FORMING PROCESSES (BLANKING & PIERCING)

1. Briefly describe the Blanking and piercing operations.

2. Distinguish the difference between cold and hot-working processes stating their advantages and

disadvantages.

3. With the aid of sketches, explain the three major cold working processes on sheet metal.

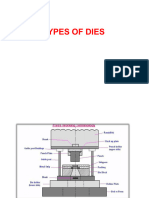

4. Describe with the aid of sketches the difference between compound, progressive and transfer

dies.

5. Explain the main factors that influence the disposition of blanks on strip width.

6. Briefly explain the major difference between a fine blanking tool and conventional compound

die. Give examples products of fine blanking.

7. Determine the original thickness of a 8 cm wide copper strip that after cold working to 0.2 mm,

will have greater than 60,000 psi tensile strength and 5 % elongation.

8. A steel blank 45mm square having a 22 mm diameter hole in the centre is to be blanked from 1

mm thick sheet. (a) Calculate the maximum punch force necessary to shear the blank in one

operation if = 390 N/mm. (b) Calculate the work done if penetration is 20 %.

9. Estimate the blanking force for a blank with 35mm wide, 47mm long and 2mm thick. Given the

tensile strength of the material is 430 MPa.

10. Calculate the maximum punch force necessary to blank a steel washer 55mm outer diameter X

35mm inner diameter with a thickness of 2mm, if tensile strength is 390 MPa, estimate the

work done if penetration is 35%.

11. The total force and work done required to blank a steel washer was 300 kN and 35 Joules

respectively. Calculate the size of the washer if the piercing force is half of blanking force and

the penetration is 25 %. Take the tensile strength as 790 MPa.

12. A hole 80 mm diameter is to be punched in a steel plate 4.5 mm thick. The shear strength of the

material is 500 MPa. With normal clearance on the tools, cutting is complete at 45 %

penetration of the punch. Give suitable diameters for the punch and die and a suitable shear

angle for the punch in order to brine the work within the capacity of a 200 kN press.

13. A circular disc of 30 mm diameter is to be produced from a stainless steel sheet whose

thickness is 2 mm. Determine the die and punch sizes for (a) blanking operation (b) piercing

operation. Hence calculate the maximum punch force and estimate the work done if %

penetration is 28 %. Take shear strength as 480 MPa.

14. The total force and work done required to blank a steel washer was 220 kN and 120 Joules

respectively. Calculate the size of the washer if the piercing force is half of blanking force and

the penetration is 21 %. Take the tensile strength as 580 MPa.

�15. Determine the centre of pressure for the 3 mm thick metal below. Hence find the blanking force

and work done. Take tensile strength for the material as 330 MPa and penetration is 22 %.

16. Determine the centre of pressure for the 2 mm thick metal below. Hence find the blanking force

and work done. Take tensile strength for the material as 470 MPa and penetration is 26 %.