Professional Documents

Culture Documents

Pwdxxa 40

Uploaded by

Otero Gabriel (Carlinhos)Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pwdxxa 40

Uploaded by

Otero Gabriel (Carlinhos)Copyright:

Available Formats

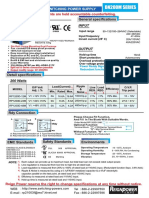

Catalog MSG14-2550/US Electronic Modules

Technical Information Series PWDXXA-40*

General Description

Series PWDXXA-40* electronic module for driving

proportional valves with spool position feedback is

compact and easy to install with DIN rail mounting

and plug-in terminals. The digital design allows for

programmable parameters such as solenoid drive

current, mins, maxs, ramps and a range of position

feedback signals. The module provides flexibility and

repeatability from unit to unit. The module parameters

are programmed with an RS-232 interface and user

friendly software (ProPxD) with default values for stan-

dard valves.

The PWDXXA-40* module contains the functions re-

quired by typical internal closed loop proportional valve

applications (series D*FC, D*1FS, RLL*R, WLL*R and

TEL valves).

D

Features

• Interface and tuning for spool position feedback.

• Programmable parameters.

• ±10V, ± 20 mA, 4-20 mA position transducer input.

• RS-232 Interface.

• User friendly programming software.

Dimensions

• Plug-in terminals.

Inch equivalents for millimeter dimensions are shown in (**)

• Four independent ramps.

• Input Enable with Status indicator.

• Differential command input.

• Compliant with European EMC Standards.

75.0

(2.95)

45.0 110.0

(1.77) (4.33)

WARNING: This product can expose you to chemicals including Lead, Nickel (Metallic), or 1,3-Butadiene which are known to the State of California to

cause cancer, and Lead or 1,3-Butadiene which is known to the State of California to cause birth defects and other reproductive harm. For more information

go to www.P65Warnings.ca.gov.

D01_Cat2550.indd, ddp, 04/19

D5 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog MSG14-2550/US Electronic Modules

Technical Information Series PWDXXA-40*

Ordering Information

PWD XX A 40

Electronic Module Position Control Module Type Technology Function Design

DC Valve Universal Series

NOTE:

Code Description Code Description Not required

40 Amplifier, 0 Standard when ordering.

MIN/MAX adjustment,

1 Linearization Option

UP/DOWN ramps,

Command input

Weight: 160g (.35 lbs.)

Specifications

D General

Model Module package for snap-on Mounting Position Any

mounting on EN 50022 rail Ambient

Package Material Polycarbonate Temperature Range -20°C to +60°C (-4°F to +140°F)

Inflammability Class V2 to V0 acc. UL 94 Protection Class IP 20 acc. DIN 40050

Electrical

Duty Ratio 100% Status Signal Off – 0 to 0.5 VDC; On – Supply

Voltage; rated max. 15 mA

Supply Voltage 18 VDC to 30 VDC, ripple < 5% eff.,

surge free Monitor Signal +10 to 0 to -10 VDC, rated max. 5 mA,

signal resolution 0.4%

Switch-on

Current Typ. 22A for 0.2 mS Adjustment Ranges

Minimum 0 to 50%

Current Maximum 50 to 100%

Consumption Max. 2.0A Ramp Time 0 to 32.5 s

Pre-fusing 2.5A medium lag Zero Offset +100 to -100%

Current 1.3/2.7/3.5 A

Command Signal +10 to 0 to -10 VDC, ripple < 0.01 % Initial Current 0 to 25%

eff., surge free, Ri = 100K ohm

Interface RS 232C, DSub 9p. male for null

+20 to 0 to -20 mA, ripple < 0.01 % modem cable

eff., surge free, Ri = 200 Ohm

EMC EN 50081-2, EN 50082-2

4 to 12 to 20 mA, ripple < 0.01 % eff.,

surge free, Ri = 200 Ohm Connection Screw terminals 0.2 to 2.5 mm²,

plug-in

< 3.6 mA = solenoid output off,

> 3.8 mA = solenoid output on (acc. Cable Specification 16 AWG overall braid shield for

NAMUR NE43) supply voltage and solenoids

Input 20 AWG overall braid shield for

Signal Resolution 0.025% sensor and signal

Differential Input 30V for terminals 5 and 6 against Cable Length 50m (164 ft.)

Voltage Max. PE (terminal 8)

Enable Signal Off – 0 to 2.5 VDC

On – 5 to 30 VDC; Ri = 30K ohm

Options

Technology Code 1 – Software adjustable transfer function with 10 compensation points for linearization of

Function valve behavior.

D01_Cat2550.indd, ddp, 04/19

D6 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog MSG14-2550/US Electronic Modules

Technical Information Series PWDXXA-40*

Block Diagram — Wiring

Signal Flow Diagram

D01_Cat2550.indd, ddp, 04/19

D7 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog MSG14-2550/US Electronic Modules

Technical Information Series PWDXXA-40*

ProPxD Interface Program Features

The new ProPxD software permits comfortable parameter • User-friendly editing of all parameters.

setting for the electronic module series PCD, PWD, PZD and

PID.

• Storage and loading of optimized parameter adjustments.

Via the clearly arranged entry mask the parameters can be • Executable with all Windows® operating systems from

Windows® 95 upwards.

noticed and modified. Storage of complete parameter sets to

floppy or hard disk is possible as well as printout or record • Communication between PC and electronic via serial

as a text file for further documentation. Stored parameter interface RS-232 and null modem cable.

sets may be loaded anytime and transmitted to the electronic

module in the same manner as the basic parameters which

• Simple to use interface program. Download free of charge

www.parker.com/euro_hcd → Services → downloads

are available for all usable valve series. Inside the electronic

a nonvolatile memory stores the data with the option for

recalling or modification.

D01_Cat2550.indd, ddp, 04/19

D8 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

You might also like

- MTS24V48VDocument2 pagesMTS24V48VLương SángNo ratings yet

- Avo240 Ds 10jul2015 Fa570e3c9bDocument6 pagesAvo240 Ds 10jul2015 Fa570e3c9bVishwakarma EnterprisesNo ratings yet

- Rail Mounting 8 Channel Isolation Module For Pt-100 RTD InputsDocument2 pagesRail Mounting 8 Channel Isolation Module For Pt-100 RTD Inputskrishna bhanu singhNo ratings yet

- Moduflex Power Core (12kW) Rev01Document2 pagesModuflex Power Core (12kW) Rev01Steven SeNo ratings yet

- EBVW020A0BDocument18 pagesEBVW020A0BЮрийNo ratings yet

- PXU PID Controller: Temperature/Process ControllersDocument3 pagesPXU PID Controller: Temperature/Process ControllersGaryNo ratings yet

- dn200m (Fuente)Document3 pagesdn200m (Fuente)piabNo ratings yet

- EBVW025A0B Barracuda Series DC-DC Converter Power Modules: FeaturesDocument18 pagesEBVW025A0B Barracuda Series DC-DC Converter Power Modules: FeaturesABHINASH MAHOR ee12b068No ratings yet

- Brochure Borri E2001 Compact OMG60323revA 01-22Document6 pagesBrochure Borri E2001 Compact OMG60323revA 01-22Mohammad TanhaNo ratings yet

- FCBC/ Smps Power Plant-MODEL DY2350 (48V/12.5A)Document1 pageFCBC/ Smps Power Plant-MODEL DY2350 (48V/12.5A)Sales DynahitechNo ratings yet

- UPS2000 H Series 6 10kVA UPS With Lithium Batteries DatasheetzDocument4 pagesUPS2000 H Series 6 10kVA UPS With Lithium Batteries Datasheetzmika.adhiNo ratings yet

- Moduflex Power Core (24kW) Rev00Document2 pagesModuflex Power Core (24kW) Rev00Denizhan AkınNo ratings yet

- Datasheet Conversor 24-48vcd Sd-200Document3 pagesDatasheet Conversor 24-48vcd Sd-200Antero CasaniNo ratings yet

- Industrial 1-Ph UPS: From 5 To 200 kVADocument6 pagesIndustrial 1-Ph UPS: From 5 To 200 kVAKasim KasimNo ratings yet

- Apit Massibus PDFDocument20 pagesApit Massibus PDFkaleesuwariNo ratings yet

- Moduflex Power Core (16kW) Rev01Document2 pagesModuflex Power Core (16kW) Rev01Denizhan AkınNo ratings yet

- UP4 Din BrochureDocument2 pagesUP4 Din BrochuresenthilrsenthilNo ratings yet

- MD22 - Raption 50 HV - V17238. - enDocument4 pagesMD22 - Raption 50 HV - V17238. - enharun_2727No ratings yet

- 2012 RCS FlyerDocument4 pages2012 RCS FlyerKarthik RajaNo ratings yet

- sdc31 eDocument1 pagesdc31 eHemraj Singh RautelaNo ratings yet

- LP1100D 12mdaDocument1 pageLP1100D 12mdalucasmosnaNo ratings yet

- Moduflex Power Core (12kW) Rev03Document2 pagesModuflex Power Core (12kW) Rev03carlos tomas diaz rojasNo ratings yet

- 3BSE069054R1 DI828 DatasheetDocument4 pages3BSE069054R1 DI828 Datasheetanthony.huamanmNo ratings yet

- FCBC / Smps Power Plant MODEL DY 6350 (48V/37.5A)Document1 pageFCBC / Smps Power Plant MODEL DY 6350 (48V/37.5A)Irshad AhmedNo ratings yet

- Leaflet UMB AC40 ENDocument4 pagesLeaflet UMB AC40 ENJOSÉ VILLALOBOS CORALNo ratings yet

- 5.1.3.1 Ficha Técnica Del Indoor DC Rectificación - DPC NOCDocument4 pages5.1.3.1 Ficha Técnica Del Indoor DC Rectificación - DPC NOCPaul Tirado UrbinaNo ratings yet

- InteliDrive Lite FPC Datasheet - 4Document4 pagesInteliDrive Lite FPC Datasheet - 4widiNo ratings yet

- NDBDocument2 pagesNDBShafiq RosmanNo ratings yet

- 4026 Frequency To Analog Converter Mag & Digital Type: 4026-xx Drop-In Type For Y3 Product DescriptionDocument2 pages4026 Frequency To Analog Converter Mag & Digital Type: 4026-xx Drop-In Type For Y3 Product DescriptionVinod Kumar PatelNo ratings yet

- Xitanium 150W 2.45 4.9A AOC 230V I220 170106Document7 pagesXitanium 150W 2.45 4.9A AOC 230V I220 170106Hytham Ramdan El BardecyNo ratings yet

- Modular Inverter Datasheet Media TSI 48Vdc - 230vac - 1.5kVA EN v1.3Document2 pagesModular Inverter Datasheet Media TSI 48Vdc - 230vac - 1.5kVA EN v1.3Charmer JiaNo ratings yet

- MDL107 EngDocument3 pagesMDL107 EngC&P GroupNo ratings yet

- NL1150D 24Document1 pageNL1150D 24carolinammiyashiroNo ratings yet

- Model LD - Large DC Volt/Current/Process Display: General Description SpecificationsDocument16 pagesModel LD - Large DC Volt/Current/Process Display: General Description SpecificationsRafael LinarezNo ratings yet

- 408 2in R2F 0516Document2 pages408 2in R2F 0516kapilNo ratings yet

- TC2000 Stereo Class-T™ Audio Controller Using Digital Power Processing (DPP™) TechnologyDocument9 pagesTC2000 Stereo Class-T™ Audio Controller Using Digital Power Processing (DPP™) TechnologyNanang BaliNo ratings yet

- Fact - Sheet - ESAA150ACTA0101 - en - Rev01 (5017272800)Document5 pagesFact - Sheet - ESAA150ACTA0101 - en - Rev01 (5017272800)PhạmNo ratings yet

- SIL/SMT40C2 Series: C-Class Non-IsolatedDocument4 pagesSIL/SMT40C2 Series: C-Class Non-IsolatedSia NasserNo ratings yet

- Brochure Borri UMB AC07 OMG60341revA 01 22Document4 pagesBrochure Borri UMB AC07 OMG60341revA 01 22reyhanvanchouwNo ratings yet

- Moduflex Power Core (18kW-5U) Rev00Document2 pagesModuflex Power Core (18kW-5U) Rev00hendrimuhariNo ratings yet

- Digital Process Indicator Selectron PIC1000Document1 pageDigital Process Indicator Selectron PIC1000industrialindiaNo ratings yet

- 100W Single Output DC-DC Converter: SeriesDocument2 pages100W Single Output DC-DC Converter: SeriesDario Lopez MorenoNo ratings yet

- Sedona Programmable Controller P-Ion: SpecificationsDocument2 pagesSedona Programmable Controller P-Ion: SpecificationsHarun KaripNo ratings yet

- PWD00 400 5715 696 UkDocument10 pagesPWD00 400 5715 696 UkANGEL MANUEL VELASCO REYESNo ratings yet

- 2080sc-If4u Micro830 and Micro850 Series PLCsDocument2 pages2080sc-If4u Micro830 and Micro850 Series PLCsrajavinugmailcomNo ratings yet

- Voltage Detector IXD5121-IXYSDocument19 pagesVoltage Detector IXD5121-IXYSBalaji PotnuriNo ratings yet

- MP 26 Digital Process Transmitter: Product ProfileDocument2 pagesMP 26 Digital Process Transmitter: Product ProfileHeri YantoNo ratings yet

- Moduflex Power Core (36kW) Rev00Document2 pagesModuflex Power Core (36kW) Rev00Denizhan AkınNo ratings yet

- Borri Rcb.E: Compact Rectifi Er Battery ChargerDocument2 pagesBorri Rcb.E: Compact Rectifi Er Battery ChargerAditya AdiaksaNo ratings yet

- Moduflex Power Core (17.4kW) Rev01Document2 pagesModuflex Power Core (17.4kW) Rev01Denizhan AkınNo ratings yet

- Moglix Remarks Model: 409 With 2 Relay Alarm + 4-20 MADC RX O/pDocument3 pagesMoglix Remarks Model: 409 With 2 Relay Alarm + 4-20 MADC RX O/pyashNo ratings yet

- Catalog Sheet IPAQ-C202 enDocument1 pageCatalog Sheet IPAQ-C202 enDiseño de Ingeniería SOLINENo ratings yet

- DPT-R8-Series - Datasheet-9.0 - Delta P SensorDocument2 pagesDPT-R8-Series - Datasheet-9.0 - Delta P SensorLê Xuân AnNo ratings yet

- jf5018-00 Rev4c (14317)Document12 pagesjf5018-00 Rev4c (14317)larryNo ratings yet

- GXT-MT 10 KVA - LX 3x3 - DatasheetDocument1 pageGXT-MT 10 KVA - LX 3x3 - DatasheetVidhyasankarNo ratings yet

- FICHA TECNICA - FUENTE DELTA - Datasheet - DRL-24V120W1ASDocument15 pagesFICHA TECNICA - FUENTE DELTA - Datasheet - DRL-24V120W1ASLore Cardenas AguirreNo ratings yet

- SQM48T20025 NBB0Document33 pagesSQM48T20025 NBB0Gabriel RacovskyNo ratings yet

- DPT R8 ManualDocument4 pagesDPT R8 Manualjose luisNo ratings yet

- B2 Temperature Indicator - Masibus - LC5296-DCDocument2 pagesB2 Temperature Indicator - Masibus - LC5296-DCHarsh ShahNo ratings yet

- SEMIKRON DataSheet SKKD 81 07897092Document4 pagesSEMIKRON DataSheet SKKD 81 07897092rahmadhaniNo ratings yet

- 6ED10522MD000BA6 Datasheet en PDFDocument2 pages6ED10522MD000BA6 Datasheet en PDFOtero Gabriel (Carlinhos)No ratings yet

- ANXFG4505Document5 pagesANXFG4505Otero Gabriel (Carlinhos)No ratings yet

- Data Sheet 6AV6643-0CD01-1AX1: General InformationDocument8 pagesData Sheet 6AV6643-0CD01-1AX1: General Informationkev YNo ratings yet

- en PDFDocument2 pagesen PDFOtero Gabriel (Carlinhos)No ratings yet

- Msds0067uk C3 PDFDocument7 pagesMsds0067uk C3 PDFOtero Gabriel (Carlinhos)No ratings yet

- E-Program Files-AN-ConnectManager-SSIS-MSDS-PDF-CLB125 - MY - EN - 20210428 - 1 PDFDocument12 pagesE-Program Files-AN-ConnectManager-SSIS-MSDS-PDF-CLB125 - MY - EN - 20210428 - 1 PDFOtero Gabriel (Carlinhos)No ratings yet

- Hipap 502p InmDocument76 pagesHipap 502p InmOtero Gabriel (Carlinhos)No ratings yet

- Sabroe Ap68 SDS en 2021Document12 pagesSabroe Ap68 SDS en 2021Otero Gabriel (Carlinhos)No ratings yet

- Geospectrum Technologies Inc.: Customizing DetectionDocument2 pagesGeospectrum Technologies Inc.: Customizing DetectionOtero Gabriel (Carlinhos)No ratings yet

- En 3rt1036-1ac20Document8 pagesEn 3rt1036-1ac20Otero Gabriel (Carlinhos)No ratings yet

- POINT I/O 24V DC Expansion Power Supply: Installation InstructionsDocument12 pagesPOINT I/O 24V DC Expansion Power Supply: Installation InstructionsOtero Gabriel (Carlinhos)No ratings yet

- Eaton 261362 A22 LED W en - GBDocument2 pagesEaton 261362 A22 LED W en - GBOtero Gabriel (Carlinhos)No ratings yet

- 3HAC023932 PS IRB 660-EnDocument64 pages3HAC023932 PS IRB 660-EnOtero Gabriel (Carlinhos)No ratings yet

- BASF Ucrete WR Parts-ABC MSDSDocument19 pagesBASF Ucrete WR Parts-ABC MSDSOtero Gabriel (Carlinhos)No ratings yet

- Data Sheet: 10.4 Inch Maritime Multi Computer (MMC)Document2 pagesData Sheet: 10.4 Inch Maritime Multi Computer (MMC)Otero Gabriel (Carlinhos)No ratings yet

- Hanna Hi 70004Document2 pagesHanna Hi 70004de HeksenketelNo ratings yet

- iSPHERE 3Document2 pagesiSPHERE 3Otero Gabriel (Carlinhos)No ratings yet

- LV TransformersDocument77 pagesLV TransformersOtero Gabriel (Carlinhos)No ratings yet

- B3645V Rev DDocument4 pagesB3645V Rev DOtero Gabriel (Carlinhos)No ratings yet

- Complinace CBD Towers Scope (SM6)Document26 pagesComplinace CBD Towers Scope (SM6)Li LiuNo ratings yet

- Global Data Center Newsletter - 2023.06.15Document22 pagesGlobal Data Center Newsletter - 2023.06.15indr4m4 7u5ufNo ratings yet

- EXPT-0-Introduction To KeilDocument4 pagesEXPT-0-Introduction To KeildharmaNo ratings yet

- Godhest-Gseennald Appaäatus: Expeaiment-2Document5 pagesGodhest-Gseennald Appaäatus: Expeaiment-2G S RehanNo ratings yet

- V9.4 Patch InstallDocument5 pagesV9.4 Patch InstallmbsahgNo ratings yet

- Impact of Artificial Intelligence On Performance of Banking Industry in Middle EastDocument9 pagesImpact of Artificial Intelligence On Performance of Banking Industry in Middle EastsheetalNo ratings yet

- Assignment#3 Atif AliDocument8 pagesAssignment#3 Atif AliAtif AliNo ratings yet

- Why Is The Data Bus Bidirectional While The Address Bus Is Unidirectional - Computer Science (Python)Document3 pagesWhy Is The Data Bus Bidirectional While The Address Bus Is Unidirectional - Computer Science (Python)ankita sonalNo ratings yet

- A Study On Consumer Buying Behavior Towards Online and Offline ShoppingDocument94 pagesA Study On Consumer Buying Behavior Towards Online and Offline ShoppingARAVINDNo ratings yet

- Release Notes: Analyzer Update October 2019Document18 pagesRelease Notes: Analyzer Update October 2019henry457No ratings yet

- Container Refrigeration: Service Parts List For 69NT40 531 Series Container Refrigeration UnitsDocument88 pagesContainer Refrigeration: Service Parts List For 69NT40 531 Series Container Refrigeration UnitsshinigamisffNo ratings yet

- Backhoe Loader Product ListDocument15 pagesBackhoe Loader Product ListMax Sashikhin100% (4)

- Diagnostic Report: Component Fault Codes 7 Total / 1 Active / 6 InactiveDocument2 pagesDiagnostic Report: Component Fault Codes 7 Total / 1 Active / 6 Inactivealexis nuñez hernandezNo ratings yet

- Uni-T UT90A Pass Pass Pass Pass Pass Pass FailDocument9 pagesUni-T UT90A Pass Pass Pass Pass Pass Pass FailJeffry SaddoyNo ratings yet

- Math Assessment - TestDocument14 pagesMath Assessment - TestRebecca Sinclair100% (1)

- General Management: Professional Certificate Program in From IIM KozhikodeDocument9 pagesGeneral Management: Professional Certificate Program in From IIM KozhikodeNirmalya SenNo ratings yet

- Engineering Management Masters Thesis TopicsDocument5 pagesEngineering Management Masters Thesis Topicsgbtrjrap100% (2)

- Xc-Rack: Instructions For Use Digital 4-Quadrant-/Combi MeterDocument20 pagesXc-Rack: Instructions For Use Digital 4-Quadrant-/Combi MeterAbu Yussif AlaboodiNo ratings yet

- CoffeDocument11 pagesCoffewashliyaturroziqahNo ratings yet

- Kovic 4Document16 pagesKovic 4Francis BurerosNo ratings yet

- Rancher 2 4 Architecture WPDocument11 pagesRancher 2 4 Architecture WPPardha Saradhi100% (1)

- Samsung Galaxy S9 ManualDocument229 pagesSamsung Galaxy S9 ManualmiguelNo ratings yet

- 02 Modul Exasol SQL - enDocument41 pages02 Modul Exasol SQL - enPeterNo ratings yet

- Summative 3-4Document5 pagesSummative 3-4Wilmar EspinosaNo ratings yet

- NATIONAL FOOD AUTHORITY-Accounts Analyst PDFDocument1 pageNATIONAL FOOD AUTHORITY-Accounts Analyst PDFJake ScotNo ratings yet

- PC1046Document15 pagesPC1046Sharafat KabirNo ratings yet

- ECA2+ Tests Language Test 4C 2018Document6 pagesECA2+ Tests Language Test 4C 2018Czarek MNo ratings yet

- 13.375 CASING Tally KH #C Wspace OutDocument14 pages13.375 CASING Tally KH #C Wspace OutnabiNo ratings yet

- Manual Programador TSX T317 PDFDocument64 pagesManual Programador TSX T317 PDFJhon Florez100% (1)

- Load Duration CurveDocument24 pagesLoad Duration CurveHesham TexNo ratings yet