Professional Documents

Culture Documents

Expansion Joint Specification Details

Expansion Joint Specification Details

Uploaded by

SK Emran Ali0 ratings0% found this document useful (0 votes)

49 views8 pagesOriginal Title

EXPANSION_JOINT_SPECIFICATION_DETAILS_

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

49 views8 pagesExpansion Joint Specification Details

Expansion Joint Specification Details

Uploaded by

SK Emran AliCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

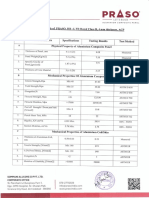

Item No - 1.10

Expansion Joint System

Providing and fixing of pan/ tray type expansion joint system of approved make (Sanfield,

Construction Specialities, Kantaflex) related with floor location (floor to floor of floor to

wall corner) with stone fixing arrangement (minimum 20mm recess depth for receiving

stone) for gap width as per site condition as per drawings and direction of Engineer-in-

Charge. The joints system will be of extruded aluminum base members, self aligning! self

centering arrangement and support plates etc. as per ASTM B221-02. The system shall be

such that it provides floor to floor floor to wall expansion control system for various

vertical locations in load application areas that accommodates multi directional seismic

movement without stress to it's components. System shall consist of metal profiles with @

universal aluminum base member designed to accommodate various project conditions

HCP Design Planning & Management

Scanned with CamScanner

and match with finish floor reatents,

e cover

eo Ce en ee) designed of width and thickness required to satisfy projects

ie 19 requirements and secured to base mombers by utilizin

nufacturer’s pre-engineered sol a s

Gpruecturate oe centering arrangement that freely rotates! moves in all

rections. The Sol - centering trangomant shall exhibit crear srhore ends that lock

and slide inside the corresponding aluminum extrusion cavity to allow freedom of

movement and flexure in all directions including vertical displacement. . The cover must

be design in such a way that there should be aluminum flange in the sides and no

requirement of any gasket or sealant should be there. Provision of Moisture Barrier

Membrane in the Joint System to have watertight joint is mandatory requirement all as per

the manufactures design and as approved by Engineer -in- Charge. (Material shall conform

to ASTM 6063). Rate shall be inclusive of edge preparation, moisture barrier, polyester

powder coating (min 50 micron) on aluminum of approved shade and make if required.

Gost of flooring stone! tile (which shall be fixed in tray of expansion Joint cover) shall be

pald in relevant tender item. Expansion joint system shall be as approved for all floor al

fevel including scaffolding ete complete.

= 1, dause - 5.4.5 shall be followed for expansion joint. system,

for floor to floor treatment shall be of approved make and finish and

roved before execution of work. Expansion joint

flooring material shall be fixed in recess part.

CPWD specification vol

Architectural expansion join

‘suitable for site condition. Sample shall get appr

system shall be of tray/ recess type, and adjoining

Expansion joints shall be installed as shown in the drawings or @$ Per manufacturer's

specification or as directed by Engineer-in-Charge.

Gleaning the surface and edge repairing’ RCC cutting shall be done 95 Per manufacturer's

requirement.

Epoxy Grouting should be done to fix the joint in pr

installation shall be done by approved applicator of

oper line and level.

f manufacture only and as per manufacturer's

specification. -

See ctor shal take responsibilty against water leakage for product and installation for five

years.

joisture barrier membrane.

hall be along with the provision of mi

‘oduct as per manufacturer specification.

Expansion joints

id floor) shall be treated with proper Pr

Corner (at wall ani

be measured and paid in Rt. Wastage shall not be measured and paid for.

The item will

Scanned with CamScanner

Item No - 1.09

Providing and fixing Premoulded Compressible, high performance closed cell, bitumen free

expansion joint filler board of specified thickness in black color of approved make, conforming

Scanned with CamScanner

10

a

12

13

14

1s

20

2a

30

31

32

to MORTH specification (clause 1015), having minimum density 95 Kg/Cum, Non Staining with

tess than 0.08% water absorption & compression recovery of 93% minimum as per

specifications including cutting to required size and shape, at all levels/allfloors/ all heights,

tte. complete, as per drawings/ specification and as directed by Engineer in Charge.

4) 75 me thick filler board

Mater

Polyurethane form filler shall be Cap cell HD-100 of approved make. It shall comply with

ASTM-D-3575/ Highway clause 1015/ BS-5628 Part-3. It shall be semi-rigid; UV resistant,

high performance laminated closed cell polyethylene foam joint filler in sheet form.

The density of polyurethane shall be 95Kgs/ cum. The water absorption shall be 0.08% max.

The operating temperature of foam filler shall be between - 40 cto +100.c

It shall be bitumen free and chemical resistant. It shall possess excellent recovery after

compression.

If gap of expansion joint shall be more than 50mm, use two board of required thickness joint

with adhesive by manufacturer's only.

If gap width is more than SOmm, contractor shall use joint sheet as per required dimension

and direction by Engineer in Charge. Sheet shall be jointed with compatible adhesive as

recommended by manufacturer, Both items shall be paid in relevant tender iter.

Workmanship

The Cap cell HD 100 board shall be cut neatly with al edges even and to the size required (size

of the structure at the expansion joint). The concrete surfaces must be clean, dry and free of

dirt, grease, oil or other contaminants that would interfere with proper adhesion. It shall be

placed resting on the existing structure at the joint before the structure adjoining to the joint is,

constructed, The board shall be snugly filled the gap in between the expansion joint. The

board shall be provided 40mm recessed on the exposed side, to accommodate backup

polyurethane rod of required diameter and polysulphide sealant (if required). At the time of

concreting, the recessed 40mm gap shall be filled with the cap cell HD board with a both

side adhesive tape to keep it in position. The same shall be removed until the gap is sealed

with the polysulphide sealant/ treated with other materia.

‘Mode of Measurement and Payment

The item will be measured and paid in sqm as per the actual area done. Wastage will not be

paid for.

If 250mm thick joint sheet (SOmm thick expansion filler board (cap cell 100) + 200 mm thick

thermocol sheet) shall be used, thermocol sheet shall be paid in relevant tender items.

tem No=1.10

Providing and fixing of pan/ tray type expansion/ selsmic joint system of approved make

related with floor location (floor to floor or floor to wall corner) with stone fixing arrangement

(minimum 20mm recess depth for receiving stone) as per drawings and direction of Engineer-

In-charge. The joints system will be of extruded aluminium base members, self aligning/ self

centering arrangement and support plates etc. as per ASTM 8221-02. The system shall be such

that it provides floor to floor /floor to wall expansion control system for various vertical

locations in load application areas that accommodates mult! directional seismic movement

without stress to it's components. System shall consist of metal profiles with a universal

——

HCP Design Planning & Management Page 13

Scanned with CamScanner

10

aa

42

13

14

1s

20

2a

22

23

24

25

26

27

|

|

t

|

28

|* Design Planning & Management

aluminum base member designed to accommodate various project conditions and match with

finish floor treatments.

‘The cover plate shall be designed of width and thickness required to satisfy proiets

renee ein) loading requirements and secured to base members, by utilizing

aaaecer’s precngineered selt-centering arrangement that freely rotates/ moves in 24

rae ee wentering arrangement shal exhibit circular sphere ends that lock and

oie ne scsponding aluminium extrusion cavity to allow freedom of mavement and

Fane ice arections including vertical displacement. The cover must be design in such a Wey

te these should be aluminium flange in the sides and no requirement of any Basket Of

sectont should be there Provision of Moisture Barrier Membrane in the Joint System to have

watertight join is mandatory requirement all as per the manufactures design ‘and as approved

by Engineer -in- Charge. (Material shall eanform to ASTM 6063) Rate shale inclusive of edge

preparation, moisture barrier, polyester powder coating (min 50 micron) on ‘aluminium of

crpoved shade and make if required. Cost of flooring stone/ tle {which shat he fixed In tray

of expansion joint cover) Expansion joint system shall be

shall be paid in relevant tender item.

as approved for all floor a

iI level including scaffolding ete complete.

i) Floor Joint of 75 mm gap

Material :

rchtectural expansion joint/ seismic joint for floor to floor treatment shall be of approved

make and finish and suitable for site condition.

Expansion joint system shall be tray/ pan type

to wall comer) with stone / adjoining floori

recess depth for receiving stone)

reas a eecication shall be followed as per item No ~ 5.12.2 of CPWD specifiation 2019

“or location (floor to floor or floor

related with flo

(minimum 20. mm

material fixing arrangement (

Vol-1

wer ser must be design in sucha way that there shouldbe aluminium flange inthe sides and

ro requirement of any gasket or sealant should be there.

Sample shall get approved before execution of work

Workmanship:

m including

Contractor shall prepare shop drawing 2s per selection of joint syste

arrangement of water barrier and got approved.

Expansion Joints system shall be installed a per approved shop drawings or as per

manufacturer's specification or as directed by Engineer-in-Charge,

Cleoning the surface and edge preparation/ RCC cutting shal be done 25 Per manufacturer's

requirement.

aan grouting oF micro concrete shall be done to fx the joint in proper line and level

roralation shall be done by approved applicator of manufacture only and as er

manufacturers specification.

cannraetor shal take responsibilty against water leakage for product and installation for Five

years.

Exparsion/ seismic joints system shall be along with the provision of moisture barrier

membrane.

Comer {at wall and floor) shall be treated with proper product as per manufacturer

specification.

‘Mode of Measurements and Payment:

Page 14

3.0 Mode of Measurement and Payment

Bt DIB PRR specications of tem no. 56.1.1, 54.114, 54.115, $4.12, 64.19 shal be

{otowed, The rate shal be inclided or exclude

folows, The re tude the cost of centering and shuttering will be as

32 The rate shallbe fora unit of one cum.

tem No= 1.14

fro’ Cind and fixing Premoulded Compressible, high performance closed éel, bitumen

CSororbansion joint filer board of 150mm thickness x black colo of approves wake

‘Charge.

pe 10 Mato

11 Palyurethane form filer shal be Cap cell HO-100 of approved make. It shall comply with

ASTN-D-3575! Highway clause 1018/ BS.5628 Part-I shal be semi-rigid UV Teocont,

high performance laminsted closed cell polyethylene foam oint filer n sheet form,

12 The density of polyurethane shall be S5Kgs/ cum. The waler absorption shal be 0.08% max.

[The operating temperature of foam filer shallbe between 40 ¢ 0 “100 c

13, It shall be btumen free and chemical resistant. N shall possess excellent recovery after

‘compression,

20 Workmanship,

241 The Cap cell HD 100 board shat be cut neaty wth all edges even and tothe size required (size

Of the structure at the expansion jm) The concrete surfaces must be clean, dy and five of

din, grease, oll or other contaminants that would interfere with proper adhesion. I shall be

placed resting on the exising structure at the jont before the structure agjoning tothe joints

Constructed. The board shall be snugly filed the gap in between the expansion join. The

board shall be provided 40mm recessed on the exposed side, to accommodate backup

Polyurethane rod of required diameter and potysulphice sealant {i requved) At the tine of

Concreting, the recessed 40mm gap shal be filed wth the eap cell HD board with a both sice

‘adhesive tape to keep iin positon. The same shall be removed unt the gap is seated with

Pe ‘the polysulphide sealant treated with other material,

3.0 Mode of Measurement and Payment

3.1. The item wit be measured and paid in sqm as per the actual area done, Wastage will not bo

paid for.

tomo 135

Providing nd xing of pal tray type expansion joint ystem of approved make (Sal,

onstruction Specie, Kata eed with fo lesion Roses ogo hee

wall comer) wit stone fing arrangement (mim 20mm recess depth for rors

tong for gop width of 1sbmm as par drawings and drecdon of Enginesin ohare 4

Joints system wil bo of exuded Shiinum Base mentber, se signing ta acters,

trrangement and support plates seu per ASTM BZZ1a The aya Selle San ed

I provges Moor to: for Moor to wal expansion contol syst for vate ea

lian nd pean ans tet econ rel nora cmc ote

without stress to ie components. Systam shall ona f mata profes wit see,

SSuminum base member designed to accommodate various proeet condone aera

wet fish Roor treatment,

HCP Design Planning & Management Page 11

il

~ Scanned with CamScanner

10

14

12

13

14

15

2.0

24

22

23

24

26

27

28

30

34

32

iho cover plate shall bo designed of width and thickness required to satisfy projects

Tiwvament and loading requirements and secured to baso members by utilizing

iovufacturer’s pre-engineered self-centering arrangoment that freely rotates! movns Inall

directions. The Self - centering a angement shall exhibit circular sphere ends that fock

and slide inside the corresponding aluminum extrusion cavity to allow freedom of

ivemont and flexure in all directions including vertical displacement.. Phe cover must be

Gesign in such a way that there should be aluminum flange in the sides and no

Fequirement of any gasket or sealant should be there, Provision of Moisture Barrier

Membrane in the Joint System to have watertight joint is mandatory requirement all as per

the manufactures design and as approved by Engineer -in- Charge: (Material shall conform

Te ASTM 6063), Rate shall be inclusive of edge preparation, moisture barrier, polyester

powder coating (rin 50 micron) on aluminum of approved ‘shade and make if required.

pot of flooring stone! tie (which shall be fixed In tray of expansion Joint cover) shall be

pald In relevant tender tem. Expansion Joint system shall be 05 ‘approved for all floor all

fevel including scaffolding etc complete.

Material :

‘Architectural expansion joint selsmic joint for oor to floor treatment shall be of approved make

‘and finish and sultable for site condition.

Eypansion jin system shall betray! pan type related with oor location (floor to floor or floor to

earner) with stone | adjoining flooring material fing arangement (minimum 20 mm recess

depth for receiving stone).

cee tot specification shall be folowed as per tem No ~ 6.122 of CPW specification 2019

Vol-I.

‘Yhe egver must be design in such a way that there should be aluminiim flange in the sides and

no requirement of any gasket or sealant should be there,

Sample shal get approved belore execution of work.

Workmanship:

Contractor shall prepare shop drawing as per selection of joint system including arrangement

‘of water barrier and got approved.

Expansion joints system shall be installed as pet approved shop drawings or as per

Expatieqlurer’s specification or as directed by EngineerIn-Charge

aaning the surface and edge preparation! RC cuting shal be ‘done as per manufacturer's

requirement.

ra pink grouting or micro concrete shal be done to fix fe joint in proper tine and level.

Norton ‘shall be done by approved applicator of ‘manufacture only and as per

manufacturer's specification.

aa acty shall take responsibilty against water leakage for product and installation for five

years.

ansion’ selsmic joints system shall be along wit the provision of moisture barrier

‘membrane,

me fat wall and fot) shal be treated with proper product a por manufacturer specification.

Mode of Measurements and Payment:

‘Te item willbe measuree and pad in Rt. Wastage shall not be measured and paid for. Rate

wre ter pusie of east of Comer elements of expansion jin. The item will be measured and

paid in Rt as per the actual area done.

tone! flooring material shall be pai in relevant tender tem

Scanned with CamScanner

32 Therate shallbe fora unt of one cum.

Item No- 1.13

Providing and fixing of expansion joint system for 100mm wide gap related with floor location

as per drawings and direction of Engineer-In-Charge. The joints system will be of extruded

aluminum base members, elf aligning / self centering arrangement and support plates etc. 25

per ASTM 6221-02. The system shall be such that it provides floor to floor /floor to wall

expansion control system for various vertical localtion in load application areas that

accommodates multi directional seismic movement without stress to it's components. System

shall consist of metal profiles with a universal aluminum base member designed to

‘accommodate various project conditions and finish floor treatments. The cover plate shall be

designed of width and thickness required to satisfy projects movement and loading

requirements and secured to base members by utilizing manufacturer's pre-engineered self-

centering arrangement that freely rotates / moves in all directions. The Self - centering

arrangement shall exhibit circular sphere ends that lock and slide inside the corresponding

aluminum extrusion cavity to allow freedom of movement and flexure in all directions

including vertical displacement. Provision of Moisture Barrier Membrane in the Joint System

to have watertight joint is mandatory requirement all as per the manufactures design and as

approved by Engineer -in- Charge. (Material shall confirm to ASTM 6063). Expansion joint

system shall be as approved for all floor all evel including scaffolding etc complete.

temNo-1.14

Providing and fixing of expansion system for 100mm wide gap of approved make related with

wall joint (internal wall to wall/ ceiling to celing/ wall to corner/ any angle) location as per

drawings and direction of Engineer-In- Charge. The joints shall be of extruded aluminum base

‘members, self aligning/ centering arrangement and support plates as per ASTM 221-02. The

‘material shall be such that it provides an Expansion Joints System suitable for vertical wall to

‘wall/ wall or ceiling at comner/ ceiling application, with no slipping down tendency amongst

the components of the Joint System. The Joint System shall utilize light weight aluminum

profiles exhibiting minimal exposed aluminum surfaces mechanically snap locking the multi

cellular to facilitate movement. Expansion joint system shall be with all mandatory

requirement as per the manufactures design and as approved by Engineer -in- Charge.

(Material shall conform to ASTM 6063). Rate shall be inclusive of edge preparation, moisture

SS

HCP Design Planning & Management Page 12

Scanned with CamScanner

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Introduction-to-Vitrified-Tile-FlooringDocument10 pagesIntroduction-to-Vitrified-Tile-FlooringSK Emran AliNo ratings yet

- CSS-0075-GypSerra Glasroc-H Ceiling with 12.5mm Board_Rev01 (1)Document2 pagesCSS-0075-GypSerra Glasroc-H Ceiling with 12.5mm Board_Rev01 (1)SK Emran AliNo ratings yet

- 1.40 Happy wall acrylic puttyDocument2 pages1.40 Happy wall acrylic puttySK Emran AliNo ratings yet

- MTC Powder CoatingDocument1 pageMTC Powder CoatingSK Emran AliNo ratings yet

- EP-1 EP-2 MergedDocument685 pagesEP-1 EP-2 MergedSK Emran AliNo ratings yet

- Weber Tile and Stone Grouting SolutionDocument2 pagesWeber Tile and Stone Grouting SolutionSK Emran AliNo ratings yet

- MTC Powder CoatingDocument1 pageMTC Powder CoatingSK Emran AliNo ratings yet

- Specifications & CertificationsDocument6 pagesSpecifications & CertificationsSK Emran AliNo ratings yet

- Ebax Data SheetDocument4 pagesEbax Data SheetSK Emran AliNo ratings yet

- MasterSeal TC 268 - 1000432082Document1 pageMasterSeal TC 268 - 1000432082SK Emran AliNo ratings yet

- List of TestsDocument1 pageList of TestsSK Emran AliNo ratings yet

- Raukantex NewDocument12 pagesRaukantex NewSK Emran AliNo ratings yet

- Adhesive Tech Data Sheet.Document1 pageAdhesive Tech Data Sheet.SK Emran AliNo ratings yet

- Kankaria PropertiesDocument2 pagesKankaria PropertiesSK Emran AliNo ratings yet

- MTC 291Document1 pageMTC 291SK Emran AliNo ratings yet

- SKM C22722072912440Document2 pagesSKM C22722072912440SK Emran AliNo ratings yet

- Sikatop Seal-107inDocument4 pagesSikatop Seal-107inSK Emran AliNo ratings yet

- Quiz CompetitionDocument3 pagesQuiz CompetitionSK Emran AliNo ratings yet

- TDS Brushbond India5Document2 pagesTDS Brushbond India5SK Emran AliNo ratings yet

- Flooring Checklist (T-1)Document1 pageFlooring Checklist (T-1)SK Emran AliNo ratings yet

- Test Report - RockwoolDocument2 pagesTest Report - RockwoolSK Emran Ali100% (1)

- Specification For: British Standard BS 6497:1984Document4 pagesSpecification For: British Standard BS 6497:1984SK Emran AliNo ratings yet

- High Pressure Compact LaminatesDocument14 pagesHigh Pressure Compact LaminatesSK Emran AliNo ratings yet

- TDS Certificate09052022131255Document3 pagesTDS Certificate09052022131255SK Emran AliNo ratings yet

- Adoni 31.07.2022Document1 pageAdoni 31.07.2022SK Emran AliNo ratings yet

- Rockwool 2nd Lot - 4Document1 pageRockwool 2nd Lot - 4SK Emran AliNo ratings yet

- 5.7 Techcryst 2K SuperstrongDocument3 pages5.7 Techcryst 2K SuperstrongSK Emran AliNo ratings yet

- Plot No. 298, Road No. 4, GIDC, Kathawada, Ahmedabad, Gujarat 38243Document2 pagesPlot No. 298, Road No. 4, GIDC, Kathawada, Ahmedabad, Gujarat 38243SK Emran AliNo ratings yet

- Comments To MS For Expansion Joint InstallationDocument1 pageComments To MS For Expansion Joint InstallationSK Emran AliNo ratings yet

- Wistara BWP (12 MM & 9 MM) .Document4 pagesWistara BWP (12 MM & 9 MM) .SK Emran AliNo ratings yet