Professional Documents

Culture Documents

Oily Water Removal From RPP To Evaporation Pond Landfill

Oily Water Removal From RPP To Evaporation Pond Landfill

Uploaded by

Shah MuzzamilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oily Water Removal From RPP To Evaporation Pond Landfill

Oily Water Removal From RPP To Evaporation Pond Landfill

Uploaded by

Shah MuzzamilCopyright:

Available Formats

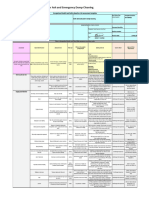

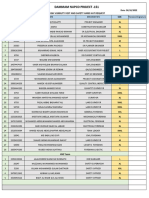

HAZARD IDENTIFICATION AND RISK ASSESSMENT & REGISTER

Risk Assessment (Baseline and full RA)

TASK/ACTIVITY/PROCESS NAME: Oily water removal from RPP to evaporation pond/landfill DEPARTMENT/AREA: EH/RPP STAGES 1 to 7

RA Number: 23-2023 DATE: 9/12/2023

SEVERITY / CONSEQUENCE (Impact/Hazard Effect) (Where an event has more than one ' Loss Type ', choose the ' Consequence' with the highest rating)

Loss Type Additional "Loss Types" may exist for

(1) Insignificant (2) Minor (3) Moderate (4) Major (5) Catastrophic

an event: Identify & rate accordingly

Medical Treatment Case Single Fatality or Loss of Quality of Life / Multiple Fatalities / Impact on health Ultimately

(S/H) Harm to People (Safety/Health) First Aid Case/Exposure to Minor Health Risk Loss Time Injury / Reversible Impact on Health

Exposure to Major Health Risk Irreversible impact on Health Fatal

(EI) Environmental Impact Minimal environment harm incident with workplace Material Environment harm (RST) Material Environment harm (RST) Serious environmental harm incident (RMT) Major environmental incident (RLT) Major environmental harm – Incident Irreversible

Partial Loss of Operation/1M SR

(BI/MD) Business Interruption / Material / Fire Damage & Substantial or Total Loss of Operation / 10M SR

No disruption to operation / 1000 SR to Less than 10k SR Brief Disruption to Operation / 10k SR to Less Than 100k SR Partial Shutdown/100k SR to Less than 1M SR To Less than10M SR

Other Consequential Losses and more

LIKELIHOOD Examples (Consider Near-Hits as well as actual events) RISK RATING / PROFILE

(5) ALMOST CERTAIN The unwanted event has occurred frequently : Occurs in order of (1) or more per year & is likely to reoccur within 1 year 11 (M) 16 (H) 20 (H) 23 (Ex) 25 (Ex)

(4) LIKELY The unwanted event has occurred infrequently : Occurs in order of less than once per year & is likely to reoccur within 5 yrs. 7 (M) 12 (M) 17 (H) 21 (Ex) 24 (Ex)

(3) POSSIBLE The unwanted event has occurred in the business at some time: or could happen within 10 years. 4 (L) 8 (M) 13 (H) 18 (H) 22 (Ex)

(2) UNLIKELY The unwanted event has occurred in the business at some time: or could happen within 20 years. 2 (L) 5 (L) 9 (M) 14 (H) 19 (H)

(1) RARE The unwanted event has never known to occur in the business or it is highly unlikely to occur within 20 years. 1 (L) 3 (L) 6 (M) 10 (M) 15 (H)

RA TEAM (Names) DESIGNATION SIGNATURE RISK RATING RISK LEVEL GUIDELINES FOR RISK MATRIX

Stop operation and review controls- Eliminate, avoid risk & implement

1. Wael koubaa QHSE Manager 21 to 25 (Ex) - Extreme high priority action plans

Proactively manage & implement specific controls/action plans-Review

2. Mohamed khan QHSE Manager Assitant 13 to 20 (H) - High after 7 days

Actively manage & monitor – Additional controls is advised & review after

3. Said Algarni Site engineer 6 to 12 (M) - Medium 14 days

Risk acceptable – Monitor & manage as appropriate with frequent review

4. Ibrahim shehri Safety officer 1 to 5 (L) - Low

DEPARTMENT / AREA: EH/RPP STAGES 1 to 7 APPROVED BY / MANAGER or SUPERVISOR haitham Mahmoud DATE: 9/12/2023 NEXT REVIEW DATE: 3/15/2023

Identify the hazard on the given task and conduct assessment of the actual site condition, all identified risk should provide with a plan to eliminate or control the risk.

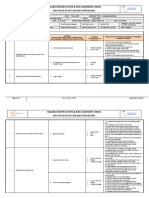

HAZARD IDENTIFICATION CONTROL RISK ASSESSMENT RISK REDUCTION ACTION PLAN

Risk Ranking /

Risk Ranking /

Consequence

Consequence

Risks Issue

Likelihood

Likelihood

Work Activity

Profile

Profile

(Possible incident) Improve existing controls / implement new Follow up by Whom Controls Implemented

Item # (Process, Equipment, Hazards [What can go wrong] Existing Controls controls (name) & By When (date) Yes/No

Materials) (Accident / ill health to

persons, fire or property loss)

1. All vacuum trucks must be inspected and approved by EH

before mobilization in the plant.

Equipment may have some

1. Damage to property. 2. Trained and experienced operators on the job. 1. Flagman / Job watcher to be present to guide the EH Supervisor/ Safety

defect that cause any undesired 3 2 6 3 1 3 YES

2. Injury to crew 3. Ensure the availability of a safety officer. moving vehicle/truck to the correct place. officer

event

4. Make sure that hand brake and wheel shocks are applied

while loading.

Mobilization of

1 vaccum truck inside 1. Vehicle entering and exiting the plant is under EH

the plant supervision.

2. Follow client driving rules and regulations.

1. Damage to property. 3. Do not exceed the speed limit of more than 20 KPH while 1. All drivers must be trained on defensive driving inside EH Supervisor/ Safety

Vehicle accident inside the plant 3 2 6 3 1 3 YES

2. Injury to crew driving inside the plant. the plant. officer

4. The flagman should wear a reflectorized vest.

5. The seat belt should be always worn when driving.

6. No use of cell phones.

1. Follow the safe manual lifting procedure such as using

correct lifting techniques to avoid any strain on the back,

improper handling, loading and and do not lift if you doubt the weight or adequacy of the

Unloading the

unloading of equipments can 1. Damage to property. equipment. EH Supervisor/ Safety

2 material in the 3 2 6 1. Train the workers about manual handling hazards. 3 1 3 YES

cause back injury or can damage 2. Injury to crew 2. Ensure there are enough members before lifting the load. officer

operation area

equipments 3. Reduce the load if the crew is not available.

4. Conduct TBT to all workers about manual handling

hazards.

1. Provide sand or use a spill kit to cover all spillage in the

area and the road.

2. Wear appropriate PPE CAT2 such as FRC long sleeves and

pants, safety shoes, helmet, and chemical gloves.

1. slips, trips accidents. 1. Train all the workers about the spills and controls. EH Supervisor/ Safety

Oily water spill 3. Ensure to cover all Oily water spills immediately to 3 2 6 3 1 3 YES

2. Soil contamination 2. The safety officer must be present all the time. officer

minimize pollution.

4. Provide bobcat equipment and manpower to conduct this

activity.

5. Provide TBT about the spill and ways for control.

1. The hoses of the vacuum truck are to be routed properly

1. Injury to person falls

to avoid any trips and falls. 1. Conduct good Housekeeping in all the areas. EH Supervisor/ Safety

Slip, trips and falls 2. damage hoses due 3 2 6 3 1 3 YES

2. The area should be properly barricaded to stop 2. Safety signs must be posted. officer

to trip

unauthorized entry.

3 Trenches area 1. The contractor safety officer is present.

2. Authorized suction truck driver.

3. Conduct orientation to all truck drivers regarding the

route.

No access way of the truck going 1. Accident 4. Follow the 20 KPH speed limit inside the plant. EH Supervisor/ Safety

3 2 6 Conduct driving safely training to all drivers. 3 1 3 YES

to the trenches area. 2. Injury 5. Wear seatbelts at all times. officer

6. Vehicle roads must be identified and marked.

7. No cell phones when driving.

8. Provide a Bankman to maneuver the truck.

9. provide TBT to all drivers regarding driving safely.

1. Barricade the trenches manhole to prevent the

unauthorized person.

2. The safety officer must be present all the time. 1. Conduct TBT and training to all workers about falling EH Supervisor/ Safety

Falling into the trenches 1. Injury to person falls 3 2 6 3 1 3 YES

3. Ensure to close the trenches manhole after finishing the hazard. officer

activity.

4. Safety signs must be posted in the area.

1. Provide sand or use a spill kit to cover all spillage in the

area and the road.

2. Wear appropriate PPE CAT2 such as FRC long sleeves and

pants, safety shoes, helmet, and chemical gloves.

1. slips, trips accidents. 1. Train all the workers about the spills and controls. EH Supervisor/ Safety

Waste water spill 3. Ensure to cover all waste water spills immediately to 3 2 6 3 1 3 YES

2. Soil contamination. 2. The safety officer must be present all the time. officer

minimize pollution.

4. Provide bobcat equipment and manpower to conduct this

activity.

5. Provide TBT about the spill and ways for control.

1. The hoses of the vacuum truck are to be routed properly

1. Injury to person falls

to avoid any trips and falls. 1. Conduct good Housekeeping in all the areas. EH Supervisor/ Safety

Slip, trips and falls 2. damage hoses due 3 2 6 3 1 3 YES

2. The area should be properly barricaded to stop 2. Safety signs must be posted. officer

to trip

unauthorized entry.

4 Drain pit area

1. The contractor safety officer is present.

2. Authorized suction truck driver.

3. Conduct orientation to all truck drivers regarding the

route.

Accident

No access way of the truck going 4. Follow the 20 KPH speed limit inside the plant. EH Supervisor/ Safety

Injury 3 2 6 Conduct driving safely training to all drivers. 3 1 3 YES

to the drain pit area. 5. Wear seatbelts at all times. officer

6. Vehicle roads must be identified and marked.

4 Drain pit area 7. No cell phones when driving.

8. Provide a Bankman to maneuver the truck.

9. provide TBT to all drivers regarding driving safely.

1. EH safety officer is present.

2. Only authorized suction truck driver.

3. Conduct orientation to all truck driver regarding the

route.

4. Follow the 20 KPH speed limit inside the plant.

Damage of section

5. Do not load the suction truck very close to the drain pit

Suction truck hit the drain pit truck and equipment . 1. Flagman must be present in the area to manoeuvre EH Supervisor/ Safety

wall. 3 2 6 3 1 3 YES

wall Damage to the drain the truck in the correct place. officer

6. Use appropriate length hose to have a safe distance from

pit

the drain pit.

7. keep the loading access free from waste water to avoid

slippery.

8. Use the wheel chocks before starting the activity.

9. No cell phones when driving

1. Barricade the drain pit manhole to prevent the

unauthorized person.

2. The safety officer must be present all the time. 1. Conduct TBT and training to all workers about falling EH Supervisor/ Safety

Falling into the drain pit 1. Injury to person falls 3 2 9 3 1 3 YES

3. Ensure to close the drain pit manhole after finishing the hazard. officer

activity.

4. Safety signs must be posted in the area.

1. Provide sand or use a spill kit to cover all spillage in the

area and the road.

2. Wear appropriate PPE CAT2 such as FRC long sleeves and

Slips , trips accident . pants, safety shoes, helmet, and chemical gloves.

1. Train all the workers about the spills and controls. EH Supervisor/ Safety

Waste water spill Soil contamination 3. Ensure to cover all waste water spills immediately to 3 2 6 3 1 3 YES

2. The safety officer must be present all the time. officer

minimize pollution.

4. Provide bobcat equipment and manpower to conduct this

activity.

5. Provide TBT about the spill and ways for control.

1. The hoses of the vacuum truck are to be routed properly

1. Injury to person falls

to avoid any trips and falls. 1. Conduct good Housekeeping in all the areas. EH Supervisor/ Safety

Slip, trips and falls 2. damage hoses due 3 2 6 3 1 3 YES

2. The area should be properly barricaded to stop 2. Safety signs must be posted. officer

to trip

unauthorized entry.

1. EH safety officer is present.

2. Only authorized suction truck driver.

5 Storm water 3. Conduct orientation to all truck driver regarding the

route.

4. Follow the 20 KPH speed limit inside the plant.

1. Damage of section

5. Do not load the suction truck very close to the drain pit

Suction truck hit the storm water truck and equipment . 1. Flagman must be present in the area to manoeuvre EH Supervisor/ Safety

wall. 3 2 6 3 1 3 YES

wall 2. Damage to the the truck in the correct place. officer

6. Use appropriate length hose to have a safe distance from

storm water

the drain pit.

7. keep the loading access free from waste water to avoid

slippery.

8. Use the wheel chocks before starting the activity.

9. No cell phones when driving

1. Barricade the storm water pit to prevent the

unauthorized person.

2. The safety officer must be present all the time. 1. Conduct TBT and training to all workers about falling EH Supervisor/ Safety

Falling into the storm water Injury to person falls 3 2 6 3 1 3 YES

3. Ensure to close the storm water pit after finishing the hazard. officer

activity.

4. Safety signs must be posted in the area.

1. Provide sand or use a spill kit to cover all spillage in the

area and the road.

2. Wear appropriate PPE CAT2 such as FRC long sleeves and

Slips , trips accident . pants, safety shoes, helmet, and chemical gloves.

1. Train all the workers about the spills and controls. EH Supervisor/ Safety

Waste water spill Soil contamination 3. Ensure to cover all waste water spills immediately to 3 2 6 3 1 3 YES

2. The safety officer must be present all the time. officer

minimize pollution.

4. Provide bobcat equipment and manpower to conduct this

activity.

5. Provide TBT about the spill and ways for control.

1. The hoses of the vacuum truck are to be routed properly

1. Injury to person falls

to avoid any trips and falls. 1. Conduct good Housekeeping in all the areas. EH Supervisor/ Safety

Slip, trips and falls 2. damage hoses due 3 2 6 3 1 3 YES

2. The area should be properly barricaded to stop 2. Safety signs must be posted. officer

to trip

unauthorized entry.

6 Condenser area 1. The contractor safety officer is present.

2. Authorized suction truck driver.

3. Conduct orientation to all truck drivers regarding the

route.

No access way of the truck going 4. Follow the 20 KPH speed limit inside the plant. EH Supervisor/ Safety

Injury to person falls, 3 2 6 1. Conduct driving safely training to all drivers. 3 1 3 YES

to the condenser area. 5. Wear seatbelts at all times. officer

6. Vehicle roads must be identified and marked.

7. No cell phones when driving.

8. Provide a Bankman to maneuver the truck.

9. provide TBT to all drivers regarding driving safely.

1. Barricade the condenser drain pit to prevent the

unauthorized person.

Falling into the condenser drain 2. The safety officer must be present all the time. 1. Conduct TBT and training to all workers about falling EH Supervisor/ Safety

Injury to person falls 3 2 6 3 1 3 YES

pit 3. Ensure to close the condenser drain pit after finishing the hazard. officer

activity.

4. Safety signs must be posted in the area.

1. Provide sand or use a spill kit to cover all spillage in the

area and the road.

2. Wear appropriate PPE CAT2 such as FRC long sleeves and

1. Train all the workers about the spills and controls.

pants, safety shoes, helmet, and chemical gloves.

1. slips, trips accidents. 2. The safety officer must be present all the time. EH Supervisor/ Safety

Spillage 3. Ensure to cover all waste water spills immediately to 3 2 6 3 1 3 YES

2. Soil contamination 3. Whiplash must be used between the hoses to prevent officer

minimize pollution.

the leak

4. Provide bobcat equipment and manpower to conduct this

activity.

5. Provide TBT about the spill and ways for control.

7 Evaporation pond 1. The hoses of the vacuum truck are to be routed properly

1. Injury to person falls

to avoid any trips and falls. 1. Conduct good Housekeeping in all the areas. EH Supervisor/ Safety

Slip, trips and falls 2. damage hoses due 3 2 6 3 1 3 YES

2. The area should be properly barricaded to stop 2. Safety signs must be posted. officer

to trip

unauthorized entry.

1. Do not get the suction truck too close to the evaporation

1. Injury

pond.

2. Damage to the plant 1. Banksman should be presented to maneuver the EH Supervisor/ Safety

falling into the evaporation pond 2. Use an appropriate length hose to have a safe distance 3 2 6 3 1 3 YES

property and suction truck. officer

from the evaporation pond.

equipment

3. A safety officer must be present.

1. Wear appropriate PPE such as a long FRC sleeve and

pants, safety shoes, helmet, and chemical gloves.

2. Ensure that PTW, SWP, and RA are acquired by the EH

before starting the activity.

3. Conduct TBT for all workers involved before starting the

activity.

4. All equipment must be properly grounded.

1. Environmental 1. Train all the workers about the spills and controls. EH Supervisor/ Safety

leakage 5. Inspect the equipment before use. 3 2 6 3 1 3 YES

pollution 2. Use whiplashes between each hose. officer

6. A safety officer must be available on-site to monitor the

activity.

7. Use an anti-static hose and ensure that all connections

are tight to avoid land contamination.

8. Ensure to cover all spills with sand or use a spill kit

immediately to minimize pollution.

9. Report each leak to the safety department.

Transferring oily 1. Provide portable fire extinguishers.

8

water to suction truck 2. EH supervisor must be available in the area to monitor the

activity.

1. Environmental 3. If a fire occurs immediately contact the fire department 1. Train the workers about fire hazards. EH Supervisor/ Safety

Fire 4 2 8 4 1 4 YES

pollution (0124227468). 2. Train the crew how to use the fire extinguishers officer

4. If a fire occurs, evacuate to the closet assembly point.

5. All equipment must be properly grounded.

6. Smoking is not allowed only in a designated areas.

1. Accident 1. Train the workers and drivers about vessel under-

1. Ensure to control pressure using a pressure gauge in the EH Supervisor/ Safety

Over pressure 2. Injury 4 2 8 pressure hazards. 4 1 4 YES

suction truck. officer

3. Property damage 2. The truck must be third partie inspected.

1. Ensure control of the level of oily water loaded in the

1. Environmental suction truck. Train the workers and drivers about vessel over load EH Supervisor/ Safety

Over load 3 2 6 3 1 3 YES

pollution 2. Ensure to cover all spills with sand or use a spill kit hazard. officer

immediately to minimize pollution.

1. PTW compliance shall be ensured.

2. Each shift will be controlled by a supervisor and safety

officer, where necessary, to ensure the implementation and

1. Environmental enforcement of safe systems and controls. 1. Train all the workers about the spill hazards and ways EH Supervisor/ Safety

spillage 3 2 6 3 1 3 YES

contamination 3. Ensure the use of PPE such as rubber boots, helmets, of control. officer

goggles, chemical gloves, and white coveralls.

4. Ensure to cover all spills with sand or use a spill kit

Transportation of Oily immediately to minimize pollution.

9 water by suction

truck 1. Drivers to follow SEC traffic rules and regulations.

2. Maintain a 20 KPH speed limit inside the plant. 1. All drivers must be trained on defensive driving inside EH Supervisor/ Safety

traffic accident 1. property damage 3 2 6 3 1 3 YES

3. The seat belt should be worn while driving. the plant. officer

4. No cell phones when driving.

1. Accident 1. All suction trucks must be inspected and approved by the

1. Qualified person should make inspection before EH Supervisor/ Safety

Flat tires 2. Injury client representative before mobilization in the plant. 3 2 6 3 1 3 YES

starting the activity officer

3. Damage to property 2. All suction truck tires must be in good condition.

1. The hoses of the vacuum truck are to be routed properly

Poor management of The poor management of hoses to avoid any trips and falls.

1. Conduct TBT and train all workers about tripping EH Supervisor/ Safety

10 the suction hoses coming from the considered area 1. slip, trip and fall 2. The area should be properly barricaded to stop 3 2 6 3 1 3 YES

hazards. officer

during vacuuming to the suction truck unauthorized entry.

3. The safety officer must be present in the area

1. Contaminated waste materials must be disposed of in

designated bins.

Improper dumping of 1. Contamination to 2. Personnel must check the label of disposal bins before 1. Conduct training to all involved persons about EH Supervisor/ Safety

2 3 6 2 2 4 YES

contaminated waste material environment disposing of them. environmental prevention pollution officer

3. Dispose of all unnecessary items properly and leave the

area clean and organized.

11 Housekeeping

11 Housekeeping

1. Follow the safe manual handling procedure or use

Improper handling, loading and Damage to property. mechanical lifting devices to lift heavy loads.

unloading of equipments can Injury to crew 2. Activity will be supervised by the EH supervisor and safety EH Supervisor/ Safety

3 2 6 1. Train the workers about manual handling hazards. 3 1 3 YES

cause back injury or can damage Improper manual officer. officer

equipments handling 3. Permit to work is available.

4. The maximum weight to carry by employees is 25 kgs.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- 2.8c Risk Assessment - 023 Scaffolding Erection, Dismantling, Modification Rev. July 2019Document9 pages2.8c Risk Assessment - 023 Scaffolding Erection, Dismantling, Modification Rev. July 2019Shah MuzzamilNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- PTW272 - Asphalt Paving 17-01-2023Document22 pagesPTW272 - Asphalt Paving 17-01-2023Shah Muzzamil0% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Internal Property Damage Report - 11-02-2023Document1 pageInternal Property Damage Report - 11-02-2023Shah MuzzamilNo ratings yet

- Wastewater Overpumping Best Practice Guide 10 January 2017Document40 pagesWastewater Overpumping Best Practice Guide 10 January 2017Shah MuzzamilNo ratings yet

- APVacuum Truck Vacuum System OperationsSWPStandardDocument25 pagesAPVacuum Truck Vacuum System OperationsSWPStandardShah MuzzamilNo ratings yet

- SevereweathertemplateDocument28 pagesSevereweathertemplateShah MuzzamilNo ratings yet

- Toaz - Info 005 Ms Manhole Construction Sew Risk Assessment From Javeed 1 PRDocument12 pagesToaz - Info 005 Ms Manhole Construction Sew Risk Assessment From Javeed 1 PRShah MuzzamilNo ratings yet

- 7H (W%RRN 2) 6$) (7 &21752/) 25 &/ ($1,1 :25.23 (5$7,216 (: (53,3 (6 $1''5$,1$ (&$1$/6Document406 pages7H (W%RRN 2) 6$) (7 &21752/) 25 &/ ($1,1 :25.23 (5$7,216 (: (53,3 (6 $1''5$,1$ (&$1$/6Shah MuzzamilNo ratings yet

- Aquatech Dewatering BrochureDocument14 pagesAquatech Dewatering BrochureShah MuzzamilNo ratings yet

- 2.8c Risk Assessment - 003 Temporary Perimeter Fencing Rev. July 2019Document6 pages2.8c Risk Assessment - 003 Temporary Perimeter Fencing Rev. July 2019Shah MuzzamilNo ratings yet

- PNABX861Document145 pagesPNABX861Shah MuzzamilNo ratings yet

- Art - 253A10.1007 - 252Fs11042 014 2047 6Document24 pagesArt - 253A10.1007 - 252Fs11042 014 2047 6Shah MuzzamilNo ratings yet

- Shelter Building Risk Assessment 2015Document2 pagesShelter Building Risk Assessment 2015Shah MuzzamilNo ratings yet

- RTE2023 AbstractsDocument61 pagesRTE2023 AbstractsShah MuzzamilNo ratings yet

- Construction Site Security Guidance Edition 1 01Document12 pagesConstruction Site Security Guidance Edition 1 01Shah MuzzamilNo ratings yet

- Dr. Michael Gürtler MBA PDFDocument59 pagesDr. Michael Gürtler MBA PDFMeena MunimNo ratings yet

- DR 12.10.21Document2 pagesDR 12.10.21Shah MuzzamilNo ratings yet

- Project Base Risk Assessment For Ash and Emergency Dump CleaningDocument1 pageProject Base Risk Assessment For Ash and Emergency Dump CleaningShah MuzzamilNo ratings yet

- Materials Handling, Storage, Use, and Disposal For ConstructionDocument23 pagesMaterials Handling, Storage, Use, and Disposal For ConstructionShah MuzzamilNo ratings yet

- 5 6093774246096406058Document14,613 pages5 6093774246096406058Shah MuzzamilNo ratings yet

- MPDFDocument6 pagesMPDFShah MuzzamilNo ratings yet

- Job Safe Procedure Air Quality Monitoring 21-2023Document3 pagesJob Safe Procedure Air Quality Monitoring 21-2023Shah MuzzamilNo ratings yet

- ScanDocument1 pageScanShah MuzzamilNo ratings yet

- HIGH VISIBILITY VEST REQUESTDocument1 pageHIGH VISIBILITY VEST REQUESTShah MuzzamilNo ratings yet

- EH-HDO-HSE01-FOR-021 Vehicle Daily InspectionDocument1 pageEH-HDO-HSE01-FOR-021 Vehicle Daily InspectionShah MuzzamilNo ratings yet

- As Built DammamDocument12 pagesAs Built DammamShah MuzzamilNo ratings yet

- Crt-Npc-Dmm-Hva-Dwg-Sd-Gn-33501 - Equipment Capacity Schedule 1-6Document1 pageCrt-Npc-Dmm-Hva-Dwg-Sd-Gn-33501 - Equipment Capacity Schedule 1-6Shah MuzzamilNo ratings yet

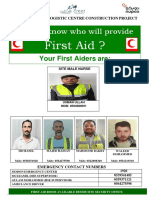

- First Aidnew - Creet UPDATED (r01)Document2 pagesFirst Aidnew - Creet UPDATED (r01)Shah MuzzamilNo ratings yet

- Effects of Activies Deu To Bad Weather (R1)Document4 pagesEffects of Activies Deu To Bad Weather (R1)Shah MuzzamilNo ratings yet

- Renewal PTW # Cable Tray WorksDocument24 pagesRenewal PTW # Cable Tray WorksShah MuzzamilNo ratings yet