Professional Documents

Culture Documents

Paper 4439

Paper 4439

Uploaded by

BensonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Paper 4439

Paper 4439

Uploaded by

BensonCopyright:

Available Formats

ISSN (Online) 2581-9429

IJARSCT

International Journal of Advanced Research in Science, Communication and Technology (IJARSCT)

Volume 2, Issue 7, May 2022

Impact Factor: 6.252

Design and Development of Pneumatic Jack in

Automobile

Mayur Kailas Lone1, Mansi Balasaheb Waje2, Shrikrushna Kakaji Bagal3,

Prajwal Dnyaneshwar Tajanpure4, Prof. S. S. Patil5

Matoshri College of Engineering and Research Centre, Nashik1,2.3.4,5

Abstract: There are many types of jacks available in the market to lift an automobile to access the

underbelly of the vehicle. However, these jacks are too huge to carry around or require the vehicle to be

taken to some garage. The dependency of an individual on garage or other services increases. During

emergencies or in places where the probability of finding a service station is very low such as hilly regions,

rural areas, forest areas and etc. It becomes extremely hard to replace a punctured tire or temporarily fix

a broken axle on one’s own. The time taken for a support system to reach is tiresome. The service provided

in high demand areas such as hilly regions or forests is also expensive. This project focuses on helping

individuals and physically challenged persons to change a punctured tire. As most of the civilians out there

are not trained to place a mechanical jack properly and lift a car. The main target of project is to improve

version of mini pneumatic jack this will be more efficient for the user this machine is pneumatic powered

which has low co-efficient of friction. A Pneumatic cylinder erected provides power to lift the Wheel. This

is a pneumatic powered machine and requires no other means of power to operate. The required

components are Compressor (portable), Receiver tank, Pneumatic cylinder, 4/3 DCV, Check valve, Flow

control valve, FRL unit, etc.

Keywords: Pneumatic Jack, Pneumatic Circuit., etc.

I. INTRODUCTION

The term Pneumatic stands for operations performed using air. The pneumatic jack is the device which is used to lift the

vehicle or a wheel of a vehicle by using pressurized fluid that is Air. Most of the vehicles are lifted by using screw jack.

This needs much human efforts and consume a lot of time. Various types of jacks or lifting devices are available like

Screw jack, Floor jack, Hydraulic bottle jack, etc. Conventionally we have always used a single portable jack for the

vehicle. Here we have designed separate Pneumatic jack for each wheel which is permanently installed on vehicle chassis.

The virtues of using a screw as a machine, essentially an inclined plane wound round a cylinder, was first demonstrated

Archimedes in 200BC with his screw used for pumping water.

There is evidence of the use of screws in the Ancient Roman world but it was the great Leonardo da Vinci in the late

1400’s who first demonstrated the use of a screw jack for lifting loads. With the industrial revolution of the late 18th and

19th centuries came the first use of screws in machine tools from English inventors such as John Wilkinson and Henry

Maudsley The most notable inventor in mechanical engineering from the early 1800’s was undoubtedly the mechanical

genius Joseph Whitworth. Over the past 60+ years, the product has evolved to push, pull, lift, lower and position loads

of anything from a few kilos to hundreds of tones. Most features now offered our competitors were actually designed and

patented Screw Jack & Duff-Norton over the years.

II. PURPOSE OF INBUILT PNEUMATIC JACK

The pneumatic jack is a device used for lifting heavy loads by the application of much smaller force. It is based on

pascal’s law, which states that intensity of pressure is transmitted equally in all direction through a mass of air at rest.

Copyright to IJARSCT DOI: 10.48175/568 817

www.ijarsct.co.in

ISSN (Online) 2581-9429

IJARSCT

International Journal of Advanced Research in Science, Communication and Technology (IJARSCT)

Volume 2, Issue 7, May 2022

Impact Factor: 6.252

III. SCOPE

Hydraulic jack or other jack causes more efforts during lifting the vehicle. To make an inbuilt pneumatic jack for the

easy to lifting the vehicle & provide seamless operation.

IV. BASIC PRINCIPLE OF PNEUMATICS

In pneumatic system electric energy converted in mechanical motion and using this air compressed to higher pressure.

The compressed air is used to developed the force. The force is used to do some mechanical work.

V. CONSTRUCTION

PNEUMATIC CIRCUIT

A pneumatic circuit is an interconnected set of components that convert compressed gas (usually air) into mechanical

work. In the normal sense of the term, the circuit must include a compressor or compressor-fed tank.

Components: Following components are used in circuit

Sr. No. Name of Component Quantity

1. Double acting cylinder 4

2. 4/3 Direction control valve 4

3. Flow control valve 1

4. Check valve 1

5. FRL unit 1

VI. PROBLEM STATEMENT

Mechanical jack requires more effort moreover not suitable for uneven surfaces. It requires more power consumption

also Maintenance is quite high as well as Suitable for small capacity and requires skilled labor. The purpose of this project

is to modify the design of existing car jack in terms of its functionality and also human factors considerations. General

idea of the project is to minimize the human effort while operating the jack.

Copyright to IJARSCT DOI: 10.48175/568 818

www.ijarsct.co.in

ISSN (Online) 2581-9429

IJARSCT

International Journal of Advanced Research in Science, Communication and Technology (IJARSCT)

Volume 2, Issue 7, May 2022

Impact Factor: 6.252

Platform Details

In this project we used Double acting cylinder with piston rod on one side.

Specifications of double acting cylinder

Bore diameter = 25 mm

Stroke length = 50mm

Pressure range = 0.1 – 10 bar

No. of cylinders = 4 nos.

In this project we have used 4/3 direction control valve with closed center type.

Symbol of 4/3 DCV

Specifications of 4/3 DCV

Manually operated

Liver operated

Rotary spool type

Closed center type

Copyright to IJARSCT DOI: 10.48175/568 819

www.ijarsct.co.in

ISSN (Online) 2581-9429

IJARSCT

International Journal of Advanced Research in Science, Communication and Technology (IJARSCT)

Volume 2, Issue 7, May 2022

Impact Factor: 6.252

Advantages

The advantages are as follows:

1. It occupies less space

2. They are also less likely to jam due to rust in the screw thread

3. It is highly effective with heavy loads

4. It lifts loads with the minimum of effort

5. It is easier to use

6. The maintenance of the vehicle will be very easy.

7. Reduces human efforts at large extent.

8. Time saving process.

9. Can be operated even when the vehicle is not in starting condition.

10. As it is electrically powered, does not harm the vehicle efficiency

VII. LIMITATIONS

1. Cost will increase slightly.

2. Weight of vehicle will increase slightly.

3. System cannot work without 12-volt DC current.

4. System required maintenance also

VIII. CONCLUSION

With some design consideration an inbuilt car lifting mechanism can easily be fitted in all light weight automobiles. The

project works on hydraulic power provided by battery. Maintenance and service of the vehicle can be easily done by this

project. With this project the usage of automobile can be made easy for women and old people. Some extra automation

like solenoid control valve can add great value to the project. The inbuilt jack is operated by battery so it can also be used

when the vehicle engine is not started.

REFERENCES

[1] Parth M. Patel, Parth S. Patel, Vaibhav H. Shah, Suril R. Shah, Automatic Hydraulic Jack Inbuilt in A Four-Wheeler,

international journal of scientific & technology research volume 5, issue 08, august 2016.

[2] Prashant D.Banakar, Prashantakumar N. K. , Hanumesha Pujar, Design and Fabrication of Inbuilt Hydraulic Jack

for Four Wheelers, Department of Mechanical Engineering, K.L.E. Institute of Technology, Hubballi, Karnataka,

India.

[3] S. Sathiyaraj, V. Selvakumar, Design and fabrication of pneumatic jack for automobile, Final year mechanical

enginee ring, jayalakshmi institute of technology, thoppur, Dharmapuri 2015.

[4] P.S. Rana, P.H. Belgel, N.A. Nagrare, C.A. Padwad, P.R. Daga, K.B. Deshbhrata, N.K. Mandavgade, Integrated

Automated Jacks for 4-wheelers, Students of Priyadarshni College of Engineering, Nagpur, India Assistant

Professor, Priyadarshni College of Engineering, Nagpur, India 2012.

[5] Shraddha S. Jadhav, Prajakta K. Patil, A. R. Kharat, The Automatic Hydraulic Jack, U.G. Student, Assistant

Professor Department of Mechanical 2015.

Copyright to IJARSCT DOI: 10.48175/568 820

www.ijarsct.co.in

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Engine &auto ElectricsDocument20 pagesEngine &auto ElectricsBensonNo ratings yet

- Quality Control and InspectionDocument6 pagesQuality Control and InspectionBensonNo ratings yet

- Trade ProjectDocument34 pagesTrade ProjectBensonNo ratings yet

- Design & Modification On Automatic and Pneumatic Jack SystemDocument4 pagesDesign & Modification On Automatic and Pneumatic Jack SystemBensonNo ratings yet

- Wom PartnershipDocument11 pagesWom PartnershipBensonNo ratings yet

- Closing and Opening Dates T3 - 2023 - 1Document1 pageClosing and Opening Dates T3 - 2023 - 1BensonNo ratings yet

- Convert - EXECUTIVE SUMMARY 5571010037 - 1706113158195Document2 pagesConvert - EXECUTIVE SUMMARY 5571010037 - 1706113158195BensonNo ratings yet

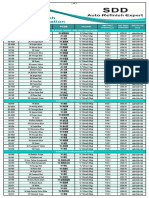

- SDD Quotation - 12.05Document5 pagesSDD Quotation - 12.05BensonNo ratings yet

- Benson Kioko Business PlanDocument37 pagesBenson Kioko Business PlanBensonNo ratings yet