Professional Documents

Culture Documents

Drawing & Extrusion

Uploaded by

anant709sk0 ratings0% found this document useful (0 votes)

4 views10 pagesQuestions on drawing and extrusion

Original Title

4. drawing & extrusion

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentQuestions on drawing and extrusion

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views10 pagesDrawing & Extrusion

Uploaded by

anant709skQuestions on drawing and extrusion

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 10

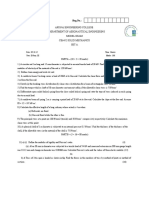

Drawing & Extrusion

1) A 20 mm diameter rod is reduced to 15 mm by

drawing in single pass. Speed of drawing is 120 m/min.

Given that semi die angle 6°, coefficient of friction

between contacting surface is 0.25, what is the power

required in drawing.

[Take yield stress of work material as 500 MPa]

2) A 12.5 mm diameter rod is reduced to 10 mm by

drawing in single pass at a Speed of 100 m/min. Assume

that semi die angle 5°, coefficient of friction is 0.15.

a)The power required in drawing.

b)Max possible reduction in dia. of the rod.

C)if the rod is subjected to a back pull of 50 Mpa, what

would be the drawn stress and max. possible reduction

in area.

(take the flow stress of the material as 400 Mpa).

3)A round rod is drawn from a dia. of 6 mm to 3mm at a

speed of drawing is 0.6 m/sec. Assume that friction and

redundant work together constitute 35% of the ideal

work of deformation.

A) the power required in this process.

B)Die pressure at the exit of the die.

(K=895 Mpa, n= 0.49)

4) A tube of 18 mm outside dia and 1.6 mm wall

thickness is to be drawn to a an outside dia of 12 mm

and wall thickness of 1 mm using a plug.

Calculate the drawing load, given that, co-efficient of

friction for the die is 0.16 and for plug 0.2, die angle is

300 and the plug is 200. Take flow stress is 1400 Mpa

and drawing speed is 0.6 m/s.

5) In extruding a cylindrical billet of length 200mm

from an initial diameter of 25mm to a final dia. of

20mm. Assume the flow stress of the material is 250

Mpa. The ideal plastic work involved in extrusion will

be kJ.

7) An aluminum alloy Is extruding in a forward

extrusion process from 150mm dia. billet to 50mm

dia. rod, the flow stress of the material is 250 Mpa.

The billet is 200 mm long. Take die angle is 600 and

coefficient of friction between contacting surface is

0.25. Determine the extrusion load.

8) A cylindrical billet of 40mm dia. And 100 mm

length is reduced by backward extrusion to a 15mm

dia. If the Johnsons equation has K=750 Mpa, n=0.15

Determine: a)Extrusion ratio b) True strain c)Ram

force

(take a=0.8 & b=1.50)

9)Classify the process of extrusion with the

help of sketches.

You might also like

- O level Physics Questions And Answer Practice Papers 3From EverandO level Physics Questions And Answer Practice Papers 3Rating: 3 out of 5 stars3/5 (1)

- O level Physics Questions And Answer Practice Papers 1From EverandO level Physics Questions And Answer Practice Papers 1Rating: 3.5 out of 5 stars3.5/5 (4)

- Virtual Buce 3Document92 pagesVirtual Buce 3Ralph Edward Santiago Moran100% (1)

- StrengthDocument101 pagesStrengthSigue Ramel Hinayas0% (1)

- DME Assignment 1Document2 pagesDME Assignment 1sumikannuNo ratings yet

- FinallDocument175 pagesFinallremeceldo dagamac100% (1)

- ME 404 A Tutorial on Bulk Deformation ProcessesDocument2 pagesME 404 A Tutorial on Bulk Deformation ProcessesSawai PariharNo ratings yet

- HW1Document3 pagesHW1peer highwayNo ratings yet

- Forming QuestionsDocument3 pagesForming QuestionsSarath Philip Mathew VenkadathNo ratings yet

- Bulk Problems PDFDocument5 pagesBulk Problems PDFSatyasankar LgNo ratings yet

- 3 End of Chapter3 Problems BULKDocument6 pages3 End of Chapter3 Problems BULKqusayNo ratings yet

- Problem Sheet MachiningDocument1 pageProblem Sheet MachiningSam vermNo ratings yet

- Rolling Operations CalculationsDocument3 pagesRolling Operations CalculationsConde SuarezNo ratings yet

- TS 3 2022 MFP1Document2 pagesTS 3 2022 MFP1Goloo yadavNo ratings yet

- TS 3 2022 MFP1Document2 pagesTS 3 2022 MFP1Goloo yadavNo ratings yet

- 5. sheet metal working& powder metallurgyDocument13 pages5. sheet metal working& powder metallurgyanant709skNo ratings yet

- Tugas Ekstruction Rivansyah 1803811-DikonversiDocument3 pagesTugas Ekstruction Rivansyah 1803811-Dikonversivansyah 01No ratings yet

- Solving Session 1 Mech422Document2 pagesSolving Session 1 Mech422Ismail Abou ZeidNo ratings yet

- Assignment 1Document1 pageAssignment 1Abdul RafayNo ratings yet

- Problemas LaminaciónDocument10 pagesProblemas LaminaciónYosmar Emmanuel Vargas TorresNo ratings yet

- Blanking & Piercing TutorialDocument2 pagesBlanking & Piercing TutorialbananaNo ratings yet

- Tutorial (Individuals) Dateline: 15/12/2011 at 5.00 PMDocument2 pagesTutorial (Individuals) Dateline: 15/12/2011 at 5.00 PMrandyooiNo ratings yet

- MD Class Test 1Document5 pagesMD Class Test 1Sambit Das0% (1)

- Stresses and Springs QuizDocument1 pageStresses and Springs Quizsutha_me20098282No ratings yet

- G For The Material Is 82 GN/m2. If The I-Section Is Replaced by A T-Section Made of TheDocument6 pagesG For The Material Is 82 GN/m2. If The I-Section Is Replaced by A T-Section Made of Theክበር ተመስጌንNo ratings yet

- Sheet1 Flat RollingDocument2 pagesSheet1 Flat RollingKhaled MansourNo ratings yet

- Practice Sheet 2Document2 pagesPractice Sheet 2GUNJAN KHULLARNo ratings yet

- Practice Sheet 2Document2 pagesPractice Sheet 2Arshpreet SinghNo ratings yet

- Production GATE/ESE METAL FORMING & SHEET METAL OPERATIONDocument60 pagesProduction GATE/ESE METAL FORMING & SHEET METAL OPERATIONDeepak KumarNo ratings yet

- Theory of Metal Cutting - NumericalsDocument2 pagesTheory of Metal Cutting - Numericalspmagrawal100% (1)

- Manufacturing Process Technology Assignment - Properties and CalculationsDocument4 pagesManufacturing Process Technology Assignment - Properties and CalculationsKKNo ratings yet

- Pattern means, investment process material, solidification ratio, sprue heightDocument9 pagesPattern means, investment process material, solidification ratio, sprue heightfaheemhaider21No ratings yet

- Cone Clutch Question BankDocument3 pagesCone Clutch Question BankSriram Nanjangud Subramanya100% (2)

- TUK University Exams June 2016 Mechanical Engineering Technology Advanced Machine DesignDocument8 pagesTUK University Exams June 2016 Mechanical Engineering Technology Advanced Machine DesignCharles OndiekiNo ratings yet

- Amd Tutorial Me Cadcam 2017Document5 pagesAmd Tutorial Me Cadcam 2017rip111176No ratings yet

- Mechanical Engineering TutorialsDocument6 pagesMechanical Engineering Tutorialsrip111176No ratings yet

- Tugas Drawing - 1803811 - Rivansyah P.ADocument6 pagesTugas Drawing - 1803811 - Rivansyah P.Avansyah 01No ratings yet

- TA202 AssignmentsDocument1 pageTA202 AssignmentsBrajesh kumarNo ratings yet

- Assignment ProblemsDocument3 pagesAssignment ProblemsKaushik SreenivasNo ratings yet

- Assignment ProcessDocument2 pagesAssignment ProcessMuhammad Nazmul Hassan KhanNo ratings yet

- Problems: Problem 1 Problem 2Document2 pagesProblems: Problem 1 Problem 2Lily Margareth ArrietaNo ratings yet

- Bending AssignmentDocument1 pageBending AssignmentGhanvir SinghNo ratings yet

- Sheet Metal Operations ME GATE 2020 Previous Year With Ans KeyDocument4 pagesSheet Metal Operations ME GATE 2020 Previous Year With Ans Keyhyper meshNo ratings yet

- Machine DesignDocument38 pagesMachine Designdeepti412No ratings yet

- Tutorial 4 Sheet Metal WorkingDocument2 pagesTutorial 4 Sheet Metal WorkingSawai PariharNo ratings yet

- Theory of Metal Cutting Numericals PDFDocument2 pagesTheory of Metal Cutting Numericals PDFsanjayNo ratings yet

- MD ConventionalDocument8 pagesMD ConventionalBipin KumarNo ratings yet

- مسائل الخواص الميكانيكيةDocument2 pagesمسائل الخواص الميكانيكيةا.م معتز باللهNo ratings yet

- Design of machine elements exam questions and solutionsDocument3 pagesDesign of machine elements exam questions and solutionsvikaskumar1986No ratings yet

- GATE - IES QuestionsDocument4 pagesGATE - IES QuestionsMahesh Chandrabhan ShindeNo ratings yet

- ForgingDocument8 pagesForgingRavi KiranNo ratings yet

- Design and Const2Document101 pagesDesign and Const2Sigue Ramel HinayasNo ratings yet

- Tarea 3 - Procesos de Conformado MasivoDocument3 pagesTarea 3 - Procesos de Conformado MasivoYuliana Montserrat SanchezNo ratings yet

- Tutorial 2Document2 pagesTutorial 2Zaid ImranNo ratings yet

- Machine DesignDocument38 pagesMachine DesignBanwari Lal PrajapatNo ratings yet

- Assignment-1Document2 pagesAssignment-1Rahul KumarNo ratings yet

- SM Model Exam QuestionDocument5 pagesSM Model Exam QuestionAravind PhoenixNo ratings yet

- Manufacturing Engineering Assignment Thapar UniversityDocument5 pagesManufacturing Engineering Assignment Thapar UniversitySaurav Kumar0% (1)

- Welding Casting Main 2021Document26 pagesWelding Casting Main 2021mohitNo ratings yet