Professional Documents

Culture Documents

Garsite Jet Refuler 5000 Gallon DATA SHEET

Uploaded by

baladiroyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Garsite Jet Refuler 5000 Gallon DATA SHEET

Uploaded by

baladiroyaCopyright:

Available Formats

Jet Refueler

5,000 Gallon / 18,700 Liter

Flow Rates: 300-600 GPM / 1,125-2,250 LPM

Base Specifications HOSE: One 2” x 50’ and one 1¼” x 50’ aviation fueling hose with N/R male

couplings, certified to API 1529

TANK OVERWING NOZZLE: Jet overwing nozzle with swivel and 100 mesh strainer

5,000 U.S. gallons (3% outage) aluminum tank fully baffled, single

compartment, overturn protection, 20” manhole with 10” fill opening with UNDERWING NOZZLE: One international standard 3-lug underwing nozzle

emergency pressure / vacuum vents and one 20” inspection manhole with quick disconnect and swivel

BOTTOM LOADING: Includes a jet level sensor control system for automatic,

CHASSIS high-level shut-off with precheck. The bottom loading adapter, capable

Conventional cab-chassis, diesel engine, automatic transmission. of accepting a standard underwing nozzle, is installed on the driver side.

(Detailed specifications available upon request.) A gauge and shut-off valve shall be supplied immediately downstream of

bottom load adapter for re-circulation and testing.

STANDARD DIMENSIONS

DEFUEL: Fuel/defuel system operates in conjunction with bottom loading

33’L x 102”W x 120”H system to include overfill protection

REFUELING SYSTEM PIPING: Schedule 10 aluminum – with 150 PSI rated working pressure

PUMP: Centrifugal type, PTO driven, hot shift. 300 GPM to 600 GPM / TEST: Flow tested with fuel for performance to rated specifications

2,400 LPM

FINISH: Cab painted factory white. Aluminum tank in natural polished finish.

FILTER/SEPARATOR: 5th Edition Horizontal Filter/Separator – 300 GPM Equipment painted silver.

rated with differential pressure gauge, air eliminator, water defense and

drain valve. F/S meets API 1581 specifications and qualification procedures SAFETY FEATURES: Static reel with 50’ cable and bonding clamp, brake

for solids and water removal. Filter Monitor is available as an option. interlock system, emergency shut-down system and two fire extinguishers

DEADMAN AND PRESSURE CONTROL: Electrically operated inline COMPLIANCE: Meets all applicable NFPA 407 & 385 codes. Design complies

deadman/pressure control and shut-off valve provides primary pressure with ATA-103 requirements.

control. Secondary pressure control regulated by mechanical hose end

control valve. Options

The above listed items are for a standard Garsite refueler. All units can be

METER: One meter, with large numeral reset counter and totalizer, registers customized to fit your specific requirements. Please contact your Garsite

in whole U.S. gallons representative for a complete list of available options and configurations.

VENTURI: Sized to compensate for pressure loss

ASME ‘U’ and ‘R’ Certified Facility

HOSE REELS: Two reels; one single wrap sized for 2½” x 50’ hose, and

one sized for 1¼” x 50’ hose, non-ferrous internals, explosion proof electric

rewind motors and switches, auxiliary manual rewind. An isolation shut-off

valve is installed immediately upstream of reel.

Garsite

Base specifications are accurate at the time of publication, and are 539 South 10th Street

subject to change without notice. Custom options are available; please Kansas City, Kansas

consult your Garsite representative for additional information.

garsite.com

©2015 Wabash National L.P. All rights reserved. Wabash® and

Wabash National® are marks owned by Wabash National, LP sales@garsite.com

GAR 0003 10.15 - V1 1-888-GARSITE (toll-free)

913-342-5600 (local or international)

You might also like

- Garsite Avgas Refuler DATA SHEETDocument1 pageGarsite Avgas Refuler DATA SHEETfuelcombNo ratings yet

- TLD WSP-900 Water Truck SpecsDocument2 pagesTLD WSP-900 Water Truck SpecsPhat DinhNo ratings yet

- Fluxometro de Inodoro SloanDocument2 pagesFluxometro de Inodoro SloanARQUITECTURA PARAGUANA CIMIENTOS DE VENEZUELA C.A.No ratings yet

- Tanque de HidroterapiaL-105-SDocument2 pagesTanque de HidroterapiaL-105-SVictor EspinozaNo ratings yet

- Brochure 20KW Gas PropanoDocument6 pagesBrochure 20KW Gas PropanoRolando CoelloNo ratings yet

- The Sullair: Portable Air CompressorDocument2 pagesThe Sullair: Portable Air Compressorandrea duranNo ratings yet

- Spesifikasi Gorman Ruup PAH3A60-6068HDocument2 pagesSpesifikasi Gorman Ruup PAH3A60-6068HAnggoro Ibnu FauzanNo ratings yet

- tc80-120 Brochure 10-19 WebDocument2 pagestc80-120 Brochure 10-19 Webvitor rodriguesNo ratings yet

- Datasheet Motor Generador Cummins Onan 30MCGBADocument4 pagesDatasheet Motor Generador Cummins Onan 30MCGBABam BANo ratings yet

- GouldsDocument4 pagesGouldsTatiana Mejías SeguraNo ratings yet

- 7044 Ops ManualDocument683 pages7044 Ops ManualsimjopaulNo ratings yet

- Especificaciones Del 375Document2 pagesEspecificaciones Del 375jordan navarroNo ratings yet

- Commercial Generator Set Hydraulic Series HG 15000: Features and Benefits Weight, Size and Sound LevelDocument4 pagesCommercial Generator Set Hydraulic Series HG 15000: Features and Benefits Weight, Size and Sound Leveleddy ortegaNo ratings yet

- VHP Series Gas Engine: 732 - 1025 BHP (546 - 764 KWB)Document2 pagesVHP Series Gas Engine: 732 - 1025 BHP (546 - 764 KWB)feryNo ratings yet

- Brochure Técnico - 2WD - 3WDDocument4 pagesBrochure Técnico - 2WD - 3WDAdrian CordovaNo ratings yet

- M J251 SpecDocument2 pagesM J251 SpecjiaozhongxingNo ratings yet

- Model J-352-LS: SpecificationsDocument2 pagesModel J-352-LS: SpecificationsjiaozhongxingNo ratings yet

- L7044GSI: VHP Series Four Gas EngineDocument2 pagesL7044GSI: VHP Series Four Gas EngineferyNo ratings yet

- Sullair 185 Spec Sheet 1Document2 pagesSullair 185 Spec Sheet 1Fortunato Noe Palomino MarcillaNo ratings yet

- File - 1784 - Push Back Cargo Tractor Model-100 ... - AeroserviciosDocument2 pagesFile - 1784 - Push Back Cargo Tractor Model-100 ... - Aeroserviciospc tuto aguilarNo ratings yet

- CLKMC 0109 UsDocument4 pagesCLKMC 0109 UsRioga RiogaNo ratings yet

- Wascomat Crossover Dryer OPL Specifications DAWF0GNM Non Meteres Card Ready GasDocument2 pagesWascomat Crossover Dryer OPL Specifications DAWF0GNM Non Meteres Card Ready Gasmairimsp2003No ratings yet

- Manual OyM - Compresor 900hDocument2 pagesManual OyM - Compresor 900hCARLOSNo ratings yet

- Technical Brochure: Submersible 4" Non-Clog Sewage PumpDocument4 pagesTechnical Brochure: Submersible 4" Non-Clog Sewage PumpLisandro Torrealba MedranoNo ratings yet

- VHP Series Gas Engine: 366 - 515 BHP (273 - 384 KWB) 366 - 515 BHP (273 - 384 KWB)Document2 pagesVHP Series Gas Engine: 366 - 515 BHP (273 - 384 KWB) 366 - 515 BHP (273 - 384 KWB)feryNo ratings yet

- L170R... Mega DS 2021Document7 pagesL170R... Mega DS 2021ชัชวาล เมตตาNo ratings yet

- VHP Series Gas Engine: 604 - 845 BHP (450 - 630 KWB)Document2 pagesVHP Series Gas Engine: 604 - 845 BHP (450 - 630 KWB)feryNo ratings yet

- Tandem Dump Truck SpecificationsDocument4 pagesTandem Dump Truck SpecificationsdeadbirdsNo ratings yet

- Super Duty, Independent Dual System Hydraulic Power Unit / Diesel PoweredDocument6 pagesSuper Duty, Independent Dual System Hydraulic Power Unit / Diesel PoweredTrần Quang ThắngNo ratings yet

- SDB Series Blower Purge Desiccant Dryers 1200-12000 SCFMDocument4 pagesSDB Series Blower Purge Desiccant Dryers 1200-12000 SCFMramiro alvarezNo ratings yet

- Heavy Duty Electric Towing Solutions: 80 Volt AC Powered TractorDocument2 pagesHeavy Duty Electric Towing Solutions: 80 Volt AC Powered TractorRodrigo BojorgesNo ratings yet

- Parker Drilling Company Rig 257: Submersible Shallow Water - Barge Drilling Rig - Caspian Sea (ABS & RMRS Certified)Document2 pagesParker Drilling Company Rig 257: Submersible Shallow Water - Barge Drilling Rig - Caspian Sea (ABS & RMRS Certified)Seyedeh Roghayeh SeyediNo ratings yet

- Model Fully Adjustable Pressure Compensated Flow Control Valve With Reverse Flow CheckDocument2 pagesModel Fully Adjustable Pressure Compensated Flow Control Valve With Reverse Flow CheckRajan BediNo ratings yet

- Sotera Diaphragm Pumps (DV Motor)Document8 pagesSotera Diaphragm Pumps (DV Motor)Imran Shahzad KhanNo ratings yet

- Manual Compresora Sullair 425Document2 pagesManual Compresora Sullair 425Franz JW Monteza100% (1)

- MR-033 FD-NMR602 06-JanDocument16 pagesMR-033 FD-NMR602 06-JanZubair KhanNo ratings yet

- Sample Brochure 4Document2 pagesSample Brochure 4Ahmad El KhatibNo ratings yet

- 10 KW Diesel Generato AGi9PDocument2 pages10 KW Diesel Generato AGi9Pmasteryoda394No ratings yet

- Compresor Sullair 260Document2 pagesCompresor Sullair 260Carmita Suarez SanturNo ratings yet

- H&P ARG Rig 335 Equipment List From Final WoDocument12 pagesH&P ARG Rig 335 Equipment List From Final WoJuan Miguel Robledo100% (1)

- Ficha Tecnica RV-5000Document6 pagesFicha Tecnica RV-5000Rolando CerezoNo ratings yet

- Spesiikasi PerallatanDocument10 pagesSpesiikasi PerallatanRafi RaziqNo ratings yet

- Ts HorizontalEndSuction 3pumpDocument2 pagesTs HorizontalEndSuction 3pumpAtwa AttllaNo ratings yet

- TDS Alpha 20 Tier 3 (EN) Rev.02Document6 pagesTDS Alpha 20 Tier 3 (EN) Rev.02Diego BernalNo ratings yet

- tc30 60 - 12 17 14 - WebDocument2 pagestc30 60 - 12 17 14 - WebMarcos MuñozNo ratings yet

- Model MS-RV: Workshop ContainerDocument6 pagesModel MS-RV: Workshop Containerjose ocanaNo ratings yet

- Alpha 20 Stage III Technical Data Sheet Global enDocument6 pagesAlpha 20 Stage III Technical Data Sheet Global enMario octavio HernándezNo ratings yet

- Series 825Y: Reduced Pressure Zone AssembliesDocument2 pagesSeries 825Y: Reduced Pressure Zone Assembliesmiljan trifkovicNo ratings yet

- Goulds GB Booster Pump SeriesDocument14 pagesGoulds GB Booster Pump SeriesWilson Jr. AnilaoNo ratings yet

- Ed 122 - 26be05aaf8Document20 pagesEd 122 - 26be05aaf8seve1No ratings yet

- Pit Cleaner Series: From The Industry-Leading InnovatorDocument4 pagesPit Cleaner Series: From The Industry-Leading InnovatorlalonusanNo ratings yet

- Ottawa 4x2 Dot Epa Certified Spec SheetDocument2 pagesOttawa 4x2 Dot Epa Certified Spec SheetTawfiq ZidanNo ratings yet

- Pump Unload Pilot Valve SUN QPABDocument2 pagesPump Unload Pilot Valve SUN QPABankesh_ghoghariNo ratings yet

- V-Pak Unidades Hidraulicas ParkerDocument20 pagesV-Pak Unidades Hidraulicas ParkerDaniel MarNo ratings yet

- Modelo Totalmente Ajustable Compensado Por Presión Control de Caudal Válvula Con Anti-Retorno de Caudal InversoDocument2 pagesModelo Totalmente Ajustable Compensado Por Presión Control de Caudal Válvula Con Anti-Retorno de Caudal InversoErasmo LimaNo ratings yet

- Brochure VARIPURE 20160519 EN PDFDocument8 pagesBrochure VARIPURE 20160519 EN PDFMhs EngineerNo ratings yet

- Free-Standing Cooler: EconomyDocument2 pagesFree-Standing Cooler: EconomyElement Back To BasicNo ratings yet

- Charmec SF 405 DV 100056996Document10 pagesCharmec SF 405 DV 100056996Roger Rojas PrimoNo ratings yet

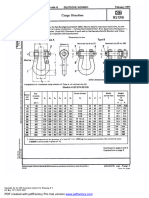

- AG Gauge Valves AEDocument51 pagesAG Gauge Valves AEbaladiroyaNo ratings yet

- Astm A487 4 (A)Document1 pageAstm A487 4 (A)baladiroyaNo ratings yet

- DIN 3570 Strap (U-Bolt)Document2 pagesDIN 3570 Strap (U-Bolt)baladiroyaNo ratings yet

- Astm A487 4 (A)Document1 pageAstm A487 4 (A)baladiroyaNo ratings yet

- Stainless Steel 420 Grade Data SheetDocument3 pagesStainless Steel 420 Grade Data SheetM. Pandu SetiawanNo ratings yet

- A216 1615228-1 PDFDocument4 pagesA216 1615228-1 PDFRajan SteeveNo ratings yet

- Large Bore High Pressure Hydraulic Cylinders SeriesDocument18 pagesLarge Bore High Pressure Hydraulic Cylinders SeriesHYDRAULICGURUNo ratings yet

- All Steel Unibody Valve: Bulletin No. 84-00C For Use As Gauge ValveDocument2 pagesAll Steel Unibody Valve: Bulletin No. 84-00C For Use As Gauge ValvebaladiroyaNo ratings yet

- Astm A216 WCBDocument1 pageAstm A216 WCBAkshay ValaNo ratings yet

- DIN 82016 Cargo ShacklesDocument3 pagesDIN 82016 Cargo ShacklesbaladiroyaNo ratings yet

- DIN 797 Fund BoltDocument1 pageDIN 797 Fund BoltbaladiroyaNo ratings yet

- ISO TR 10358-1993 ScanDocument54 pagesISO TR 10358-1993 ScanbaladiroyaNo ratings yet

- DIN 1662 HexBoltFlngDocument11 pagesDIN 1662 HexBoltFlngbaladiroyaNo ratings yet

- DIN 609 Hex Fit BoltDocument10 pagesDIN 609 Hex Fit BoltbaladiroyaNo ratings yet

- Corrosion Engineering Handbook - Fundamentals of Metallic Corrosion 2nd Ed - P. Schweitzer (CRCDocument750 pagesCorrosion Engineering Handbook - Fundamentals of Metallic Corrosion 2nd Ed - P. Schweitzer (CRCGiuseppe Gori100% (14)

- DIN 7157 - Fit TolerancesDocument5 pagesDIN 7157 - Fit TolerancesbaladiroyaNo ratings yet

- XPPHCDocument14 pagesXPPHCbaladiroyaNo ratings yet

- ASTM E433 71 (Reapproved 2018)Document5 pagesASTM E433 71 (Reapproved 2018)VICTOR SEGOVIANo ratings yet

- 7-I.H.S. Standart Store: مﺎﻜﺤﺘﺳا ﻲﺸﺸﻛ) (مﺎﻜﺤﺘﺳا ﻲﺸﺸﻛ) (MN/m MN/m MN/m MN/m MN/m MN/mDocument32 pages7-I.H.S. Standart Store: مﺎﻜﺤﺘﺳا ﻲﺸﺸﻛ) (مﺎﻜﺤﺘﺳا ﻲﺸﺸﻛ) (MN/m MN/m MN/m MN/m MN/m MN/mHOSSIENNo ratings yet

- Clamp PDFDocument20 pagesClamp PDFyury1102No ratings yet

- Weld-Overlay - Cladding - Solutions - 2017 - ENDocument36 pagesWeld-Overlay - Cladding - Solutions - 2017 - ENbaladiroyaNo ratings yet

- XPPHCDocument14 pagesXPPHCbaladiroyaNo ratings yet

- Table-1-ASME-B36.10M-2015-pip ScheduleDocument18 pagesTable-1-ASME-B36.10M-2015-pip SchedulebaladiroyaNo ratings yet

- Terastandard - Bsi Bs Iso 5597 267Document26 pagesTerastandard - Bsi Bs Iso 5597 267baladiroyaNo ratings yet

- Retenes TimkenDocument237 pagesRetenes TimkenJOSTINNo ratings yet

- DIN 3771-1 (O'ring)Document27 pagesDIN 3771-1 (O'ring)baladiroyaNo ratings yet

- Astm E165-NdtDocument20 pagesAstm E165-NdtbaladiroyaNo ratings yet

- Oring KoyoDocument126 pagesOring KoyoTan Minh Tam TruongNo ratings yet

- Terastandard - Bsi Bs Iso 5597 267Document26 pagesTerastandard - Bsi Bs Iso 5597 267baladiroyaNo ratings yet

- World Air Forces 2010Document32 pagesWorld Air Forces 2010Jason Coley100% (1)

- Fighter Comparison by Kirk WebberDocument1 pageFighter Comparison by Kirk WebberDoug AllenNo ratings yet

- Aerial RefuelingDocument20 pagesAerial RefuelingAbhijit MirajkarNo ratings yet

- Traveller - Classic - Game 06 - Dark Nebula - Rules and Charts PDFDocument13 pagesTraveller - Classic - Game 06 - Dark Nebula - Rules and Charts PDFTess Mercer100% (1)

- Alcpt 63Document14 pagesAlcpt 63Mohammed Hashim75% (8)

- SAC History Jan - Jun 58 Vol I Study 73Document98 pagesSAC History Jan - Jun 58 Vol I Study 73Douglas Keeney100% (1)

- TM 55-1520-210-23-1Document1,300 pagesTM 55-1520-210-23-1Leonardo Gonzalez Rocha100% (9)

- Ma Sir AhDocument7 pagesMa Sir AhParthasarathi GangulyNo ratings yet

- Free A320 Oral Questions 2001Document20 pagesFree A320 Oral Questions 2001brainstol80% (5)

- The Superior Solution: Combat Search and RescueDocument12 pagesThe Superior Solution: Combat Search and RescueVictor PileggiNo ratings yet

- Airbus Military - A400MDocument7 pagesAirbus Military - A400MAviationaddict100% (2)

- Fse100 FinalDocument37 pagesFse100 Finalapi-456985970100% (1)

- "Accidents Involving Nuclear Weapons" (DASA Technical Letter 20-3, 15 October 1967), Appendix IDocument225 pages"Accidents Involving Nuclear Weapons" (DASA Technical Letter 20-3, 15 October 1967), Appendix Inuclearsecrecy100% (1)

- Chapter 12 - Servicing: HelicopterDocument44 pagesChapter 12 - Servicing: HelicopterLuis HernandezNo ratings yet

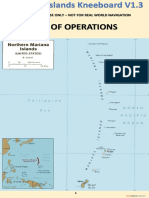

- DCS - Marianas - Kneeboard - V1.3 (15nov21)Document14 pagesDCS - Marianas - Kneeboard - V1.3 (15nov21)trtr5150No ratings yet

- 11-100 - Offloading SystemsDocument2 pages11-100 - Offloading SystemsAnonymous 2CMPbqwBNo ratings yet

- Fuel Tank Truck Afd-091005-058Document40 pagesFuel Tank Truck Afd-091005-058cascade1100% (1)

- Icing Certification of Korean Utility Helicopter KUH 1 Artificial Icing Flight TestDocument9 pagesIcing Certification of Korean Utility Helicopter KUH 1 Artificial Icing Flight TestUniNo ratings yet

- Brevity Words NATODocument102 pagesBrevity Words NATOGermanSilvaCarreraNo ratings yet

- A Full Retaliatory ResponseDocument10 pagesA Full Retaliatory ResponseKIRU SILVIUNo ratings yet

- Business and Commercial Aviation MagazineDocument10 pagesBusiness and Commercial Aviation MagazineveenadivyakishNo ratings yet

- Army Aviation Digest - Jun 1970Document68 pagesArmy Aviation Digest - Jun 1970Aviation/Space History Library100% (1)

- Gripen NG BrochureDocument10 pagesGripen NG Brochurevs_3457000100% (1)

- Air Force 2020-11Document73 pagesAir Force 2020-11Marta JNo ratings yet

- Hydrant Dispencer Fueling of Antonov 158Document56 pagesHydrant Dispencer Fueling of Antonov 158Viacheslav ChornyiNo ratings yet

- SM64015 PCT - 202344Document12 pagesSM64015 PCT - 202344HenryNo ratings yet

- SAO2020 FCS Brochure Aircraft Fuel Systems CapabilitiesDocument94 pagesSAO2020 FCS Brochure Aircraft Fuel Systems CapabilitiesSaraNo ratings yet

- The Aircraft EncyclopediaDocument196 pagesThe Aircraft Encyclopediaa h100% (11)

- ATA 28 - Fuel Systems ModuleDocument32 pagesATA 28 - Fuel Systems ModulejavalderaNo ratings yet

- 19-Underway Replenishment 3Document32 pages19-Underway Replenishment 3ErnestoDom100% (1)