Professional Documents

Culture Documents

Coils 1994

Uploaded by

Aritz CalvoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Coils 1994

Uploaded by

Aritz CalvoCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/230829931

Experimental investigation of natural convection from vertical

helical coiled tubes

Article in International Journal of Heat and Mass Transfer · March 1994

DOI: 10.1016/0017-9310(94)90138-4

CITATIONS READS

75 483

1 author:

Mohamed El-Sayed Ali

King Saud University

145 PUBLICATIONS 3,317 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Free convection heat transfer from different objects View project

New insulating materials View project

All content following this page was uploaded by Mohamed El-Sayed Ali on 11 September 2017.

The user has requested enhancement of the downloaded file.

/nr.J.

Hem Mass Tmsf;r. Vol.37,No.4,pp.

665671,1994

Copyright CI 1994 Elsevier Science Ltd

Pergamon Printed inGreat Britain.All rights reserved

0017-9310/94$6.00+0.00

Experimental investigation of natural convection

from vertical helical coiled tubes

MOHAME~ E. ALIT

Helwan University, Faculty of Engineering and Technology, El-Mattaria, P.O. 11718, Cairo, Egypt

(Received 10 August 1992 and infinal form 8 June 1993)

Abstract-An experimental study has been made on steady state natural convection heat transfer from

vertical helical coiled tubes. Average heat transfer coefficients were obtained for turbulent natural con-

vection to water. The experiments have been carried out for four coil diameter to tube diameter ratios, for

five and ten coil turns, and for five pitch to outer diameter ratios. The data are correlated with the Rayleigh

number for two different coil sets. The heat transfer coefficientdecreaseswith coil length for tube diameter

d, = 0.012 m, but increases with coil length for do = 0.00s m. A critical D/do is obtained for a maximum

heat transfer coefficient for tube diameter of 0.012 m with either fve or ten coil turns.

using two different tube coils having ratios 014 = 17

and 104, In their experiment the fluid was heated

HELICALLY coiled tubes are used frequently in heating,

by electrical dissipation through the tube wall. Most

refrigerating and HVAC applications, and in steam

recently, Garimella et al. [4] have investigated the heat

generator and condenser designs in power plants

transfer in coiled annular ducts using equation (2) to

because of their large surface area per unit volume. In

estimate the heat transfer coefficient inside the inner

spite of their widespread use, there is no info~ation

duct to map the shell-side heat transfer coefficient.

available on natural convection from such coils. How-

They reported that coiling augments the heat transfer

ever, correlations in the literature for natural con-

coefficient above the values for a straight annulus in

vection from vertical and horizontal plates and cyl-

the laminar region. However, this augmentation is less

inders are available. The foregoing considerations

than that for a coiled circular tube and it decreases at

provided motivation for the present research to fill

the transition region.

the gap in the literature.

Laminar and turbulent natural convection to air,

The discussion of prior work in turbulent forced

water, and other liquids from vertical flat plates and

and natural convection will be divided into two cate-

cylinders were reported by many authors over differ-

gories : forced flow inside helically coiled circular

ent ranges of Ra. In the range 10” ,< Ra < lOI of

tubes and natural convection from vertical cylinders

interest here for turbulent natural convection to water

and plates. All cited equations will be written using

correlations have been reported by Fujii et al. [5] for

the parameter definitions in this paper.

a vertical circular cylinder and by Vliet and Liu [6]

The criterion for transition from laminar to tur-

for a vertical plate.

bulent flow in curved pipes was established exper-

Fujii et al. [S] obtained local heat transfer coefficient

imentally by Ito {l] and can be represented by

correlations for water, spindle oil, and Mobiltherm

Re, = 2 x 104(d,/D)o.3’. (1) oil on the outside surface of a vertical cylinder. For

water in turbulent flow, they reported the following

Turbulent heat transfer inside helically coiled tubes

results for uniform wall temperature and uniform heat

has been studied by Rogers and Mayhew [2] who

flux, respectively :

used water flowing through steam-heated tubes for

diameter ratios D/4 = 10.8, 13.3, and 20.1. The physi- Nu, = 0.13 (&z,)‘.“~, 4x 10’” < Ra X.< 8 x 10”

cal properties in their correlation

Nu, = 0.129 (Rax)0,33,

Nu = 0.023 (Re)0.85 (Pr)0.4(d;/D)0.’ (2)

3.6 x IO9 < Ra, < 1.33 x 10”.

were evaluated at the arithmetic mean of the bulk

temperature of the fluid at inlet and outlet. Similar The following correlation in terms of the present

studies were conducted by Seban and McLaughlin [3] definition of Ra,

Nu x = 0 .484 (Ra x)“.z8zI

4.17 x IO” ,< Ra, < 5.3 x IO” (3)

t Current address : Mechanical Engineering Department,

College of Engineering, King Saud University, P.O. Box 800, has been reported by Vliet and Liu [6] to fit their

Riyadh 11421,Saudi Arabia. experimental data for turbulent natural convection

666 M. E. ALI

NOMENCLATURE

.4 surface area ]mz] V fluid velocity inside coil.

( specific heat [kJ kg ’ K ‘1

D helix coil diameter [m]

ri tube diameter [m] Greek symbols

9 acceleration due to gravity [m s ‘1 % thermal diffusivity [m’s ‘1

H coil height [m] P coefficient for thermal expansion [K ‘1

II heat transfer coefficient [kW m ’ K ‘1 0 bulk arithmetic mean temperature [ C]

x thermal conductivity [W m- ’ K ‘1 \’ kinematic viscosity [m’s ‘1,

L coil length [m]

/i7 mass flow rate [kg s ‘1

N number of coil turns Subscripts

NU Nusselt number, hLjk or hH/k after the run

PI Prandtl number, V/X ; before the run

P coil pitch [m] C coil

Q heat transfer [kW] H coil characteristic length

RU Rayleigh number, sp( T, - T,)L’/va OI i inner

g/i( f, - T2)ff l;\‘x in inlet

RCJ Reynolds number, J’cI,,ir L coil characteristic length

T temperature [K] Im logarithmic mean

T, average hot water temperature. 0 outer

[(~,),,,+(T~h,m out outlet

T? average ambient water temperature. S slanted

[(7-\\L+(~\,~Ji2 t transition

C’ overall heat transfer coefficient W water.

boundary layers on a vertical plate of constant heat 2. EXPERIMENTAL APPARATUS AND

flux. Notice that the above equation results in a slight PROCEDURE

decrease in the heat transfer coefficient along the vcr-

tical plate. The analytical expression for turbulent A schematic diagram of the experimental apparatus

natural convection from a vertical flat plate of con- is sketched in Fig. 1. The testing coil (8) is fixed in an

stant temperature using the 1/7th power law is ambient temperature bath (1) which serves as the

reported in ref. [7] as coolant. The hot temperature bath (2) contains a

stirrer (3). a 10 kW heater (4), and a temperature

controller. Flow of hot turbulent water is pumped

through the coil with a 1.5 hp centrifugal pump (5).

for Ra, > 10”. For air (Pr = 0.72), equation (4) is The hot water loop circuit is completed when water

only 1% different from the experimental correlation from the pump returns to the hot water tank (2).

reported by Kreith [S] for natural convection from a Tanks (1) and (2) are cylindrical vessels 0.90 m deep.

vertical cylinder to air for 10’ < Ra < 10” and also 0.6 m diameter, and they were filled to approximately

by McAdams [9] for convection from short vertical 0.025 m from the top with tap water. The volume flow

plates to air. rate through the coil is measured by a flowmeter (6)

This paper presents the results of an experimental and temperatures arc measured with calibrated iron

study of turbulent natural convection heat transfer constantan (type J) thermocouples (7) at the inlet and

from vertical helical coiled tubes to water. The inves- outlet of the firs1 and Last turn of the coil, respectively.

tigation focuses on the determination of avcragc heat A thermocouple housing shown in Fig. 2(a) has cir-

transfer coefficients. Nusselt numbers have been cor- cuitry designed to directly measure the inlet tem-

related as a function of the Rayleigh number and arc perature, the outlet temperature, and their difference.

compared to other available correlations in the same Thermocouples are rated to meet the ANSI special

range for vertical plates and cylinders, respectively. limits of error 0.5 C or 0.4% whichever is greater. The

Section 2 describes the experimental apparatus and thermocouples are separated from the tube bottom

test procedure. This is followed by the analysis of housing by a two mil layer of mercury. A total of 6

experiments in Section 3 with results and discussion 11 temperature difference measurements are made for

in Section 4. Summary and conclusions are given in every p/d,. The coils are formed from initially straight

Section 5. tubing (brass 70% CU and 30% ZN with thermal

Experimental investigation of natural convection 667

FIG. 1. Schematic diagram of the experimental apparatus. (1) Constant temperature bath, (2) test reservoir,

(3) stirrer, (4) heater, (5) centrifugal pump, (6) flowmeter, (7) thermocouples, and (8) testing coil.

turn is measured using a vernier caliper and the helix

coil diameter is obtained from the following equation

D= (5)

N ’

The coil length is calculated from L = TLDNand the

coil turns are separated from each other using Plexi-

glas spacers with a specific length to fix the pitch of

the coil. The water in tank (2) was heated and well

mixed using a 10 kW heater (4) and a stirrer (3).

(a) (b) Data were collected for one pitch to coil diameter

FIG. 2. (a) Thermocouple housing (dimensions in mm), and ratio for hot temperatures ranging from 35 to 80°C.

(b) physical parameters of the helical coils tested. The temperature was increased by 5°C for each run

and the procedure was repeated for the other test coils.

After every run the ambient water in tank (1) was

conductivity k = 104.00 W m-l Km’ [lo]) polished to drained and filled again with fresh tap water to keep

minimize the error due to radiation. Fine sand filled the ambient water temperature nearly the same before

the tubes before bending, and this was washed out each run. The experiments are designed so that the

with hot water to preserve the smoothness of the inner outer (external tube-side) heat transfer coefficients

surface. Only a very slight ellipticity of the flow cross could be calculated using measured overall heat trans-

section and distortion of wall thickness are introduced fer coefficients and predicted inner (internal tube-side)

by the bending process. The inner and outer diameter, heat transfer coefficients. The mass flow rate is main-

and the wall thickness of every coil was measured tained constant for each coil but it has a higher value

by using a sample cut of that coil. Table 1 lists the for the large diameter tube than that of the

dimensions and parameters of the coils used in this small diameter one. The procedure outlined above

investigation. To allow for the obliquity of the helix, is used to generate natural convection heat trans-

the slanted outer turn diameter D, (Fig. 2(b)) for each fer data over the Prandtl number range 3.44 < Pr

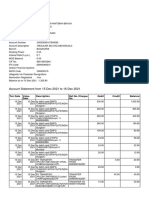

Table 1. Physical dimensions of the test coils

Coil no. d, (m) d0 (m) D (m) L (4 pido N Wo

1 0.011 0.012 0.2495 7.8383 1.5, 2, 3, 3.5 10 20.792

2 0.011 0.012 0.2495 3.9191 1.5, 2, 3, 3.5 5 20.792

3 0.011 0.012 0.1671 5.2490 1.5, 2, 3.5, 4 10 13.923

4 0.011 0.012 0.1671 2.6245 1.5, 3.5,4 5 13.923

5 0.011 0.012 0.1190 3.7375 1.5, 2, 3, 3.5 10 9.914

6 0.011 0.012 0.1190 1.8687 1.5, 2, 3, 3.5,4 5 9.914

7 0.007 0.008 0.1597 5.0157 1.5, 2, 3, 3.5 10 19.957

8 0.007 0.008 0.1597 2.5078 1.5, 2, 3, 3.5 5 19.957

9 0.007 0.008 0.0793 2.4917 1.5, 2, 3, 3.5 10 9.914

10 0.007 0.008 0.0793 1.2458 1.5, 2, 3, 3.5 5 9.914

668 M. E. Al.1

< 5.30. The variation in Prandtl number is due

to the difference in temperature between individual

runs.

3. ANALYSIS OF EXPERIMENTS

In the following discussion, the physical properties

of the hot water inside the tube coil are assumed

constant along the coil length and cvaluatcd at the

average bulk temperature for each run. Heat loss from

the coil can be calculated from

e = 7f7c[(~c),r, - (~~L,l. (6)

where Q is the heat loss from the coil, vi? is the hot

water flow rate, (T,),,, is the coil inlet temperature,

(TJ,,, is the coil outlet temperature, and c is the hot

water specific heat. Having obtained a value for the

rate of heat transfer Q, the overall heat transfer

coefficient U is calculated from FIG. 3. Average turbulent heat transfer correlation Ibr \er-

tical coils in water with coil length as a characteristic length.

Q = C’AT,,,, (7)

where AT,,,, is the log-mean temperature diffcrcncc

d,, = 0.008 m. The upper data are for three O:ct,, dia-

meter ratios 20.797. 13.923, and 9.914 while the

lower data are for Did,, of 19.957 and 9.914. In both

cases data have been taken for both five and ten coil

and U is defined as

turns. A least-squares power law fit through the two

data sets yields the following correlations

Nu, = 0.685 (Rtr, )” “)‘.

Once U is calculated from equation (7), h, is evaluated d,, = O.O12m, 3 x IO” < Ra,_ < 8 x 10” (I I)

from equation (2). k for the coil material is given.

Nu, = 0.00044 (/?a, )” ““+

and then the outer heat transfer coefficient /I, can

be calculated from equation (9). Direct temperature L/,,= O.O08m, 6x IO” < Ktr, < I x IO”. (12)

measurements of the ambient water temperature in

Equation (4) was evaluated at Pr = 4.37 cor-

tank (I) were made before and after each run. In

responding to the average Prandtl number for water

calculating the physical properties for the non-

used in the present experiment and the resulting cor-

dimensional groups the bulk arithmetic mean tem-

relation is

perature is used

Nu, = 0.0195 (Ru, )““. (13)

Correlations (3) and (13) are plotted as dashed lines

in Fig. 3 for comparison with the present results.

All temperature measurements in this experiment are Although the exponent in equations (11) and (I 2)

accurate to +O.Ol”C. is sensitive to experimental scatter in the data, the

The coil length L has been adopted as the charac- results are clearly adequate to show that the exponent

teristic length in the nondimensional groups. is less than 113 in equation (I I) and is greater than

However, the coil height H is also used to determine 1:‘3 in equation (12). It is clear that the heat transfer

the range of Rayleigh number and Nusselt number in coefficient h,, decreases slightly with boundary-layer

both cases and its relation to the region of natural length for equation (11) as

convection. The equation for the coil height is

12”!X L Cl‘I(. (14)

H = Np, where N is the number of coil turns and p is

the coil pitch. However. lz,, increases rapidly with boundary-layer

length for equation (12) as

4. RESULTS AND DISCUSSION h,, x L” <dh. (15)

The experimental data points of all coil sets are Fquations (1 I) and (12) suggest that increasing the

presented in Fig. 3 by plotting Nu, against Ru, on a tube diameter for fixed L and for the same value of

logarithmic scale. As seen in this figure there are two Ra, enhances /7,,.

groups of data, the upper group corresponding to In an attempt to ascertain the effect of the coil

tube diameter d, = 0.0 I2 m and a lower group having height Has a characteristic length in Ra and Nu, Figs.

Experimental investigation of natural convection 669

10’ < RaH < 10” could be defined as a transition

region from laminar to turbulent flow since the heat

transfer coefficients increase abruptly as for a vertical

wall in water (Fujii et al. [5]). This behavior of

abruptly increasing h, can be seen from the following

best-fit correlations for two different D/d0

Nun = 0.016 (Ra,)0.433,

D

- = 19.957, 2 x 10’ < Ra, < 5 x 10” (17)

&

Nun = 0.0023 (Ru,)‘.~~,

D

- = 9.914, 3.5 x 10’ < Ra, < 7 x 10”. (18)

do

These equations suggest that h, is increasing with H

for this set of data as

FIG. 4. Average turbulent heat transfer correlation for a

vertical set of coils with do = 0.012 m in water compared h 0 cc Ho.299 and h, cc Ho.482 (19)

with the previous results on flat plates.

which agree with the assumption that h, increases

rapidly with H in the transion region from laminar to

turbulent flow for both diameter ratios. However, the

4 and 5 were constructed. The data are presented by rate of increase of h, for D/do = 9.914 is higher than

plotting Nu, against Ra, for do = 0.012 m and for that for D/d,, = 19.957.

D/d, of 20.792, 13.923, and 9.914 in Fig. 4 and for Figures 6 and 7 were constructed to see the effect

do = 0.008 m and for D/d, of 19.957 and 9.914 in Fig. of the number of coil turns on the heat transfer

5. The best power law fit through the data in Fig. 4 is

coefficient h,. In Fig. 6 the data are presented for

given by two diameter ratios 13.923,9.914, at do = 0.012 m by

Nub = 0.257 (Ru~)‘-~*~, 6 x 10’ < RaH < 3 x lo”, plotting Nu, against RaL. The best-fit lines to this data

(16) are

indicating that h, is decreasing very slightly or it could Nu,_ = 5.11 (RaL)o.2’4N0.296,

be constant along the coil height because the exponent

D

in equation (16) may vary due to experimental uncer- - = 13.923, 4.8 x 1012 < (Ra,) < 4 x lOI (20)

tainty to reach the value l/3. In other words, increas- do

ing the coil height results in a very slight decrease in Nu, = 2.64 (RaL)o-*28N0~324,

h, or has no influence on h, for tube diameter

D

do = 0.012 m. Figure 5 shows two regions, one laminar - = 9.914, 2.8 x 10” < (Ra,) < 1 x 1014. (21)

and the other turbulent, since turbulent nature con- d,

vection is distinguished by Ra > 109. The range

_

--

NUH

N””

E

E

0.016 R.“-=

O.OOZJ Fm,-*

10’

1

,I

_,

NUL

/ / 0 D/d, = 19.957

- I

I . D/d, = 9.914

10’ ~“‘~~” ’ 1”““’ ‘a”*“, ( “,~‘a~ “‘U

IO” IO* 1010 IO” 1012 10’3

RaH FIG. 6. Average turbulent heat transfer correlation for two

FIG. 5. Average heat transfer correlation for a vertical set of coils with do = 0.012 m; N = 5 and 10 for each diameter

coils with do = 0.008 m in water. ratio D/d,.

670 M E

Figure 8 was constructed to see the effect of the

diameter ratio D/do on the h, by plotting the measured

values of h, for different D/do on a dimensional linear

scale against the total coil surface area. These values

of /I, for each coil are the average value for that coil :

thus there are two values of h,, one for five and the

other for ten coil turns. In Fig. 8 each group of data

NUL points for N = 5 and 10 having pi,, = 0.012 m arc

connected by dashed lines. One can SW that h, exhibits

a maximum for N = 5 and 10. In other words. there

exists a critical diameter ratio for five and ten coil

turns corresponding to a maximum /z,,. The critical

D/d<, was found to be 14.4 for five and 13.0 for ten

coil turns. respectively. Unfortunately, there are

insufficient data to determine the critical diamctcr

ratio for the data having d0 = 0.008 m.

RaL

FIG. 7. Turbulent average heat transfer correlation for two

coils having d, = 0.008 m ; N = 5 and 10 for each diameter

ratio D/d,,. 5. SUMMARY AND CONCLUSIONS

Experimental studies on turbulent natural con-

vection heat transfer from vertical helical coils to

water were performed. Average heat transfer

Equations (20) and (21) suggest that h, slightly

measurements were made for Rayleigh numbers up to

decreases as N increases for D/d<, = 13.923 and is

10” and for two sets of coils. The first set has

almost constant for D/d, = 9.914. Furthermore, since

do = 0.012 m and three D/d<, of 20.792, 13.923, and

the decreasing rate of h, is very low or zero

9.941 and the second set has d,, = 0.008 m and two

D/d,, of 19.957 and 9.941. Using I, as a characteristic

h,, cc Nmooh’ and h, cc No”” (22)

length it was found that the transition region to tur-

bulence is marked by an abrupt increase in h,,

credence is given to the idea mentioned above that the

for d,, = 0.008 m while the turbulent region for d0 =

boundary layer flow is indeed turbulent.

0.012 m is marked by a slightly decreasing or nearly

Figure 7 shows the experimental data for

constant value of h,. The same behavior holds when

D/d0 = 19.975,9.914 and for five and ten coil turns in

N is used as the characteristic length. However, the

a logarithmic scale for do = 0.008 m. The least-squares

range of Ra, is less than the range of Ra, The

fits to the measurements are given by

correlation covering the first set of coils is

Nu, = 0.258 (Ra, )” ““N’.03’, Nu I = 0.685 (Ra 1 )Ozqi

D

~-- = 19.957, 3 x 1012 G (Ran) d 2 x 1012 (23)

do

D

Nu,, = 0.002 @a,)“-J”’ N” 371,

-1

4

- = 9.914, 5 x 10” $ (&) < 3 x 10”. (24)

do

The above equations show that

h, cc Nu77x and h, oc N’~“’ (25)

for equations (23) and (24) respectively, indicating

that h, increases abruptly as N increases for the same

diameter ratio, and the rate of increase is very high

compared to the rate of decrease for the set of data in

Fig. 6. The explanation for the different heat transfer

rate is that, as mentioned before, the data in Fig. 7 A (m2)

for d,, = 0.008 m are in a region of transition from FIG. 8. Variation of average heat transfer coefficient /I, with

laminar to turbulent flow, while the data in Fig. 6 are coil outer surface area for all D/d,. Dashed lines connect the

entirely in the turbulent region. average data points for the five and ten turn coils.

Experimental investigation of natural convection 671

which results in a slight decrease in the heat transfer REFERENCES

coefficient with coil length for the same diameter ratio. 1. H. Ito, Friction factors for turbulent flow in curved

The equation covering the second set of coils is pipes, Trans. ASME D81, 123-134 (1959).

2. G. F. C. Rogers and Y. R. Mayhew, Heat transfer and

iVz.&= 0.00044 (Ra,)O 5’6 pressure loss in helically coiled tubes with turbulent flow,

Int. J. Heat Mass Transfer 7, 1207-1216 (1964).

3. R. A. Seban and E. F. McLaughlin, Heat transfer in

which shows an abrupt increase in the heat transfer tube coils with laminar and turbulent flow, Znt. J. Heat

coefficient. It was also found that increasing the num- Mass Transfer 6,387-395 (1963).

ber of turns for the same diameter ratio results in a 4. S. Garimella, D. E. Richards and R. N. Christensen,

Experimental investigation of heat transfer in coiled

decreasing heat transfer coefficient for the first set of

annular ducts, ASME J. Heat Transfer 110, 329-336

coils (do = 0.012 m) but an increasing heat transfer (1988).

coefficient for the second set of coils (d, = 0.008 m). 5. T. Fujii, M. Takeuchi, M. Fujii, K. Suzaki and H.

Finally, a maximum heat transfer coefficient for the Uehara, Experiments on natural convection heat trans-

fer from the outer surface of a vertical cylinder to liquids,

first set of coils (& = 0.12 m) was obtained at the

Int. J. Heat Mass Transfer 13,753-785 (1970).

critical diameter ratio of 14.4 when IV = 5 and 13.0 6. G. C. Vliet and C. K. Liu, An experimental study of

when N = 10. turbulent natural convection boundary layers, ASME J.

Heat Transfer 91,517-531 (1969).

7. L. C. Burmeister, Convective Heat Transfer, p. 543.

Acknowledgements-The author would like to acknowledge Wiley, New York (1983).

Professor Kamal El-Din Hassan for introducing the 8. F. Kieith, Principles of Heat Transfer, p. 335. Int. Text-

problem. The author also acknowledges the gracious hos- book Co.. Scranton. Pennsylvania (1958).

pitality of the Mechanical Engineering Department at the 9. W. H. h&Adams, Heat ?ransn&ion. McGraw-Hill,

University of Colorado at Boulder (U.S.A.) and especially New York (1954).

that of his host Professor Patrick D. Weidman for interesting 10. M. Fogiel, The Heat Transfer Problem Solver, p. 768.

discussion on the subject of this paper. REA, New York (1984).

View publication stats

You might also like

- Experimental Study of Natural Convection Heat Transfer From An EnclosedDocument8 pagesExperimental Study of Natural Convection Heat Transfer From An EnclosedAnonymous vVsidh3nNo ratings yet

- Natural Convection Heat Transfer From A Long Heated Vertical Cylinder To An Adjacent Air Gap of Concentric and Eccentric ConditionsDocument6 pagesNatural Convection Heat Transfer From A Long Heated Vertical Cylinder To An Adjacent Air Gap of Concentric and Eccentric ConditionskarthikeyanNo ratings yet

- Experimental Thermal and Fluid Science: Olivier Reymond, Darina B. Murray, Tadhg S. O'DonovanDocument8 pagesExperimental Thermal and Fluid Science: Olivier Reymond, Darina B. Murray, Tadhg S. O'DonovanEgwu Francis obinnaNo ratings yet

- Coiled flow inverter heat exchanger studyDocument11 pagesCoiled flow inverter heat exchanger studyJuan JerezNo ratings yet

- Paper 3Document9 pagesPaper 3edabunadaNo ratings yet

- Experimental Studies on Heat Transfer in Helical CoilsDocument13 pagesExperimental Studies on Heat Transfer in Helical CoilsAnonymous mXicTi8hBNo ratings yet

- 4 CylindersDocument13 pages4 CylindersParth PatpatiyaNo ratings yet

- Aljabair2020 ImporatantDocument12 pagesAljabair2020 ImporatantDjamila BENYOUCEFNo ratings yet

- International Journal of Heat and Mass Transfer: Y.G. Park, M.Y. Ha, J. ParkDocument22 pagesInternational Journal of Heat and Mass Transfer: Y.G. Park, M.Y. Ha, J. ParkEng-MustafaHathalAl-SaraiNo ratings yet

- Experimental Study of Heat Transfer To Flowing Air Inside A Circular Tube With Longitudinal Continuous and Interrupted FinsDocument16 pagesExperimental Study of Heat Transfer To Flowing Air Inside A Circular Tube With Longitudinal Continuous and Interrupted Finsvivek mishraNo ratings yet

- Transient Analysis of Natural Convection Around A Pair of Circul 2018Document13 pagesTransient Analysis of Natural Convection Around A Pair of Circul 2018weonNo ratings yet

- Natural Convection in A Cross-Fin Heat Sink - 2018Document8 pagesNatural Convection in A Cross-Fin Heat Sink - 2018RameshNo ratings yet

- Elliptical Kaam Se Exactly Milta HuaDocument13 pagesElliptical Kaam Se Exactly Milta HuaParth PatpatiyaNo ratings yet

- Experimental Thermal and Fluid Science: Yu Wang, Ya-Ling He, Yong-Gang Lei, Jie ZhangDocument9 pagesExperimental Thermal and Fluid Science: Yu Wang, Ya-Ling He, Yong-Gang Lei, Jie ZhangPrerak ShahNo ratings yet

- Forced Convection Heat Transfer Around Heated InclDocument8 pagesForced Convection Heat Transfer Around Heated InclweonNo ratings yet

- International Communications in Heat and Mass TransferDocument11 pagesInternational Communications in Heat and Mass TransferzermiNo ratings yet

- Heat Transfer Augmentation in Spirally Corrugated Coiled TubesDocument12 pagesHeat Transfer Augmentation in Spirally Corrugated Coiled TubesLuthfi AdyNo ratings yet

- Experimental Thermal and Fluid Science: C. Butler, D. Newport, M. GeronDocument10 pagesExperimental Thermal and Fluid Science: C. Butler, D. Newport, M. GeronAnkit PandaNo ratings yet

- Naphon 2005Document11 pagesNaphon 2005Amoul DhahriNo ratings yet

- Heat TransferDocument11 pagesHeat Transfersonia beziNo ratings yet

- 1 - Vertical Cylinder With Annular FinsDocument14 pages1 - Vertical Cylinder With Annular FinsMANISH SINGH IET Lucknow StudentNo ratings yet

- Eshita Pal 2016 Articulo 39Document27 pagesEshita Pal 2016 Articulo 39GiovanniRoblesZarateNo ratings yet

- An Experimental Study of Thermal Performance of Shell-And-coil Heat ExchangersDocument7 pagesAn Experimental Study of Thermal Performance of Shell-And-coil Heat ExchangersAbul Lais NalbandNo ratings yet

- Nano Fluid PDF (Research Paper)Document12 pagesNano Fluid PDF (Research Paper)Vicky SharmaNo ratings yet

- Experimental Thermal and Fluid Science: M.R. SalimpourDocument5 pagesExperimental Thermal and Fluid Science: M.R. Salimpourmartin sabusNo ratings yet

- International Journal of Heat and Mass Transfer: Yong Gap Park, Hyun Sik Yoon, Man Yeong HaDocument15 pagesInternational Journal of Heat and Mass Transfer: Yong Gap Park, Hyun Sik Yoon, Man Yeong HaEng-MustafaHathalAl-SaraiNo ratings yet

- Performance Enhancement of Shell and Helical Coil Water Coolers Using Different Geometric and Fins ConditionsDocument21 pagesPerformance Enhancement of Shell and Helical Coil Water Coolers Using Different Geometric and Fins ConditionssnehalNo ratings yet

- International Journal of Heat and Mass Transfer: Zi-Tao Yu, Xu Xu, Ya-Cai Hu, Li-Wu Fan, Ke-Fa CenDocument9 pagesInternational Journal of Heat and Mass Transfer: Zi-Tao Yu, Xu Xu, Ya-Cai Hu, Li-Wu Fan, Ke-Fa CenNarendra KumarNo ratings yet

- PergamonDocument6 pagesPergamonArchana SomanNo ratings yet

- Materials Today: Proceedings: Deep Chatterjee, Nirmal K. Manna, Nirmalendu BiswasDocument7 pagesMaterials Today: Proceedings: Deep Chatterjee, Nirmal K. Manna, Nirmalendu BiswasSayan DasNo ratings yet

- Natural Convection Heat Transfer On A Vertical C 2014 International JournalDocument8 pagesNatural Convection Heat Transfer On A Vertical C 2014 International JournalAnonymous vVsidh3nNo ratings yet

- Paper AcademicoDocument12 pagesPaper AcademicoVinicio ParraNo ratings yet

- International Communications in Heat and Mass Transfer: Goutam Saha, Manosh C. PaulDocument13 pagesInternational Communications in Heat and Mass Transfer: Goutam Saha, Manosh C. PaulAhmad Imam Rifa'iNo ratings yet

- Experimental Study of Turbulent Forced Convection Heat Transfer and FrictionDocument10 pagesExperimental Study of Turbulent Forced Convection Heat Transfer and FrictionGuilherme RighetoNo ratings yet

- Latent Heat-of-Fusion Energy Storage Experiments On Heat Transfer From Cylinders During MeltingDocument6 pagesLatent Heat-of-Fusion Energy Storage Experiments On Heat Transfer From Cylinders During MeltingGabriel SaavedraNo ratings yet

- Zheng Yang 2016Document14 pagesZheng Yang 2016Fábio A. BodnarNo ratings yet

- Paper 5Document13 pagesPaper 5edabunadaNo ratings yet

- Triangular PDFDocument10 pagesTriangular PDFhossein soltanipourNo ratings yet

- Nov Ijmte - AsDocument11 pagesNov Ijmte - AsSwapnil DeyNo ratings yet

- International Journal of Heat and Mass TransferDocument20 pagesInternational Journal of Heat and Mass TransferEng-MustafaHathalAl-SaraiNo ratings yet

- Dirk Er 2002Document22 pagesDirk Er 2002MArioNo ratings yet

- International Journal of Thermal Sciences: R. Nebbali, K. BouhadefDocument12 pagesInternational Journal of Thermal Sciences: R. Nebbali, K. BouhadefAbdelkaderNo ratings yet

- International Journal of Heat and Mass Transfer: Hui Han, Ya-Ling He, Yin-Shi Li, Yu Wang, Ming WuDocument10 pagesInternational Journal of Heat and Mass Transfer: Hui Han, Ya-Ling He, Yin-Shi Li, Yu Wang, Ming WuAnonymous 7BQxlt8cNo ratings yet

- Kung Jhang - 2014 - With Slot - ExperimentalDocument10 pagesKung Jhang - 2014 - With Slot - Experimentalsasanka sekhar mohantyNo ratings yet

- AIChE Journal - March 1968 - Evans - Transient Natural Convection in A Vertical CylinderDocument9 pagesAIChE Journal - March 1968 - Evans - Transient Natural Convection in A Vertical CylinderRajeshkumarNo ratings yet

- Method of Heat and Mass Transfer in Film Evaporation EnhancementDocument12 pagesMethod of Heat and Mass Transfer in Film Evaporation EnhancementSoha AsaNo ratings yet

- Heat Transfer in Packed BedsDocument10 pagesHeat Transfer in Packed BedsAdriano HenriqueNo ratings yet

- Helical Coil Heat Exchanger: Experimental Study of Heat TransferDocument60 pagesHelical Coil Heat Exchanger: Experimental Study of Heat TransferP K MisraNo ratings yet

- Trasferencia de CalorDocument16 pagesTrasferencia de CalorAnonymous yEArzu2BNo ratings yet

- Effect of Thermal Buoyancy On A Fluid Flowing Past A Pair of Side-By-Side Square Bluff-Bodies in A Low-Reynolds Number Flow RegimeDocument1 pageEffect of Thermal Buoyancy On A Fluid Flowing Past A Pair of Side-By-Side Square Bluff-Bodies in A Low-Reynolds Number Flow Regimeঅনিরুদ্ধ সান্যালNo ratings yet

- Wall Effects on Turbulent Flow and Heat Transfer in Tube BundlesDocument13 pagesWall Effects on Turbulent Flow and Heat Transfer in Tube BundlesMeshal Al-mutairiNo ratings yet

- 2022 CSTE IkramDocument11 pages2022 CSTE IkramRajeshwari Chitrangada Devi DasiNo ratings yet

- Numerical Simulation of A Cylindrical Heat Pipe and Performance StudyDocument7 pagesNumerical Simulation of A Cylindrical Heat Pipe and Performance StudypouriyaNo ratings yet

- Case Studies in Thermal Engineering: Ashkan AlimoradiDocument8 pagesCase Studies in Thermal Engineering: Ashkan Alimoradimohamed mostafaNo ratings yet

- 1 s2.0 S0017931013005772 MainDocument10 pages1 s2.0 S0017931013005772 MainWadï AmlalNo ratings yet

- Rufer Et Kezios - 1966 - Analysis of Two-Phase, One-Component Stratified FLDocument8 pagesRufer Et Kezios - 1966 - Analysis of Two-Phase, One-Component Stratified FLMartinNo ratings yet

- Agounoun1 2016Document8 pagesAgounoun1 2016El Idrissi MoulayNo ratings yet

- International Journal of Heat and Mass Transfer: Shou-Shing Hsieh, Chih-Yi LinDocument11 pagesInternational Journal of Heat and Mass Transfer: Shou-Shing Hsieh, Chih-Yi LinPankaj SinghNo ratings yet

- Heat and Fluid Flow in Power System Components: Hmt The Science & Applications of Heat and Mass TransferFrom EverandHeat and Fluid Flow in Power System Components: Hmt The Science & Applications of Heat and Mass TransferA. M. A. RezkNo ratings yet

- Advances in Heat Pipe Technology: Proceedings of the IVth International Heat Pipe Conference, 7-10 September 1981, London, UKFrom EverandAdvances in Heat Pipe Technology: Proceedings of the IVth International Heat Pipe Conference, 7-10 September 1981, London, UKNo ratings yet

- Workshop (03W 2205)Document152 pagesWorkshop (03W 2205)Евгений Губарев0% (2)

- Lesson 1 Cultural BackgroundDocument5 pagesLesson 1 Cultural BackgroundAngel Angeleri-priftis.No ratings yet

- VAPOR PRESSURE TESTER SETTINGSDocument22 pagesVAPOR PRESSURE TESTER SETTINGSKratos EspejoNo ratings yet

- OSI vs TCP/IP Communication Protocols ExplainedDocument33 pagesOSI vs TCP/IP Communication Protocols ExplainedKiran ZahraNo ratings yet

- Mr. RONAK J BHUVA's SBI account statement from 15-16 Dec 2021Document2 pagesMr. RONAK J BHUVA's SBI account statement from 15-16 Dec 2021Ronak BhuvaNo ratings yet

- Operational Risk Business Continuity Program Management in NYC Resume Laura WilsonDocument2 pagesOperational Risk Business Continuity Program Management in NYC Resume Laura WilsonLauraWilson2No ratings yet

- GTM Unix Prog Manual 4.4Document605 pagesGTM Unix Prog Manual 4.4maxedroomNo ratings yet

- Science Granting Councils Initiative (SGCI) in Sub-Saharan Africa-2019 Regional Meeting-Addis Ababa-EthiopiaDocument23 pagesScience Granting Councils Initiative (SGCI) in Sub-Saharan Africa-2019 Regional Meeting-Addis Ababa-EthiopiaSempiri Geoffery KasiwukiraNo ratings yet

- Calculation of The Theoretical Weight of SteelsDocument2 pagesCalculation of The Theoretical Weight of SteelshorascanmanNo ratings yet

- Oracle® Inventory: Consigned Inventory From Supplier Process Guide Release 12.1Document76 pagesOracle® Inventory: Consigned Inventory From Supplier Process Guide Release 12.1Guillermo ToddNo ratings yet

- Petro Refinery LLC Linear Programming ExerciseDocument12 pagesPetro Refinery LLC Linear Programming ExerciseNISHANT SINGH50% (2)

- Piping Isometrics ChecklistDocument2 pagesPiping Isometrics Checklistvniranjan100% (1)

- Vibration and Pulsation Analysis SolutionsDocument12 pagesVibration and Pulsation Analysis Solutions4jawwy markme026No ratings yet

- GEA31885 TM2500 Brochure PDFDocument8 pagesGEA31885 TM2500 Brochure PDFThanapaet RittirutNo ratings yet

- LUDV Control Block of Mono and Sandwich Plate Design Type M7-22Document16 pagesLUDV Control Block of Mono and Sandwich Plate Design Type M7-22W Morales100% (2)

- CV Tool and Die MakerDocument3 pagesCV Tool and Die MakerMohammed AseerNo ratings yet

- 382 All PDFDocument72 pages382 All PDFthanh nguyenNo ratings yet

- Transformers: Interpreting Nameplate Data and ConnectionsDocument13 pagesTransformers: Interpreting Nameplate Data and ConnectionsNaren BharadwajNo ratings yet

- 2G-3G-LTE - Priority Based Cell Reselection Strategy - 05012016Document12 pages2G-3G-LTE - Priority Based Cell Reselection Strategy - 05012016saifEEE010% (1)

- Octans 3000 To RTS Gen5Document1 pageOctans 3000 To RTS Gen5Leandro Pereira delfinoNo ratings yet

- Solution Manual of Theory of Machines by R S KhurmiDocument2 pagesSolution Manual of Theory of Machines by R S KhurmiJasim Almuhandis19% (88)

- BA 301 Final Exam QuestionsDocument14 pagesBA 301 Final Exam QuestionsJakeSimmonsNo ratings yet

- 1241 ID Pengaruh Sistem Informasi Manajemen Sim Terhadap Efektifitas Pengambilan KeputusDocument11 pages1241 ID Pengaruh Sistem Informasi Manajemen Sim Terhadap Efektifitas Pengambilan KeputustithaNo ratings yet

- DQT Tdqit Smarttech Case StudyDocument3 pagesDQT Tdqit Smarttech Case Studyjoedirte1No ratings yet

- Cache file structure and contentsDocument1 pageCache file structure and contentsHiruksha Yajeewa100% (1)

- TechRef StationController PDFDocument28 pagesTechRef StationController PDFAlexNo ratings yet

- Geiger Counter TutotialDocument3 pagesGeiger Counter Tutotialapi-248437787No ratings yet

- Eclectic IqDocument17 pagesEclectic IqriyanNo ratings yet