – contains the graphics being used in the continuous process demo area

• Library Demo – contains the graphics being used in the library object demo area

• PlantPAx 5_0 – contains the PlantPAx 5.0 Process Library graphics from the PCDC download

• PlantPAx-GraphicsFramework – contains the graphics objects for the HMI framework template

4

�Communication Setup

The FactoryTalk Linx server is in the PlantPAx_Data_Area folder. When configuring the controller

shortcut, ensure that “Upload all extended tag properties” and “Display pass-through values for tag

extended properties” are checked, and FT Linx is subscribed to “All Alarms & Events Notification

Messages”. The default path is configured to use Logix Echo to emulate the controller.

Quick Start

Slurry Area Startup

Once the controller file has been downloaded and the controller shortcut has been configured, launch

the HMI Client from the Desktop.

5

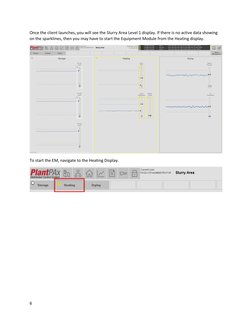

�Once the client launches, you will see the Slurry Area Level 1 display. If there is no active data showing

on the sparklines, then you may have to start the Equipment Module from the Heating display.

To start the EM, navigate to the Heating Display.

6

�Launch the Demo Control EM faceplate

Click the Display Tree View button on the EM faceplate to launch the Ownership/Organization tree view.

7

�Click the root node of the tree “PAx Demo” to launch the group command faceplate for the organization

tree.

This group command faceplate allows us to control all the devices in this demo area because they are

configured beneath the root node in the organization model (You can see all the configured devices by

clicking the arrow beside PAx Demo to expand the org tree). On the faceplate, click the button to

acknowledge all alarms, then click to put all devices into Program mode. Thanks to the Ownership and

Organization model, we can propagate commands to all devices beneath the root node from this

faceplate.

8

�Now that all devices are in Program mode, we need to put the Equipment Module back into Operator

mode so that we can start the EM. From the EM faceplate, click on the Command Source button and

request Operator control.

Now that the EM is back in Operator control mode, click the button to put the EM into Auto mode. The

equipment simulation should start, and values will begin populating.

9

�PlantPAx Library Area

To navigate from the A1000 Slurry area to the PlantPAx Library Object area, click on the Display

Navigation Map button on the client header. Select Library Area from the popup.

The main overview display gives examples of each firmware instruction available in the PlantPAx 5.0

library. You can see more detailed examples of control strategies and objects by clicking the navigation

buttons on the navigation bar.

10

�Each object group contains examples of each available global object as well as a description for the given

strategy or object.

PlantPAx Process Library

The PlantPAx Process Library is a predefined library of controller code (controller firmware based for 5.0

and Add-On Instructions in versions 4.x and below), display elements (global objects), and faceplates

that let you quickly assemble large applications with proven strategies, rich functionality, and known

performance.

Where to Get the Rockwell Automation Library of Process Objects

The PlantPAx Process Library can be downloaded from the Product Compatibility Download Center at:

[Link]

11

�Logix Designer PlantPAx 5.0 Firmware Instructions

The new PlantPAx 5.0 Embedded objects are the next generation of the Process Library, available when

using one of the new Process Controllers. These new controllers extend the existing Logix controller

family. Everything that a standard controller does, these controllers do. They share the same software

tools and are meant to provide a more process focused experience for customers.

The user no longer needs to download the PlantPAx Process Library manually add AOIs to their Logix

application. PlantPAx Objects are now native to the design pallet of Logix Designer in v33. Efficiency

tools and HMI objects are still available through download via Rockwell Automation Product Compatibility

and Download Center.

Previously released libraries will continue to be available and supported. They are compatible with the

new Process Controllers as well as the older controllers.

Examples of various Process Library objects are used throughout the PlantPAx_R5_00_Demo ACD file

located on the Desktop of the demo image. To insert a new firmware-based object, simply navigate to

the PlantPAx tab of the instruction bar in Studio 5000 Logix Designer and select an object from the list.

SAMA Diagrams

The PlantPAx 5.0 Process Objects have introduced a new way to explore the operating logic of the

instruction block by providing a SAMA diagram interface within the instruction configuration interface.

These new SAMA diagrams provide an intuitive, consistent experience with objects and firmware

instructions. These intuitive diagrams greatly reduce the number of steps required to configure a new

object in your project.

While online with the controller, navigate to the FIC1201 Routine under the A1200_Heating_S program.

Click on the ellipses button of the PAI block for FT1201 to open the configuration interface.

12

�Both the General and PV fail check tabs show examples of the new SAMA diagrams available with the

PlantPAx 5.0 Process Objects. Navigate to other Process Objects in the controller file to see other SAMA

diagram examples.

13

�PlantPAx Tasking Model

The new PlantPAx tasking model allows users to start a project with Fast, Normal, Slow, and System

periodic tasks already created. These tasks are created with the period, priority, and names already

specified according to PlantPAx guidelines. The benefits of this task model are a shorter time dedicated

to project creation and layout, consistent project structure across controllers, and more predictable

performance estimates.

To enable the PlantPAx task model in your P-Controller, open the Controller Properties and navigate to

the PlantPAx tab. Check the box for Use PlantPAx Tasking Model.

14

�Instruction Counter

A new feature that will be exclusive to the PlantPAx Process Controller is the ability to see a dashboard of

each task and the instructions used in your controller file. This feature can be used with the embedded

webpage to see CPU utilization and to avoid task overlap.

This feature enables consistent performance and visibility into task loading during the engineering cycle.

It allows the engineer an easier way to identify the number of control strategies being used in a

processor. This information can be used along with published guidance from our PlantPAx

Characterization Lab to ensure the performance of your system.

The Instruction Usage can be accessed by clicking the Instruction Usage button on the PlantPAx tab.

The popup window shows how many instances of each object type there are per routine based on the

PlantPAx Tasking Model of Fast, Normal, Slow, and System tasks.

15

� ISA 101 Framework

▪ Build for usability - account for cognitive and physical characteristics of users (avoid overload)

▪ Enable detection, diagnosis and response to abnormal conditions

▪ Grey scale (not unique to Rockwell – ISA 101)

▪ Only use colors to represent anomalies and abnormal states

▪ Avoid animation

▪ Navigation

▪ Consistent and intuitive

• Level 1 – Operator Area specific overview

The first display that opens when you launch the PlantPAx 5.0 Demo client is the Slurry Area Level 1

display. On this display you can see trends and analog input indicators for critical process attributes.

These level 1 objects do not launch faceplates and are meant as information only to alert an operator

that an action must be taken.

16

�• Level 2 – Primary Operator displays

Navigate to the Heating Level 2 display by clicking on the button indicated in the graphic below.

Other buttons on the L2 button bar will launch similar examples, but these other displays do not

have corresponding Level 3 displays associated with them. Level 2 graphics are the main operator

control displays where they can perform normal operation of the plant.

• Level 3 – Non-routine Operator displays

Navigate to the Exchanger Level 3 display by clicking on the button indicated in the graphic below.

Level 3 displays are typically used for specialized operations, maintenance, diagnostics, etc.…

• Level 4 – Faceplates – Clicking on any of the PlantPAx library objects from a Level 2 or Level 3 display

will launch the faceplate for that object. Level 1 objects are information only and cannot be clicked.

17

�Why ISA 101 Greyscale is important

• Built for usability - account for cognitive and physical characteristics of users (avoid overload)

o Enable detection, diagnosis, and response to abnormal conditions

• Greyscale (not unique to Rockwell – ISA 101)

o Only use colors to represent anomalies and abnormal states

o Avoid animation

• Consistent and intuitive navigation

System Diagnostics

New to the Process Controller with v33 firmware is the ability to configure Automatic Diagnostics in the

Controller Properties. To enable Automatic Diagnostics, open the controller properties for the PlantPAx

5.0 demo controller. Check the box to enable Automatic Diagnostics under the Advanced tab of the

controller properties as shown below.

18

�FactoryTalk View SE 12 now gives us the ability to create an Automatic Diagnostic Event Summary object

on a graphic. To view this summary, click on the System Status button on the header bar. Automatic

Diagnostics will be displayed on this screen.

Security

There are several FactoryTalk users configured for use with this demo to demonstrate both PlantPAx

user security and area-based security.

Username Password Permissions

Windows Administrator Rockwell1 All

Engineer Rockwell1 All Areas / PlantPAx_Engineering

Maintenance Rockwell1 All Areas / PlantPAx_Maintenance

MaintSup Rockwell1 All Areas / PlantPAx_Maintenance_Supervisor

Manager Rockwell1 All Areas / PlantPAx_Manager

Operator Rockwell1 All Areas / PlantPAx_Operators

OpSup Rockwell1 All Areas / PlantPAx_Operating_Supervisor

A1100_Operator Rockwell1 A1100_Advanced / A1100_Basic / Operators

A1200_Operator Rockwell1 A1200_Advanced / A1200_Basic / Operators

A1300_Operator Rockwell1 A1300_Advanced / A1300_Basic / Operators

Permissions for the different user groups can be modified for each user group by navigating to the

Security folder in the HMI Tag editor in FactoryTalk View Studio.

User Group Security Code

PlantPAx_Operators A

PlantPAx_Operating_Supervisor B

19

� PlantPAx_Maintenance C

PlantPAx_Maintenance_Supervisor D

PlantPAx_Engineering E

PlantPAx_Manager F

PlantPAx_Admin G

20

�Prebuilt Faceplates

The PlantPAx Process Library v5.0 can be downloaded for free from our Product Compatibility and

Download Center. This library is built to be used with the firmware based PlantPAx instructions available

in the P-Controller. This library contains premade device faceplates that drive consistency across

projects and various device types, have built-in navigation to related faceplates, interlocks and

permissives, motor runtime, and valve statistics among other things.

Faceplate Navigation

Navigate to the Exchanger Level 3 display. Click on the Steam Flow Control PPID object to launch the

FIC1202 faceplate

The PPID object faceplates are a great example of the ability to configure inter-faceplate navigation in

the PlantPAx library objects. From this single PPID faceplate, we can configure navigation to the PV, SP,

and CV points as well as interlocks. Click on any of these areas to launch the respective faceplate.

21

�Interlocks

The Process Interlocks (PINTLK) instruction collects, or sums up, the interlock conditions that stop or de-

energize a running or energized piece of equipment. This instruction can also help prevent equipment

from starting or being energized. Interlocks are always evaluated to de-energize equipment. For

permissive conditions that must be made to start the equipment, but are ignored once the equipment is

running, use the Process Permissive (PPERM) instruction. The PINTLK instruction provides:

• Interlock input OK check: Each input is compared with its configured OK state. If the input is not

in its OK state, it raises an interlock condition unless bypassed.

• Interlock Condition Latching: If the input is configured as latched, the interlock condition is

latched until reset, unless the latch defeat input is true. If the input is not configured as latched,

the interlock condition clears when the input returns to its OK state.

• Interlock Bypass: If the input is configured as able to be bypassed and interlocks are bypassed,

the input does not raise an interlock condition, even if it is not in its OK state. If the input is

configured as not able to be bypassed or if interlocks are not bypassed, the input raises an

interlock condition. Engineering configures which interlocks can be bypassed. Maintenance

chooses which inputs to bypass from the interlocks that are allowed by engineering.

• First Out: If no interlock conditions are raised (OK to run), the first interlock condition to be

raised is marked as the first out. If multiple interlock conditions are raised in the same scan, they

are all marked as first out.

• Latch Defeat: A latch defeat function reduces the number of operator actions that are required

to start equipment. The latch defeat input is set when the equipment is not running. When the

latch defeat input is true, the latched configuration of inputs is ignored, and all interlock

conditions clear when their corresponding inputs are in their OK states. This action saves the

operator from having to reset before starting the equipment.

• Summary Status: Summarizes its 32 interlock input conditions into two primary status bits:

• Status OK. Indicates all interlock conditions are clear and ready to run.

Navigate to the Heating L2 display and select the PLLS Motor Group Control object.

22

�From the faceplate, click on the Interlock navigation button. This will launch the Interlock object that is

configured to work with this PLLS object. When using the provided Process Control Strategies that are

included with the PlantPAx Process Library download, the PINTLK object is pre-configured to work with

the appropriate objects.

From the Interlock faceplate, we can see what, if any, interlocks are tripped. We also can configure

navigation to the interlock parent object, or optionally a logic block. Click on the Pro FT1201 Alarm

interlock to launch the FT1201 object faceplate.

23

�The FT1201 faceplate is launched by clicking on the interlock.

Logic Block

The Process Boolean Logic with Snapshot (PBL) instruction executes up to eight gates of configurable

Boolean logic. Gate types available include AND, OR, XOR (Exclusive-OR), Set/Reset, Select, and Majority.

Each gate provides up to four input conditions that are individually invertible using a configuration

setting. The PBL Instruction can record its current state:

• After a change in output state.

• On Operator or Program command.

• Based on a logic loopback input.

A common use for the PBL block is when an interlock or permissive requires a logic operation on

multiple inputs.

Navigate to the Heating L2 display and select the PLLS Motor Group Control object.

24

� From the faceplate, click on the Interlock navigation button.

Click on either the Pro Upstream Path Open or Pro Downstream Path Open interlocks to launch a

PBL faceplate.

25

� On this faceplate you can see the logic being applied to this interlock. Additionally, you can click on

any of the inputs to navigate to the faceplate of the input object.

26

�Motor Runtime

The Process Run Time and Start Counter (PRT) instruction records the total run time and number of

instances the motor or other equipment starts. The PRT is a software implementation of the mechanical

hour meter that displays the total motor runtime. Maintenance personnel use the run time and

equipment start variables to create a maintenance schedule for the applicable equipment.

Navigate to the Exchanger L3 display and click one of the Slurry Pump motor objects.

From the PMTR faceplate, click on the Maintenance tab

27

�Click the Display Runtime Accumulator Faceplate button

The Runtime faceplate for the motor object is launched. Click on the buttons along the left-hand side to

zero any of the values.

28

�Valve Statistics

The Process Valve Statistics Object (PVLVS) instruction monitors a two-state (open and close) valve and

records statistics for stroke times and stroke counts to aid in planning maintenance or diagnosing valve

and actuator problems. The PVLVS instruction is designed to work with the PVLV (solenoid, motor, and

hand operated) valve instruction. The PVLVS instruction records these statistics:

• Amount of time in the current state (closed, opening, opened, closing, stopped/other)

• Amount of time the valve was in each state the last time it was in that state (closed, opening,

opened, closing, stopped/other)

• Maximum amount of time spent in each state (closed, opening, opened, closing, and

stopped/other); these are the highest values achieved by the previous statistics

• Total amount of time spent in each state (closed, opening, opened, closing, stopped/other)

• Moving average of the last 10 closing (close stroke) times

• Moving average of the last 10 opening (open stroke) times

• Number of completed open strokes (from closed to opened)

• Number of completed close strokes (from opened to closed)

• Number of incomplete open strokes (from closed to opening and back to closed)

• Number of incomplete close strokes (from opened to closing and back to opened)

• Number of times the valve was in the stopped/other state

• Number of open strokes that took longer than the configured Slow Open Time

• Number of close strokes that took longer than the configured Slow Close Time

Navigate to the Exchanger L3 display and click on any of the valve objects to launch the faceplate.

29

�From the valve faceplate, navigate to the maintenance tab and click to launch the Valve Stats faceplate

30

�Instruction Help

Logix Instruction Help

New with PlantPAx 5.0 and the P-Controller is the convenience of built-in instruction help for PlantPAx

objects. Instruction help can be launched in several ways. You can right-click on an instruction and select

Instruction Help or select the object and press the F1 key.

Another way to access the instruction help is by clicking the ellipses button in the top right corner of an

object, then clicking Help on the configuration popup.

31

�HMI Instruction Help

The PlantPAx Process Library 5.0 download from PCDC includes a folder of PDF instruction help files. In

order to use these help files, you first need to update the HelpFilePath HMI tag located in the RALibrary

folder. Copy your file location path into the Initial Value field.

32

�With the file path pointing to the location of your PDF help files, you can now click the Instruction Help

button on any faceplate to launch the help PDF for that instruction.

Detection / Troubleshooting

Abnormal situations indicated with icons (with or without color)

• Substitute values (see breadcrumbs on display & faceplates)

• First-out Detection (from interlock faceplate)

• Generate alarm on Analog input (choose alarm that is pre-configured to display on trend (yet to

be determined)

o View on display

o View on banner

o View on Alarm Summary

o View on Trend Display

o Demonstrate Rollup of alarms on Navigation bars

Alarming

Alarm Rollups

The PlantPAx Process Library objects along with the HMI framework allow users to easily identify and

react to alarm conditions in their system. Alarms are indicated in the persistent alarm banner on the

header bar of the HMI framework, as well as indicated by breadcrumbs and outlines throughout the

Level 1, Level 2, Level 3 graphics and on the object faceplates.

33

�To simulate an alarm in the system, navigate to the Heating L2 display and click one of the Slurry Tank

Level indicators to launch the faceplate.

Trigger an alarm condition by either changing a threshold value or entering a substitute PV.

34

�For this example, I have entered a substitute PV of 10% to trigger a PV Low alarm.

To demonstrate the alarm roll-ups, navigate back to the Level 1 display by clicking the Home button on

the top banner of the HMI Client. Here you can see that the alarm is announced in the Alarm & Event

banner, it is indicated on the Storage navigation button, and it is shown in the Storage area of the Level

1 display.

35

�Following the breadcrumbs, click on the Storage navigation button. The device that is in alarm is

highlighted.

Clicking on the object shows which alarm is tripped and allows the user to acknowledge the alarm.

36

�Clicking on the Alarms tab of the faceplate shows a comprehensive list of the alarms that are configured

for each object as well as which alarms are currently active. Example:

Alarm Summary

The PlantPAx graphic framework has pre-configured templates for Alarm Summary, Alarm History,

Alarm Shelved, and Alarm Explorer displays. Click on the Alarms button next to the alarm banner to

launch the Alarm Summary display.

37

�The Alarm History display shows the alarm activity stored in the FTAE_History SQL database.

Alarm Shelved displays a list of any shelved alarms in the application.

38

�Alarm Explorer shows a list of the configured alarms in the application.

Maintenance

Substitute Values

The PlantPAx Process Library allows substitute values to be entered in the event of a disconnected or

failed sensor so that the user can easily keep their process running. Substitute values can be entered by

launching the faceplate, enabling the Substitute PV on the faceplate, then entering the desired value.

Click to launch one of the Analog Input level indicators on the Heating L2 display.

39

�Navigate to the Maintenance tab and toggle the switch to Use Substitute PV. You can now enter a value

into the Substitute PV field.

Also note that there is an indicator on both the device object and the faceplate to lead operators or

maintenance workers to the Substitute PV. This ensures that users are easily made aware that the

device is not in normal operating mode and will direct them to where they can return the device to

normal.

Bypass Interlocks

Another maintenance function built into the PlantPAx Process Library is the ability to bypass interlocks

and permissives. This allows the user to maintain plant operations in the event of a sensor failure or

other issue preventing a device from starting or running.

To bypass an interlock, we first need to simulate an interlock trip. This will be simulated easiest by taking

Operator control of devices. First, navigate to the Heating L2 display and launch the Demo Control EM

faceplate. Click Stop to stop the continuous process.

40

�Next, use the EM’s ownership model to put all the owned objects into Operator mode. Click on the

Display Tree View button on the EM faceplate.

Click on the PAx Demo root node, then click on the Operator group command to

Click on the PAx Demo root node, then click on the Operator group command to command all devices to

Operator mode.

41

�Now, navigate to the Exchanger L3 display. Notice that several objects indicate that their interlocks are

not OK. Click on the Motor Group Control PLLS object and launch the Interlock faceplate to see the

interlocks that need to be satisfied in order to start the slurry pumps.

There are two interlocks that need to be satisfied in order to start the pump group.

42

�Click on the Maintenance tab and enable bypass of the Pro Upstream Path Open interlock.

Back on the home tab, click on the Pro Downstream Path Open to manually satisfy the interlock. Click on

the FV1201D Opened Input and open the valve. The interlock will now be satisfied.

43

�Next, navigate back to the LLS1201 faceplate. Click on the Maintenance tab, and toggle the Bypass

Enabled switch to bypass the Pro Upstream Path Open interlock. All interlocks will now show satisfied.

Navigate back to the Home tab and start the motors.

44

�Highly Integrated HART

With the new Highly Integrated HART, instrument configuration has been built into the device tree for

Studio 5000 Logix Designer. This brings the device configuration closer to being just another I/O object in

the tree. We have also created PlantPAx specific data types for HART that will reduce the data mapping

effort to use the PlantPAx embedded library with them. The new intuitive integration of HART into the I/O

configuration of Logix Designer works similar to how we integrate Rockwell Automation power products

and I/O devices.

• It allows the adding and replacement of HART devices online.

• Integrated device diagnostics via the profile

• Integrated device information view

In the PlantPAx_R5_00_Demo ACD file we have configured several HART devices in the I/O tree. Open

the ACD and see any of the HART devices configured in the tree.

45

�Highly Integrated Hart is currently unique to the 5094 HART modules. Right click on one of the HART

devices and open the properties.

With the new 5094 HART device add-on profiles, you now have a choice to use PlantPAx connection

parameters. This can be seen in the Module Definition of the HART devices. PlantPAx connection types

are optimized to be used with the PAH instruction. To see an example of the instruction, open the

A1200_Heating_S program in the Slow task. Open the FIC1202 routine. This routine has a PAH

instruction connected to the PAI analog input instruction.

46

�On the HMI Client, navigate to the Heating L2 display. Launch the Steam Control FIC1202 PPID faceplate.

Click on the PV navigation button to launch the FT1202 PAI faceplate.

47

�Navigate to the Maintenance tab and click the Display Smart Device Faceplate button. This will launch

the faceplate for the PAH HART object.

SSRS Reports

The PlantPAx Process Library download includes a set of standard SSRS reports. These reports have been

deployed on this image and include Alarm & Event reports, Object Reports, AssetCentre Reports, and

Event Frame Reports. To access the reports on this image, simply launch Google Chrome from the task

bar and click on the SSRS Reports bookmark.

48

�When prompted, sign in using the Administrator username and password Rockwell1.

Once the reporting services webpage loads, click on Rockwell Automation Standard Reports to access

the list of reports.

49

�The available reports will be displayed.

The reports can be accessed from within the client by clicking on the “Reports” button on the header

bar from anywhere in the application.

50