Professional Documents

Culture Documents

Zamak Chemical Propietats - ZL

Uploaded by

Siva Kumar PLOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Zamak Chemical Propietats - ZL

Uploaded by

Siva Kumar PLCopyright:

Available Formats

Zamak

Commercial name for a zinc base alloy with aluminum, copper and magnesium. Versatile material

used to obtain die casting pieces in high volumes with high precision and detail reproductibility

eliminating machining and reducing costs.

Chemical properties

DESIGNATION ABBREV. ALLOY Weight Aluminium Magnesium Copper Lead Cadmium Tin Iron Nickel Silicium Titanium Chromium Zinc

( Al ) ( Mg ) ( Cu ) ( Pb ) ( Cd ) ( Sn ) ( Fe ) ( Ni ) ( Si ) ( Ti ) ( Cr ) ( Zn )

min. 3,8 0,035 2,7 --- --- --- --- --- --- --- --- rest.

ZAMAK 2 ZL2 ZnAl4Cu3

max. 4,2 0,06 3,3 0,003 0,003 0,001 0,02 0,001 0,02 --- --- rest.

min. 3,8 0,035 0,7 --- --- --- --- --- --- --- --- rest.

ZAMAK 3 ZL3 ZnAl4

max. 4,2 0,06 1,1 0,003 0,003 0,001 0,02 0,001 0,02 --- --- rest.

min. 3,8 0,035 0,7 --- --- --- --- --- --- --- --- rest.

ZAMAK 5 ZL5 ZnAl4Cu1

max. 4,2 0,06 1,1 0,003 0,003 0,001 0,02 0,001 0,02 --- --- rest.

min. 5,6 --- 1,2 --- --- --- --- --- --- --- --- rest.

ZAMAK 6 ZL6 ZnAl6Cu1

max. 6,0 0,005 1,6 0,003 0,003 0,001 0,02 --- 0,02 --- --- rest.

min. 8,2 0,02 0,9 --- --- --- --- --- --- --- --- rest.

ZAMAK 8 ZL8 ZnAl8Cu1

max. 8,8 0,03 1,3 0,005 0,005 0,002 0,035 0,001 0,035 --- --- rest.

min. 10,8 0,02 0,5 --- --- --- --- --- --- --- --- rest.

ZAMAK 12 ZL12 ZnAl11Cu1

max. 11,5 0,03 1,2 0,005 0,005 0,002 0,05 --- 0,05 --- --- rest.

min. 0,01 --- 1,0 --- --- --- --- --- --- 0,15 0,1 rest.

ZAMAK 16 ZL16 ZnCu1CrTi

max. 0,04 0,02 1,5 0,005 0,005 0,003 0,04 --- 0,04 0,25 0,2 rest.

min. 25,5 0,012 2,0 --- --- --- --- --- --- 0,15 0,1 rest.

ZAMAK 27 ZL27 ZnAl27Cu2

max. 28,0 0,02 2,5 0,005 0,005 0,002 0,07 --- 0,04 0,25 0,2 rest.

Physical properties

ZAMAK 2 ZAMAK 3 ZAMAK 5 ZAMAK 8 ZAMAK 12 ZAMAK 27

Density

(Kg/m^3) at 21 º C 6,7 6,7 6.7 6,3 6,0 5,0

Solidification

shrinkage (%) 1,25 1,17 1,17 1,1 0,7 0,75

Casting

shrinkage (%) 0,6 0,6 0,6 0,7 0,7 0,75

Freezing

range (0) 379 , 390 381 , 387 379 , 388 375 , 404 377 , 432 376 , 484

Casting

temperature 420 , 425 400 , 420 400 , 420 415 , 430 470 , 530 550 , 580

Specific heat capcity

( J/kg/∫C ) at 20 - 100 ™C 418,7 418,7 418,7 435,4 450 534,4

Thermal expansion

( 10E-6 linear per ∫C at 20-100 ∫C) 27 27 27 23,3 24,2 26,2

Thermal conductivity

( W/m/hr/m^2/ ∫C at 70-140∫C ) 104,7 113 108,9 114,7 116 125,5

Electrical conductivity %

( IACS ) 25 27 26 27,7 28,3 29,7

Electrical resitivity

( µm O cm at 20∫C) 6,3694 6,3694 6,5359 6,2 6,1 5,8

Artesans, s/n - Pol. Ind de Valls - 43800 VALLS - SPAIN

Tel. 977 612 412 - Fax 977 612 936 - E-MAIL: comercial@funmak.com WEB: www.funmak.com 1

Mechanical properties

ZAMAK 2 As cast Aged Sand Cast

Tensile strength ( MPa ) 360 331 252

Shear Strength ( Mpa ) 317 214 227

Elongation ( % in 51 mm ) 7 2 3

Hardness

( Brinell - 500 kg ) 100 98 100

Impact strength

( Energy , Joules ) 47 68 7,4

Fatigue strengh 5x10E8 cycles ( Mpa ) 58,6 --- 0

Yield strength

( 0,2% offset ) ( Mpa ) --- --- ---

ZAMAK 3 As cast Aged Sand Cast

Tensile strength ( MPa ) 252 283 241

Shear Strength ( Mpa ) 227 214 ---

Elongation ( % in 51 mm ) 3 10 16

Hardness

( Brinell - 500 kg ) 100 82 72

Impact strength

( Energy , Joules ) 7,4 58,3 55,6

Fatigue strengh 5x10E8 cycles ( Mpa ) 56,5 --- ---

Yield strength

( 0,2% offset ) ( Mpa ) 0 47,6 ---

ZAMAK 5 As cast Aged Sand Cast

Tensile strength ( MPa ) 328 269 ---

Shear Strength ( Mpa ) 262 --- ---

Elongation ( % in 51 mm ) 7 13 ---

Hardness

( Brinell - 500 kg ) 91 80 ---

Impact strength

( Energy , Joules ) 65,1 54,2 ---

Fatigue strengh 5x10E8 cycles ( Mpa ) 56,5 --- ---

Yield strength

( 0,2% offset ) ( Mpa ) --- --- ---

ZAMAK 8 As cast Aged Sand Cast

Tensile strength ( MPa ) 375 300 220÷225

Shear Strength ( Mpa ) 275 227 241

Elongation ( % in 51 mm ) 6÷10 20 1÷2

Hardness

( Brinell - 500 kg ) 100÷106 91 85÷90

Impact strength

( Energy , Joules ) 42 17 ---

Fatigue strengh 5x10E8 cycles ( Mpa ) 103 --- 52

Yield strength

( 0,2% offset ) ( Mpa ) 240 240 210

Artesans, s/n - Pol. Ind de Valls - 43800 VALLS - SPAIN

Tel. 977 612 412 - Fax 977 612 936 - E-MAIL: comercial@funmak.com WEB: www.funmak.com 2

ZAMAK 12 As cast Aged Sand Cast

Tensile strength ( MPa ) 404 310 275÷317

Shear Strength ( Mpa ) 296 241 207

Elongation ( % in 51 mm ) 4÷7 10 1÷2

Hardness

( Brinell - 500 kg ) 100÷106 91 92÷96

Impact strength

( Energy , Joules ) 42 17 25

Fatigue strengh 5x10E8 cycles ( Mpa ) 103 --- 103

Yield strength

( 0,2% offset ) ( Mpa ) 320 241 207

ZAMAK 27 As cast Aged Sand Cast

Tensile strength ( MPa ) 426 360 400÷441

Shear Strength ( Mpa ) 325 257 290

Elongation ( % in 51 mm ) 2÷3 2÷3 3÷6

Hardness

( Brinell - 500 kg ) 116÷122 100 110÷120

Impact strength

( Energy , Joules ) 5 2,2 47

Fatigue strengh 5x10E8 cycles ( Mpa ) 145 --- 172

Yield strength

( 0,2% offset ) ( Mpa ) 371 317 372

Some uses of zamak

Automotive, Bathroom fittings, Office items, Faucet, Locks, Hardware

Bibliography about zamak

- “How to Cast Small Metal and Rubber Parts”

William A. Cannon

- “Metalcasting”

by C. W. Ammen

- “Failure of Materials in Mechanical Design: Analysis, Prediction, Prevention, 2nd Edition”

by Jack A. Collins

- “Alloy data”

NADCA Product Specification Standarts

- “The diecasting of Zamak”

Luigi Andreoni

- “Replacement of steel with scratched Zamak for metal finiching decorative purposes”

Artesans, s/n - Pol. Ind de Valls - 43800 VALLS - SPAIN

Tel. 977 612 412 - Fax 977 612 936 - E-MAIL: comercial@funmak.com WEB: www.funmak.com 3

You might also like

- Date IEEE 34 NodesDocument8 pagesDate IEEE 34 NodesJavier HurtadoNo ratings yet

- Ejercicio 6Document5 pagesEjercicio 6Mario Cohen FontalvoNo ratings yet

- Apendice6 PDFDocument1 pageApendice6 PDFPaul ValdesNo ratings yet

- Problema de 3 ReservoriosDocument26 pagesProblema de 3 ReservoriosFranco Camacho CanchariNo ratings yet

- Dimensi Saluran IrigasiDocument10 pagesDimensi Saluran IrigasiNaufal Kusumawardana naufalkusumawardana.2019No ratings yet

- Cálculo de Carga 1Document4 pagesCálculo de Carga 1Patricia Jimena Venegas LópezNo ratings yet

- FreesiaDocument328 pagesFreesiamohd firdaus bin ibrahimNo ratings yet

- Tabel Hal 18Document2 pagesTabel Hal 18Vicka Tri UtamiNo ratings yet

- Tab 1 - KC e Ks-MarkdownDocument2 pagesTab 1 - KC e Ks-MarkdownMatheus Lima FerreiraNo ratings yet

- Tab 1 - KC e Ks PDFDocument2 pagesTab 1 - KC e Ks PDFTsukíí Marília Belmonte100% (1)

- Composicao Acos 6656Document1 pageComposicao Acos 6656Pedro CeriolliNo ratings yet

- Full Circle Horizontal: Km/jamDocument2 pagesFull Circle Horizontal: Km/jamAudi EuodiaNo ratings yet

- Laporan Mutasi Persediaan Obat TH 2018 Rsud CLPDocument73 pagesLaporan Mutasi Persediaan Obat TH 2018 Rsud CLPandardianNo ratings yet

- Líneas de Influencia-1Document4 pagesLíneas de Influencia-1aldoNo ratings yet

- Fases Hilos F.D. F.P. F.T. F.A. M V In Id e% ΔV z: Tablero General de EmergenciaDocument56 pagesFases Hilos F.D. F.P. F.T. F.A. M V In Id e% ΔV z: Tablero General de EmergenciaariakinerakNo ratings yet

- Aiwa AV-DV95-Service-ManualDocument36 pagesAiwa AV-DV95-Service-ManualWebSpare PartsNo ratings yet

- LHP S 16 BS Po.028Document2 pagesLHP S 16 BS Po.028Aang WardhanaNo ratings yet

- PvreDocument2 pagesPvreHanip Ridho SaputraNo ratings yet

- Aceleracion EspectralDocument6 pagesAceleracion EspectralCarlos OscarNo ratings yet

- AIWAAVDV75Document32 pagesAIWAAVDV75vedran54No ratings yet

- Aiwa AV-DV75-Service-ManualDocument32 pagesAiwa AV-DV75-Service-ManualWebSpare PartsNo ratings yet

- Cap 5Document6 pagesCap 5Gabriel Rocabado RiveroNo ratings yet

- SUELOSDocument4 pagesSUELOSHans100% (1)

- Leccion1 U3Document4 pagesLeccion1 U3Kevin VillafuerteNo ratings yet

- BARCH HIDROLIKA (Autosaved) 1Document9 pagesBARCH HIDROLIKA (Autosaved) 1Dinda KurniawatiNo ratings yet

- ConductividadDocument3 pagesConductividadGermán Darío Gaite AlvaradoNo ratings yet

- Model FacturaDocument16 pagesModel FacturajoanrgNo ratings yet

- Cortante y Torsion Ejercicio Armado ClaseDocument7 pagesCortante y Torsion Ejercicio Armado Clasecaticacas10No ratings yet

- Actividad 7Document5 pagesActividad 7nunezquispecarlosefrainNo ratings yet

- Pier CapDocument11 pagesPier CapPartha Sarathi BiswasNo ratings yet

- TransistoresDocument15 pagesTransistoreshenriquebiriNo ratings yet

- Aiwa TV C1300uDocument5 pagesAiwa TV C1300umasava03No ratings yet

- PRACTICASDocument22 pagesPRACTICASmarc cerdán olmNo ratings yet

- S - Tema 02 - MaquiSA - CG - CiFDocument2 pagesS - Tema 02 - MaquiSA - CG - CiFalexandravc0No ratings yet

- Tugas P-19Document4 pagesTugas P-19vhvnx2jmdmNo ratings yet

- Tablas de Kva-M Varios ConductoresDocument3 pagesTablas de Kva-M Varios ConductoresHéctor Porras100% (1)

- Libro HidraDocument6 pagesLibro HidraAlejandro BarreraNo ratings yet

- EST-13.2.Diseño Columnas O2 EntreparquesDocument2,071 pagesEST-13.2.Diseño Columnas O2 EntreparquesSebastián González SáenzNo ratings yet

- Hidraulica 2Document7 pagesHidraulica 2GABRIELANo ratings yet

- Grafik Variable SpeedDocument3 pagesGrafik Variable SpeedBaso Muhammad Agung A.No ratings yet

- PTC NTCDocument2 pagesPTC NTCNabil Augusto Londono LucasNo ratings yet

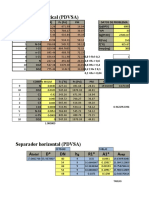

- Separador Trifasico ExamenDocument19 pagesSeparador Trifasico ExamenTania Colque AvendañoNo ratings yet

- Service Manual: NSX-BL23 NSX-BL34Document19 pagesService Manual: NSX-BL23 NSX-BL34antonio carlos clementino cruzNo ratings yet

- Aiwa NSX BL23 - LH Service ID1404Document19 pagesAiwa NSX BL23 - LH Service ID1404Osvald CsNo ratings yet

- Exemple OptimitzacioDocument1 pageExemple OptimitzacioSERGI HIDALGONo ratings yet

- Report ServletDocument4 pagesReport ServletdonyNo ratings yet

- Matriz de Cálculo de Crecimiento BacterianoDocument9 pagesMatriz de Cálculo de Crecimiento BacterianojavierNo ratings yet

- Wiley TablesDocument101 pagesWiley TablesAkhidNo ratings yet

- Rs. HR SubrantasDocument19 pagesRs. HR Subrantasdwi prasetyoNo ratings yet

- End MillsDocument26 pagesEnd MillsMatija HNo ratings yet

- Analisis Sismico DinamicoDocument29 pagesAnalisis Sismico DinamicoHenry Corro MantillaNo ratings yet

- Solución Taller de Repaso 1 - Punto 2Document7 pagesSolución Taller de Repaso 1 - Punto 2Nicolas Gutierrez AlarconNo ratings yet

- ACEROSDocument2 pagesACEROSNeider AmayaNo ratings yet

- Exemple 7.1Document4 pagesExemple 7.1Marta BotifollNo ratings yet

- Aiwa XR Mk29Document17 pagesAiwa XR Mk29cacliuNo ratings yet

- II UnidadDocument2 pagesII UnidadLuis Manuel Miguel AcostaNo ratings yet

- Numeros Decimales Division1Document1 pageNumeros Decimales Division1Colegio El AlbaNo ratings yet

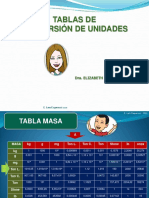

- Tabla de Conversión de UnidadesDocument16 pagesTabla de Conversión de UnidadesBruno CastilloNo ratings yet