Professional Documents

Culture Documents

JO MSW Bypassing Critical Protections Standard

Uploaded by

cbatanaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JO MSW Bypassing Critical Protections Standard

Uploaded by

cbatanaCopyright:

Available Formats

JOSOP 407 — Bypassing Critical

Protections Standard

Approved 27 February 2008

Version 1.1.1.A Posted 30 March 2009

JO – Bypassing Critical Protections Standard

Table of Contents

1.0 Purpose, Objectives and Scope......................................................................................... 3

1.1 Purpose ...................................................................................................................... 3

1.2 Objective.................................................................................................................... 3

1.3 Scope ......................................................................................................................... 3

2.0 Requirements ..................................................................................................................... 3

3.0 Terms and Definitions ....................................................................................................... 4

4.0 Roles, Responsibilities and Training Requirements....................................................... 5

4.1 Initial Training ........................................................................................................... 5

4.2 Refresher Training ..................................................................................................... 6

5.0 Standard Instructions ....................................................................................................... 6

5.1 Bypassing Steps ......................................................................................................... 6

5.2 Assessing and Managing Hazards ............................................................................. 6

5.3 Bypass Administration and Controls ......................................................................... 7

5.3.1 Layers of Protection ......................................................................................... 7

5.3.2 Minimizing Personnel and Critical Protection Devices in Bypass at Any One

Time ................................................................................................................. 7

5.3.3 Identifying Bypassed Critical Protection Devices ........................................... 7

5.3.4 Monitoring of Operating Conditions/Parameters............................................. 8

5.4 Monitoring and Audit ................................................................................................ 9

6.0 Records ............................................................................................................................. 10

6.1 Required Records .................................................................................................... 10

6.2 Retention Requirements .......................................................................................... 10

7.0 References ........................................................................................................................ 10

8.0 Other Guidance Documents ........................................................................................... 10

9.0 Document Control ........................................................................................................... 10

Appendix A: JO Critical Protection Bypass Register .......................................................... 12

Appendix B: JO Critical Protections Bypass Audit Sheet ................................................... 13

ii Version 1.1.1.A Posted 30 March 2009.

Printed 15 August 2013. Uncontrolled when printed.

JOSOP407JO_MSW_BypassingCriticalProtectionsStandard(updated).doc

JO – Bypassing Critical Protections Standard

1.0 Purpose, Objectives and Scope

1.1 Purpose

The purpose of this standard is to ensure that bypassing of critical protections is

performed in a safe and controlled manner.

1.2 Objective

This standard establishes the requirements for the safe performance of the necessary

bypassing of critical protections.

NOTE: Each Global Upstream strategic business unit (SBU) or location may have

additional regulatory requirements.

1.3 Scope

This Bypassing Critical Protection Standard covers work performed by JO employees

and their delegates and contractors within JO operational control.

This standard is applicable to plant/platform critical protective devices or systems where

it is possible to apply a hardware or software bypass, force, inhibit, override, or their

electrical equivalent.

This standard does not apply to the following:

• When the purpose of the bypass is for Lockout/tagout. For lockout/tagout, please

see JO – Isolation of Hazardous Energy Standard.

• “Startup overrides” designed with automatic removal after a specified time delay

• Permanent bypasses, the application of bypasses that change the basis of design as

it relates to safety and/or critical protections that are already properly isolated, must

be managed under the JO - Management of Change Process and/or the JO -

Isolation of Hazardous Energy Standard.

NOTE: This system is not intended to replace the Isolation of Hazardous Energy

Standard. However, on occasion it may be used in conjunction with the Isolation of

Hazardous Energy Standard.

2.0 Requirements

1. Personnel involved in the authorization, approval, and implementation of

bypassing critical protections shall be trained and competent in the roles for which

they are responsible.

2. Hazards involved with bypassing critical protections for maintenance or testing,

planned or unplanned, must be assessed, and alternative protections must be

identified.

3. Bypassing, isolating, or removing critical protections during upset/abnormal

operating conditions in order to maintain production is strictly forbidden.

4. Only a minimum number of critical protective devices shall be bypassed at a time.

There shall be at least one other layer of protection whenever a critical protection is

on bypass.

5. Facility management shall conduct periodic audits and verifications to ensure

compliance to this standard.

Version 1.1.1.A Posted 30 March 2009. 3

Printed 15 August 2013. Uncontrolled when printed.

JOSOP407JO_MSW_BypassingCriticalProtectionsStandard(updated).doc

JO – Bypassing Critical Protections Standard

3.0 Terms and Definitions

The following terms and definitions apply to the JO – Safe Work Practice (SWP) –

Bypassing Critical Protections:

Bypass - To temporarily block out, isolate, override, inhibit, force, jumper, or disable a

device or system so that it will not perform its designed function for the purpose of

testing, maintenance and startup.

NOTE: For the purpose of this standard, the words “bypass,” “isolate,” “override,”

“inhibit,” “force,” “jumper,” “block,” “disable” or any other term used to describe the

temporary act of disabling a critical protective device or system have the same meaning.

Critical Protections - Devices or systems designed to protect personnel, the

environment, process, equipment and properties from an undesirable event. Functional

critical protections are a vital component of safety systems. They are designed and

installed to ensure safe, reliable and environmentally sound operations. Critical

protections consist of hardware and software which include, but are not limited to, the

following:

• Shutdown devices or systems such as Pressure Safety Low Low (PSLL), Pressure

Safety High High (PSHH), Emergency Shutdown (ESD) valves, etc.

• Fire and gas detection and fire suppression devices such as fire pumps, deluge

systems, fusible loops, CO2 fire extinguishing systems, etc.

• Pressure Safety Valve (PSV), Blowdown Valve (BDV) and associated valves

• Safety critical manual valves that are (normally) locked open or closed

• Equipment safeguards, overspeed trip, fired equipment flame detectors and similar

safety systems

Effective Monitoring - Effective monitoring is, in effect, taking the place of the critical

protections. An individual must be able to manually provide the same level of protection

as the bypassed critical protection(s) in a timely manner in order to prevent an

undesirable event. (Leaving the area for breaks, parts, supplies or tools would

compromise effective monitoring.)

Flag/Tag - A hanging, removable placard that identifies the status of a critical protection

device. Tags should only be used on bypassed or temporarily out-of-service devices or

components.

In-Service - The device or component is performing its designed function.

Layers of Protection (LOPs) or Lines of Defense (LODs) - Measures for prevention

and mitigation of major accidents. These LOPs serve either to prevent an initiating event

from developing into an incident, or to mitigate the consequences of an incident once it

occurs.

Maintenance - Adjustments or repairs, typically for a short duration (e.g., 15 minutes),

that can be performed without compromising effective monitoring.

Out-of-Service - A device or component is out-of-service (OOS) when it is not being

used to perform its intended function, and it is properly isolated by the use of the JO

Isolation of Hazardous Energy SWP standard.

4 Version 1.1.1.A. Posted 30 March 2009.

Printed 15 August 2013. Uncontrolled when printed.

JOSOP407JO_MSW_BypassingCriticalProtectionsStandard(updated).doc

JO – Bypassing Critical Protections Standard

Properly Isolated Protection - Protective devices or systems that are properly isolated

or disconnected by means of positive isolation; for example, a blind flange to prevent

transfer or communication of any fluids.

Qualified Person - A person who has successfully completed a production safety system

training program and who is familiar with the site-specific monitoring procedures of that

facility. Any person who has not received the required training must be directly

supervised by a qualified person when engaged in installing, testing, inspecting, flagging,

bypassing, monitoring or maintaining critical protections.

Remote Site - Satellite or subordinate offshore platform that is not bridge-connected to

the parent facility, or an onshore site that is controlled remotely by its parent facility

using SCADA (Supervisory Control and Data Acquisition).

Remote Monitoring - Monitoring of operating parameters on a remote site by a

qualified person at a central location by means of a telecommunications system such as

SCADA.

Startup - The period of time required for the production process to stabilize while

resuming normal operations.

Testing - The process of validating the set point and/or functionality of a device or

system.

Temporarily Out-of-Service - A component is temporarily out-of-service when it is in

standby, shutdown or not-in-use mode, but when needed, can easily be returned to

service. These components are NOT isolated from production facilities.

4.0 Roles, Responsibilities and Training Requirements

There must be clearly defined roles, and personnel must meet the training and

competency requirements of this standard prior to starting work. JO is responsible for

establishing the methodology to achieve competence.

When selecting personnel for these positions, consideration should be given to their level

of experience and their past performance.

The following roles and responsibilities are specific to Bypassing Critical Protections

and are further defined in the JO –Training Requirements Tool:

• Qualified Person

Ensure effective monitoring and layers of protection are in place when bypassing systems

Monitoring of operating parameters on a remote site

Utilize management of change process when appropriate

May participate in hazard analysis and identification of controls to be implemented to eliminate or

minimize risk

Partakes in post-job debrief if required

Ensures competent personnel perform required functions

Stops the work if unsafe conditions develop

For updates refer to JO_MSW_TrainingRequirementsTool.doc

4.1 Initial Training

Personnel must meet the competency requirements of this standardized safe work

practice prior to starting work. Refer to the JO – Training Requirements Tool.

Version 1.1.1.A Posted 30 March 2009. 5

Printed 15 August 2013. Uncontrolled when printed.

JOSOP407JO_MSW_BypassingCriticalProtectionsStandard(updated).doc

JO – Bypassing Critical Protections Standard

4.2 Refresher Training

Refresher training must be provided as follows:

• As required by applicable regulations or JO policy

• As needed when identified by verification, inspections, incidents or audits.

5.0 Standard Instructions

When considering work that involves bypassing critical protection devices, always

consider whether there is a viable alternative to performing a bypass while equipment,

operations or process is shut down.

5.1 Bypassing Steps

The following steps should be followed when placing a critical protection device in

bypass:

1. Identify critical protection devices to be temporarily bypassed

2. Obtain approval to bypass devices

3. Flag devices to be bypassed

4. Perform bypass

5. Monitor the bypassed or blocked-out functions

6. Complete startup, shutdown, operation, maintenance, or testing activities

7. Return critical protective device or system to normal service, and verify

functionality

8. Check/verify work completion and notify affected personnel before removing the

bypasses and flags

5.2 Assessing and Managing Hazards

Bypassing critical protections must be managed in accordance with the JO – Managing

Safe Work Process and the JO Permit to Work Standard.

NOTE: For longer term bypasses, the JO – Isolation of Hazardous Energy Standard

and JO – Management of Change Process should be consulted.

A hazard analysis shall be conducted to assess the potential consequences and effects

prior to the application of bypasses, inhibits/overrides, force, or disable. This includes

the use of any bypass that is required for plant startup that does not time out or that

reverts to a live state when the plant returns to normal operating condition.

A hazard analysis that has previously been used for this purpose may be used again,

providing it has been reviewed, updated and signed off as current.

A completed hazard analysis may indicate that the override, inhibit or force may not

safely be applied, or that further, detailed hazard analysis is required in consultation with

other subject matter experts (SMEs).

6 Version 1.1.1.A. Posted 30 March 2009.

Printed 15 August 2013. Uncontrolled when printed.

JOSOP407JO_MSW_BypassingCriticalProtectionsStandard(updated).doc

JO – Bypassing Critical Protections Standard

5.3 Bypass Administration and Controls

5.3.1 Layers of Protection

Layers of protection shall be considered before bypassing any critical protection device

or system. The minimum number of layers of protection for any initiating event at any

time must be maintained when bypassing critical protection devices or systems.

The hierarchy of the layer of protection must start with the design (inherent safety).

Assuming the design of the equipment meets JO standards, the next layer of protection to

be considered is control.

5.3.2 Minimizing Personnel and Critical Protection Devices in

Bypass at Any One Time

Only the minimum number of critical protection devices shall be bypassed at any one

time.

The number of personnel who monitor protection devices in lieu of automatic protection

shall be kept to an absolute minimum. Any person asked to perform the function of a

critical protection device while that protective device is in bypass shall know and

understand the procedures regarding this type of monitoring.

If the requirements of section 5.2 Assessing and Managing Hazards are met, protective

devices or systems may be bypassed to allow startup, maintenance or testing tasks to be

performed.

Although it may be convenient to override extra critical protection devices to

prevent nuisance shut-ins or to use “group override,” use of such group devices is

not permitted.

As soon as the task is completed, the protection device must be placed back in service.

Remove the flag/tag and notify the affected personnel.

5.3.3 Identifying Bypassed Critical Protection Devices

Critical protection devices that have been bypassed must be identified by a bypass flag or

tag at the bypass or isolation point.

JO/facility shall identify bypassed critical protection devices or systems by a minimum

of two identification methods. Two of these three may be used in any combination:

bypass register, flagging, and/or bypass display board.

Critical protection devices and systems which are temporarily out of service shall be

tagged “temporarily out of service.” These flags or tags shall be fitted to the devices

being bypassed where they are located, such as at the local control panel, isolation valve,

etc.

The purpose of a flag or tag is to be a visual reminder/alert to personnel that a critical

protection is in bypass.

5.3.3.1 Personal Tags

A sufficient number of bypass flags/tags shall be provided to each qualified person.

These flags/tags should be accounted for at the end of each work shift. This

requirement has the following benefits:

• Provides immediate availability of flags/tags

• Provides built-in compliance so that only a minimum number of devices may

be bypassed

Version 1.1.1.A Posted 30 March 2009. 7

Printed 15 August 2013. Uncontrolled when printed.

JOSOP407JO_MSW_BypassingCriticalProtectionsStandard(updated).doc

JO – Bypassing Critical Protections Standard

• Serves as a reminder to the qualified person to review the day’s work and

account for flagged devices placed on bypass

5.3.3.2 Bypass Tag Display Board

Bypass tag display board(s) may be used as another means of control and

communication. The board should be located at each facility in the control room or at

the panels, whichever location is deemed more effective by the workgroup.

The bypass tag display board provides the following advantages:

• Flags are readily accessible any time a critical protection device or system

needs to be bypassed.

• Tag display boards visually alert personnel that a critical protection device or

system is on bypass if a flag/tag is missing from its hanger.

• The tag display board serves as a reminder to personnel to review the day’s

work and to account for flagged critical protection devices or systems placed

on bypass.

5.3.3.3 Bypass Register

Bypass register(s) may be used as another means of control and communication. The

register should be located at each facility in the control room or at the panels,

whichever location is deemed more effective by the work group. A sample bypass

register is provided in Appendix A: JO Critical Protection Bypass Register.

The bypass register provides the following advantages:

• The register serves as a reminder to personnel to review the day’s work and to

account for flagged critical protection devices or systems placed on bypass.

5.3.3.4 Secondary Flagging

A secondary flagging device shall be installed on the front of an auxiliary control

panel so that it is clearly visible if the condition or operating mode of a bypassed

critical protection device cannot easily be seen (i.e., devices/isolation valves are

inside a control panel, slave panels, plugged relay ports, on a boat landing ESD, etc.).

5.3.4 Monitoring of Operating Conditions/Parameters

5.3.4.1 Site-Specific Monitoring

Any critical protection device on a piece of equipment that does not have an equal

and redundant device to detect the same condition shall be continually monitored by

a qualified person(s) at the location while the device is in bypass.

When a qualified person is monitoring a bypassed critical protection device, he or she

is taking the place of the critical protection device, and must be able to manually

provide the same level of protection as the critical protection device in a timely

manner to prevent an undesirable event. Qualified personnel shall monitor the

bypassed or blocked-out functions until the critical protection device or system is

placed back in service.

The area controller at the location shall determine the process, procedures, and

number of personnel required to provide effective monitoring for each critical

protection device or system that is placed in bypass. Effective monitoring can be

conducted by one individual on more than one critical protection device in the same

8 Version 1.1.1.A. Posted 30 March 2009.

Printed 15 August 2013. Uncontrolled when printed.

JOSOP407JO_MSW_BypassingCriticalProtectionsStandard(updated).doc

JO – Bypassing Critical Protections Standard

general area, provided the person can freely move around the general area of

production equipment and effectively monitor more than one process simultaneously.

Qualified persons who are bypassing critical protection devices or systems will be

responsible for answering the following questions:

• What is the process variable to be monitored?

• What device will be used to monitor the process variable?

• How will the process be controlled?

• At what point must the qualified person react to prevent an undesirable event?

• Will this procedure provide the same level of protection as the critical

protection device?

• How many people are required to effectively monitor the bypassed

system/equipment?

NOTE: It is not necessary to monitor the bypassed critical protection device or

system function which has been placed out-of-service. However, the pressure safety

valve on any out-of-service component must be left in service, maintained, and tested

in accordance with company policy or applicable regulatory requirements.

5.3.4.2 Remote Monitoring

On some occasions, there may be a need to bypass critical protection devices or

systems, and monitor the operating parameter using the Supervisory Control and

Data Acquisition (SCADA) system. The only time that bypassed critical protection

devices or systems may be remotely bypassed and monitored is when all of the

following conditions are met:

• The SCADA control operator must place the critical protection device or

system on bypass only as part of a reset or startup activity.

• Radio communications must be maintained at all times between the person at

the remote location and the SCADA control operator.

• The SCADA control operator may only monitor a minimum number of critical

protection devices. If multiple critical protection devices or systems are to be

monitored, the SCADA control operator must be able to view the appropriate

data on one SCADA screen.

• The bypassed critical protection device or system must be returned to service

immediately after it has been cleared and the process has stabilized.

• Remote monitoring of mechanically disabled critical protection devices or

systems (e.g., “pinning” a pneumatic relay) is not allowed.

• Other site-specific guidelines may be required. These should be documented

and maintained at the remote control facility.

5.4 Monitoring and Audit

Routine monitoring and auditing shall be conducted to ensure that this standard is being

applied properly.

The supervisor responsible for the work area shall monitor and conduct periodic audits to

review the integrity of the bypassing procedure. Appendix B: JO Critical Protections

Bypass Audit Sheet may be used.

Version 1.1.1.A Posted 30 March 2009. 9

Printed 15 August 2013. Uncontrolled when printed.

JOSOP407JO_MSW_BypassingCriticalProtectionsStandard(updated).doc

JO – Bypassing Critical Protections Standard

6.0 Records

6.1 Required Records

The following records will be kept:

• Copies of permits and associated documentation shall be maintained in accordance

with the JO Permit to Work Standard.

6.2 Retention Requirements

Documentation shall be retained as required by local regulation, JO policy, or for a

minimum of six months, whichever is greater.

7.0 References

Table 1. Document List

Title File Name

JO – Training Requirements Tool JO_MSW_TrainingRequirementsTool.doc

JO – Isolation of Hazardous Energy Standard JO_MSW_IsolationofHazardousEnergy

Standard.doc

8.0 Other Guidance Documents

Table 2. Document List

Title File Name

American Petroleum Institute (API) American Petroleum Institute (API)

Recommended Practice (RP) 14-C, Safety

Analysis for Production Platforms

9.0 Document Control

Table 1: Document Control Information

Description GU Common SBU-Specific

Approval Date 27 February 2008 17 December 2008

10 Version 1.1.1.A. Posted 30 March 2009.

Printed 15 August 2013. Uncontrolled when printed.

JOSOP407JO_MSW_BypassingCriticalProtectionsStandard(updated).doc

JO – Bypassing Critical Protections Standard

Description GU Common SBU-Specific

Next Revision Due 27 February 2011 17 December 2011

Control Number

Table 2: Document History

Version Date Notes

Number

1.0 27 February 2008 Initial Release

1.1 8 December 2008 Added bookmarks for OE Mentor

1.1.1 17 December SAC Adoption of MSW

2008

1.1.1.A 30 March 2009 JO Version Created

Version 1.1.1.A Posted 30 March 2009. 11

Printed 15 August 2013. Uncontrolled when printed.

JOSOP407JO_MSW_BypassingCriticalProtectionsStandard(updated).doc

JO – Bypassing Critical Protections Standard

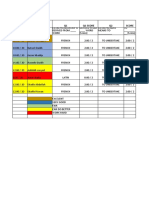

Appendix A: JO Critical Protection Bypass Register

Date Time Operator On Tag Description Reason for Bypass Date Back in Time Back in Operator on

Bypassed Bypassed Duty Number Service Service Duty

For Shift Handover:

I have reviewed and confirmed that this Bypass Register is correct and current.

Outgoing shift responsible person - Name: ___________________________ Signature: ____________________Date:___________ Time: ______________

Incoming shift responsible person - Name: ___________________________ Signature: ____________________Date:___________ Time: _____________

12 Version 1.1.1.A. Posted 30 March 2009.

Printed 15 August 2013. Uncontrolled when printed.

JOSOP407JO_MSW_BypassingCriticalProtectionsStandard(updated).doc

JO - Bypassing Critical Protections

Appendix B: JO Critical Protections Bypass Audit Sheet

TOTAL NUMBER OF BYPASSES/INHIBITS/OVERRIDES BYPASSES/ OVERRIDES

AT TIME OF AUDIT INHIBITS

Comments

(Mandatory where answer is No)

Is the Bypass/Inhibit/Override classified correctly? Yes/No

Is the Bypass/Inhibit/Override Hazard Analysis completed and Yes/No

documented correctly?

Was the appropriate level of authorization given before allowing Yes/No

bypass to take place?

Do the Bypass/Inhibit/Override Registers reflect the true Yes/No

equipment inhibit status and correctly reflect the status of the

Hazard Analysis forms?

Are identified additional control measures in place? Yes/No

Have actions to be taken in the event of a genuine trip/alarm on Yes/No

the device inhibited/overridden been identified?

Are bypassed devices or systems properly flagged or tagged? Yes/No

Are inhibits/overrides that have been removed correctly signed Yes/No

off?

Did outgoing shift and incoming shift review and sign off Bypass Yes/No

Register?

Identify any inhibits/overrides that are continually in use or frequently installed and request engineering support

for a solution.

Remedial actions required:

General comments:

Audited by (Print Name): Signature: Time: Date:

NOTE: Attach photocopies of relevant documents as appropriate.

Version 1.1.1.A. Posted 30 March 2009. 13

Printed 15 August 2013. Uncontrolled when printed.

JOSOP407JO_MSW_BypassingCriticalProtectionsStandard(updated).doc

You might also like

- BD Solutions PDFDocument31 pagesBD Solutions PDFLoya Yang100% (3)

- 01.-Panel Descarga 4004R (579-354)Document102 pages01.-Panel Descarga 4004R (579-354)Carlos Talivento Andrade100% (3)

- Landscape Composition Lite by Mads Peter IversenDocument25 pagesLandscape Composition Lite by Mads Peter IversenEduar Osorno100% (2)

- Durabilt 5MV TGEH-6685Document78 pagesDurabilt 5MV TGEH-6685Luis Cordoba0% (1)

- Studio 5000 Logix Designer Advanced Lab ManualDocument280 pagesStudio 5000 Logix Designer Advanced Lab ManualOtávio Martins100% (1)

- SMC Flex User ManualDocument140 pagesSMC Flex User ManualjoaoNo ratings yet

- ASCO RCS-Safety-ManualV9535R2x PDFDocument22 pagesASCO RCS-Safety-ManualV9535R2x PDFpaul_brightNo ratings yet

- Isolation LOTO Procedure V1 0Document14 pagesIsolation LOTO Procedure V1 0Aceel Fitch100% (2)

- A Feasibility Study of Using Two-Component Polyurethane Adhesive in PDFDocument6 pagesA Feasibility Study of Using Two-Component Polyurethane Adhesive in PDFALINo ratings yet

- SWP Bypassing Critical Protections GuidelinesDocument10 pagesSWP Bypassing Critical Protections Guidelinesesakkiraj1590100% (1)

- KMS-0024 Fusesaver Control Panel - Type 1 Operating Instructions R05Document28 pagesKMS-0024 Fusesaver Control Panel - Type 1 Operating Instructions R05jean alvesNo ratings yet

- L13 - Studio 5000® and Logix Advanced Lab: For Classroom Use Only!Document216 pagesL13 - Studio 5000® and Logix Advanced Lab: For Classroom Use Only!cuongvcs100% (1)

- Procedimiento de Trabajo Seguro para ExcavacionesDocument10 pagesProcedimiento de Trabajo Seguro para ExcavacionesJeduardo Ch-mezaNo ratings yet

- Ai 5303 Tips05 SIEMENS ManualDocument34 pagesAi 5303 Tips05 SIEMENS ManualrogeriolucenaNo ratings yet

- Test Frame User GuideF0435F24EC43Document26 pagesTest Frame User GuideF0435F24EC43Francisco PestañoNo ratings yet

- 579-989 - Installation Guide 4010ESDocument112 pages579-989 - Installation Guide 4010ESLuis Garcia NoriegaNo ratings yet

- Introduction To Safety SystemsDocument24 pagesIntroduction To Safety SystemsThiyagarajan SankaranNo ratings yet

- HES203 - Isolation of Hazardous Energy Standard PDFDocument32 pagesHES203 - Isolation of Hazardous Energy Standard PDFmahdi_gNo ratings yet

- IBU Work at HeightDocument28 pagesIBU Work at HeightAndrianto BakriNo ratings yet

- 320Document22 pages320Muneendra SharmaNo ratings yet

- Controller Setting Kit Software (ACT Controller) : Product NameDocument33 pagesController Setting Kit Software (ACT Controller) : Product NameCesar ChaconNo ratings yet

- Fall UseGuide-2015 PDFDocument29 pagesFall UseGuide-2015 PDFAbdel Nasser Al-sheikh YousefNo ratings yet

- Hướng dẫn sử dụng thiết bị đo lưu lượng gió Testo 420Document26 pagesHướng dẫn sử dụng thiết bị đo lưu lượng gió Testo 420Testo Việt NamNo ratings yet

- ThinManager Basics LabDocument151 pagesThinManager Basics Labvõ cường100% (1)

- Explosion Suspension SystemDocument19 pagesExplosion Suspension SystemMohamed AAmerNo ratings yet

- Somachine Basic Example Guide: Importing Twido Drive Macros To M221 Xsample - Twido - Macro - Drive - Conversion - SmbeDocument42 pagesSomachine Basic Example Guide: Importing Twido Drive Macros To M221 Xsample - Twido - Macro - Drive - Conversion - SmbeMagda DiazNo ratings yet

- PRO 4 5 0001 1 02-Energy-IsolationDocument23 pagesPRO 4 5 0001 1 02-Energy-IsolationNOUREDINENo ratings yet

- Lesson 7 Control of Hazardous Energy: 10 Hour OSHA ConstructionDocument29 pagesLesson 7 Control of Hazardous Energy: 10 Hour OSHA ConstructionCarlos LopézNo ratings yet

- Testo Probes A700000008644025Document50 pagesTesto Probes A700000008644025americo vazNo ratings yet

- Cis WSH Cetsp27 114797 7Document77 pagesCis WSH Cetsp27 114797 7naveedNo ratings yet

- SIS-OW351 - 45 - Ovation SIS Safety ManualDocument37 pagesSIS-OW351 - 45 - Ovation SIS Safety ManualRicardas KragnysNo ratings yet

- Sifang - csc-211 Multifunction Protection Ied Manual (Fosf.451.152e) - v1.00Document48 pagesSifang - csc-211 Multifunction Protection Ied Manual (Fosf.451.152e) - v1.00MarkusKunNo ratings yet

- Sargas-Pj1 FSM en RFLP 250915Document150 pagesSargas-Pj1 FSM en RFLP 250915william lozadaNo ratings yet

- EI-LOTO Written Program Final-REV 06-01-2016Document51 pagesEI-LOTO Written Program Final-REV 06-01-2016AnilNo ratings yet

- Instruction Manual: SK-H SeriesDocument12 pagesInstruction Manual: SK-H SeriesDbxbxn CbdnfnNo ratings yet

- Ultrasil™ Polymer-Housed Varistar™ Surge Arrester Iec 60099-4 For MV Systems To 36 KV Installation InstructionsDocument8 pagesUltrasil™ Polymer-Housed Varistar™ Surge Arrester Iec 60099-4 For MV Systems To 36 KV Installation InstructionsNguyen Anh TuNo ratings yet

- Ns Tast GD 003Document40 pagesNs Tast GD 003cbatanaNo ratings yet

- GF Pre Acp DNP3 EngDocument164 pagesGF Pre Acp DNP3 EngEduardo CampoverdeNo ratings yet

- 975 Uf Uvir Manual Del UsuarioDocument84 pages975 Uf Uvir Manual Del Usuariojose roberto reyes reyesNo ratings yet

- SA R7 Service Manual Rev3.0 ENGDocument216 pagesSA R7 Service Manual Rev3.0 ENGcezary.klosowski.marmedNo ratings yet

- Lockout Tagout Program June 2003Document9 pagesLockout Tagout Program June 2003labn7No ratings yet

- CopieDocument62 pagesCopieYacine BoumertitNo ratings yet

- LOTO Policy Template - Go To File - Download To EditDocument19 pagesLOTO Policy Template - Go To File - Download To EdithamidsohailNo ratings yet

- Asco Pilot Valve Operating ManualDocument7 pagesAsco Pilot Valve Operating ManualSankar SasmalNo ratings yet

- 200 A, 15 and 25 KV Class Loadbreak Bushing Insert S500121Document8 pages200 A, 15 and 25 KV Class Loadbreak Bushing Insert S500121Roberto CedilloNo ratings yet

- Aoralscan 2 - User Manual - V1.0.0.30Document118 pagesAoralscan 2 - User Manual - V1.0.0.30Bagus Nenda WijayaNo ratings yet

- E-C.2.4-HQ-PRO-001 Process and Mechanical Valving and Isolation PhilosophyDocument16 pagesE-C.2.4-HQ-PRO-001 Process and Mechanical Valving and Isolation Philosophyagaricus100% (2)

- 501 2012 6 28 27 39 561Document26 pages501 2012 6 28 27 39 561MITHILESH KUMARNo ratings yet

- 20 Autopulse Z-10Document89 pages20 Autopulse Z-10zayagoraNo ratings yet

- SO Safety Manual F300K DLT7663 19 AEN 003Document22 pagesSO Safety Manual F300K DLT7663 19 AEN 003Ali JamaliNo ratings yet

- SIFANG CSC-101 - V1.20 - Numerical EHV Transmission Line Protection Equipment Manual - 2014-01Document115 pagesSIFANG CSC-101 - V1.20 - Numerical EHV Transmission Line Protection Equipment Manual - 2014-01MarkusKunNo ratings yet

- Form 6 Microprocessor-Based Recloser Control Automatic Source Transfer (AST) Application InstructionsDocument44 pagesForm 6 Microprocessor-Based Recloser Control Automatic Source Transfer (AST) Application InstructionsRachmad Adi WidodoNo ratings yet

- Paxprimo Vatech Installation CablesDocument72 pagesPaxprimo Vatech Installation CablesJoseluis MoralesNo ratings yet

- SUNGROW SG320 - 350HX User Manual enDocument127 pagesSUNGROW SG320 - 350HX User Manual enJhossaffMackenzieNo ratings yet

- Perating Nstructions: Movitrac B KeypadDocument32 pagesPerating Nstructions: Movitrac B Keypaddrdmg22No ratings yet

- DroppedObjectsPreventionStandard - Eng 05 05 17 PDFDocument15 pagesDroppedObjectsPreventionStandard - Eng 05 05 17 PDFAndrew LiddellNo ratings yet

- FT Historian IN11Document100 pagesFT Historian IN11Uriel Lv100% (1)

- NK-O3 Safety Manuals (Rev.1)Document18 pagesNK-O3 Safety Manuals (Rev.1)greatenick.nbNo ratings yet

- Quick Reference Guide Kurzanleitung Instruction de Service Guía de Referencias Rápidas Guida Di Riferimento RapidoDocument402 pagesQuick Reference Guide Kurzanleitung Instruction de Service Guía de Referencias Rápidas Guida Di Riferimento RapidoRoger RiveroNo ratings yet

- Lockout Tagout Program: University of WashingtonDocument12 pagesLockout Tagout Program: University of WashingtonVictorNo ratings yet

- Process IsolationDocument13 pagesProcess IsolationBhuran AkshayNo ratings yet

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- TD3 AutoDocument2 pagesTD3 AutocbatanaNo ratings yet

- 11 Champs MaturesDocument73 pages11 Champs MaturescbatanaNo ratings yet

- Ns Tast GD 003Document40 pagesNs Tast GD 003cbatanaNo ratings yet

- Gs36j40b20-01en - 002 SFM R302Document4 pagesGs36j40b20-01en - 002 SFM R302cbatanaNo ratings yet

- Pedagogical Practice in Teaching - Learning Mathematics in Secondary in School LevelDocument8 pagesPedagogical Practice in Teaching - Learning Mathematics in Secondary in School LevelapfgNo ratings yet

- M.Arch Synopsis Structure PDFDocument5 pagesM.Arch Synopsis Structure PDFTeja VedulaNo ratings yet

- DESIGNDocument29 pagesDESIGNerick kazindukiNo ratings yet

- Biovia Materials Studio Dmol: DatasheetDocument3 pagesBiovia Materials Studio Dmol: DatasheettonymailinatorNo ratings yet

- Batch 3 UnescoDocument27 pagesBatch 3 UnescoHeaven Diaz100% (1)

- Springer Reassessing European Impressions of Indian AstronomyDocument7 pagesSpringer Reassessing European Impressions of Indian AstronomyAnkur KakkarNo ratings yet

- Signal Estimation & Detection TheoryDocument6 pagesSignal Estimation & Detection TheoryMANISH TIWARINo ratings yet

- Review Article Tracing The Recorded History of ThiDocument61 pagesReview Article Tracing The Recorded History of ThiPreparaduriasFisicaMatematicaNo ratings yet

- Unisonic Technologies Co., LTD: 9A, 700V N-CHANNEL Power MosfetDocument4 pagesUnisonic Technologies Co., LTD: 9A, 700V N-CHANNEL Power MosfetJoshi Joseph JoyNo ratings yet

- Physical Science SHS Lesson 14.4 Models of The UniverseDocument23 pagesPhysical Science SHS Lesson 14.4 Models of The UniverseJoy DolorosaNo ratings yet

- CMC Chapter 03Document59 pagesCMC Chapter 03api-294176229No ratings yet

- D & E - Module 4Document43 pagesD & E - Module 4vivekNo ratings yet

- Notes & Notes: Biostatistics & EBMDocument35 pagesNotes & Notes: Biostatistics & EBMamhhospital0No ratings yet

- HIC SEA IV - Delegate ProspectusDocument12 pagesHIC SEA IV - Delegate ProspectusNguyễn Hồng PhượngNo ratings yet

- Angl 5Document24 pagesAngl 5Latika ChoudhuryNo ratings yet

- SYM Starter U04 OSEWorksheetDocument4 pagesSYM Starter U04 OSEWorksheetCarolinaNo ratings yet

- Spring 2018 Graduate Course Descriptions - 0Document25 pagesSpring 2018 Graduate Course Descriptions - 0IvanNo ratings yet

- Book Report Project GuidelinesDocument2 pagesBook Report Project GuidelinesArmando Jose Medina MirandaNo ratings yet

- Energy Tech - 2016 - WesterhoffDocument11 pagesEnergy Tech - 2016 - WesterhoffMario CastilloNo ratings yet

- Journal of Pharmaceutical Sciences: Naseem Ahmad Charoo, Mark Durivage, Ziyaur Rahman, Mohamad Haitham AyadDocument6 pagesJournal of Pharmaceutical Sciences: Naseem Ahmad Charoo, Mark Durivage, Ziyaur Rahman, Mohamad Haitham Ayadmehrdarou.qaNo ratings yet

- Daily Lesson PlanDocument15 pagesDaily Lesson PlanNur MaizanNo ratings yet

- Entrepreneurship Development Test 2 Assessment SheetDocument7 pagesEntrepreneurship Development Test 2 Assessment SheetHaseeb ShaikhNo ratings yet

- The Cement Industry in EthiopiaDocument7 pagesThe Cement Industry in EthiopiaTesfaye Azanie1No ratings yet

- Causes of Decay of BuildingsDocument20 pagesCauses of Decay of Buildingsthrigya myakalaNo ratings yet

- Iso 3745 2012 en PDFDocument11 pagesIso 3745 2012 en PDFMARIO ALBERTO MANILLA CORDOBANo ratings yet

- Shormista AssignmentDocument31 pagesShormista AssignmentSwakshar DebNo ratings yet

- 3QGB Screw PumpDocument7 pages3QGB Screw PumpWily WayerNo ratings yet