Professional Documents

Culture Documents

Methods of Production Knowledge Sheet

Uploaded by

ruby.shipseyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Methods of Production Knowledge Sheet

Uploaded by

ruby.shipseyCopyright:

Available Formats

GCSE Business

Business Operations CRUSHING

MOULDED

PLASTIC Production

Functions of Production Department

CL

EA Definition: The process of changing inputs such as

• Production planning and scheduling ➔ making NI

NG labour services into goods and services that can be sold.

sure that the correct number of items are

produced to fulfil order on time

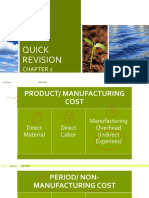

Methods of

JOB FLOW

PRODUCTION PRODUCTION

• Deciding the best production methods to use

• Managing product quality (including process

Production

LEAD

BATCH

control and monitoring) PRODUCTION

PRODUCTION

POLYPROPYLENE REFINING

???

Method of

Job Batch Flow/Mass

Production:

Definition • Involves the manufacture of an individual good • Found when a small number of identical • Goods are produced continuously usually on a

from start to finish. products are made at once. production line.

• Each product is different and offers a unique • Each batch goes through one stage of the • Partly finished goods move along the assembly

good for the consumer or meets specific production process before moving onto next line with parts being added through the

consumer requirements. stage. process.

Examples Wedding dresses, Hairdresser Clothing Manufacturer, Bakery Golf balls

Advantages ☑ Unique ➔ bespoke ➔ to customer specification. ☑ More products can be produced ➔ allow for ☑ Efficient use of labour and machines ➔

higher sales. division of labour.

☑ Higher quality ➔ product is made one at a time

➔ everyone different. ☑ Costs for producing each product (unit costs) ☑ Produces similar/identical goods ➔ production

are lower. quicker.

☑ Production is more efficient ➔ workers can ☑ Reduce unit costs of production ➔ benefit

specialize in performing specific tasks. from economies of scale.

☑ Specialist machinery can be used ➔ speed up

production.

Disadvantages

☒ Expensive ➔ workers tend to have higher skills ☒ Products no longer produced to a unique ☒ Machinery is expensive ➔ smaller businesses

and therefore higher wages. specification may not be able to afford it.

☒ Time-consuming ➔ completion takes longer ☒ Quality is not as high compared to job ☒ Lack of flexibility ➔ flow production produces

due to greater attention to detail and high production ➔ less time and care is taken on identical products ➔ what if the customer wants

quality. individual products a slight modification?

☒ Replacements more difficult to find ➔ ☒ High level of stock may be needed ➔ materials ☒ Bored workers ➔ could lead to lower quality.

products were made for a specific purpose to a have to be stored and this is expensive.

particular design. ☒ Machines have to be cleaned and reset before

producing a different batch ➔ this takes time

and adds to costs.

You might also like

- CA Real Estate Exam Prep - Transfer of PropertyDocument5 pagesCA Real Estate Exam Prep - Transfer of PropertyThu-An Nguyen Thanh100% (1)

- Hoa Sen Pestel and Swot AnalysisDocument29 pagesHoa Sen Pestel and Swot AnalysisTran My Yen (FGW HCM)50% (2)

- Apparel Internship (Aquarelle)Document38 pagesApparel Internship (Aquarelle)farid thashfin100% (2)

- Methods of Production: Business OperationsDocument1 pageMethods of Production: Business Operationsruby.shipseyNo ratings yet

- Production Methods: Job Prouction or Customised Production Process ProductionDocument8 pagesProduction Methods: Job Prouction or Customised Production Process ProductionBerta Ros PlaNo ratings yet

- Chapter 17 - ProductionDocument43 pagesChapter 17 - ProductionBasma FadlyNo ratings yet

- 2.1 Production MethodsDocument4 pages2.1 Production Methodsashraf zhafryNo ratings yet

- Chapter 17 - ProductionDocument43 pagesChapter 17 - Productionalanoud obeidatNo ratings yet

- Methods of ProductionDocument17 pagesMethods of ProductionTyler IlesNo ratings yet

- Introduction To ManufacturingDocument48 pagesIntroduction To ManufacturingSyakir ImanNo ratings yet

- Lecture 4 5Document15 pagesLecture 4 5abhisar 123No ratings yet

- 32.operations Planning-Production MethodsDocument7 pages32.operations Planning-Production MethodsAndrei PrunilaNo ratings yet

- OperationsDocument19 pagesOperationssivanesshniNo ratings yet

- Pma1113 Chapter 3Document28 pagesPma1113 Chapter 3SurayaaNo ratings yet

- Production and Operations Management (Finished)Document11 pagesProduction and Operations Management (Finished)kingfearless27No ratings yet

- BMCG2323 CHP 1 Introduction To ManufacturingDocument43 pagesBMCG2323 CHP 1 Introduction To ManufacturingMuhd ShaddetnyNo ratings yet

- POM2.1 - Introduction To POM2Document31 pagesPOM2.1 - Introduction To POM2Akash ChandakNo ratings yet

- SAP PP Training Material: ConfidentialDocument13 pagesSAP PP Training Material: ConfidentialMahesh Kamdey100% (1)

- Design of Goods and ServicesDocument27 pagesDesign of Goods and ServicesAmir AhmadNo ratings yet

- Handout 5 - BUS 309-UpdatedDocument22 pagesHandout 5 - BUS 309-UpdatedahmedeNo ratings yet

- Plant LayoutDocument17 pagesPlant LayoutChintan GosarNo ratings yet

- Operation ManagementDocument6 pagesOperation ManagementWinter NaiNo ratings yet

- UNIT 13 - Operations ManagmentDocument61 pagesUNIT 13 - Operations ManagmentDimu GunawardanaNo ratings yet

- Types of Production & Methods of ProductionDocument44 pagesTypes of Production & Methods of ProductionIsthiak Uddin Chowdhury EfthyNo ratings yet

- Chapter 18 (Production of Goods & Services) - 17.02.08Document24 pagesChapter 18 (Production of Goods & Services) - 17.02.08Kelvin LauNo ratings yet

- 1-BMCG2323 Introduction To ManufacturingDocument56 pages1-BMCG2323 Introduction To Manufacturinghemarubini96100% (1)

- 5.2 ProductionDocument45 pages5.2 ProductionAdam Savvedes-LawNo ratings yet

- Facility LayoutDocument54 pagesFacility LayoutSimayan Pati100% (11)

- Production Plant Powerpoint PPT Template BundlesDocument13 pagesProduction Plant Powerpoint PPT Template BundlesShyna GargNo ratings yet

- Value Streams: Fundamentals of Manufacturing Excellence ProgramDocument30 pagesValue Streams: Fundamentals of Manufacturing Excellence ProgramTuan AnhNo ratings yet

- Presentation On: Capacity Plannig AND LayoutDocument30 pagesPresentation On: Capacity Plannig AND LayoutPuja RajaniNo ratings yet

- Chap 6 Process Strategies and Capacity PlanningDocument27 pagesChap 6 Process Strategies and Capacity PlanningSoleha SaariNo ratings yet

- Ch1 IntroductionDocument38 pagesCh1 Introductionmd1nemesis1No ratings yet

- Production of Goods & ServicesDocument46 pagesProduction of Goods & ServicesmitchNo ratings yet

- Activity Based Costing ReviewerDocument2 pagesActivity Based Costing ReviewerFrancois MarcialNo ratings yet

- (New) Industrial Manufacuring ProcessesDocument74 pages(New) Industrial Manufacuring ProcessesEnigma YTNo ratings yet

- CV Mohammad ShukriDocument5 pagesCV Mohammad ShukriMohammed Shukri Al QudraNo ratings yet

- Types of Production ProcessDocument24 pagesTypes of Production ProcessPRIYANK89% (18)

- Chapter 4 Process Planning-1Document24 pagesChapter 4 Process Planning-1nescafe okNo ratings yet

- PIM - 13-14 (Compatibility Mode)Document9 pagesPIM - 13-14 (Compatibility Mode)Shravan KumarNo ratings yet

- Job ProductionDocument4 pagesJob ProductionTiana 'Chandie' ChandlerNo ratings yet

- CH 20Document5 pagesCH 20meelas123No ratings yet

- 3 Process Methods Dan Waktu StandarDocument30 pages3 Process Methods Dan Waktu StandarMiaa KNo ratings yet

- UNIT 13 - Operations ManagmentDocument23 pagesUNIT 13 - Operations ManagmentDimu GunawardanaNo ratings yet

- Context of ManufacturingDocument23 pagesContext of ManufacturingmashalerahNo ratings yet

- Typical Problems in Sales Forecasting and Customer Service Chapter - 14Document11 pagesTypical Problems in Sales Forecasting and Customer Service Chapter - 14Teneg82No ratings yet

- Process Choice: Prof. Ajith Kumar JDocument30 pagesProcess Choice: Prof. Ajith Kumar JDeepNo ratings yet

- Industrial EngineeringDocument143 pagesIndustrial EngineeringANo ratings yet

- Types of LayoutDocument19 pagesTypes of Layoutmuneerpp100% (5)

- QOM Question Bank For End-Sem ExaminationDocument9 pagesQOM Question Bank For End-Sem ExaminationAyushi ShahNo ratings yet

- Production and Operations Management (Finished)Document12 pagesProduction and Operations Management (Finished)kingfearless27No ratings yet

- 4to IB - Cycle 26 - Production MethodsDocument26 pages4to IB - Cycle 26 - Production MethodsDaniela SánchezNo ratings yet

- Product Layout: Thah ADocument22 pagesProduct Layout: Thah AjoyanuNo ratings yet

- Production and Total Quality Management: Name Roll NoDocument10 pagesProduction and Total Quality Management: Name Roll NoMohammad Hamayoon HemmatNo ratings yet

- Chapter 7 - Facilities and Layouts - 1ST PartDocument65 pagesChapter 7 - Facilities and Layouts - 1ST Partsume shquidecNo ratings yet

- American Connector CompanyDocument9 pagesAmerican Connector CompanyAntariksha GangulyNo ratings yet

- Design For ManufacturingDocument32 pagesDesign For ManufacturingJoan Sebastian DazaNo ratings yet

- DesignDocument35 pagesDesignbamneakashfunNo ratings yet

- Planning: Planning Check Sample Check Sample Check Sample Check Sample Final CheckDocument1 pagePlanning: Planning Check Sample Check Sample Check Sample Check Sample Final CheckDavid Ramirez AlanocaNo ratings yet

- Production Management New Unit 1Document47 pagesProduction Management New Unit 1Saif Ali KhanNo ratings yet

- Process Design: Weeks 4 (Chapter 7)Document17 pagesProcess Design: Weeks 4 (Chapter 7)Faizal Akbar100% (1)

- SMED – How to Do a Quick Changeover?: Toyota Production System ConceptsFrom EverandSMED – How to Do a Quick Changeover?: Toyota Production System ConceptsRating: 4.5 out of 5 stars4.5/5 (2)

- Technology Knowledge SheetDocument2 pagesTechnology Knowledge Sheetruby.shipseyNo ratings yet

- Quality Knowledge SheetDocument2 pagesQuality Knowledge Sheetruby.shipseyNo ratings yet

- Pricing: PriceDocument1 pagePricing: Priceruby.shipseyNo ratings yet

- Organisation Knowledge SheetDocument1 pageOrganisation Knowledge Sheetruby.shipseyNo ratings yet

- Developing A Global Transport Costs Dataset - UNCTAD - Paper85 - Ser-Rp-2022d5 - enDocument68 pagesDeveloping A Global Transport Costs Dataset - UNCTAD - Paper85 - Ser-Rp-2022d5 - enLean ZechNo ratings yet

- Bad Cover Letter Examples PDFDocument4 pagesBad Cover Letter Examples PDFsitoj1b1myv3100% (1)

- Amerikadaki Türk EmlakçılarDocument17 pagesAmerikadaki Türk EmlakçılarAkin UstaNo ratings yet

- Inventory Policy and ProcedureDocument6 pagesInventory Policy and ProcedureAbhay SrivastavaNo ratings yet

- Unilever Annual Report and Accounts 2022Document241 pagesUnilever Annual Report and Accounts 2022Genji MaNo ratings yet

- The Digital Firm: Electronic Business and Electronic CommerceDocument29 pagesThe Digital Firm: Electronic Business and Electronic CommerceMuhammad Arslan AkramNo ratings yet

- International Marketing NoteDocument45 pagesInternational Marketing Noteteshome100% (1)

- To AnalyseDocument40 pagesTo AnalyseShaik SaniaNo ratings yet

- BK - The Long View - Brian FetherstonhaughDocument12 pagesBK - The Long View - Brian FetherstonhaughPablo StorageNo ratings yet

- Your Adv Plus Banking: Account SummaryDocument2 pagesYour Adv Plus Banking: Account SummaryjohanNo ratings yet

- The Impace of Exchange Rates On ASEAN TradeDocument30 pagesThe Impace of Exchange Rates On ASEAN TradeDo HuongNo ratings yet

- Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocument44 pagesDate Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceASHOK KUMARNo ratings yet

- Green RoadDocument10 pagesGreen RoadRoshanNo ratings yet

- MKT Apple Pay PDFDocument3 pagesMKT Apple Pay PDFavar2No ratings yet

- Flipkart Labels 11 Jun 2023 02 03Document1 pageFlipkart Labels 11 Jun 2023 02 03umang charayaNo ratings yet

- Introduction To Configuration: SAP University Alliances Authors Simha R. MagalDocument39 pagesIntroduction To Configuration: SAP University Alliances Authors Simha R. Magalsumber kocakNo ratings yet

- Business Ethics-Ethics Code For Morinda CorporationDocument6 pagesBusiness Ethics-Ethics Code For Morinda CorporationherrajohnNo ratings yet

- Inds Konsolidasian 2013Document100 pagesInds Konsolidasian 2013Mieta Salma HayatieNo ratings yet

- Helios Huddel Sheesham Wood Coffee Table With StoDocument1 pageHelios Huddel Sheesham Wood Coffee Table With StoPranav RanjanNo ratings yet

- Support Network Critical To Coker Crane Success Laughlin Sutar Konecranes DCU Mumbai 2016 PDFDocument25 pagesSupport Network Critical To Coker Crane Success Laughlin Sutar Konecranes DCU Mumbai 2016 PDFFayaz MohammedNo ratings yet

- UCT APM M2U2 NotesDocument14 pagesUCT APM M2U2 Notesherbster972No ratings yet

- 2005 2006Document39 pages2005 2006Rico PerdanaNo ratings yet

- Entrepreneurship: Environmental Factors and Sources of OpportunitiesDocument15 pagesEntrepreneurship: Environmental Factors and Sources of OpportunitiesSyrine Myles SullivanNo ratings yet

- 7 Types of Waste PDFDocument20 pages7 Types of Waste PDFjogedhayalNo ratings yet

- What Is Etherisc 1.0 enDocument16 pagesWhat Is Etherisc 1.0 enGabriel JuradoNo ratings yet

- Research Proposal - Ankit KumarDocument5 pagesResearch Proposal - Ankit KumarAnkit KumarNo ratings yet

- Coca-Cola: Presented by TeamDocument17 pagesCoca-Cola: Presented by TeamMustika ZakiahNo ratings yet

- Solved Jim and Andrea Kerslake Want To Open A Restaurant inDocument1 pageSolved Jim and Andrea Kerslake Want To Open A Restaurant inAnbu jaromiaNo ratings yet