Professional Documents

Culture Documents

PFD Aco Revisi 3

Uploaded by

Lie HendraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PFD Aco Revisi 3

Uploaded by

Lie HendraCopyright:

Available Formats

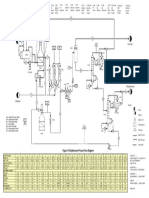

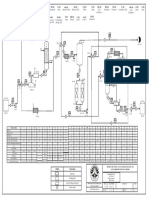

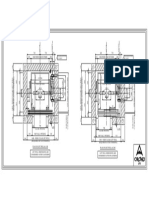

V-501 P-501 A/B H-501 R-501 E-501 P-504 A/B V-502 A/B E-502 T-501 P-5013 A/B E-503

V-502 A/B E-502 T-501 P-5013 A/B E-503 V-503 T-502 E-505 V-504

Mixing ACO Fired Reactor Kettle ACO Vessel ACO ACO DO ACO Accumulator DO DO Accumulator

Vessel Centrifugal Heater Cooler Centrifugal Kettle Recycle Centrifugal Coloumn Vessel Purification Coloumn Vessel

Pump Pump Reboiler Coloumn Pump Condenser Coloumn Condenser

E-506 E-504

1628.7 Kettle DO

25 Cooler Kettle

110.0

Acetylated Castrol Oil Reboiler

1

0.02

175.0

V-501 10,703

136.0

151.0 10,703 H-501 Gum

151.0

105.0

230.0

8

2

3 T-501 E-503

10,703

10,703

175.0

P-501 A/B 380.0

136.0

195.0

4 7

V-502 A/B V-503

R-501 P-502 A/B

378.6

119.2

10,703

105.0

175.0

148.0 Asetic Acid

9074.4

170.0

6 11

110.0 10,703

342.8

14 lps 1628.7

183.0 108.0

9074.4 125.0

5 344.8

E-502 9

90.0

E-505

10 T-502 cw

bfw E-501

9074.4 lps

170.0

V-504

65.0

P-503 A/B

13

bfw

P-504 A/B E-506

Hps 1250.0

E-504 252.8

125.0

Dry Oil

12

UNIVERSITAS RIAU

FAKULTAS TEKNIK

JURUSAN TEKNIK KIMIA

JL. HR Soebrantas Kampus Binawidya KM 2,5 Panam, Pekanbaru 28293

JUDUL : Drying Oil Process Flow Diagram

KEY Digambar Oleh: Asisten Dosen : Dosen Pengampu: Nilai:

Mass Flow(kg/h) Redo Aditya Grinaldi

M. Baihaqi Wardana

Temperature(°C) Rafly Yose Putra Prof. Edy Saputra,S.T.,M.T.,PhD

Khairulpati Harianja

Pressure(kPa) Tanggal: Ukuran Tugas ke: Revisi: Skala: Page:

Kertas:

17/11/2023 A3 9 2 1 of 1

You might also like

- PFD ACO KelompokDocument3 pagesPFD ACO KelompokLie HendraNo ratings yet

- From Internet ReportDocument21 pagesFrom Internet ReportmrahmedNo ratings yet

- Styrene Production ReactionsDocument19 pagesStyrene Production ReactionsAna Carolina Meza OrozcoNo ratings yet

- Gamtek PFD Massa TemperatureDocument1 pageGamtek PFD Massa TemperatureSalwa AssyifaNo ratings yet

- Yes PDFDocument1 pageYes PDFAthia Hasna NurhanifahNo ratings yet

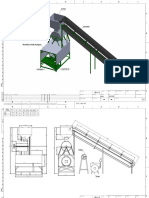

- Brucket Rod Cyldr BulwarkDocument1 pageBrucket Rod Cyldr BulwarkOozaru SaiyaNo ratings yet

- 24 TS GX120 2013Document4 pages24 TS GX120 2013Stephen ChávezNo ratings yet

- Horizontal Shaft Gasoline (Petrol) Engine: 2.2 KW (3.0 HP) / 3 600 MinDocument4 pagesHorizontal Shaft Gasoline (Petrol) Engine: 2.2 KW (3.0 HP) / 3 600 MinKRUTIK CHAVDANo ratings yet

- Benzene: Figure 1 Ethylbenzene Process Flow DiagramDocument1 pageBenzene: Figure 1 Ethylbenzene Process Flow DiagramOkta Abdul ChoirNo ratings yet

- Fxsq100-125a Dim 3d094917a enDocument1 pageFxsq100-125a Dim 3d094917a enDragos PicuNo ratings yet

- Fxsq100-125a Dim 3d094917a enDocument1 pageFxsq100-125a Dim 3d094917a enDragos PicuNo ratings yet

- 4DDocument1 page4DFitri WahyuniNo ratings yet

- OrganizedDocument29 pagesOrganizedDimasNo ratings yet

- HPE FM 2 Pump 0820 P UCPDocument1 pageHPE FM 2 Pump 0820 P UCPbondsivamaniNo ratings yet

- LW12.8-60 Hub Adapter Design Guide - RevBDocument2 pagesLW12.8-60 Hub Adapter Design Guide - RevBankurNo ratings yet

- TS-10 Heat & Mass Balance Diagrams M701JAC FinalDocument6 pagesTS-10 Heat & Mass Balance Diagrams M701JAC FinalRamesh-NairNo ratings yet

- Myers: HR Series Convertible Jet PumpsDocument2 pagesMyers: HR Series Convertible Jet PumpsDiana AguayoNo ratings yet

- 2HH-38A-R4-V2 Line DrawingDocument1 page2HH-38A-R4-V2 Line DrawingDaniel Heitor Silva AssisNo ratings yet

- 10P 2L8M B5 V2 Line DrawingDocument1 page10P 2L8M B5 V2 Line Drawingyou are awesomeNo ratings yet

- Two-Pipe AC Fan Coil Unit: Three-Row DuctDocument2 pagesTwo-Pipe AC Fan Coil Unit: Three-Row Ductnomi1873No ratings yet

- Manual 2016 Kaos Evo 2.5!12!15 Tamanho GrandeDocument2 pagesManual 2016 Kaos Evo 2.5!12!15 Tamanho GrandeDeivid Weber100% (1)

- RV365D-M-V2 Line DrawingDocument1 pageRV365D-M-V2 Line Drawingyou are awesomeNo ratings yet

- PFD X Hysys Act 2 Modif Buat 4CDocument1 pagePFD X Hysys Act 2 Modif Buat 4CMasterNo ratings yet

- Technical Specification: Omnibloc DdhoDocument5 pagesTechnical Specification: Omnibloc DdhoRyan PatraNo ratings yet

- Airlock Rotary Motor Base Part1Document1 pageAirlock Rotary Motor Base Part1Sek PyroNo ratings yet

- Horizontal Shaft Gasoline (Petrol) Engine: 2.2 KW (3.0 HP) / 3 600 MinDocument4 pagesHorizontal Shaft Gasoline (Petrol) Engine: 2.2 KW (3.0 HP) / 3 600 MinGerfelin Nsinda MambaNo ratings yet

- HPE FM 5 Pump 1200 P UCPDocument1 pageHPE FM 5 Pump 1200 P UCPbondsivamaniNo ratings yet

- S-02 floor plan dimensionsDocument1 pageS-02 floor plan dimensionsGary HurtadoNo ratings yet

- Scale and drainage details for underground water tankDocument1 pageScale and drainage details for underground water tankKuteesa CharlesNo ratings yet

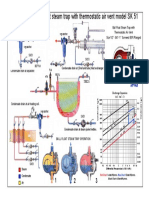

- Application For SK-51Document1 pageApplication For SK-51constantin.iacomi3837No ratings yet

- 1981 FSM All WindsorsDocument46 pages1981 FSM All WindsorsDiego Armando Martinez UrquijoNo ratings yet

- Fixed Pallat DesignDocument2 pagesFixed Pallat DesignKailas PhatangareNo ratings yet

- COMMSCOPE EGZHHTT-65B-R6 (Disegno)Document1 pageCOMMSCOPE EGZHHTT-65B-R6 (Disegno)21n23mNo ratings yet

- CCD replacement plate and mounting kitDocument1 pageCCD replacement plate and mounting kitAlexVelasquezQNo ratings yet

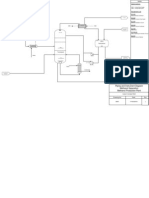

- Reactor R-101 Reactor R-102 Reboiler E-104: UdaraDocument1 pageReactor R-101 Reactor R-102 Reboiler E-104: UdaraNurici Isnaeni Khoiri 2207111420No ratings yet

- Diesel Vacuum Pump Units (En) - Hüdig GMBH & Co. KGDocument4 pagesDiesel Vacuum Pump Units (En) - Hüdig GMBH & Co. KGashahulhjNo ratings yet

- Valve & Primer Corporation: Manufactured To AWWA C-512 Standards ISO Connections AvailableDocument4 pagesValve & Primer Corporation: Manufactured To AWWA C-512 Standards ISO Connections AvailableSergio Veliz RNo ratings yet

- Disassembly of Screw JackDocument1 pageDisassembly of Screw JackSantosh KonduskarNo ratings yet

- Horizontal Shaft Gasoline (Petrol) Engine: GenerationDocument4 pagesHorizontal Shaft Gasoline (Petrol) Engine: Generationjosé delmoteNo ratings yet

- Series 7354 Equilibrium Float ValvesDocument2 pagesSeries 7354 Equilibrium Float ValvesDota NgNo ratings yet

- Separation PFDDocument2 pagesSeparation PFDFyxd55No ratings yet

- 6P-MRL With Min ShaftDocument1 page6P-MRL With Min ShaftNagarajan SNo ratings yet

- Volvo Penta Inboard Diesel: Technical DataDocument2 pagesVolvo Penta Inboard Diesel: Technical Datahusan shahNo ratings yet

- B&Q 32-33Document1 pageB&Q 32-33api-27602672No ratings yet

- Tasha Modul3Document1 pageTasha Modul3Aqsal FahrizqaNo ratings yet

- Integrasi Panas YaDocument1 pageIntegrasi Panas YaFitri WahyuniNo ratings yet

- 641 Final Detail of Dranage Spout, RCC Railing & Bearing-Railing 1Document1 page641 Final Detail of Dranage Spout, RCC Railing & Bearing-Railing 1shashi rajhansNo ratings yet

- Pump DrawingDocument1 pagePump DrawingOcta RioNo ratings yet

- Latihan PFD 1Document1 pageLatihan PFD 1Muhammad Rafi HerdianaNo ratings yet

- 23 V2403mdi 27Document2 pages23 V2403mdi 27DaniloBarreraNo ratings yet

- RV4-65D-M-V2 Line DrawingDocument1 pageRV4-65D-M-V2 Line Drawingyou are awesomeNo ratings yet

- PLAN AT ELEVATION +105.132 (T.O.S) Bracket Arrangement PHASE SS-0838-01-13Document1 pagePLAN AT ELEVATION +105.132 (T.O.S) Bracket Arrangement PHASE SS-0838-01-13raziNo ratings yet

- DH GF HF Bio-X Vent AutoclaveDocument2 pagesDH GF HF Bio-X Vent AutoclaveOrlindo WagnerNo ratings yet

- Moist Air Properties Using Psychrometric ChartDocument42 pagesMoist Air Properties Using Psychrometric Chartshahad mNo ratings yet

- Shelter 1 Drawing Rev0Document1 pageShelter 1 Drawing Rev0Choon Wei WongNo ratings yet

- DIN ISO 276811 tolerance chartDocument5 pagesDIN ISO 276811 tolerance chartSugeng Hadi SusiloNo ratings yet

- Ta2 PDFDocument5 pagesTa2 PDFSugeng Hadi SusiloNo ratings yet

- InputDocument3 pagesInputSugeng Hadi SusiloNo ratings yet

- ABB - Synchronous Condensers Q&ADocument10 pagesABB - Synchronous Condensers Q&AAL DuarteNo ratings yet

- Problem Set - 1 INSTDocument1 pageProblem Set - 1 INSTMuhammad Jawad IsmaeelNo ratings yet

- RES Question BankDocument11 pagesRES Question Bankthiyagarajan_jayasriNo ratings yet

- Acetone PFDDocument1 pageAcetone PFDAshokNo ratings yet

- Eet-04 GepDocument2 pagesEet-04 GepNmg KumarNo ratings yet

- 110-Ee-380 110-Ee-381 110-Ee-384 110-Ee-386 110-RB-380 A/b 110-VV-385Document1 page110-Ee-380 110-Ee-381 110-Ee-384 110-Ee-386 110-RB-380 A/b 110-VV-385DIPANKAR LALANo ratings yet

- Soal Pas Bhs. Inggris KLS Xi Paket CDocument9 pagesSoal Pas Bhs. Inggris KLS Xi Paket CZayn Danish Aruna ShanumNo ratings yet

- Discussion Text MateriDocument2 pagesDiscussion Text Materimarlena dzaka100% (1)

- Part Ii: Pronunciation:: Thư viện Đề thi - Trắc nghiệm - Tài liệu học tập miễn phíDocument46 pagesPart Ii: Pronunciation:: Thư viện Đề thi - Trắc nghiệm - Tài liệu học tập miễn phíNguyễn ViViNo ratings yet

- Free Study Resources for Engineers, Doctors & More at Studynama.comDocument29 pagesFree Study Resources for Engineers, Doctors & More at Studynama.comswechchha adhikariNo ratings yet

- PDFsam - MANUAL DE PARTES LINCOLN BIG RED 500Document2 pagesPDFsam - MANUAL DE PARTES LINCOLN BIG RED 500Luis Chan ChanNo ratings yet

- Pakistan's Energy Crisis EvolutionDocument63 pagesPakistan's Energy Crisis EvolutionAyaan KhaanNo ratings yet

- Metallurgical Challenges Associated With Using Grade 91 Steels at Elevated TemperatureDocument21 pagesMetallurgical Challenges Associated With Using Grade 91 Steels at Elevated TemperatureKuthuraikaranNo ratings yet

- Discuss The Processes of The Following PlantsDocument1 pageDiscuss The Processes of The Following PlantsEric John CruzNo ratings yet

- ESBWR Natural Circulation Fact SheetDocument1 pageESBWR Natural Circulation Fact SheetBorja PumaresNo ratings yet

- Small Modular Reactors For Enhancing Energy SecuriDocument28 pagesSmall Modular Reactors For Enhancing Energy SecuriTechZenNo ratings yet

- How To Anchor An International Conference - Symposium (Part-3)Document11 pagesHow To Anchor An International Conference - Symposium (Part-3)sivaenotesNo ratings yet

- Generation of ElectricityDocument43 pagesGeneration of ElectricityHafizah AyobNo ratings yet

- APR1400 SSAR Closure of Unresolved and Generic Safety IssuesDocument199 pagesAPR1400 SSAR Closure of Unresolved and Generic Safety IssuesAbdalrahman Taha (Jíɾaïya)No ratings yet

- Codigos de Fallas Cat C 15 - C 16Document1 pageCodigos de Fallas Cat C 15 - C 16Carlos bustamanteNo ratings yet

- Sci-2 mp2Document16 pagesSci-2 mp2Hitesh Batuk vadgamaNo ratings yet

- Power Plant IntroductionDocument15 pagesPower Plant IntroductionBlackNo ratings yet

- UNIT IV Nuclear Power PlantDocument54 pagesUNIT IV Nuclear Power Plantsai venkatsharmaNo ratings yet

- Fukushima Poster FinalDocument1 pageFukushima Poster FinalDaniel PopaNo ratings yet

- Btech Oe 3 Sem Energy Science and Engineering Koe033 2022Document2 pagesBtech Oe 3 Sem Energy Science and Engineering Koe033 2022akash GuptaNo ratings yet

- 2013 Halfen Price ListDocument244 pages2013 Halfen Price Listpicco666No ratings yet

- power-plant-engineering-by-p-k-nag-solution-manualDocument5 pagespower-plant-engineering-by-p-k-nag-solution-manualCabagnot Piolo JuliusNo ratings yet

- Energy Company Meeting by SlidesgoDocument28 pagesEnergy Company Meeting by SlidesgoSumaiya IrfanNo ratings yet

- Renewable Energy Thesis PDFDocument7 pagesRenewable Energy Thesis PDFmkdswzgig100% (1)

- Iso 17874 1 2010 en PDFDocument11 pagesIso 17874 1 2010 en PDFfahadkhanffcNo ratings yet