Professional Documents

Culture Documents

White 1788 Sewing Machine Instruction Manual

Uploaded by

iliiexpugnansCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

White 1788 Sewing Machine Instruction Manual

Uploaded by

iliiexpugnansCopyright:

Available Formats

WflNVIN N

1 O113

8O

3N1HDV ONIM3S

aei °L Ie3

V9

Downloaded from www.Manualslib.com manuals search engine

Downloaded from www.Manualslib.com manuals search engine

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be

tolowed, including the following:

Read all instructions before using

(this sewing machine)

DANGER To reduce the risk of electric shock:

An appliance should never be left unattended wrien plugged in. Always unplug this

appliance from the electric outlet immediately after using and before cleaning.

Always unplug before relamping, Replace bulb with same tyPe rated 15 watts.

WARNING To reduce the risk of burns, fire,

electric shock, or Injury to persons:

Operate sewing machine only when mounted in sewing machine table, case, and the

ike. See the installation instructions.

1, [Jo not allow to be used as a toy. Close attention is necessary when this appliance

is used by or near children.

2. Use this appliance only for its Intended use as described in this manual. Use only

attachments recommended by the manufacturer as contained in this manual.

a Never operate this appliance if it has a damaged cord or plug, if it is not working

properly, if it has been dropped or damaged, or dropped into water, Return the.

appliance to the nearest authorized dealer or service center for examination, repair,

electrical or mechanical adjustment.

open

& Never operate the appliance with any air openings blocked, Keep ventilation

ngs of the sewing machine and foot controller free from the accumulation of lint.

dust, and loose cloth,

5, Never drop or insert any object into any opening,

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is

being administered.

8. To disconnect, turn all controls to the off (“0”) position, then remove plug from

outlet,

9. Do not unplug by puiing on cord. To unplug, grasp the plug, not the cord.

io. Keep fingers away from all moving parts. Special care is required around the sewing

machine needle.

11. Always use the proper needle plate. The wrong plate can cause the needle to break.

12, Do not use bent needles.

13. Cc not pull or push fabric while stitching. It may deflect the needle causing it to

break.

14. Unplug the sewing machine when making any adjustments in the needle area,

such as threading needle, changing needle, threading bobbin, or changing

presser foot, etc.

15. Always unplug sewing machine from the electrical outlet when removing covers,

lubricating, or when making any other user servicing adjustments mentioned In the

instruction manual.

SAVE THESE INSTRUCTIONS

Downloaded from www.Manualslib.com manuals search engine

CONTENTS

amefP.i & 2

3

es sori

8efore sewing (Power supply and Swng • 4

Take out extension tableS free arm sewing

Winding the bobbrn 6

Removing bobbin case and bobbin

Inserting bobbin into bobbin case 7

Inserting bobbin case rito shuttle race 8

Threading upper thread & Twin needle threading 9

Drawing up bobbin thread 10

Changing sewing directions

Adiusting thread tension 12

Regulating the presser foot pressure 13

Drop feed

Chaigirg needle 14

Fabric. Thread. Needle table 15

Sewing (pattern selector) and operation table 16

To start sewing 17

To finish seam 18

Straight ititch 19

Zigzag sewing 19

Overcasting 20

Stretch stitch 20

Blind stitch 21 & 22

Button sewing 23

Binding 23

Zipper sewing 24

Button hole sewing 25

Hemming 26

Twin Needle 27

Embroidery 27

Quilter . 28

Seam guide .

28

Maintenance (Cleaning and oiling) . 29

checking Per1ormane Pob4ems WHAT TO DO .

. 30

Downloaded from www.Manualslib.com manuals search engine

NAME OF PARTS (FRONT VIEW)

1 Pattern selector dial

2 Take up lever

3 Tread tension dial

4 Tread guide for upper

threading

5 Presser foot

6 Shuttle cover

7 Zigzag WI rith Dial

S Spoolpin

9 Top cover

10 Stitch length dial

11 Reverse button

12 Face cover

13 Handle

Downloaded from www.Manualslib.com manuals search engine

(REAR VIEW)

Bobbin winder spindle

Bobbin winder stopper Upper thread guide

Stop Motion knob

Hand wheel

Thumb screw

Needle plate

Presser foot lever

Accessories Box

—2--

Downloaded from www.Manualslib.com manuals search engine

m

U,

0

0

C’,

m

C,

C,

1?

IIn

C,)

1’

C

1

It 0

Downloaded from www.Manualslib.com manuals search engine

3EFORE SEWING

Fit plug into the machine.

2. Plug the machine to the power

supply.

3. Sewing speed can be varied by

the fool conirol.

Use only FDM model KD-1 902 foot

controller with sewing machine.

Sewing lamp

REMOVE OFUNSTALL BULB

1. Open face cover in direction of

arrow.

2. Remove bulb by unscrew

ing it counter-clockwise.

3. Install a new bulb by screwing It

in clockwise.

4. Use a screw type bulb with

i2W/I 5W(Max).

IMPORTANT When leaving the sowing machine unattended, the

plug must be removed from the socket outlet.

When servicIng the sewing machine, or when removing covers or

changing lamps, the machine must be disconnected from the supply

by removing the plug from the socket outlet.

—4—

Downloaded from www.Manualslib.com manuals search engine

REMOVING EXTENSION TABLE

To convert the machine from flat-bed us€

to free-arm use simply remove the ex

tension table as shown.

FREE-ARM SEWING

1. Especially useful when sewing

sleeves, pants leg, tubular

fabrics etc more easily.

2. To sew tubular just slip the

sleeve or pants leg on the free

arm as shown above.

3. This sewing machine can be

used as a flat bed machine.

but easily converts to free

arm machine by removing the

extension table.

—5—

Downloaded from www.Manualslib.com manuals search engine

__ __ _

_

_

WINDING THE BOBB1N

1. Release stop motion knob.

Inside 2. Thread as shown.

3. P’ace bobbrn onto spindle

and hand-wind thread onto

bobbin in an anti-clockwise

(1 direction for 5 or 6 turns.

se

(When bobbin is filled re-tighten

stop motion knob)

Tightefl

Istop

motiofl knob

r8obbin 4. Push bobbin winder indle

winder against stopper, in direction

sPindle.....”1 of arrow, and depress foot

pedal.

5. When bobbin winding is com

pleted return spindle to its

original position.

(0 x Note:

If the bobbin winding should be

— —=

uneven (it is factory set) the

thread guide can be raised or

lowered to achieve the correct

winding.

Remove the top cover and adjust

with a suitable tool.

—6—-

Downloaded from www.Manualslib.com manuals search engine

BOBBIN

REMOVING BOBBIN CASE AND

LL

1. Raise needle to its highest 2. Open hinged atch of

position and open the bobbin case and pull bob

shuttle race co’der. bin case out of machine.

3. Release the latch and bob

bin will fall out easily.

CASE

INSERTING BOBBIN INTO BOBBIN

1, Pull off 5cm of thread 2. Guide the arid of thread

from bobbin and insert it into slot.

into bobbin case as shown.

Tension spring

3. Pull into slot and under

tension spring and draw

out about 10 cm of

thread.

—7—

Downloaded from www.Manualslib.com manuals search engine

INSERTING BOBBIN CASE INTO SHUTTLE RACE

Hinged latch

t. Ensure needle is at its highest position.

Pulling thread to the front, open the

latch of bobbin case and hold it.

Insert

2. Holding latch open, place bobbin case

onto centre pin in shuttle and release

latch.

—8—

Downloaded from www.Manualslib.com manuals search engine

THREADING UPPER THREAD

Thread the machine from A to G as illustrated.

A. Through the thread guide.

8. Between the tension discs.

C. Up and into the tension spring.

0. Into the thread takeup lever from right to left.

E. Down behind the thread guide.

F. Behind the needle clamp thread guide.

G. Through the need’e from front to backFig. 1 & 2

also illustrates threading for twin needle sewing

(see page 27>

—9—

Downloaded from www.Manualslib.com manuals search engine

DRAWING UP BOBBIN THREAD

1. Hold upper mread with left

hand, turn the hand wheel

slowly towards you until the

needle goes down and comes

up. Then stop the hand

wheel when the takeup lever

is at its highest position.

Lightly draw up the upper

thread will be brought up in a

loop.

2. Pull out both threads and

place them together under

presser foot to the rear of

machine.

—10—

Downloaded from www.Manualslib.com manuals search engine

CHANGING SEWING DIRECTIONS

1, Lower needle down into fabric and

raise presser foot, pivot the fabric

arourd the needle to change direction

as desired.

DZ

2. Put down presser foot and

start to sew.

—11—

Downloaded from www.Manualslib.com manuals search engine

ADJUSTING UPPER THREAD TENSION

It is only normally necessary to adjust

the upper thread tension to achieve the

correct balance between the upper and

3 lower threads.

The higher the number on the dial the

greater the tension.

Correct flcorrect

Inside of fabric

Upper thread

Fabric Upper thread

Bobbin thread

ADJUSTING LOWER THREAD Increase

TENSION

Lower thread tension can be adjusted by

Decrease

turning the screw on the bobbin case

slightly to the right (clock-wise) to

increase tension, (Anti-clockwise) to the

left to decrease tension.

As a general guide only, the user can achieve the correct

tension for normal sewing, by carefully suspending the

wound bobbin in its case by the thread. If the bobbin

and case immediately fall to the ground, the tension is too

loose and should be increased. The correct tension is

obtained when a slight jerk of the thread causes the bobbin

to drop a short distance only. If this action does not move

the bobbin the tension is too tight and should be loosened

until the desired effect is achieved.

—12—

Downloaded from www.Manualslib.com manuals search engine

REGULATING THE PRESSER FOOT PRESSURE

1. Adjust lever to desired pressure. For light fabrics use 3, for medium fabrics

use 12, for heavy fabrics use 1.

2. Insufficient pressure may cause poor feeding, skipped stitches, or difllculty

in guiding the fabric.

3. No. pressure adjustment is required when darning or sewing freehand

embroidery.

DROP FEED

wer ‘eed dog by push ng eve-, down n direction of arrow.

iNo feeding of fabric)

Used when sewing on buttons, free hand embroidery. etc.

or general sewing, a’se heght of feed dog by Iiftng ever in

direction of arrow

— 13 —

Downloaded from www.Manualslib.com manuals search engine

C)IANGING NEEDLE

Needle clamo screw

Tighten

\LOO5fl

I Flat face side

away from you.

1. Raise needle to its hiies position.

2. Loosen nedne clamp screw and remove old needle.

3, With the flat side of the needle facing away from you,

insert needle as far up as it will go.

4. Tghten the needle clamp screw securely.

—14—

Downloaded from www.Manualslib.com manuals search engine

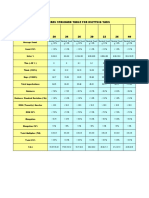

NEEDLE’ GUIDE

FABRIC-ThREAD

Length of

stitches

Indica

tion of

Pressure of tension

Thread Needte presser foot ST. ZZ.

Fabric

\\ Pressure

regulation

Stitch length

\

Nylon 80 Cotton

Light

Tricot 60S. Fbe 11

o.53

c\ Silk 50 silk

053

50S.Fibe

Wool silk Silk 11

Medium 60.80

Gingham Cotton

0.5-4 0.5—4

I hin Jerse 60 S. Fibe

Gabardine 50 Silk )

Heavy Denim 50 cotton 14

1—4 0.5—4

cE”\ Jersey 0 S. Fiber 14

3 ::

..J:

; .!

Tweed 50 Silk 14

As a general rule use shorter stitch lengths on

finer fabrics and longer stitch lengths

with finer fabrics and heavier thread and

with heavier fabrics, finer thread and needlas

t’ or ‘stretch’ needles on difficult

needles with heavier fabrics. Use special ‘ball poin

stretchy fabrics.

— 15—

Downloaded from www.Manualslib.com manuals search engine

— 9L —

Downloaded from www.Manualslib.com manuals search engine

TO START SEWING

Important Hints

1. Raise the takeup lever to its highest position wher starting and stopping

sewing.

2. Hold both threads about 10 cms to the rear of machine for the first two to

three stitches.

3. Sufficient fabric should be placed under needle before lowering presser font.

4. Depress footlSpeed control and start to sew.

5. Test the machine stitches on a scrap of fabric you plan to use, adjusting the

machine for the length of stitch and tension suitable to your fabric.

Attention

1. When turrwig the hand wheel manualPj, always turn it toward you.

2. Guide the cloth gently with your hand.

3. To preent breaking needle always stop with the needle out of the fabric.

—. 17—

Downloaded from www.Manualslib.com manuals search engine

TO FNtSH SEAM

I Sew to the e9e Of seam

saw in reverse tor

2PuSh the re,erse button an

about 34 cms.

3.aiSe needle tO its highest postiOfl.

fabric to rea of

4Litt presser loot and puWout the

machineS

5.Cut threads as shown on the thread cutter

Thread cg

Downloaded from www.Manualslib.com manuals search engine

STRAIGHT STITCH

1. This type of stitching is the

one used most frequently.

for both strait and zig-zag sewing.

2. The zig-zag presser foot can be used

use smaller stitch size and Teft needle posi

tion.

3. For sewing Iit fabric,

(Refer to page i for dial setting).

ZIGZAG SEWING Pattern selector position.

purpose stitch.

Zig-zag stitching is a general

very short stitch

Satin stitching is a “closed up”,

sewing initials,

length, and can be used for

patterns, applique. etc.

Downloaded from www.Manualslib.com manuals search engine

OVERCAST ING

Use these stitches for oversewing rough

edges.

STRAiGHT STRETCH STITCH

Use this stitch with knitted.tricot or other

stretchy fabrics.

The stitch enables your seam to stretch

with out breaking the thread.

It Is also a very strong straight stitch for

areas under stress.

— 20 —

Downloaded from www.Manualslib.com manuals search engine

NLliS ONfl8

PI0z L 1JMO4S

7 UMO4 R WES 4SU O

— —

Downloaded from www.Manualslib.com manuals search engine

Adtwkd needle position

Needle is not piercing Needle is pierces edge

edge of fold at of fold too much,

(A) (B)

Correct seam

—22—

Downloaded from www.Manualslib.com manuals search engine

BUTTON SEWING

(Use droø teed seepage 13)

I lower drop feed.

2Ptace button presser foot in position and attach firmly.

3.Ptaoe button between presser foot and fabric and lower presser foot.

4.Manualty turn hand wheel towards you ensuring that the needle enters

into both holes of button without obstruction.

(Increase or decrease width setting).

5.Sew about 7 stitches.

6PulI both threads to the underside and tie together.

BINDING

[[ I I [ I ]

To sew fabrics edge to edge select

— 23 —

Downloaded from www.Manualslib.com manuals search engine

ZIPPER SEWING

Select straight stitch.

%

1. Fold the fabric about 2cm and

%

place fabric under foot,

2. Zipper loot is designed to sew close

to a raised edge preventing sewing

on Zpper.

I

1. To sew the left side of the zipper.

set the zipper foot on the left side.

of the needle,

2. To sew the right side of the

zipper bring the toot to the right

side of the needle.

sew as illustrated.

—24—

Downloaded from www.Manualslib.com manuals search engine

BUTTON HOLE SEWING

Select stitch length dial in area Indicated.

Pattern

Steps Settings

selector dial

I]

1 Set dial to “1” pOsition.

2. Sew leftside.

: 3. Raise the needle

4. “2” position.

Set dial to

F 5. Sew 5.6 stitches.

6. Raise the needle

7. Set dial to

]

“3” position.

8. Sew right side.

9. Raise the needle

10. Set dial to “4” position.

L 11. SewS-6 stitches.

12. Raise the needle

Before sewing fit button-hole foot Cut buttonhole along centre with

as shown. cutter as shown.

— 25 —

Downloaded from www.Manualslib.com manuals search engine

____

___

_____

_____

_____

HEMMING

4

1mm.-t

20mm

\\\

Replace the loot wIth the

1. Raise the foot and the needle to its highest position.

hemmer foot.

2. Fold over the fabric edge by about 3mm and

place it under the foot. Secure the

folded edge with a few stitches. Take out the workpieca and draw the hem

into the hemmer foot by pulling the threads.

S.

3. Lower the foot and sew the hem.

4. During sewing, fold the fabric to the left a lttle and allow it to run into the

hammer foot.

5. Make re that the fabric does not move under the ght half of the foot. The

fabric must be fed into the scroll of the hemmer %uticiently so that the work-

piece edge runs freely through the groove under the foot.

Only suitable materials can be used and some practice may be necessary to acheie

best results.

— 26 —

Downloaded from www.Manualslib.com manuals search engine

TWIN NEEDLE (option&)

through the same

Thread mjhine as for normal sewing passing both threads

procedure:

exceeding this

NB. Sewing width should not exceed the third widest stitch width,

will result in breaking of needles.

EMBROIDERY

(Use droc. feed see page 13)

Lower feed dog and move hooped fabric slowly to form the desired effect.

—27 —

Downloaded from www.Manualslib.com manuals search engine

QUILTER

cN

%%

1. Insert supporter of quilter.

2. Moie quilter and adjust stitch distance.

SEAM GUIDE

seam of regular

1. Use seam guide when sewing a long

distance from edge of material.

of needle plate,

2. Set guide in hole on bed, at right

and adjust distanc e.

al touching

3. Run machine with edge of materi

rew a

guide. Position cloth guide at an angle to

curved seam.

— 28 —

Downloaded from www.Manualslib.com manuals search engine

MAINTENANCE (CLEANING AND OILING)

1. Raise needle to its highest position.

2. Take out bobbin case.

3. Turn latch knob A as illustrated.

4. Take off shuttle race cover.

5. Take out shuttle hook.

6. Clean and oil shuttle race and hook.

then replace in the reverse order.

C

Cleaning snuttle race

(A) Latch knob

18) Shuttle race cover

(C) Shuttle hook

Open face cover and oil points

Cleaning feed dog

indicated.

— 29

Downloaded from www.Manualslib.com manuals search engine

presser foot. Draw the

MooqramiFreehand Embroidery: Set stitch length to 0. Remove the

pencil. P’ace the fabric in a hoop with

monogram or cesign on the fabric with a fabric marking

Place the hooped fabric under the needle,

stabilizer under the fabric. Set the stitch width to 5.

easy to forget with no foot on the machinet) and follow

be sure to lower the presser bar (this is

design with the stitching. Move the hoop without turning it. You must move

the maried letter or

the fabric’

the stitch length to O.

12. Stippling: The stippling technique is a freehand stitch for quilting. Set

under the needle to create a

Lower the feed teeth. Hoop the quilt or facric. Move the fabric

wavy straight stitch quilting (stippling).

(optional accessory

13. Twin Needle Sewing: Replace the standard needle with a twin needle

available at any sewing machine store). There are two spool pins on the top of your machine.

separate them

Place a spool on each spool pin. Thread the threads as for normal sewing but

or narrow zigzag for a

at the needle and thread one through each needle. Use straight stitch

decorative look.

between the two

14. Pin-tucks: Insert a twin needle (optional accessory) with 16mm or 2.0mm

needles and thread as in number 13 above for twin needle sewing. Put on an optional applique

presser foot or optional twin needle pin-tuck foot. Stitch rows of straight stitch twin needle

sewing on a lightweight fabric.

on the reverse

15. Reverse Sewing: To sew backwards with a straight stitch or a zigzag push in

butlon marked with R. As long as the button is held in, the machine will sew in reverse.

to the

16. Applique: Stitch applique designs in place with a zigzag satin stitch. Fuse the applique

fabric with a fusible web. Place tear-a-way stabilizer under the fabric. Try the stitch on a scrap

of stabilized fabric before sewing on your project and adjust the stitch length as needed. For

best results, thread the top with a decorative rayon thread. Use medium to wide zigzag stitch.

The larger the applique, the wider the width. Set the stitch length at 1’ and begin to sew on

your scrap. Turn the stitch length dial toward 0 until the zigzag stitching is very close together

and satiny. This is called a satin stitch. An open toe applique foot, which is available as an

optional accessory, will feed smoothly over the satin stitch thanks to a tunnel on the underside

of the foot and the open toe gives visibility as you sew around the applique.

17. Straight Stretch Stitch: Ideal for knits and seams where extra reinforcement is needed so the

seam does not pop.

Your new White Sewing Machine will help you create beautiful garments, gifts, projects for your

home and more. Why not start a project today? Happy Sewingl

— 32 —

Downloaded from www.Manualslib.com manuals search engine

Downloaded from www.Manualslib.com manuals search engine

You might also like

- White 1766 Sewing Machine Instruction ManualDocument33 pagesWhite 1766 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- The Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional RiggingFrom EverandThe Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional RiggingNo ratings yet

- White 1927 UsMan (EN)Document54 pagesWhite 1927 UsMan (EN)Gisell ZapataNo ratings yet

- The Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional Rigging, Second EditionFrom EverandThe Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional Rigging, Second EditionRating: 5 out of 5 stars5/5 (2)

- Bernette B33 Sewing Machine Instruction ManualDocument32 pagesBernette B33 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- White 1755 Sewing Machine Instruction ManualDocument34 pagesWhite 1755 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- White 1515/1525 Sewing Machine Instruction ManualDocument36 pagesWhite 1515/1525 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- White 140 Sewing Machine Instruction ManualDocument35 pagesWhite 140 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Huskystar 219 224 Manual enDocument56 pagesHuskystar 219 224 Manual enljubica100% (2)

- Janome 1422 Sewing Machine Instruction ManualDocument42 pagesJanome 1422 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Instruction Manual FOR Sewing Machine: WhiteDocument33 pagesInstruction Manual FOR Sewing Machine: WhiteBhupinder GillNo ratings yet

- Husqvarna/Viking Scandinavia 100 Sewing Machine Instruction ManualDocument32 pagesHusqvarna/Viking Scandinavia 100 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Pfaff 1216/1217 Sewing Machine Instruction ManualDocument35 pagesPfaff 1216/1217 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Pfaff Creative 1467A Sewing Machine Instruction ManualDocument192 pagesPfaff Creative 1467A Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- White 1010 Sewing Machine Instruction ManualDocument46 pagesWhite 1010 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Pfaff Synchtronic 1229 Sewing Machine Instruction ManualDocument38 pagesPfaff Synchtronic 1229 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Zanussi ZAN2250 Sewing Machine Instruction ManualDocument76 pagesZanussi ZAN2250 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Euro-Pro: Instruction ManualDocument21 pagesEuro-Pro: Instruction ManualVlade NaumovskiNo ratings yet

- Euro-Pro: Instruction ManualDocument23 pagesEuro-Pro: Instruction Manualksolomon75No ratings yet

- White 1500/1505 Sewing Machine Instruction ManualDocument47 pagesWhite 1500/1505 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Husqvarna/Viking Prelude 350/370 Sewing Machine Instruction ManualDocument36 pagesHusqvarna/Viking Prelude 350/370 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- EuroPro 372/373/374/377 Sewing Machine Instruction ManualDocument21 pagesEuroPro 372/373/374/377 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- White Sewing Machine ManualDocument37 pagesWhite Sewing Machine ManualShannon Daniels Clark100% (1)

- Husqvarna/Viking Scandinavia 300 Sewing Machine Instruction ManualDocument60 pagesHusqvarna/Viking Scandinavia 300 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Husqvarna/Viking Lena Sewing Machine Instruction ManualDocument32 pagesHusqvarna/Viking Lena Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- White 1744 Sewing Machine Instruction ManualDocument32 pagesWhite 1744 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Husqvarna/Viking Scandinavia 200 Sewing Machine Instruction ManualDocument44 pagesHusqvarna/Viking Scandinavia 200 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Baby Lock Jazz BLMJZ Sewing Machine Instruction ManualDocument42 pagesBaby Lock Jazz BLMJZ Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Husqvarna/Viking Iris Sewing Machine Instruction ManualDocument52 pagesHusqvarna/Viking Iris Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Pfaff 1025 Sewing Machine Instruction ManualDocument27 pagesPfaff 1025 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Domestic 712 Sewing Machine Instruction ManualDocument48 pagesDomestic 712 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- White 1422 Sewing Machine Instruction ManualDocument42 pagesWhite 1422 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Pfaff 1029 Sewing Machine Instruction ManualDocument40 pagesPfaff 1029 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Huskystar 207/215 Sewing Machine Instruction ManualDocument40 pagesHuskystar 207/215 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- 5060007.0.04 b37 EN 2017 04 GZD InHouse 3mm PDFDocument60 pages5060007.0.04 b37 EN 2017 04 GZD InHouse 3mm PDFjurasNo ratings yet

- Downloaded From Manuals Search EngineDocument30 pagesDownloaded From Manuals Search EngineSavery SaveryNo ratings yet

- White 1919 Sewing Machine Instruction ManualDocument48 pagesWhite 1919 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Pfaff 259 Sewing Machine Instruction ManualDocument54 pagesPfaff 259 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Scandinavia 300Document60 pagesScandinavia 300Leonardo QuevedoNo ratings yet

- Domestic 1665 Sewing Machine Instruction ManualDocument55 pagesDomestic 1665 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- De Luxe 311 BB S InstructionDocument50 pagesDe Luxe 311 BB S InstructioniliiexpugnansNo ratings yet

- Pfaff Hobby1010/1037 Sewing Machine Instruction ManualDocument15 pagesPfaff Hobby1010/1037 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Husqvarna/Viking Freesia 415/425 Sewing Machine Instruction ManualDocument52 pagesHusqvarna/Viking Freesia 415/425 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Baby Lock Audrey BL67 Sewing Machine Instruction ManualDocument38 pagesBaby Lock Audrey BL67 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Husqvarna/Viking Platinum 715/735/755Document60 pagesHusqvarna/Viking Platinum 715/735/755iliiexpugnansNo ratings yet

- White 1066 Sewing Machine Instruction ManualDocument26 pagesWhite 1066 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Pfaff Hobby 1142 Sewing Machine Instruction ManualDocument56 pagesPfaff Hobby 1142 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Bernette Rome 8 Sewing Machine Instruction ManualDocument75 pagesBernette Rome 8 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- 1409 Instruction ManualDocument28 pages1409 Instruction ManualAjay Singh Patial100% (1)

- Singer M1000/M1005 Sewing Machine Instruction ManualDocument20 pagesSinger M1000/M1005 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- User's Guide: Keeping The World SewingDocument64 pagesUser's Guide: Keeping The World SewingNostalgia234No ratings yet

- Pfaff SZA-645F Sewing Machine Instruction ManualDocument45 pagesPfaff SZA-645F Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Pfaff Classic Style 2025 Sewing Machine Instruction ManualDocument88 pagesPfaff Classic Style 2025 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Kenmore 158.1232 Sewing Machine Instruction ManualDocument44 pagesKenmore 158.1232 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Pfaff Tiptronic 1029Document40 pagesPfaff Tiptronic 1029Juhász MariannNo ratings yet

- Pfaff 1540 Sewing Machine Instruction ManualDocument82 pagesPfaff 1540 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Pfaff Dorina 72/75/77 Sewing Machine Instruction ManualDocument50 pagesPfaff Dorina 72/75/77 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Privileg Sewing Machine: Safety Important NotesDocument48 pagesPrivileg Sewing Machine: Safety Important NotesJhwazkd100% (1)

- 808 - White 675 XDocument48 pages808 - White 675 XADS MultimediaNo ratings yet

- Learn to Sew! Doll ClothesDocument42 pagesLearn to Sew! Doll ClothesiliiexpugnansNo ratings yet

- Singer Sewing Skills Reference Book PDFDocument60 pagesSinger Sewing Skills Reference Book PDFmeisterwant100% (1)

- Learn to Sew! Singer Manual of Family Sewing MachinesDocument81 pagesLearn to Sew! Singer Manual of Family Sewing Machinesiliiexpugnans100% (1)

- Learn to Sew! Your Sewing Machine (Home Ec Book)Document122 pagesLearn to Sew! Your Sewing Machine (Home Ec Book)iliiexpugnansNo ratings yet

- 0345 1 00Document205 pages0345 1 00MulderNo ratings yet

- SFhandbookDocument36 pagesSFhandbookbawaneatulNo ratings yet

- (1921) Manual of Work Garment Manufacture: How To Improve Quality and Reduce CostsDocument102 pages(1921) Manual of Work Garment Manufacture: How To Improve Quality and Reduce CostsHerbert Hillary Booker 2nd100% (1)

- Sewing Tools and Sewing Machine Operations: NtroductionDocument29 pagesSewing Tools and Sewing Machine Operations: Ntroductiongeorge odoyoNo ratings yet

- Sewing For The Apparel IndustryDocument571 pagesSewing For The Apparel IndustryEmmasu2509No ratings yet

- Learn to Sew! Sewing Fur and Fake FurDocument52 pagesLearn to Sew! Sewing Fur and Fake FuriliiexpugnansNo ratings yet

- Learn to Sew! Pro GuideDocument164 pagesLearn to Sew! Pro GuideiliiexpugnansNo ratings yet

- Sewing for Twentieth Century DollsDocument264 pagesSewing for Twentieth Century DollsiliiexpugnansNo ratings yet

- History of GarmentsDocument116 pagesHistory of GarmentsJanaki RamasamyNo ratings yet

- Learn to Sew! Singer Student Manual (1960)Document12 pagesLearn to Sew! Singer Student Manual (1960)iliiexpugnansNo ratings yet

- Practical Sewing and DressmakingDocument246 pagesPractical Sewing and Dressmakingsurya100% (2)

- Anette Fisher - Sewing For Fashion Designers - 2015 PDFDocument321 pagesAnette Fisher - Sewing For Fashion Designers - 2015 PDFLedy Johana Velasquez97% (33)

- Learn to Sew! Sewing GlossaryDocument3 pagesLearn to Sew! Sewing GlossaryiliiexpugnansNo ratings yet

- 16. Sewing Handbook for Use in Extension Work Author Blanche E. HydeDocument60 pages16. Sewing Handbook for Use in Extension Work Author Blanche E. Hyderosiw65051No ratings yet

- CT-LMH 019 PDFDocument4 pagesCT-LMH 019 PDFGemma serdanNo ratings yet

- Learn to Sew! Sewing Equipment 4-HDocument8 pagesLearn to Sew! Sewing Equipment 4-HiliiexpugnansNo ratings yet

- Perfect Women's Shirt Fit GuideDocument15 pagesPerfect Women's Shirt Fit Guideমমিন উদ্দিনNo ratings yet

- PATTERN LindqvistLic PDFDocument95 pagesPATTERN LindqvistLic PDFمصطفى عبدالرحيمNo ratings yet

- HowToMeasure2013 PDFDocument27 pagesHowToMeasure2013 PDFoovianNo ratings yet

- Ivsm 101Document42 pagesIvsm 101AM SureshNo ratings yet

- Learn To Design Your Own Clothes PDFDocument44 pagesLearn To Design Your Own Clothes PDFn.t. donkorNo ratings yet

- Learn to Sew! Measuring for Tailored Shirts & SuitsDocument25 pagesLearn to Sew! Measuring for Tailored Shirts & SuitsiliiexpugnansNo ratings yet

- Pattern Making 1922 (Sewing)Document163 pagesPattern Making 1922 (Sewing)Okafor PrinceNo ratings yet

- Clothing Construction and Wardrobe PlanningDocument568 pagesClothing Construction and Wardrobe Planningromeropoulos0% (1)

- CursoDocument164 pagesCursobox100% (4)

- Army - fm10 16 - General Fabric RepairDocument171 pagesArmy - fm10 16 - General Fabric RepairMeowmix100% (4)

- Cardigan PatternDocument3 pagesCardigan PatternLori SimmonsNo ratings yet

- The Venetian Wrap - M23080 MDBB v1687802320184Document3 pagesThe Venetian Wrap - M23080 MDBB v1687802320184Raluca-Maria BucurNo ratings yet

- Personalized Baby AfghanDocument8 pagesPersonalized Baby AfghanKrista LabineNo ratings yet

- Quality Management System in TextilesDocument62 pagesQuality Management System in TextilesShivam AgnihotriNo ratings yet

- Pfaff 92 Sewing Machine Instruction ManualDocument53 pagesPfaff 92 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Batman Amigurumi Pattern (Crochet)Document15 pagesBatman Amigurumi Pattern (Crochet)magdaNo ratings yet

- Dilekshome - Dilek Candan - Cotton RabbitDocument13 pagesDilekshome - Dilek Candan - Cotton Rabbitmelatia71No ratings yet

- Uster Standards For Knitting YarnDocument1 pageUster Standards For Knitting YarnBalwinder Singh100% (6)

- Nansy Oops Spider EngDocument5 pagesNansy Oops Spider EngmonicamauderNo ratings yet

- McCall - Dressmaking Made Easy - 1939 PDFDocument91 pagesMcCall - Dressmaking Made Easy - 1939 PDFЮрий Панин100% (2)

- Welcome To The World of AdfDocument24 pagesWelcome To The World of AdfAlvarin CsboyNo ratings yet

- Free Purse Sewing Patterns EbookDocument69 pagesFree Purse Sewing Patterns EbookPhuoc Loc Nguyen Pham100% (16)

- Pocket Bear Sewing Pattern by TeacupLionDocument12 pagesPocket Bear Sewing Pattern by TeacupLionStorage Girl100% (2)

- Preemie Snow Suit & HatDocument6 pagesPreemie Snow Suit & HatAnis PaskaliaNo ratings yet

- Educ-321 PPT (Seesion Plan)Document19 pagesEduc-321 PPT (Seesion Plan)Dave Vertucio OfficialNo ratings yet

- FeedmachanismDocument74 pagesFeedmachanismaqsa imranNo ratings yet

- Internship Training: Submitted by - Gaurav Sisodiya Sanmitra Pomane Akash Nimbalkar Girish MohiteDocument30 pagesInternship Training: Submitted by - Gaurav Sisodiya Sanmitra Pomane Akash Nimbalkar Girish MohiteAditya RainaNo ratings yet

- Pineapple Lace TopDocument4 pagesPineapple Lace TopRux JitaruNo ratings yet

- LycraDocument7 pagesLycraFiaz juttNo ratings yet

- GMT Ut 3 Async 2 K S Suryaprakasavel 18BTT201Document4 pagesGMT Ut 3 Async 2 K S Suryaprakasavel 18BTT201SURYA VELNo ratings yet

- Blue Cotton Denim Kurtis Size Chart & DetailsDocument4 pagesBlue Cotton Denim Kurtis Size Chart & DetailsAnurag KanaujiaNo ratings yet

- Piglet - Winnie The Pooh: Crochet PatternDocument6 pagesPiglet - Winnie The Pooh: Crochet Patternly100% (7)

- Nahar PresentationDocument28 pagesNahar Presentationsurbhi168950% (2)

- NOBITA Doll PatternDocument14 pagesNOBITA Doll PatternNhi PhamNo ratings yet

- Pfaff 1025 Sewing Machine Instruction ManualDocument27 pagesPfaff 1025 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- 2001 2010 Ten Year SO IndexDocument36 pages2001 2010 Ten Year SO IndexSad ElfNo ratings yet

- Singer Instruction Manual PDFDocument70 pagesSinger Instruction Manual PDFEdenRageNo ratings yet

- Jacquard Shedding MechanismDocument10 pagesJacquard Shedding MechanismShanto MaloNo ratings yet

- Doll LolaDocument31 pagesDoll Lolajanne.vesiroos100% (3)

- Sarwat Halima Saima Habib Sadia AminDocument51 pagesSarwat Halima Saima Habib Sadia AminMikaScripnicNo ratings yet