Professional Documents

Culture Documents

DOWSIL 121 Structural Glazing Sealant Product Data 1799934

Uploaded by

bogzskieOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DOWSIL 121 Structural Glazing Sealant Product Data 1799934

Uploaded by

bogzskieCopyright:

Available Formats

Technical Data Sheet

DOWSIL™ 121 Structural Glazing Sealant

Fast-curing, two-part, neutral-cure, RTV silicone sealant for use in structural and

weatherseal applications.

Features & • Approved for structural and weatherseal applications1

Benefits • High level of mechanical properties

• Structural capability

• Odorless and non-corrosive cure

• Excellent stability through wide temperature range: -50°C to 150°C

• Stable viscosity for base and catalyst, no heating required

• The cured product exhibits excellent weathering characteristics, and a high resistance

to ultra-violet radiation, ozone, heat and humidity

• Primerless adhesion to alodine and anodized aluminum2

• Adhesion to DOWSIL™ structural sealants for reglazing applications

• Adhesion and structural strength achieved in 24–48 hours

• Meets ASTM C 719 Class 25 (G, A, O)

• Meets ASTM C1184 Structural Sealant Specification

Applications • Repair and/or replacement of structurally glazed glass and other substrates where a

fast cure is required

• On-site structural glazing, including storefront systems

• Attachment of panel stiffeners where quick cure is required

• In-shop structural glazing where the use of a two-part pump is not viable

1All structural glazing applications MUST be reviewed by the Dow technical staff. If their recommendations are followed, Dow

will issue a project-specific adhesive warranty.

2Certain sealing materials used in the anodizing process may increase the potential for use of primer to gain adhesion within a

24-hour period. DOWSIL™ Primer-C OS is recommended for fast and consistent adhesion, especially to Kynar, polyester

powder coat and other high-performance substrates approved for architectural structural glazing applications.

UNRESTRICTED – May be shared with anyone

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

DOWSIL™ 121 Structural Glazing Sealant

Page 1 of 5 © 2018–2019 The Dow Chemical Company. All rights reserved. Form No. 63-1257-01 J

Typical Properties

Specification Writers: These values are not intended for use in preparing specifications.

Test3 Property4 Unit Result

As Supplied – As Tested at 23°C (75°F) and 50% RH

Color

– Base Black/dark gray

– Catalyst White

Physical Form Paste

ASTM D1475 Specific Density

– Base kg/l 1.35

– Catalyst kg/l 1.24

As Catalyzed – Mixed at 1:1 Base to Catalyst by Volume

Working Time minutes 15–45

Unit Handling Time at 23°C (75°F), minimum5 hours min 245

VOC Content, mixed6 g/L < 25

ASTM D2202 Flow/Sag (slump) inches (mm) < 0.2 (< 5)

Cured – After 1 day at 75°F (23°C) and 50% RH

ASTM C661 Durometer, Type A points 30

ASTM D412 Tensile Strength psi (MPa) 300 (2.1)

ASTM C1135 Tensile Strength at 25% psi (MPa) 26 (0.18)

ASTM C1135 Tensile Strength, Ultimate psi (MPa) 74 (0.62)

ASTM C1135 Elongation, Ultimate % 300

Cured – After 7 days at 75°F (23°C) and 50% RH

ASTM C661 Durometer, Type A points 30–40

ASTM D412 Tensile Strength psi (MPa) 300 (2.1)

ASTM C1135 Tensile Strength at 25% psi (MPa) 40 (0.28)

ASTM C1135 Tensile Strength, Ultimate psi (MPa) 135 (0.93)

ASTM C1135 Elongation, Ultimate % 325

ASTM C 719 Movement Capability % ± 25

3ASTM: American Society for Testing and Materials.

4All testing was conducted using an 18-element, ½ inch (1.3 cm) diameter static mixer and a pneumatic two-part gun operating

at 87 psi (6 bar).

5Adhesion must be confirmed prior to removing temporary attachments or shipping to the job site. In general terms, glazed

units can be moved or temporary attachments removed within 24 hrs depending on the temperature and relative humidity

(RH). DOWSIL™ 121 Structural Glazing Sealant can achieve the necessary strength and adhesion properties in 24 hours

when applied and cured at 23°C and 50% RH. Check adhesion before moving units.

6Based on South Coast Air Quality Management District of California. Maximum VOC is listed both inclusive and exclusive of

water and exempt compounds.

UNRESTRICTED – May be shared with anyone

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

DOWSIL™ 121 Structural Glazing Sealant

Page 2 of 5 © 2018–2019 The Dow Chemical Company. All rights reserved. Form No. 63-1257-01 J

Description DOWSIL™ 121 Structural Glazing Sealant is a two-part silicone formulation designed

specifically for use in structural glazing applications in field and factory applications. The

material is supplied in a two-part cartridge in which the catalyst is a smooth, white paste and

the base is tinted either black or gray. Once catalyzed, the material cures into a medium-

modulus, flexible silicone rubber that is flexible for use in structural and weatherseal

applications. It can be used in deep, narrow joints to obtain a complete cure.

DOWSIL™ 121 Structural Glazing Sealant cures in deep section within 24 hours and

generally achieves full adhesion within 48 hours. However, full cure time depends on joint

design, substrate type, temperature and humidity.

How To Use Complete design and installation guidelines are contained in the Americas Technical

Manual, European Silicone Structural Glazing Manual, DOWSIL™ 121 Structural Glazing

Sealant Installation Guide, and the DOWSIL™ 121 Structural Glazing European Application

Guide. They must be followed for warrantable applications when using this product.

Preparation

Clean all joints and glazing pockets, removing all foreign matter and contaminants such as

grease, oil, dust, water, frost, surface dirt, old sealants or glazing compounds and protective

coatings.

In reglazing applications where the structural sealant is performing per specification, a thin

(less than 1/16 inch) layer of the existing DOWSIL™ sealant should remain on the

substrate. DOWSIL™ 121 Structural Glazing Sealant will achieve primerless adhesion to

the cured sealant.

UNRESTRICTED – May be shared with anyone

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

DOWSIL™ 121 Structural Glazing Sealant

Page 3 of 5 © 2018–2019 The Dow Chemical Company. All rights reserved. Form No. 63-1257-01 J

How To Use Application

(Cont.) Install backup material or joint filler, setting blocks, spacer shims, and tape. Mask areas

adjacent to joints to ensure clean sealant lines.

DOWSIL™ 121 Structural Glazing Sealant curing agent and base must be thoroughly mixed

using an airless mixing system. DOWSIL™ 121 Structural Glazing Sealant is compatible

with most existing pneumatic dispensing tools that accommodate 2 x 200 ml cartridges.

The air pressure used to dispense the material should be limited to 90 psi (6 bar) to ensure

a good mix and to prevent damage to the sealant cartridge.

Remove the attached plug of the cartridge by following the instructions in the Installation

Guide; do NOT cut it off. Insert the cartridge into the pneumatic and/or battery dispensing

tool and run material out of the cartridge to ensure that both base and catalyst are being

extruded. Then, attach a new static mixer to the cartridge, and the material is ready for use.

Eighteen-element static mixers are included in the packaging and are required to mix the

material. A new static mixer must be used for each cartridge to ensure proper mixing of the

material. Neither hand-mixing nor mechanical mixing is satisfactory due to the incorporation

of air, resulting in altered physical properties.

Handling PRODUCT SAFETY INFORMATION REQUIRED FOR SAFE USE IS NOT INCLUDED IN

Precautions THIS DOCUMENT. BEFORE HANDLING, READ PRODUCT AND SAFETY DATA SHEETS

AND CONTAINER LABELS FOR SAFE USE, PHYSICAL AND HEALTH HAZARD

INFORMATION. THE SAFETY DATA SHEET IS AVAILABLE ON THE DOW WEBSITE AT

CONSUMER.DOW.COM, OR FROM YOUR DOW SALES APPLICATION ENGINEER, OR

DISTRIBUTOR, OR BY CALLING DOW CUSTOMER SERVICE.

Usable Life and When stored in original, unopened containers in a dry location below 30°C (86°F),

Storage DOWSIL™ 121 Structural Glazing Sealant has a shelf life of 12 months from date of

manufacture. Refer to product packaging for “Use By” date.

Packaging DOWSIL™ 121 Structural Glazing Sealant is available in kits of 400 ml net fill (2 x 200

Information ml)/13.5 fl. oz. net fill (2 x 6.8 fl. oz.) cartridges.

UNRESTRICTED – May be shared with anyone

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

DOWSIL™ 121 Structural Glazing Sealant

Page 4 of 5 © 2018–2019 The Dow Chemical Company. All rights reserved. Form No. 63-1257-01 J

Limitations DOWSIL™ 121 Structural Glazing Sealant should not be applied:

• To building materials that bleed oils, plasticizers or solvents – materials such as

impregnated wood, oil-based caulks, green or partially vulcanized rubber gaskets, and

tapes

• On surfaces that will require painting or staining

• Once the air temperature falls below 0°F (-18°C)

• On frost-laden or wet surfaces

• In areas where abrasion and physical abuse are encountered

• In below-grade or continuous water immersion applications

• To surfaces that will be in direct contact with food

This product is neither tested nor represented as suitable for medical or pharmaceutical

uses.

Health And To support customers in their product safety needs, Dow has an extensive Product

Environmental Stewardship organization and a team of product safety and regulatory compliance specialists

available in each area.

Information

For further information, please see our website, consumer.dow.com or consult your local

Dow representative.

consumer.dow.com LIMITED WARRANTY INFORMATION – PLEASE READ CAREFULLY

The information contained herein is offered in good faith and is believed to be accurate. However, because conditions and

methods of use of our products are beyond our control, this information should not be used in substitution for customer’s tests

to ensure that our products are safe, effective, and fully satisfactory for the intended end use. Suggestions of use shall not be

taken as inducements to infringe any patent.

Dow’s sole warranty is that our products will meet the sales specifications in effect at the time of shipment.

Your exclusive remedy for breach of such warranty is limited to refund of purchase price or replacement of any product shown

to be other than as warranted.

TO THE FULLEST EXTENT PERMITTED BY APPLICABLE LAW, DOW SPECIFICALLY DISCLAIMS ANY OTHER

EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY.

DOW DISCLAIMS LIABILITY FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Page 5 of 5 ®Trademark of The Dow Chemical Company Form No. 63-1257-01 J

You might also like

- DC 121 Structural Glazing Sealant TDSDocument3 pagesDC 121 Structural Glazing Sealant TDSANo ratings yet

- DOWSIL™ 121 Structural Glazing Sealant: Features & BenefitsDocument3 pagesDOWSIL™ 121 Structural Glazing Sealant: Features & BenefitsANo ratings yet

- LLDPE-218BJ EditDocument3 pagesLLDPE-218BJ EditChu ChuNo ratings yet

- DTM Acrylic Pimer Finish B66W1Document4 pagesDTM Acrylic Pimer Finish B66W1Vernon Jiménez FonsecaNo ratings yet

- SABIC® PP COPO - 412MK49 (MFR 45 DG - Min 2.16 KG)Document2 pagesSABIC® PP COPO - 412MK49 (MFR 45 DG - Min 2.16 KG)yang chinaNo ratings yet

- Controlled Volatility RTV Ablative Silicone: Description ApplicationDocument3 pagesControlled Volatility RTV Ablative Silicone: Description ApplicationLU CHUNHUINo ratings yet

- XIAMETER™ RBB-2030-40 Base: Features & Benefits ApplicationsDocument3 pagesXIAMETER™ RBB-2030-40 Base: Features & Benefits ApplicationsDaniela Alejandra Daza LancherosNo ratings yet

- LH-3750 - Daelim IndustrialDocument2 pagesLH-3750 - Daelim IndustrialAkoyoNo ratings yet

- SABIC® PP - 513MN40 - Global - Technical - Data - SheetDocument2 pagesSABIC® PP - 513MN40 - Global - Technical - Data - SheetmeshaktimanNo ratings yet

- SABIC® HDPE - M200056 - Global - Technical - Data - SheetDocument2 pagesSABIC® HDPE - M200056 - Global - Technical - Data - SheetAhmed Elgazar100% (1)

- SABIC® PP - 528K - Global - Technical - Data - SheetDocument1 pageSABIC® PP - 528K - Global - Technical - Data - SheetjituniNo ratings yet

- Cardolite NX 2016Document2 pagesCardolite NX 2016Lê TiếnNo ratings yet

- Sikaflex 252 TDSDocument3 pagesSikaflex 252 TDSxingobuilderNo ratings yet

- SABIC® HDPE - C0549 - GlobalDocument2 pagesSABIC® HDPE - C0549 - Globaltechnical kmiNo ratings yet

- DOWSIL 995 Silicone Structural Sealant Product Data 1799968Document4 pagesDOWSIL 995 Silicone Structural Sealant Product Data 1799968bogzskieNo ratings yet

- 3 Property R3450 EngDocument1 page3 Property R3450 EngMohit MohataNo ratings yet

- Globalene 7011: Polypropylene Impact copolymer 聚丙烯耐衝擊共聚合物Document1 pageGlobalene 7011: Polypropylene Impact copolymer 聚丙烯耐衝擊共聚合物medo.k016No ratings yet

- Dymonic 100 Data SheetDocument2 pagesDymonic 100 Data SheetDavid LuongNo ratings yet

- Mdpe 3305MQDocument2 pagesMdpe 3305MQHữu LộcNo ratings yet

- Protective & Marine Coatings: DTM Acrylic Primer/FinishDocument4 pagesProtective & Marine Coatings: DTM Acrylic Primer/FinishAna CabreraNo ratings yet

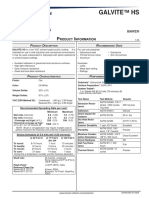

- Protective & Marine Coatings: Galvite™ HsDocument4 pagesProtective & Marine Coatings: Galvite™ HsAna CabreraNo ratings yet

- YUPLENE® R930Y - SK Geo CentricDocument2 pagesYUPLENE® R930Y - SK Geo CentricChu ChuNo ratings yet

- NC-558 TDS enDocument2 pagesNC-558 TDS enniteshacharya100% (1)

- Sabic PP 575P: Polypropylene Homopolymer For Injection MoldingDocument2 pagesSabic PP 575P: Polypropylene Homopolymer For Injection MoldingDynamic SaravananNo ratings yet

- DTM Acrylic Coating: Protective & Marine CoatingsDocument4 pagesDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraNo ratings yet

- Solid Surface Resin - SpecsDocument3 pagesSolid Surface Resin - SpecsAmr Abdelmegid abdelsalam husseinNo ratings yet

- Product PDF 4956Document2 pagesProduct PDF 4956Mohammad PoostforushNo ratings yet

- SABIC® PP - 5271K - Global - Technical - Data - SheetDocument1 pageSABIC® PP - 5271K - Global - Technical - Data - SheetjituniNo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- 62 1260 01 Dowsil 995 Silicone Structural Glazing SealantDocument5 pages62 1260 01 Dowsil 995 Silicone Structural Glazing SealantAAqNo ratings yet

- Vulkem 45SSL DSDocument2 pagesVulkem 45SSL DSshinellajohnsonNo ratings yet

- Pmma Plexigals Hfi7-101Document4 pagesPmma Plexigals Hfi7-101countzeroaslNo ratings yet

- Estane Skythane S185A TPU: TypeDocument1 pageEstane Skythane S185A TPU: Typejuliushasan2No ratings yet

- Random PP R390Y: Application / Use CaseDocument1 pageRandom PP R390Y: Application / Use CaseEmre UzunogluNo ratings yet

- DC 995Document3 pagesDC 995Andrea Nicola TurcatoNo ratings yet

- NG30-02JBK - Next PolymersDocument4 pagesNG30-02JBK - Next PolymersdigiarkanandNo ratings yet

- Sabic Hdpe B5429: High Density PolyethyleneDocument2 pagesSabic Hdpe B5429: High Density Polyethylenegetasew altasebNo ratings yet

- Santoprene™ 121-75M100: Thermoplastic VulcanizateDocument3 pagesSantoprene™ 121-75M100: Thermoplastic VulcanizateBrian García AguirreNo ratings yet

- Product PDF 210710Document1 pageProduct PDF 210710vaibhav ShindeNo ratings yet

- 400 00119895en Infuse 9500 TdsDocument2 pages400 00119895en Infuse 9500 TdsJorge CamargoNo ratings yet

- Hoja Tecnica Sabic 5707NDocument2 pagesHoja Tecnica Sabic 5707NJaimito Ramirez RodasNo ratings yet

- DOWSIL™ 995 Silicone Structural Sealant Technical Data SheetDocument5 pagesDOWSIL™ 995 Silicone Structural Sealant Technical Data SheetKharisma Utomo GroupNo ratings yet

- Sabic 37MK10Document2 pagesSabic 37MK10Chu ChuNo ratings yet

- SABIC®-PP QR6731K Global Technical Data SheetDocument2 pagesSABIC®-PP QR6731K Global Technical Data SheetPhahad HasimNo ratings yet

- Dow Corning 993 Product InfoDocument4 pagesDow Corning 993 Product InfoLloyd R. PonceNo ratings yet

- DOWSIL™ 795 Structural Glazing Sealant Technical Data SheetDocument5 pagesDOWSIL™ 795 Structural Glazing Sealant Technical Data SheetTrung Nguyễn NgọcNo ratings yet

- SABIC® HDPE - M200056 - Global - Technical - Data - SheetDocument2 pagesSABIC® HDPE - M200056 - Global - Technical - Data - SheetRishiNo ratings yet

- Loctite Nordbak Wear Resistant Putty: Product Description MixedDocument3 pagesLoctite Nordbak Wear Resistant Putty: Product Description MixedFurqan ShabbirNo ratings yet

- Hyspin ZZ Range: DescriptionDocument2 pagesHyspin ZZ Range: DescriptionDaniel VuletaNo ratings yet

- HT 521 82055 170 ENDocument5 pagesHT 521 82055 170 ENEdward AguillónNo ratings yet

- Down Corning 795Document3 pagesDown Corning 795RiverPlaceNo ratings yet

- Gengear Series SPL-A Up To 320Document3 pagesGengear Series SPL-A Up To 320Hakim AmmorNo ratings yet

- 745Document2 pages745idrees.theheroNo ratings yet

- TDS - Acrylic V825 - From PolyOneDocument2 pagesTDS - Acrylic V825 - From PolyOneVio Amariei0% (1)

- SABIC® HDPE M200056 (MFR 20 DG - Min 2.16 KG)Document2 pagesSABIC® HDPE M200056 (MFR 20 DG - Min 2.16 KG)SENADJKI AHMEDNo ratings yet

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- d1 4 Wps 675 070 12 Digital FormDocument1 paged1 4 Wps 675 070 12 Digital FormAamer MohammedNo ratings yet

- Sample Refrigeration UnitDocument29 pagesSample Refrigeration UnitatiqahNo ratings yet

- 7th Sem Civil Engineering SyllabusDocument82 pages7th Sem Civil Engineering SyllabusJacky GurnaniNo ratings yet

- Textbook of Heat Transfer Sukhatme S PDocument122 pagesTextbook of Heat Transfer Sukhatme S PSamer HouzaynNo ratings yet

- Mdf-Manual Eng Low ResDocument45 pagesMdf-Manual Eng Low ResNader ShdeedNo ratings yet

- Fire Rated Sandstone FRP Door BrochureDocument2 pagesFire Rated Sandstone FRP Door BrochureSpecial-Lite DoorsNo ratings yet

- PlumbingDocument16 pagesPlumbingMelvin EsguerraNo ratings yet

- DVC VT (Ju) DSTPSDocument41 pagesDVC VT (Ju) DSTPSAngel Tania BasuNo ratings yet

- AMRI ISORIA Broad Market Type Series Booklet DataDocument12 pagesAMRI ISORIA Broad Market Type Series Booklet Datarudiskw456No ratings yet

- Santoprene m200 en PDFDocument2 pagesSantoprene m200 en PDFMarcos Antonio RossiNo ratings yet

- Corporate Office Address: Desa Kedung Pani, Kel. Wates, Kec. Ngaliyan, Semarang 50188, Indonesia. Tel: +62 - 24 - 7628224 Fax: +62 - 24 - 7628223Document19 pagesCorporate Office Address: Desa Kedung Pani, Kel. Wates, Kec. Ngaliyan, Semarang 50188, Indonesia. Tel: +62 - 24 - 7628224 Fax: +62 - 24 - 7628223Imam BuchairiNo ratings yet

- Correlation Between The Performance of Solid Masonry Prisms and Wallettes Under CompressionDocument29 pagesCorrelation Between The Performance of Solid Masonry Prisms and Wallettes Under CompressionSURAJ BHOSALENo ratings yet

- RS43012 0Document35 pagesRS43012 0emilio mendez olveraNo ratings yet

- 3D Modelling of Frozen Ground and Associated Volume ExpansionDocument2 pages3D Modelling of Frozen Ground and Associated Volume ExpansionsogeekNo ratings yet

- 01 - Panel Mdp-Panel LayoutDocument1 page01 - Panel Mdp-Panel LayoutaaronmyrroNo ratings yet

- Airlift Pump DWGDocument18 pagesAirlift Pump DWGravichandiran_a2001100% (2)

- Intergas HRE MV1 PDFDocument48 pagesIntergas HRE MV1 PDFRichard KrillNo ratings yet

- 2016 DEKS Product Catalogue SmallDocument71 pages2016 DEKS Product Catalogue SmallKedar BhideNo ratings yet

- Flexseal PU425 (K - 27.02.2020)Document2 pagesFlexseal PU425 (K - 27.02.2020)Mohamed RusfanNo ratings yet

- Capacity 7000KW Heavy Oil Fired Thermal Oil Boiler Quotation From Henan Yuanda Boiler FactoryDocument11 pagesCapacity 7000KW Heavy Oil Fired Thermal Oil Boiler Quotation From Henan Yuanda Boiler Factorykariem noweerNo ratings yet

- Partial Replacement of Cement With Glass Powder and Egg Shell (Powder) Ash in ConcreteDocument51 pagesPartial Replacement of Cement With Glass Powder and Egg Shell (Powder) Ash in Concreteshivanand hippargaNo ratings yet

- Jsa Jis G 3459 Amd 1Document14 pagesJsa Jis G 3459 Amd 1farhad100% (1)

- MTFDocument12 pagesMTFCupido Jr. SabatinNo ratings yet

- Lessons I Learned During Installation and Wiring of LV SwitchboardDocument15 pagesLessons I Learned During Installation and Wiring of LV SwitchboardKim Daniel EstoyNo ratings yet

- Bill of Quantities (Boq)Document22 pagesBill of Quantities (Boq)DADADADGGGNo ratings yet

- ISA RP60 1 1990 Control Center FacilitiesDocument22 pagesISA RP60 1 1990 Control Center FacilitiesDaniel Arrieta DarrásNo ratings yet

- Durelloy: Heat Treated Hot Roll AlloyDocument7 pagesDurelloy: Heat Treated Hot Roll AlloyPeterWayNo ratings yet

- Cable Volatge Drop For Different Size of Cables (1.1.19)Document24 pagesCable Volatge Drop For Different Size of Cables (1.1.19)jiguparmar1516No ratings yet

- 11 355 Afm PDFDocument7 pages11 355 Afm PDFbansiNo ratings yet

- Model WS Specific Application Window Sprinklers Horizontal and Pendent Vertical Sidewall 5.6 K-FactorDocument8 pagesModel WS Specific Application Window Sprinklers Horizontal and Pendent Vertical Sidewall 5.6 K-FactorMuralee KaushikNo ratings yet