Professional Documents

Culture Documents

Efm32gg stk3700 Ug

Uploaded by

hiteshmediaaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Efm32gg stk3700 Ug

Uploaded by

hiteshmediaaCopyright:

Available Formats

...

the world's most energy friendly microcontrollers

USER MANUAL

Starter Kit EFM32GG-STK3700

The EFM32 Giant Gecko Starter Kit is a feature rich platform for evaluation,

prototyping and application development for the EFM32 Giant Gecko MCU family

with the ARM Cortex-M4 CPU core.

Main features:

• Advanced Energy Monitoring provides real-time information about the energy

consumption of an application or prototype design.

• On-board debugger with the possiblity to debug external targets.

• Several sensors, a 160-segment LCD Display, backup domain capacitor and an

on-board NAND Flash.

...the world's most energy friendly microcontrollers

1 Introduction

1.1 Description

The EFM32GG-STK3700 is an excellent starting point to get familiar with the EFM32 Giant Gecko

microcontrollers. The kit contains sensors and peripherals demonstrating some of the MCU's many

capabilities. The kit can also serve as a starting point for application development.

1.2 Features

• EFM32GG990F1024 MCU with 1 MB Flash and 128 KB RAM.

• Advanced Energy Monitoring system for precise current tracking.

• Integrated Segger J-Link USB debugger/emulator with debug out functionality.

• 160 segment Energy Micro LCD.

• 20 pin expansion header.

• Breakout pads for easy access to I/O pins.

• Power sources include USB and CR2032 battery.

• 2 user buttons, 2 user LEDs and a touch slider.

• Ambient Light Sensor and Inductive-capacitive metal sensor.

• EFM32 OPAMP footprint.

• 32 MB NAND Flash.

• USB Micro-AB (OTG) connector.

• 0.03F Super Capacitor for backup power domain.

• Crystals for LFXO and HFXO: 32.768kHz and 48.000MHz.

1.3 Getting Started

The first step to get started with your new EFM32GG-STK3700 is to go to

[http://www.energymicro.com/simplicity]

The Simplicity Studio software package contains all the tools, drivers, software examples and

documentation needed to use the EFM32 Giant Gecko Starter Kit Some important tools for use with the

EFM32GG-STK3700 are:

• energyAware Commander

• energyAware Profiler

The energyAware Commander is a tool for updating the kit's firmware, programming the MCU and

launching demos.

The energyAware Profiler is the PC-side interface to the Advanced Energy Monitor. It provides the

possibility to do energy-debugging and profiling of application code.

2013-10-10 - t0014_0.21 2 www.silabs.com

...the world's most energy friendly microcontrollers

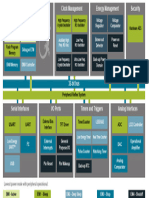

2 Kit Block Diagram

An overview of the EFM32 Giant Gecko Starter Kit is shown in Figure 2.1

Figure 2.1. EFM32GG-STK3700 Block Diagram

USB Mini- B 8x 20 Segm ent LCD

Connector

GPIO EXP Header

DEBUG

BOARD

CONTROLLER

UART

LESENSE

Light Sensor

EFM32 Giant Gecko

32Mx 8 NAND Microcontroller

EBI

Flash LESENSE

LC Sensor

Device/ Host

ACMP

GPIO

User Buttons USB OTG

& LEDs Connector Touch Slider

2013-10-10 - t0014_0.21 3 www.silabs.com

...the world's most energy friendly microcontrollers

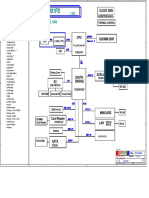

3 Kit Hardware Layout

The layout of the EFM32 Giant Gecko Starter Kit is shown below.

Figure 3.1. EFM32GG-STK3700 hardware layout

Debug

32MB NAND BU Capacitor Am bient Header

8x 20 Segm ent

LCD Flash Light Sensor

USB

Interface

EFM32 Reset

Ex pansion

Header

CR2032 User Push- buttons

Battery

LC Sensor

Power Source

Select

EFM32 Giant EFM32 Touch

User LEDs Gecko MCU USB Slider EFM32 Debug

2013-10-10 - t0014_0.21 4 www.silabs.com

...the world's most energy friendly microcontrollers

4 Power Supply and Reset

4.1 MCU Power Selection

The EFM32 Giant Gecko MCU on the EFM32GG-STK3700 is designed to be powered by three different

sources:

• Through the on-board debugger.

• Through the EFM32's own USB regulator.

• By a 3V Battery.

Selecting the power source is done with the slide switch in the lower left corner of the board. Figure

Figure 4.1 shows how the different power sources can be selected with the slide switch.

Figure 4.1. EFM32GG-STK3700 Power Switch

BG

T

B

US

BA

5V

Advanced 3.3V

Energy

USB Mini- B

Monitor DBG

Connector

USB VMCU

BAT

EFM32

USB_VREGO USB_VREGI

MCU

(3.3V) (5V) USB OTG

Connector

3V Lithium Battery

(CR2032)

With the switch in the DBG position, an on-board low noise LDO with a fixed output voltage of 3.3V

is used to power the MCU. This LDO is again powered from the "J-Link" USB cable. The Advanced

Energy Monitor is now also connected in series, allowing accurate high speed current measurements

and energy debugging/profiling.

With the switch in the USB position, the integrated linear regulator in the EFM32 Giant Gecko MCU is

used to power the rest of the chip as well as the USB PHY. This allows a USB device application where

the MCU acts as a bus powered device.

Finally, with the switch in the BAT position, a 20mm coin cell battery in the CR2032 socket can be used

to power the device.

Note

The Advanced Energy Monitor can only measure the current consumption of the EFM32

when the power selection switch is in the DBG position.

4.2 Board Controller Power

The Board Controller is responsible for important features such as the debugger and the Advanced

Energy Monitor, and is powered exclusively through the USB port in the top left corner of the board.

This part of the kit resides on a separate power domain, so a different power source can be selected for

the MCU while retaining debugging functionality. This power domain is also isolated to prevent current

leakage from the MCU power domain when power to the Board Controller is removed.

2013-10-10 - t0014_0.21 5 www.silabs.com

...the world's most energy friendly microcontrollers

4.3 Backup Power Domain

The kit contains a backup capacitor that can be used together with the EFM32 Giant Gecko's backup

power domain. In this case, all other power sources are removed from the kit, and only a small part of

the EFM32 runs off the capacitor. It is also possible to enter backup mode while the Board Controller is

powered by selecting either BAT or USB with no battery in the socket or USB cable in the connector.

4.4 MCU Reset

The EFM32 MCU can be reset by a few different sources:

• The RESET button.

• The on-board debugger.

• An external debugger by pulling the #RST pin low.

4.5 Board Controller Reset

The Board Controller can be reset by removing and re-inserting the J-Link USB cable. Removing the

Board Controller USB cable will not reset the EFM32, but whenever the Board Controller is powered up

again, it will issue a RESET to the EFM32 through the on-board debugger.

2013-10-10 - t0014_0.21 6 www.silabs.com

...the world's most energy friendly microcontrollers

5 Peripherals

The starter kit has a set of peripherals that showcase some of the features of the EFM32 Giant Gecko

microcontroller.

Be aware that most EFM32 I/O routed to peripherals are also routed to the breakout pads. This must be

taken into consideration when using the breakout pads for your application.

5.1 Push Buttons and LEDs

The kit has two user push buttons marked PB0 and PB1. They are connected to the EFM32, and are

debounced by RC filters with a time constant of 1ms. The buttons are connected to pins PB9 and PB10.

In addition to the two push buttons, the kit also features two yellow LEDs marked LED0 and LED1, that

are controlled by GPIO pins on the EFM32. The LEDs are connected to pins PE2 and PE3 in an active-

high configuration.

Figure 5.1. Buttons/LEDs

UIF_LED0

PE2

UIF_LED1

PE3

UIF_PB0

PB9 User Buttons

PB10

UIF_PB1 & LEDs

EFM32 MCU

5.2 LCD

A 28-pin Energy Micro LCD display is connected to the EFM32. The LCD has 8 common lines and 20

segment lines, giving a total of 160 segments in 8-plexed mode. These lines are not shared on the

breakout pads.

Figure 5.2. 160 Segment LCD

PA[11..7] LCD_SEG[39..35]

PB[2..0] LCD_SEG[34..32]

PD[12..9] LCD_SEG[31..28]

PA[6..0], PA15 LCD_SEG[19..12] 8x 20 Segm ent LCD

PB[6..3] LCD_COM[7..4]

PE[7..4] LCD_COM[3..0]

EFM32 MCU

Capacitors for the EFM32 Giant Gecko LCD boost function are also available on the EFM32GG-

STK3700.

2013-10-10 - t0014_0.21 7 www.silabs.com

...the world's most energy friendly microcontrollers

5.3 Capacitive Touch Slider

A touch slider utilizing the capacitive touch capability is available. It is placed beneath the two push

buttons on the kit. The slider interpolates 4 separate pads to find the exact position of a finger. For low

power operation, the touch slider can be used together with LESENSE to continuously scan all 4 pads,

using LESENSE channels 8 to 11.

Figure 5.3. Touch Slider

UIF_TOUCH0

PC8 (ACMP1_CH0)

UIF_TOUCH1

PC9 (ACMP1_CH1)

UIF_TOUCH2

PC10 (ACMP1_CH2)

PC11 (ACMP1_CH3)

UIF_TOUCH3 Touch Slider

EFM32 MCU

The capacitive touch slider works by sensing changes in the capacitance of the pads when touched by a

human finger. Sensing the changes in capacitance is done by setting up the touch pad as part of an RC

relaxation oscillator using the EFM32's analog comparator, and then counting the number of oscillations

during a fixed period of time.

5.4 Ambient Light Sensor

The kit has a light sensitive, transistor type, ambient light sensor connected to the low energy sensor

interface of the EFM32 Giant Gecko MCU. The sensor is placed above the push buttons and can be

used to sense changes in ambient light levels.

Figure 5.4. Light Sensor

LIGHT_EXCITE

PD6 (LES_ALTEX0)

PC6 (ACMP0_CH6) LIGHT_SENSE TEMT6200FX01

22K

EFM32 MCU

Two pins are used for the light sensor operation: one for excitation, and one for sensing. The sense pin

is connected to ACMP0 CH6. Both the excitation pin and the sense pin can be controlled directly from

the EFM32's LESENSE module.

2013-10-10 - t0014_0.21 8 www.silabs.com

...the world's most energy friendly microcontrollers

5.5 LC Sensor

In the bottom right corner there is an inductive-capacitive sensor for demonstrating the low energy sensor

interface. By setting up oscillating currents in the inductor, metal nearby the inductor can be sensed by

measuring the oscillation decay time. The effective range is a few millimeters.

Figure 5.5. LC Metal Sensor

DAC_LC_EXCITE

100 nF

390 uH

330 pF

PB12 (DAC0_OUT1)

PC7 (ACMP0_CH7)

1.5K

LES_LC_SENSE

EFM32 MCU Metal Object

2013-10-10 - t0014_0.21 9 www.silabs.com

...the world's most energy friendly microcontrollers

5.6 NAND Flash

A 32MB NAND Flash is connected to the external bus interface of the EFM32 Giant Gecko MCU. The

interface is a simple 8-bit parallel interface. This peripheral demonstrates the EFM32 Giant Gecko's EBI

module's NAND support with built in ECC generation.

Figure 5.6. NAND Flash Interface

VMCU

PB15 NAND_PWR_EN

PE[15..8] EBI_AD[7..0] I/ O[7..0]

PC1 EBI_A24 ALE

PC2 EBI_A25 CLE

PF8 EBI_WE# WE#

PF9 EBI_RE# RE#

PD13 NAND_WP# WP#

PD14 NAND_CE# CE#

PD15 NAND_R/ B# R/ B#

EFM32 MCU NAND256W3A

A separate power switch is used to enable/disable the NAND flash, thus avoiding excess current draw

when not used. When NAND_PWR_EN is high, the NAND flash is powered from the same supply as

the EFM32 MCU. It is recommended to keep the write-protect line low during power transitions.

The ALE (address latch enable) and CLE (command latch enable) pins of the NAND Flash are connected

to the EBI Address pins 24 and 25, and the CE (chip enable) line is connected to a general GPIO pin.

This causes the NAND data, address and command registers to be mapped in the EFM32's address

space as:

Data register: 0x80000000

Address register: 0x81000000

Command 0x82000000

register:

5.7 Backup Domain Capacitor

A small super capacitor is provided to evaluate the EFM32 Giant Gecko MCU's backup power domain.

The capacitor has a nominal value of 33 mF, and is connected with a 100 ohm series resistor to the

BU_VIN pin of the EFM32.

Because of the extremely low power consumption of the EFM32 in backup mode (400nA), the capacitor

can power a clock application using the low frequency crystal oscillator (LFXO) for more than 8 hours.

The series resistor allows measuring of the current drawn from the capacitor into the EFM32 device, by

simply using a multimeter to measure the voltage across it. Please refer to the schematic and assembly

drawings to locate the series resistor.

2013-10-10 - t0014_0.21 10 www.silabs.com

...the world's most energy friendly microcontrollers

5.8 USB Micro-AB Connector

The EFM32GG-STK3700 board is equipped with a USB Micro-AB connector supporting USB Device

and Embedded Host modes. The figure below shows how the USB lines are connected to the EFM32.

The USB_VBUSEN line is connected to a current limited switch which supplies the VBUS line with 5V

when operating as a USB Host. The current limited switch also has a flag signal connected to the EFM32

which can notify it in case excessive current is drawn by the attached device. Note that the "J-Link" USB

cable must be inserted to provide 5V to the device when operating the EFM32 in host mode.

Figure 5.7. EFM32 USB Connector

5V

Overcurrent

PF6 (GPIO)

VBUS Enable

PF5 (USB_VBUSEN)

ID

PF12 (USB_ID)

D-

PF10 (USB_DM)

D+

PF11 (USB_DP)

VBUS USB OTG

USB_VBUS

Connector

USB_VREGI

USB_VREGO

1uF 4.7uF

5.9 Op-Amp Footprint

If the kit is flipped over there is a silk-print model of a typical operational amplifier feedback circuit. The

actual operational amplifier is one of the op-amps inside the EFM32. By soldering 0603 sized resistors

the EFM32 internal operational amplifier can be evaluated with exact resistor values.

2013-10-10 - t0014_0.21 11 www.silabs.com

...the world's most energy friendly microcontrollers

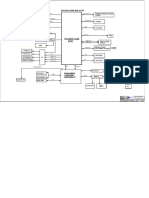

6 Advanced Energy Monitor

6.1 Usage

The AEM (Advanced Energy Monitor) data is collected by the board controller and can be displayed

by the energyAware Profiler, available through Simplicity Studio. By using the energyAware Profiler,

current consumption and voltage can be measured and linked to the actual code running on the EFM32

in realtime.

6.2 AEM theory of operation

In order to be able to accurately measure current ranging from 0.1uA to 50mA (114dB dynamic range), a

current sense amplifier is utilized together with a dual gain stage. The current sense amplifier measures

the voltage drop over a small series resistor, and the gain stage further amplifies this voltage with two

different gain settings to obtain two current ranges. The transition between these two ranges occurs

around 250uA. Digital filtering and averaging is done within the Board Controller before the samples are

exported to the energyAware Profiler application.

During startup of the kit, an automatic calibration of the AEM is performed. This calibration compensates

for the offset error in the sense amplifiers.

Figure 6.1. Advanced Energy Monitor

5V

3.3V VMCU

LDO 4.7R

Sense Resistor Power Select

Switch

Current Sense Sensors &

EFM32

Am plifier Peripherals

HG

AEM Dual Gain

Stage

Processing

LG

6.3 AEM accuracy and performance

The Advanced Energy Monitor is capable of measuring currents in the range of 0.1uA to 50mA. For

currents above 250uA, the AEM is accurate within 0.1mA. When measuring currents below 250uA, the

accuracy increases to 1uA. Even though the absolute accuracy is 1uA in the sub 250uA range, the

AEM is able to detect changes in the current consumption as small as 100nA. The AEM produces 6250

current samples per second.

Note

The current measurement will only be correct when powering the EFM32 from USB power

through the debugger (power select switch set to "DBG").

2013-10-10 - t0014_0.21 12 www.silabs.com

...the world's most energy friendly microcontrollers

7 Board Controller

The kit contains a board controller that is responsible for performing various board level tasks, such

as handling the debugger and the Advanced Energy Monitor. An interface is provided between the

EFM32 and the board controller in the form of a UART connection. The connection is enabled by setting

the EFM_BC_EN (PF7) line high, and using the lines EFM_BC_TX (PE0) and EFM_BC_RX (PE1) for

communicating.

Specific library functions has been provided in the kit Board Support Package that supports various

requests to be made to the board controller, such as quering AEM voltage or current. To use these

functions, the Board Support Package must be installed. See the Chapter 8 to find out more.

Note

The board controller is only available when USB power is connected.

2013-10-10 - t0014_0.21 13 www.silabs.com

...the world's most energy friendly microcontrollers

8 Board Support Package

The Board Support Package (BSP) is a set of C source and header files that enables easy access to,

and control over some board specific features.

Compared to the Energy Micro development kit, the functionality is limited. Unless you need/want some

of the functions contained in the BSP, there is really no need to include or use it. The EFM32 in the Starter

Kit is fully usable without BSP support, and you can use all peripherals in the emlib without the BSP.

The BSP use EFM32 peripheral UART0, Location 1 (TX pin PE0, RX pin PE1) on baudrate 115200-8-

N-1 to communicate with the board controller.

Note

The BSP is only functional when the Starter Kit is USB-powered, using these function calls

with USB disconnected will give unpredictable results.

8.1 Installation location

When installing Simplicity Studio, the BSP will be installed in the user directory, typically in a location

such as

Win7: C:\Users\[username]\AppData\Roaming\energymicro\kits\EFM32GG_STK3700\

or something similar (depending on your OS/Windows version). All files in the board support package

are prefixed by stk.

8.2 Application Programming Interface

To use the BSP, include the Starter Kit header file, like this:

#include "bsp.h"

All functions in the BSP are prefixed with BSP_. The main initialization routine is defined as

void BSP_Init ( BSP_INIT_STK_BCUART )

and must be called before any access to the STK-functions. This function call will setup the UART

communication channel with a 115800 baud rate. This baud rate depends on the current core clock, so

correct clock configuration should be set before calling this function.

float BSP_CurrentGet ( void )

Returns instant current usage in milliamperes.

float BSP_VoltageGet ( void )

Returns instant voltage (VMCU) reading in volt.

8.3 Example Applications

Under the kits/EFM32GG_STK3700/examples folder in your installation directory, you will find an

example program using the BSP, with corresponding project/Makefiles for the supported IDEs.

The examples folder also contains examples showing how to use the different peripherals on the

EFM32GG-STK3700.

8.4 How to include in your own applications

The easiest way to include the BSP in your application is to base your work on the example application

that use the BSP. The following items are recommended for correct configuration:

2013-10-10 - t0014_0.21 14 www.silabs.com

...the world's most energy friendly microcontrollers

1. Make sure you define the correct part number (i.e. EFM32GG990F1024) as a preprocessor defined

symbol

2. Make sure you define the correct part number (i.e. EFM32GG990F1024) for your project file

3. Add and include the EFM32_CMSIS-files (startup_efm32.s, system_efm32.c, core_cm3.c) to your

project

4. Add and include all BSP package .c-files, with the bsp-prefix to your project

5. Configure include paths to point at the CMSIS/CM3/CoreSupport and CMSIS/CM3/DeviceSupport/

EnergyMicro/EFM32 directories

6. Configure include paths to point to the kits/EFM32GG_STK3700/bsp directory

Make sure you call "BSP_Init()" early at startup, and you should be all set.

2013-10-10 - t0014_0.21 15 www.silabs.com

...the world's most energy friendly microcontrollers

9 Connectors

9.1 Breakout pads

Many of the EFM32's pins are routed out to "breakout pads" at the top and bottom edges of the kit. A

2.54mm pitch pin header can be soldered in for easy access to these pins. Most I/O pins are available,

with the exception of pins used to drive the LCD and some pins used to drive the NAND flash.

Note

Some of the breakout pads are shared by on-board EFM peripherals. The schematic must

be consulted to make sure that it is OK to use a shared pin in your application.

Figure 9.1. Breakout pads and Expansion Header

3 V CU

G 5

PD 3

VM 4

PB 0

PB 1

PD 2

PB D

PD D

PD D

1

0

1

2

3

4

5

6

7

8

1

1

3

1

9

1

1

N

N

PB

PD

PD

PD

PD

PD

PD

PD

PD

5V

EXP Header

Top row Bottom row

3 V3 GND

5V PD7

PD6 PC6

PD5 PB1 2

PD4 PB1 1

PD3 PC5

PD2 PC4

PD1 PC3

PD0 PC0

VMCU GND

5V

PA

PA 2

PA 3

G 4

PE D

PE

PE

PE

G

PC D

PC

PC

PC

G

PF D

PF

VM

3 V CU

G

#RD

SW SE

SWD I O

SWCLK

N

N

8

9

0

1

2

3

0

1

2

7

1

1

1

E

3

O

T

Note

Pins PC3, PC4, PC5 and PC6 are also available as surface mounted pads beneath the

USB Micro-AB connector

9.2 Expansion header

On the right hand side of the board an angled 20 pin expansion header is provided to allow connection of

peripherals or plugin boards. The connecter contains a number of I/O pins that can be used with most of

the EFM32 Giant Gecko's features. Additionally, the VMCU, 3V3 and 5V power rails are also exported.

Figure Figure 9.1 shows the pin assignment of the expansion header. With the exception of a few pins,

most of the Expansion Header's pins are the same as those on the EFM32 Gecko or EFM32 Tiny Gecko

starter kits.

Some of the chip peripheral functions that are available on the Expansion Header are listed in table

Table 9.1.

2013-10-10 - t0014_0.21 16 www.silabs.com

...the world's most energy friendly microcontrollers

Figure 9.2. Expansion Header

GND 1 2 VMCU

PC0 3 4 PD0

PC3 5 6 PD1

PC4 7 8 PD2

PC5 9 10 PD3

PB11 11 12 PD4

PB12 13 14 PD5

PC6 15 16 PD6

PD7 17 18 5V

GND 19 20 3V3

Table 9.1. Some peripheral functions available on Expansion Header

Peripheral Peripheral pin MCU Pin EXP Header pin number

USART/SPI USART1_TX PD0 4

USART1_RX PD1 6

USART1_CLK PD2 8

USART1_CS PD3 10

I²C I2C1_SDA PC4 7

I2C1_SCL PC5 9

Low Energy UART LEUART0_TX PD4 12

LEUART0_RX PD5 14

Analog to Digital ADC0_CH0 PD0 4

Converter

ADC0_CH1 PD1 6

ADC0_CH2 PD2 8

ADC0_CH3 PD3 10

ADC0_CH4 PD4 12

ADC0_CH5 PD5 14

ADC0_CH6 PD6 16

ADC0_CH7 PD7 17

Digital to Analog DAC0_CH0 PB11 11

Converter

DAC0_CH1 PB12 13

Analog Comparator ACMP0_CH0 PC0 3

ACMP0_CH3 PC3 5

ACMP0_CH4 PC4 7

ACMP0_CH5 PC5 9

ACMP0_CH6 PC6 15

ACMP0_O PD6 16

ACMP1_O PD7 17

Operational Amplifier OPAMP_N0 PC5 9

OPAMP_P0 PC4 7

2013-10-10 - t0014_0.21 17 www.silabs.com

...the world's most energy friendly microcontrollers

Peripheral Peripheral pin MCU Pin EXP Header pin number

OPAMP_OUT0 PB11 11

OPAMP_N1 PD7 17

OPAMP_P1 PD6 16

OPAMP_OUT1 PB12 13

OPAMP_N2 PD3 10

OPAMP_P2 PD4 12

OPAMP_OUT2 PD5, PD0 14, 4

Timer Compare/Capture TIMER0_CC0 PD1 6

TIMER0_CC1 PD2 8

TIMER0_CC2 PD3 10

TIMER1_CC0 PD6 16

TIMER1_CC1 PD7 17

TIMER1_CC2 PB11 11

Low Energy Timer LETIM0_OUT0 PD6, PB11, PC4 16, 11, 7

LETIM0_OUT1 PD7, PB12, PC5 17, 13, 9

Low Energy Sensor LES_CH0 PC0 3

Interface (LESENSE)

LES_CH3 PC3 5

LES_CH4 PC4 7

LES_CH5 PC5 9

LES_CH6 PC6 15

LES_ALTEX0 PD6 16

LES_ALTEX1 PD7 17

Pulse Counter PCNT0_S0IN PD6 16

PCNT0_S1IN PD7 17

PCNT1_S0IN PC4 7

PCNT1_S1IN PC5 9

PCNT2_S0IN PD0 4

PCNT2_S1IN PD1 6

Peripheral Reflex System PRS_CH2 PC0 3

(PRS)

Note

Please note that this table only sums up some of the alternate functions available on

the expansion header. Consult the EFM32GG990F1024 datasheet for a complete list of

alternate functions.

2013-10-10 - t0014_0.21 18 www.silabs.com

...the world's most energy friendly microcontrollers

9.3 Debug connector

This connector is used for Debug In and Debug Out (see chapter on Debugging). The pinout is described

in Table 9.2.

Figure 9.3. Debug Connector

VTARGET 1 2 NC

#TRST 3 4 GND

TDI 5 6 GND

TMS/ SWDIO 7 8 GND

TCK/ SWCLK 9 10 GND

RTCK 11 12 GND

TDO/ SWO 13 14 GND

#RESET 15 16 GND

PD 17 18 Cable Detect

PD 19 20 GND

Table 9.2. Debug connector pinout

Pin Function Note

number

1 VTARGET Target voltage on the debugged application.

2 NC Not Connected

3 #TRST JTAG tap reset

5 TDI JTAG data in

7 TMS/SWDIO JTAG TMS or Serial Wire data I/O

9 TCK/SWCLK JTAG TCK or Serial Wire clock

11 RTCK JTAG RTCK

13 TDO/SWO JTAG TDO or Serial Wire Output

15 #RESET Target MCU reset

17 PD This pin has a 100k pulldown.

18 Cable detect This signal must be pulled to ground by the external debugger or application for cable

insertion detection.

19 PD This pin has a 100k pulldown.

4, 6, 8, GND

10, 12,

14, 16,

20

9.4 Trace Header

A header with connections to the Embedded Trace Module (ETM) in the EFM32 Giant Gecko MCU is

provided on the reverse side of the PCB. The header is not mounted by default, but a 20-pin, 1.27mm

pitch SMD header can be soldered on to allow an external trace emulator to be connected.

In addition to the serial wire debug pins, this header also contains the ETM_CLK and ETM_TD signals.

The pinout is described in Table 9.3. Please refer to the kit assembly drawing to locate the trace header,

which has the reference P200.

2013-10-10 - t0014_0.21 19 www.silabs.com

...the world's most energy friendly microcontrollers

Figure 9.4. Trace Header

VTref 1 2 SWDIO/ TMS

GND 3 4 SWCLK/ TCK

GND 5 6 SWO/ TDO

NC 7 8 TDI (NC)

GND 9 10 nRESET

NC 11 12 TRACECLK

NC 13 14 TRACE- DATA[0]

GND 15 16 TRACE- DATA[1]

GND 17 18 TRACE- DATA[2]

GND 19 20 TRACE- DATA[3]

Table 9.3. Trace header pinout

Pin Function Note

number

1 VTref Target reference voltage.

2 SWDIO/TMS Serial Wire Data Input/Output

4 SWCLK/TCK Serial Wire Clock input

6 SWO/TDO Serial Wire Output trace port

8 TDI Not Connected on the EFM32GG-STK3700

10 nRESET Target CPU reset signal.

12 TRACECLK Trace clock output. Trace clock = 1/2 CPU clock.

14 TRACE-DATA[0] Trace data output pin 0.

16 TRACE-DATA[1] Trace data output pin 1.

18 TRACE-DATA[2] Trace data output pin 2.

20 TRACE-DATA[3] Trace data output pin 3.

7, 11, 13 NC Not Connected

3, 5, 9, GND

15, 17,

19

Note

The EFM32GG-STK3700 debugger does not contain any trace functionality apart from

the basic functionality provided with Serial Wire View (SWV). This header is only useful

together with an external trace emulator.

2013-10-10 - t0014_0.21 20 www.silabs.com

...the world's most energy friendly microcontrollers

10 Integrated Development Environments

The Energy Micro software packages contains various examples in source form to use with the Starter

Kit. The following IDEs are supported.

10.1 IAR Embedded Workbench for ARM

An evaluation version of IAR Embedded Workbench for ARM is included on a CD in the EFM32GG-

STK3700 package. Check the quick start guide for where to find updates, and IAR's own documentation

on how to use it. You will find the IAR project file in the

iar

subfolder of each project

10.2 Rowley Associates - CrossWorks for ARM

See the quick start guide for download details for CrossWorks for ARM. You will find CrossWorks project

files in the

rowley

subfolder of each project.

10.3 CodeSourcery - Sourcery G++

See the quick start guide for download details for Sourcery G++. The

codesourcery

subfolder contains Makefiles for use with the Sourcery G++ development environment.

10.4 Keil - MDK-ARM

See the quick start guide for download details for evaluation versions of Keil MDK-ARM. The

arm

subfolder in each project contains project files for MDK-ARM. Please see the MDK-ARM documentation

for usage details.

2013-10-10 - t0014_0.21 21 www.silabs.com

...the world's most energy friendly microcontrollers

11 energyAware Commander and Upgrades

The energyAware Commander is a program that comes with Simplicity Studio. It can perform various

kit and EFM32 specific tasks.

11.1 eA Commander Operation

This utility gives the ability to program the EFM32, upgrade the kit, lock and unlock devices and more.

Some of the features will only work with Energy Micro kits, while other will work with a J-Link debugger

connected. Press the "F1" button, or select the "Help->Help" menu item for a full description.

11.2 Upgrades

Upgrading the kit is done through Simplicity Studio. The Studio will automatically check for new updates

on startup.

You can also use the energyAware Commander for manual upgrades. Select the "Kit" icon, use the

"Browse" button to select the correct file ending in ".emz", and press the "Install package button".

2013-10-10 - t0014_0.21 22 www.silabs.com

...the world's most energy friendly microcontrollers

12 Schematics, Assy Drawings and BOM

The schematics, assembly drawings and bill of materials (BOM) for the EFM32 Giant Gecko Starter Kit

board is available through Simplicity Studio when the kit documentation package has been installed.

2013-10-10 - t0014_0.21 23 www.silabs.com

...the world's most energy friendly microcontrollers

13 Kit Revision History and Errata

13.1 Revision History

The kit revision can be found printed on the box label of the kit, as outlined in the figure below.

Figure 13.1. Revision info

Table 13.1. Kit Revision History

Kit Revision Released Description

A05 18.10.2012 Added USB micro-B to USB A female adapter cable to kit BOM.

A04 15.06.2012 Updated PCB to improve USB micro-AB connector footprint.

A03 15.05.2012 Updated PCB to add test-points for EFM32 USB.

A02 26.04.2012 Initial production version

13.2 Errata

Table 13.2. Kit Errata

Kit Revision Problem Description

A02 Footprint of C250 is One of the capacitors on the OPAMP footprint, as described in

wrong. Section 5.9, is a 0402 sized footprint instead of 0603. This is a

minor problem, and might cause some difficulties when trying to

add a capacitor here. The error is only present on PCB's marked

"PCB2200 REV. A02".

2013-10-10 - t0014_0.21 24 www.silabs.com

...the world's most energy friendly microcontrollers

14 Document Revision History

Table 14.1. Document Revision History

Revision Effective Date Change Description

Number

0.21 10.10.2013 Updated document template and Silicon Labs contact/legal information.

0.20 10.04.2013 Updated kit revision section.

0.11 31.05.2012 Fixed error in expansion header pinout shown in Figure 9.1

0.10 15.05.2012 First version with revision history.

2013-10-10 - t0014_0.21 25 www.silabs.com

...the world's most energy friendly microcontrollers

A Disclaimer and Trademarks

A.1 Disclaimer

Silicon Laboratories intends to provide customers with the latest, accurate, and in-depth documentation

of all peripherals and modules available for system and software implementers using or intending to use

the Silicon Laboratories products. Characterization data, available modules and peripherals, memory

sizes and memory addresses refer to each specific device, and "Typical" parameters provided can and

do vary in different applications. Application examples described herein are for illustrative purposes

only. Silicon Laboratories reserves the right to make changes without further notice and limitation to

product information, specifications, and descriptions herein, and does not give warranties as to the

accuracy or completeness of the included information. Silicon Laboratories shall have no liability for

the consequences of use of the information supplied herein. This document does not imply or express

copyright licenses granted hereunder to design or fabricate any integrated circuits. The products must

not be used within any Life Support System without the specific written consent of Silicon Laboratories.

A "Life Support System" is any product or system intended to support or sustain life and/or health, which,

if it fails, can be reasonably expected to result in significant personal injury or death. Silicon Laboratories

products are generally not intended for military applications. Silicon Laboratories products shall under no

circumstances be used in weapons of mass destruction including (but not limited to) nuclear, biological

or chemical weapons, or missiles capable of delivering such weapons.

A.2 Trademark Information

Silicon Laboratories Inc., Silicon Laboratories, Silicon Labs, SiLabs and the Silicon Labs logo, CMEMS®,

EFM, EFM32, EFR, Energy Micro, Energy Micro logo and combinations thereof, "the world’s most

energy friendly microcontrollers", Ember®, EZLink®, EZMac®, EZRadio®, EZRadioPRO®, DSPLL®,

ISOmodem®, Precision32®, ProSLIC®, SiPHY®, USBXpress® and others are trademarks or registered

trademarks of Silicon Laboratories Inc. ARM, CORTEX, Cortex-M3 and THUMB are trademarks or

registered trademarks of ARM Holdings. Keil is a registered trademark of ARM Limited. All other products

or brand names mentioned herein are trademarks of their respective holders.

2013-10-10 - t0014_0.21 26 www.silabs.com

...the world's most energy friendly microcontrollers

B Contact Information

Silicon Laboratories Inc.

400 West Cesar Chavez

Austin, TX 78701

Please visit the Silicon Labs Technical Support web page:

http://www.silabs.com/support/pages/contacttechnicalsupport.aspx

and register to submit a technical support request.

2013-10-10 - t0014_0.21 27 www.silabs.com

...the world's most energy friendly microcontrollers

Table of Contents

1. Introduction .............................................................................................................................................. 2

1.1. Description .................................................................................................................................... 2

1.2. Features ....................................................................................................................................... 2

1.3. Getting Started ............................................................................................................................... 2

2. Kit Block Diagram ..................................................................................................................................... 3

3. Kit Hardware Layout .................................................................................................................................. 4

4. Power Supply and Reset ............................................................................................................................ 5

4.1. MCU Power Selection ..................................................................................................................... 5

4.2. Board Controller Power .................................................................................................................... 5

4.3. Backup Power Domain .................................................................................................................... 6

4.4. MCU Reset ................................................................................................................................... 6

4.5. Board Controller Reset .................................................................................................................... 6

5. Peripherals ............................................................................................................................................... 7

5.1. Push Buttons and LEDs ................................................................................................................... 7

5.2. LCD ............................................................................................................................................. 7

5.3. Capacitive Touch Slider ................................................................................................................... 8

5.4. Ambient Light Sensor ...................................................................................................................... 8

5.5. LC Sensor ..................................................................................................................................... 9

5.6. NAND Flash ................................................................................................................................. 10

5.7. Backup Domain Capacitor .............................................................................................................. 10

5.8. USB Micro-AB Connector ............................................................................................................... 11

5.9. Op-Amp Footprint .......................................................................................................................... 11

6. Advanced Energy Monitor ......................................................................................................................... 12

6.1. Usage ......................................................................................................................................... 12

6.2. AEM theory of operation ................................................................................................................. 12

6.3. AEM accuracy and performance ...................................................................................................... 12

7. Board Controller ...................................................................................................................................... 13

8. Board Support Package ............................................................................................................................ 14

8.1. Installation location ........................................................................................................................ 14

8.2. Application Programming Interface ................................................................................................... 14

8.3. Example Applications ..................................................................................................................... 14

8.4. How to include in your own applications ............................................................................................ 14

9. Connectors ............................................................................................................................................. 16

9.1. Breakout pads .............................................................................................................................. 16

9.2. Expansion header ......................................................................................................................... 16

9.3. Debug connector ........................................................................................................................... 19

9.4. Trace Header ............................................................................................................................... 19

10. Integrated Development Environments ....................................................................................................... 21

10.1. IAR Embedded Workbench for ARM ............................................................................................... 21

10.2. Rowley Associates - CrossWorks for ARM ....................................................................................... 21

10.3. CodeSourcery - Sourcery G++ ....................................................................................................... 21

10.4. Keil - MDK-ARM ......................................................................................................................... 21

11. energyAware Commander and Upgrades ................................................................................................... 22

11.1. eA Commander Operation ............................................................................................................. 22

11.2. Upgrades ................................................................................................................................... 22

12. Schematics, Assy Drawings and BOM ....................................................................................................... 23

13. Kit Revision History and Errata ................................................................................................................. 24

13.1. Revision History .......................................................................................................................... 24

13.2. Errata ........................................................................................................................................ 24

14. Document Revision History ...................................................................................................................... 25

A. Disclaimer and Trademarks ....................................................................................................................... 26

A.1. Disclaimer ................................................................................................................................... 26

A.2. Trademark Information ................................................................................................................... 26

B. Contact Information ................................................................................................................................. 27

B.1. ................................................................................................................................................. 27

2013-10-10 - t0014_0.21 28 www.silabs.com

...the world's most energy friendly microcontrollers

List of Figures

2.1. EFM32GG-STK3700 Block Diagram ........................................................................................................... 3

3.1. EFM32GG-STK3700 hardware layout ......................................................................................................... 4

4.1. EFM32GG-STK3700 Power Switch ............................................................................................................ 5

5.1. Buttons/LEDs ......................................................................................................................................... 7

5.2. 160 Segment LCD .................................................................................................................................. 7

5.3. Touch Slider .......................................................................................................................................... 8

5.4. Light Sensor .......................................................................................................................................... 8

5.5. LC Metal Sensor .................................................................................................................................... 9

5.6. NAND Flash Interface ............................................................................................................................ 10

5.7. EFM32 USB Connector .......................................................................................................................... 11

6.1. Advanced Energy Monitor ....................................................................................................................... 12

9.1. Breakout pads and Expansion Header ...................................................................................................... 16

9.2. Expansion Header ................................................................................................................................. 17

9.3. Debug Connector .................................................................................................................................. 19

9.4. Trace Header ....................................................................................................................................... 20

13.1. Revision info ...................................................................................................................................... 24

2013-10-10 - t0014_0.21 29 www.silabs.com

...the world's most energy friendly microcontrollers

List of Tables

9.1. Some peripheral functions available on Expansion Header ............................................................................ 17

9.2. Debug connector pinout ......................................................................................................................... 19

9.3. Trace header pinout .............................................................................................................................. 20

13.1. Kit Revision History ............................................................................................................................. 24

13.2. Kit Errata ........................................................................................................................................... 24

14.1. Document Revision History ................................................................................................................... 25

2013-10-10 - t0014_0.21 30 www.silabs.com

You might also like

- Microcontroller Compete Course PDFDocument106 pagesMicrocontroller Compete Course PDFRidaNo ratings yet

- S8254A E.en - PTDocument24 pagesS8254A E.en - PTleandroNo ratings yet

- Embedded Unit Testing FrameworkDocument125 pagesEmbedded Unit Testing Frameworkdinokid08100% (1)

- Et STM32F103 PDFDocument25 pagesEt STM32F103 PDFabd01111100% (2)

- Arm 32Document20 pagesArm 32Surbhi Pal0% (1)

- Arm Cortex m3 and m4 Mcu ArchitectureDocument7 pagesArm Cortex m3 and m4 Mcu ArchitecturerockingjoeNo ratings yet

- MIMXRT1050EVKBHUGDocument18 pagesMIMXRT1050EVKBHUGFaris FarisNo ratings yet

- Efm 32 GGDocument1 pageEfm 32 GGJavier Pueyo SerranoNo ratings yet

- Infineon-XMC Link Board Users Manual - pdf-UserManual-v01 00-ENDocument12 pagesInfineon-XMC Link Board Users Manual - pdf-UserManual-v01 00-ENNik NameNo ratings yet

- An633 PDFDocument86 pagesAn633 PDFdhilaNo ratings yet

- An633 PDFDocument86 pagesAn633 PDFdhilaNo ratings yet

- An633 PDFDocument86 pagesAn633 PDFdhilaNo ratings yet

- Ecee AVR Mega32 - Users ManualDocument40 pagesEcee AVR Mega32 - Users Manualgoaltech100% (1)

- Discovery Kit With STM32L053C8 MCUDocument6 pagesDiscovery Kit With STM32L053C8 MCUarNo ratings yet

- t0008 Efm32 g8xx STK User ManualDocument40 pagest0008 Efm32 g8xx STK User Manualkunalkundanam1046No ratings yet

- Infineon-EZ-PD CCG3 USB Type-C Controller With Power Delivery-DataSheet-V11 00-EnDocument46 pagesInfineon-EZ-PD CCG3 USB Type-C Controller With Power Delivery-DataSheet-V11 00-Endea iuoNo ratings yet

- Esquema Elétrico Asus Nexus 7 ME370TDocument44 pagesEsquema Elétrico Asus Nexus 7 ME370TCarlos VenturaNo ratings yet

- Asus FE171MG: Trouble Shooting GuideDocument51 pagesAsus FE171MG: Trouble Shooting GuideWilliam SequeraNo ratings yet

- Discovery Kit With STM32F303VC MCUDocument5 pagesDiscovery Kit With STM32F303VC MCUesyNo ratings yet

- Asus 1001PX N455 Rev1.2G SchematicDocument41 pagesAsus 1001PX N455 Rev1.2G SchematicCosti.HNo ratings yet

- Nanocam C1U Datasheet: Camera Payload For Nano-SatellitesDocument13 pagesNanocam C1U Datasheet: Camera Payload For Nano-SatellitesERNESTONo ratings yet

- 32 F 401 CdiscoveryDocument4 pages32 F 401 CdiscoveryTrung Đặng VănNo ratings yet

- Linemaster LSC 805 4 DatasheetDocument7 pagesLinemaster LSC 805 4 DatasheetAndres Emilio Veloso RamirezNo ratings yet

- chipKIT Max32 - RMDocument23 pageschipKIT Max32 - RMrifaipadNo ratings yet

- Asus Eee PC 1015PE Rev1.2G SchematicDocument42 pagesAsus Eee PC 1015PE Rev1.2G SchematicGolek WaeNo ratings yet

- EM - A8316C - 200B - ENE V2.0B (Block-Diagram)Document1 pageEM - A8316C - 200B - ENE V2.0B (Block-Diagram)LABORATORIO ACCOMPUTERNo ratings yet

- stm32l476g EvalDocument4 pagesstm32l476g Evalfelipe.mottaNo ratings yet

- ETL Freescale Prog 805P18 UGDocument19 pagesETL Freescale Prog 805P18 UGArtur KrzyżanowskiNo ratings yet

- Ingenic Semiconductor Co. LTD Jz7420 Multimedia Application Processor. Data Sheet. Revision 0.3 November 2007Document38 pagesIngenic Semiconductor Co. LTD Jz7420 Multimedia Application Processor. Data Sheet. Revision 0.3 November 2007Lenina Viktoriya TeknyetovaNo ratings yet

- E32-900MBL-01 UserManual Des v1.1Document16 pagesE32-900MBL-01 UserManual Des v1.1Teodosia MansillaNo ratings yet

- Asus Eepc 1015cx PDFDocument43 pagesAsus Eepc 1015cx PDFluisNo ratings yet

- Designing A Low-Cost, High-Accuracy Infrared Thermometer: Application ReportDocument15 pagesDesigning A Low-Cost, High-Accuracy Infrared Thermometer: Application ReportfayçalNo ratings yet

- TMS320C2000™ DC/DC LED Lighting Developer's Kit Quick Start GuideDocument7 pagesTMS320C2000™ DC/DC LED Lighting Developer's Kit Quick Start GuideManu MathewNo ratings yet

- BevalDocument6 pagesBevalVladimirNo ratings yet

- Module - 02 ArchitectureDocument18 pagesModule - 02 ArchitectureMaria MEKLINo ratings yet

- Service Manual For IQ320Document27 pagesService Manual For IQ320KaterineCespedesBacarrezaNo ratings yet

- Emdoor Confidential: Gemini Lake SOCDocument55 pagesEmdoor Confidential: Gemini Lake SOCTukytukyNo ratings yet

- Module 2: ArchitectureDocument18 pagesModule 2: Architectureabs4everonlineNo ratings yet

- 32F411Ediscovery: Discovery Kit With STM32F411VE MCUDocument5 pages32F411Ediscovery: Discovery Kit With STM32F411VE MCUPrakash ChandraNo ratings yet

- Adc 3g AP-fcxxxxm0nxx-2tx Spec Rev1.1Document16 pagesAdc 3g AP-fcxxxxm0nxx-2tx Spec Rev1.1vspuriNo ratings yet

- Ug303 stk3301Document28 pagesUg303 stk3301Sm NoteNo ratings yet

- Efm32G890 Datasheet: EFM32G890 Microcontrollers Are Suited For All Battery Operated ApplicationsDocument71 pagesEfm32G890 Datasheet: EFM32G890 Microcontrollers Are Suited For All Battery Operated ApplicationsamerosperosNo ratings yet

- Mini-Itx D2963-S Mini-Itx D2963-S: Technotes V1.0Document78 pagesMini-Itx D2963-S Mini-Itx D2963-S: Technotes V1.0palprodNo ratings yet

- Asus Eee PC 1015p Rev 1.2gDocument42 pagesAsus Eee PC 1015p Rev 1.2gRusdi Cahyono0% (1)

- Nucleo F401reDocument7 pagesNucleo F401repravsaieenNo ratings yet

- AX309 English UG.1.0Document35 pagesAX309 English UG.1.0Bijan AmiriNo ratings yet

- Asus Eee PC 1001PX Rev 1 2G SchematicsDocument41 pagesAsus Eee PC 1001PX Rev 1 2G Schematicsxack880% (1)

- M5Stickc Plus: Tutorial&Quick-StartDocument6 pagesM5Stickc Plus: Tutorial&Quick-Startnexus [HD]No ratings yet

- ESP32 RC Sound & Light Controller: Quick Start ManualDocument11 pagesESP32 RC Sound & Light Controller: Quick Start Manualjeans jeansNo ratings yet

- Ina219 PowerMeterDocument17 pagesIna219 PowerMeterU CNo ratings yet

- Mistralxg - A Usb Connected, Pic-Based Midi Synthesizer: Let'S Get Technical!Document9 pagesMistralxg - A Usb Connected, Pic-Based Midi Synthesizer: Let'S Get Technical!CristobalzqNo ratings yet

- Arduino Pro Micro - Deskthority WikiDocument3 pagesArduino Pro Micro - Deskthority WikiBlew WhaleNo ratings yet

- An0043 Efm32 Debug Trace CapabilitiesDocument28 pagesAn0043 Efm32 Debug Trace CapabilitiesahimpliNo ratings yet

- H61MLV2 Ih61w-Mhs-V8.0sDocument40 pagesH61MLV2 Ih61w-Mhs-V8.0sjose chepe100% (1)

- Azure Sphere MT3620 Development Kit Product Brief-2018-09-10Document2 pagesAzure Sphere MT3620 Development Kit Product Brief-2018-09-10Engr Walley Erfan KhanNo ratings yet

- Toshiba Servo Drive PresentationDocument24 pagesToshiba Servo Drive PresentationRSX SNo ratings yet

- Parametri Si EroriDocument112 pagesParametri Si EroriRobert sebastian BeldescuNo ratings yet

- Um2581 Stm32l5 Nucleo144 Board Mb1361 StmicroelectronicsDocument49 pagesUm2581 Stm32l5 Nucleo144 Board Mb1361 Stmicroelectronicstomasz bartnikNo ratings yet

- Tinno Ev730 Service ManualDocument44 pagesTinno Ev730 Service ManualEdgar Jose Aranguibel MorilloNo ratings yet

- User Guide MDB-II ENDocument56 pagesUser Guide MDB-II ENgilberto floresNo ratings yet

- MB Manual Z790-Aorus-Master 1001 e 221121Document45 pagesMB Manual Z790-Aorus-Master 1001 e 221121Karel KalistaNo ratings yet

- LM1117Document12 pagesLM1117hiteshmediaaNo ratings yet

- DEV-16996 WebDocument3 pagesDEV-16996 WebhiteshmediaaNo ratings yet

- La77000v TLM eDocument1 pageLa77000v TLM ehiteshmediaaNo ratings yet

- ML610Q793Document24 pagesML610Q793hiteshmediaaNo ratings yet

- TRF37T05IRGETDocument1 pageTRF37T05IRGEThiteshmediaaNo ratings yet

- Ad9361 PDFDocument36 pagesAd9361 PDFTuấnPhạmNo ratings yet

- XC9572Document9 pagesXC9572Andres GuerreroNo ratings yet

- Grand Theft Auto San Andreas Cheats 43730Document2 pagesGrand Theft Auto San Andreas Cheats 43730hiteshmediaaNo ratings yet

- P060508Document90 pagesP060508hiteshmediaaNo ratings yet

- Grand Theft Auto San Andreas Cheats 43730Document2 pagesGrand Theft Auto San Andreas Cheats 43730hiteshmediaaNo ratings yet

- Cource Registration SystemDocument21 pagesCource Registration SystemhiteshmediaaNo ratings yet

- Rti Act HindiDocument26 pagesRti Act HindiGhanendra KumarNo ratings yet

- Best Basic Electronics ExptsDocument72 pagesBest Basic Electronics Exptsshanakhan99No ratings yet

- Scheme It 2009-10 Main III IVDocument2 pagesScheme It 2009-10 Main III IVhiteshmediaaNo ratings yet

- 5-6 Sem SyallabusDocument33 pages5-6 Sem SyallabusHemant SoniNo ratings yet

- MU Prospectus 2010Document97 pagesMU Prospectus 2010hiteshmediaaNo ratings yet

- C1 Embedded SystemsDocument18 pagesC1 Embedded SystemsAnonymous lthyNbKA2No ratings yet

- BRD2201A A02 SchematicDocument10 pagesBRD2201A A02 Schematickunalkundanam1046No ratings yet

- List of Common Microcontrollers: AlteraDocument28 pagesList of Common Microcontrollers: AlteraFelix ArtNo ratings yet

- An1256 Using SL RCP With Openthread Border RouterDocument12 pagesAn1256 Using SL RCP With Openthread Border RouterrNo ratings yet

- Ug379 - Slexpwfx200 Users GuideDocument19 pagesUg379 - Slexpwfx200 Users GuideQuoc AnhNo ratings yet

- CP210X Com PortDocument10 pagesCP210X Com PortKaléoVontecNo ratings yet

- Introduction To Wireless MbusDocument19 pagesIntroduction To Wireless MbusprasanthvvNo ratings yet

- Si47961 62 ShortDocument5 pagesSi47961 62 ShortIndraz NilNo ratings yet

- AN1269: Dynamic Multiprotocol Development With Bluetooth and Proprietary Protocols On RAIL in GSDK v3.xDocument18 pagesAN1269: Dynamic Multiprotocol Development With Bluetooth and Proprietary Protocols On RAIL in GSDK v3.xLe HieuNo ratings yet

- An107 - Implementing 16-Bit PWM Using The PCADocument18 pagesAn107 - Implementing 16-Bit PWM Using The PCAMot. Schutzen '90No ratings yet

- QSG 108Document20 pagesQSG 108Khang PhươngNo ratings yet

- cp2108 Errata PDFDocument7 pagescp2108 Errata PDFAtiq AnwarNo ratings yet

- Eeprom EmulatedDocument15 pagesEeprom EmulatedHans ClarinNo ratings yet

- bgm13p Datasheet PDFDocument104 pagesbgm13p Datasheet PDFFranklinNo ratings yet

- AN0021Document19 pagesAN0021periodoNo ratings yet

- Silicon LabsDocument40 pagesSilicon LabskarkeraNo ratings yet

- An0059.0 Uart Flow ControlDocument11 pagesAn0059.0 Uart Flow Controla769No ratings yet

- An0002 Efm32 Hardware Design ConsiderationsDocument16 pagesAn0002 Efm32 Hardware Design ConsiderationsRam SakthiNo ratings yet

- qsg139 Getting Started With BluetoothDocument43 pagesqsg139 Getting Started With BluetoothJerkUpNo ratings yet

- AN0948.2: EFM32 and EFR32 Series 2 DC-to-DC ConverterDocument21 pagesAN0948.2: EFM32 and EFR32 Series 2 DC-to-DC ConverterAsnake TegenawNo ratings yet

- An0043 Efm32 Debug Trace CapabilitiesDocument28 pagesAn0043 Efm32 Debug Trace CapabilitiesahimpliNo ratings yet

- qsg170 Openthread SDK Quick Start GuideDocument30 pagesqsg170 Openthread SDK Quick Start GuiderNo ratings yet

- USB Hardware Design Guide: AN0046 - Application NoteDocument25 pagesUSB Hardware Design Guide: AN0046 - Application NotekaraislimNo ratings yet

- Resume 1 Page RamDocument1 pageResume 1 Page RamRamnarayan ShreyasNo ratings yet

- EFM32 Zero Gecko Family EFM32ZG Data SheetDocument104 pagesEFM32 Zero Gecko Family EFM32ZG Data SheetHans ClarinNo ratings yet

- t0008 Efm32 g8xx STK User ManualDocument40 pagest0008 Efm32 g8xx STK User Manualkunalkundanam1046No ratings yet

- PDF Edne Nov 2013Document48 pagesPDF Edne Nov 2013torinomg100% (1)