Professional Documents

Culture Documents

Mobile Crane Safe Work Method Statement-SAMPLE

Uploaded by

kwame fosterOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mobile Crane Safe Work Method Statement-SAMPLE

Uploaded by

kwame fosterCopyright:

Available Formats

Company Name:

Company Address:

ABN/NZBN:

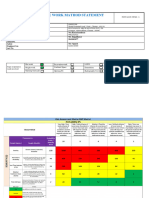

MOBILE CRANE SAFE WORK METHOD STATEMENT (SWMS)

Business Contact: Phone #: Principal Contractor (PC):

Responsible person (for monitoring SWMS and work): PC Address:

Signature: Date: PC Phone #: Date SWMS provided to PC:

Contact Phone #: Job Site Address:

If yes – This SWMS must align with requirements of the Site

E

SITE MANAGEMENT PLAN Is the work associated with a Construction Project? Yes No Management Plan in place for the Construction Project.

THIS WORK ACTIVITY INVOLVES THE FOLLOWING “HIGH-RISK CONSTRUCTION WORK” (HRCW - IDENTIFIED IN THE JOB TASK COLUMN)

PL

Confined spaces Mobile plant movement Demolition of a load-bearing structure Asbestos disturbance

Using explosives Diving work Artificial extremes of temperature Tilt-up or pre-cast concrete

Pressurised gas distribution mains or piping chemical, fuel or refrigerant lines energised electrical installations or services

M

Structures or buildings involving structural alterations or repairs that require temporary support to prevent collapse

Involves a risk of a person falling from 2m or more, including work on telecommunications towers Work in a ceiling space (W.A. Only)

Working at depths greater than 1.5 metres, including tunnels or mines Work in an area that may have a contaminated or flammable atmosphere

SA

Work carried out adjacent to a road, railway or shipping lane, traffic corridor In or near water or other liquid that involves the risk of drowning

WORKING WITH A RISK OF A FALL OVER 2 METRES. Select the fall from height 'hierarchy of control level' considered when establishing controls:

L 1: Work on the ground or solid construction L 4: Use a fall arrest system e.g., safety harness, catch platforms

L 2: Use a passive fall restraint system e.g., guard rails, scaffolding, EWP L 5: Implement administrative controls e.g., signage, or instruction

L 3: Use a work positioning system e.g., travel restraint, rope access Other?

More than one of these measures to reduce risk can be used. For example, engineering controls like edge protection can be implemented with administrative controls

like training and use of this SWMS, while wearing PPE (non-slip shoes). Please describe why it is not reasonably practicable to use higher-order control measures.

E.g. The job is less than 5 minutes on a ladder.

DOCUMENT #: VERSION #: 1 DEVELOPED BY AUTHORISED BY REVIEW #:

MOBILE CRANE SAFE WORK METHOD STATEMENT © SafetyCulture All Rights Reserved ISSUE DATE: REVISION DATE: Page 1 of 16

Company Name:

Company Address:

ABN/NZBN:

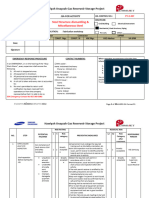

Personal Protective Equipment (PPE)

FOOT HEARING HIGH HEAD EYE FACE HAND PROTECTIVE BREATHING SUN SAFETY Do not wear rings,

PROTECTION PROTECTION VISIBILITY PROTECTION PROTECTION PROTECTION PROTECTION CLOTHING PROTECTION PROTECTION HARNESS watches or

jewellery that may

become

entangled. Long

and loose hair

must be tied back.

CONTROL MEASURES RESPONSIBLE

JOB TASK HAZARDS IR INHERENT RISK-RATING (IR) BEFORE CONTROLS - RESIDUAL RISK-RATING (RR) AFTER CONTROLS

RR

PERSON

E

1. Planning Contact with 4A Liaise with electrical entities where necessary regarding the supply of electricity and control 2M Supervisor

overhead electric measures for working around existing power supply (e.g. de-energising powerlines) including and

lines loading bays and site access. Operator to

PL

undertake all

Inadequate crane 3H Assess the size and complexity of the work to be undertaken 2M

planning

team Determine the crane crew required for the task. Consider:

processes

o Number of operators and doggers required

o Number of riggers required for the activities

o Whether a trained safety observer is required for maintaining electrical exclusion zones

M

o Whether a crane coordinator should be appointed.

Lack of training 4A All operators have the appropriate Heavy Vehicle licence for mobile crane 2M

resulting in injuries The Operator holds a valid certificate to operate such a crane – e.g. C2 for cranes with a

& fatalities capacity up to 20 tonnes; C6 up to 60 tonnes; C1 up to 100 tonnes, and CO greater than 100

SA

tonnes

Operation High-Risk Work Licence

E.g. Crane Slewing mobile crane—with a capacity of up to 60 tonnes

E.g. Dogman Dogging

E.g. Rigger Basic rigging - Intermediate rigging - Advanced rigging

Ensure that all relevant workers have undertaken training and received instruction in the use

of control measures. Include:

o Appropriate mathematical procedures for estimation and measurement of loads

o Knowledge of types of crane and their functions

o Types of lifting equipment and slinging techniques for their use.

DOCUMENT #: VERSION #: 1 DEVELOPED BY AUTHORISED BY REVIEW #:

MOBILE CRANE SAFE WORK METHOD STATEMENT © SafetyCulture All Rights Reserved ISSUE DATE: REVISION DATE: Page 3 of 16

Company Name:

Company Address:

ABN/NZBN:

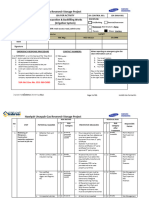

CONTROL MEASURES RESPONSIBLE

JOB TASK HAZARDS IR INHERENT RISK-RATING (IR) BEFORE CONTROLS - RESIDUAL RISK-RATING (RR) AFTER CONTROLS

RR

PERSON

Fuels, oils & chemicals - Minimum amounts of hazardous substances kept on site

Labelled and securely stored

Refuelling of vehicles/equipment undertaken at least 6m from drains and waterways

Follow SDS directions for disposal of chemicals in approved waste containers

A spill kit is available at all times & spills cleaned up immediately follow SDS directions

Waterways & soils - Do not wash out plant, equipment or containers where residue can

enter waterways or drains

Native vegetation & weeds - Ensure that plant is washed free of dirt, vegetation, debris

E

before travelling between sites.

Vehicle movement - Follow the TMP, only travel on established tracks and roads

Use designated entry and exit points

Terrestrial fauna - No domestic animals are to be taken on-site

PL

Ensure all food scraps placed in lidded bins.

6. House Slips 3H Maintain housekeeping throughout the shift & clean-up 2M Operator to

keeping Trips Ensure sufficient lighting to detect changes in level (using temporary lighting as required) ensure

Falls Do not jump from elevated edges >180mm, step carefully and use prepared access areas control

The work area is clean and uncluttered as possible measures

M

Do not place equipment where it could become a trip hazard followed

Check for stored items, corners or other obstructions that could cause tripping

Ensure there is room to manoeuvre and no obstacles in the way

Check the end destination is prepared correctly for placement of the materials/equipment

SA

Clean spills immediately

Footwear is suitable. Snug-fitting shoes/boots with flat, non-slip soles, no loose soles, long

laces, oily soles, or caked with mud or other contaminants.

7. Manual tasks Musculoskeletal 3H Materials/equipment placed as close to the work area as possible 2M Workers to

Disorder (MSD) Weight of an object should be known; avoid lifting loads more than 1/4 of your body weight ensure

injuries Do not use extreme force to move items control

Hold lifted items close to the body whenever possible: measures

o Keeping knees bent and back straight and lift, unload keeping knees bent followed

Use team lifts and mechanical means for heavy items

Schedule regular breaks and practice job rotation

Avoid overreaching, long periods of repetitive movements, awkward and sustained positions,

twisting and side-bending.

DOCUMENT #: VERSION #: 1 DEVELOPED BY AUTHORISED BY REVIEW #:

MOBILE CRANE SAFE WORK METHOD STATEMENT © SafetyCulture All Rights Reserved ISSUE DATE: REVISION DATE: Page 7 of 16

You might also like

- Unit IG2: Risk Assessment: Declaration: by Submitting This Assessment (Parts 1Document19 pagesUnit IG2: Risk Assessment: Declaration: by Submitting This Assessment (Parts 1Abdur80% (10)

- Programmatic Safety Plan (PSP) : Required For High Risk Routine & Repetitive WorkDocument4 pagesProgrammatic Safety Plan (PSP) : Required For High Risk Routine & Repetitive WorkSteve ParkerNo ratings yet

- Excavation Working in Trenches Swms 10281-6Document17 pagesExcavation Working in Trenches Swms 10281-6JamesNo ratings yet

- Electric Powerlines Working Near Swms 10590-3Document12 pagesElectric Powerlines Working Near Swms 10590-3JamesNo ratings yet

- Construction Report 1Document15 pagesConstruction Report 1Faroo wazir78% (9)

- JSA InsulationDocument8 pagesJSA InsulationOlavilam Prakash100% (3)

- Construction Labourer Swms 10556-4Document16 pagesConstruction Labourer Swms 10556-4JamesNo ratings yet

- Painting (General Safety) SWMS 10183-4 - SAMPLEDocument6 pagesPainting (General Safety) SWMS 10183-4 - SAMPLEKunal PanchalNo ratings yet

- IGC 2 - Installation of Automatic Fare Gate System - SubmissionDocument18 pagesIGC 2 - Installation of Automatic Fare Gate System - SubmissionVivek Vj67% (3)

- Swms TemplateDocument8 pagesSwms Templateracing.phreakNo ratings yet

- Drilling Piling Swms 10 15763 SAMPLEDocument7 pagesDrilling Piling Swms 10 15763 SAMPLEAlok JagannathNo ratings yet

- Master Builders SA - Safe Work Method Statement - Timber Roof Truss Installation CraneDocument6 pagesMaster Builders SA - Safe Work Method Statement - Timber Roof Truss Installation CraneDaniel JulianNo ratings yet

- Method Statement WeldingDocument9 pagesMethod Statement Weldingkiki270977No ratings yet

- SWMS Template 30013 14Document6 pagesSWMS Template 30013 14Zeeshan AliNo ratings yet

- Concrete Pumping (Boom-Line) SWMS 10065-7Document13 pagesConcrete Pumping (Boom-Line) SWMS 10065-7caringbahngconstructionsNo ratings yet

- Concrete Placement Finishing Swms 10064-7Document12 pagesConcrete Placement Finishing Swms 10064-7JamesNo ratings yet

- SwmsDocument3 pagesSwmsAhmed AbdulmajeedNo ratings yet

- Fencing Safe Work Method Statement-SAMPLEDocument3 pagesFencing Safe Work Method Statement-SAMPLErohantparrNo ratings yet

- Concrete Piling SWMS 10612-3 - SAMPLEDocument3 pagesConcrete Piling SWMS 10612-3 - SAMPLELeonieNo ratings yet

- Erecting Suspended Powered Scaffolds SWMSDocument3 pagesErecting Suspended Powered Scaffolds SWMSJHM100% (1)

- SWMS Gemko Innovation PTY LTD Wicks Park ProjectDocument13 pagesSWMS Gemko Innovation PTY LTD Wicks Park ProjectMerwan BourknaNo ratings yet

- Documents - Pub - Heights Working at Swms No Safe Work Method This Swms Covers The Risk ManagementDocument16 pagesDocuments - Pub - Heights Working at Swms No Safe Work Method This Swms Covers The Risk ManagementVepxvia NadiradzeNo ratings yet

- 10147-9 SampleDocument3 pages10147-9 SampleSun ShadeNo ratings yet

- Crane Truck Mounted Hiab Swms 2020Document20 pagesCrane Truck Mounted Hiab Swms 2020adrian.eadeNo ratings yet

- Whs f014 Safe Work Method Statement FormDocument9 pagesWhs f014 Safe Work Method Statement FormTamo Kim ChowNo ratings yet

- SWMS Mobile ScaffoldingDocument14 pagesSWMS Mobile Scaffoldingnur agusNo ratings yet

- SWMS No 6 Threaded Rod InstallingDocument6 pagesSWMS No 6 Threaded Rod InstallingMokka SamaiyalNo ratings yet

- 5T Excavator and Skid Steer Loader Combo On Site Safe Work Method Statement SWMSDocument18 pages5T Excavator and Skid Steer Loader Combo On Site Safe Work Method Statement SWMSsupportNo ratings yet

- CLC - 9040 5.19.3 Job Safety Practices Rev 02 Radiography ActivityDocument4 pagesCLC - 9040 5.19.3 Job Safety Practices Rev 02 Radiography ActivityshafieNo ratings yet

- Guide To Solar Safe InstallationDocument23 pagesGuide To Solar Safe InstallationOubahsis NissrineNo ratings yet

- Safe Work Method Statement (SWMS) : Hot Work (Welding, Cutting, Grinding, Gas Cutting, in FGD-Unit#1&2)Document6 pagesSafe Work Method Statement (SWMS) : Hot Work (Welding, Cutting, Grinding, Gas Cutting, in FGD-Unit#1&2)tamoor sarwarNo ratings yet

- Sample: V S T S W M S (SWMS)Document3 pagesSample: V S T S W M S (SWMS)SteveNo ratings yet

- Jsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007Document30 pagesJsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007elmsm14No ratings yet

- Method Statement: QC InspectorDocument7 pagesMethod Statement: QC InspectorCobbinah MarkNo ratings yet

- GGH Basket RemovelDocument9 pagesGGH Basket Removeltamoor sarwarNo ratings yet

- RAMS Air Conditioning Unit InstallDocument10 pagesRAMS Air Conditioning Unit InstallMohammad SaleemNo ratings yet

- SWMS No 11 Duct CuttingDocument5 pagesSWMS No 11 Duct CuttingMokka SamaiyalNo ratings yet

- Samal Dattatreya 00724769, Ig2-Nviron Consulting PVT LTDDocument22 pagesSamal Dattatreya 00724769, Ig2-Nviron Consulting PVT LTDanandmg41No ratings yet

- Asphalt Paver Safe Work Method Statement 10454-2 - SAMPLEDocument4 pagesAsphalt Paver Safe Work Method Statement 10454-2 - SAMPLEGeo WorkNo ratings yet

- Programmatic Safety Plan (PSP) : Required For High Risk Routine & Repetitive WorkDocument4 pagesProgrammatic Safety Plan (PSP) : Required For High Risk Routine & Repetitive WorkSteve ParkerNo ratings yet

- Ritesh Ig2 Forms Electronic Submission v3 28.07.2021Document19 pagesRitesh Ig2 Forms Electronic Submission v3 28.07.2021NishanthNo ratings yet

- Ig2 Forms Electronic Submission v5.1Document14 pagesIg2 Forms Electronic Submission v5.1khalifa983No ratings yet

- SWMS-Manual Handling WebsiteDocument12 pagesSWMS-Manual Handling WebsitevsfchanNo ratings yet

- JSA For SealantDocument11 pagesJSA For SealantdipmipNo ratings yet

- SIM ARABIA - JSA For Excavation and Backfilling Works (Irrigation System)Document11 pagesSIM ARABIA - JSA For Excavation and Backfilling Works (Irrigation System)Rana AhmedNo ratings yet

- Sample Safe Work Method Statement (SWMS)Document9 pagesSample Safe Work Method Statement (SWMS)Faisal JailaniNo ratings yet

- OT Permit For TopoyoDocument1 pageOT Permit For TopoyoekkyagungNo ratings yet

- IM-WI-09-SOP-S20 Site Specific SOP For Precast Boundary Wall InstallationDocument11 pagesIM-WI-09-SOP-S20 Site Specific SOP For Precast Boundary Wall InstallationBalasubramaniamkamarajNo ratings yet

- Operation of Vehicle Mounted Crane: Safe Work Method StatementDocument9 pagesOperation of Vehicle Mounted Crane: Safe Work Method StatementMuhd AqibNo ratings yet

- Safe Work Method Statement Hot Works: OST Constructional Projects LLCDocument8 pagesSafe Work Method Statement Hot Works: OST Constructional Projects LLCIrfan UllahNo ratings yet

- 3 JSA For SealantDocument11 pages3 JSA For SealantAkbar SyahrezaNo ratings yet

- Risk Assessment & Method Statement: Insert Company Name/LogoDocument14 pagesRisk Assessment & Method Statement: Insert Company Name/Logoahmed khairyNo ratings yet

- Ra Sample LTC 21-Oct-2023Document31 pagesRa Sample LTC 21-Oct-2023EULET RICHARDNo ratings yet

- SWMS Cherry PickerDocument15 pagesSWMS Cherry Pickervictor0% (1)

- 2022 SWMS - Combined SWMSDocument8 pages2022 SWMS - Combined SWMSSteveNo ratings yet

- 10 Important Precautions When Working On Low Voltage Energized EquipmentDocument1 page10 Important Precautions When Working On Low Voltage Energized Equipmentjitendra jhaNo ratings yet

- Safety Training (Work at Height)Document60 pagesSafety Training (Work at Height)chafikhatchane2No ratings yet

- Safe - Work - Method - Statement - Roof - Truss - Installation V1.0Document8 pagesSafe - Work - Method - Statement - Roof - Truss - Installation V1.0hurairamughal666No ratings yet

- SafeworkpmitsDocument27 pagesSafeworkpmitsChewy ChocoNo ratings yet

- Excel ToolkitDocument1 pageExcel Toolkitkwame fosterNo ratings yet

- Risk and Opportunity RegisterDocument2 pagesRisk and Opportunity Registerkwame fosterNo ratings yet

- Block WorksDocument4 pagesBlock Workskwame fosterNo ratings yet

- Sds Portland CementDocument11 pagesSds Portland Cementkwame fosterNo ratings yet

- Risk Assessment With Advanced Hierachy of Controls DemoDocument1 pageRisk Assessment With Advanced Hierachy of Controls Demokwame fosterNo ratings yet

- Project ScheduleDocument1 pageProject Schedulekwame fosterNo ratings yet

- Emergency Drill Plan 2024Document2 pagesEmergency Drill Plan 2024kwame fosterNo ratings yet

- U660e Zip in - BDocument11 pagesU660e Zip in - BVladimir Sadovets100% (1)

- HDP ANT TNA510A10 160401 ENDocument2 pagesHDP ANT TNA510A10 160401 ENErik Joel Manrique AlvaNo ratings yet

- IGA225 Integrated Governor & Actuator: InstallationDocument8 pagesIGA225 Integrated Governor & Actuator: InstallationthyagoenergNo ratings yet

- Land NavigationDocument7 pagesLand NavigationElijah Dave BuenaventuraNo ratings yet

- 28 27 - Bell - Gossett - HistoricalDocument7 pages28 27 - Bell - Gossett - HistoricalthepimpoNo ratings yet

- Geodesic Dome Dims - 2V DOME: Estimated DimensionDocument12 pagesGeodesic Dome Dims - 2V DOME: Estimated DimensionmarinerNo ratings yet

- Data Sheet: Three Phase Induction Motor - Squirrel Cage RotorDocument1 pageData Sheet: Three Phase Induction Motor - Squirrel Cage Rotorasdsd dsdaNo ratings yet

- Presentation1 VDocument17 pagesPresentation1 VVikram.SNo ratings yet

- Ship ParticularsDocument1 pageShip ParticularsEmin AbishovNo ratings yet

- Handout RPS - V1.0Document121 pagesHandout RPS - V1.0Adegbola AdedipeNo ratings yet

- Engine Solutions BrochDocument11 pagesEngine Solutions BrochmarkelovfyodorNo ratings yet

- Piña Chan y Navarrete-Archaeological Research in The Lower Grijalva River RegionDocument65 pagesPiña Chan y Navarrete-Archaeological Research in The Lower Grijalva River RegionggarfuNo ratings yet

- Geostationary & Polar-Orbiting SatellitesDocument83 pagesGeostationary & Polar-Orbiting SatellitesAngelie LapeNo ratings yet

- Journal: Construction Journal Unswagati CirebonDocument15 pagesJournal: Construction Journal Unswagati CirebonAbdoel KhalimNo ratings yet

- HackMaster QuickStart GuideDocument41 pagesHackMaster QuickStart Guidesullivbt100% (3)

- Birch Paper CompanyDocument2 pagesBirch Paper CompanyMAHFUDNo ratings yet

- Lal Imli InternDocument51 pagesLal Imli InternShivam Verma50% (2)

- Grade 7 Olympiad: Answer The QuestionsDocument3 pagesGrade 7 Olympiad: Answer The QuestionsRishit KunwarNo ratings yet

- EP Bearing & Chassis GreaseDocument2 pagesEP Bearing & Chassis Greasechem KhanNo ratings yet

- Imat Test Specification 2015Document17 pagesImat Test Specification 2015mariolara22No ratings yet

- JFNR 201801Document12 pagesJFNR 201801saprifarmasiNo ratings yet

- Effect of Consumption of The Nutrient-Dense, Freshwater Small FishDocument17 pagesEffect of Consumption of The Nutrient-Dense, Freshwater Small FishFaisalNo ratings yet

- Logic of MetisDocument4 pagesLogic of Metisapi-399928223No ratings yet

- ERGNOMICSOFTRACTORvol 16 No 1Document112 pagesERGNOMICSOFTRACTORvol 16 No 1Yosun KarasuNo ratings yet

- Marketing I - Price ListDocument3 pagesMarketing I - Price ListthimotiusNo ratings yet

- Case Studies in Thermal EngineeringDocument7 pagesCase Studies in Thermal EngineeringtöreNo ratings yet

- 1Document2 pages1Santiago OrtizNo ratings yet

- Desoldering Tool: Designed For Lead FreeDocument2 pagesDesoldering Tool: Designed For Lead FreeMarco Antonio Ortiz RomeroNo ratings yet

- Answering Questions About The Clone IssueDocument3 pagesAnswering Questions About The Clone IssueAlienraces1No ratings yet

- Eatwell Guide BookletDocument12 pagesEatwell Guide BookletPaul des Perrieres100% (1)