Professional Documents

Culture Documents

Harmful Agents Risk Priority Index (HARPI)

Uploaded by

igor_239934024Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Harmful Agents Risk Priority Index (HARPI)

Uploaded by

igor_239934024Copyright:

Available Formats

Iran J Public Health, Vol. 52, No. 10, Oct 2023, pp.

2157-2168 Original Article

Workplace Risk Factors Assessment in North-Azadegan Oil

Field Based on Harmful Agents Risk Priority Index (HARPI)

Ali Askari 1, Mohsen Poursadeghiyan 2, Alimardan Alinia 3, Arash Sephvand 4,

Emad Jafarzadeh 5, Gebraeil Nasl-Saraji 1, *Ali Salehi Sahlabadi 6

1. Department of Occupational Health, School of Public Health, Tehran University of Medical Sciences, Tehran, Iran

2. Department of Occupational Health, School of Health, Ardabil University of Medical Sciences, Ardabil, Iran

3. Department of HSE, MAPNA-Group, Tehran, Iran

4. Department of Occupational Health and Safety, Atlantic International University, Hawaii, USA

5. Department of Toxicology and Pharmacology, Faculty of Pharmacy, Tehran University of Medical Sciences, Tehran, Iran

6. Workplace Health Promotion Research Center, Department of Occupational Health and Safety at Work, School of Public Health

and Safety, Shahid Beheshti University of Medical Sciences, Tehran, Iran

*Corresponding Author: Email: asalehi529@sbmu.ac.ir

(Received 04 Jul 2022; accepted 21 Sep 2022)

Abstract

Background: Considering the necessity of health risk management, the present study conducted to provide a

comprehensive model for identifying, evaluating, and prioritizing occupational health risks in an oilfield.

Methods: We conducted this descriptive-analytical cross-sectional study in 2022 at the North-Azadegan oil

field in Iran. The occupational health risk was assessed using the "Harmful Agents Risk Priority Index" (HAR-

PI) method.

Results: Among the employees for the office section in all job groups, ergonomic risks due to people's posture

while working has the highest risk score and is the most critical risk for implementing corrective actions. In the

operational section, for the HSE group, benzene, the production group, Electromagnetic Fields (EMFs), and

other groups, undesirable lighting has the highest risk score, and exposure to Toluene, Ethylbenzene, Xylenes

(TEX) has the lowest risk score. In this oil field, controlling exposure to benzene, correcting ergonomic condi-

tions, and controlling noise exposure, with scores of 81.3,74.85 and 71.36, have the highest priority, respective-

ly. Sequentially, Toluene, Xylene, and ethylbenzene, with scores of 10.25,11.61, and 11.61, have the lowest con-

trol priority.

Conclusion: The proposed model can prioritize the workplaces' harmful agents based on the HARPI score due

to exposure to chemicals, physical factors, and analysis posture.

Keywords: Environmental exposure; Occupational health; Oil and gas industry; Risk priority number

Introduction

Todays, energy demands are key in determining on a country's economic growth. Nonetheless,

the progress of nations' industrial sectors. Partic- the growing concern regarding safety, health, and

ularly, the oil industry makes a significant impact the environment is inseparable from the devel-

Copyright © 2023 Askari et al. Published by Tehran University of Medical Sciences.

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International license.

(https://creativecommons.org/licenses/by-nc/4.0/). Non-commercial uses of the work are permitted, provided the original work is properly cited

2157 Available at: http://ijph.tums.ac.ir

Askari et al.: Workplace Risk Factors Assessment in North-Azadegan Oil Field Based …

opment of these industries (1).Millions of health risks have been assessed independently

accidents and occupational diseases occur due to exposure to harmful factors in the work-

worldwide (2). According to the WHO statistics, place in most studies (13).

55 million people die annually due to Non- Thus, we aimed to provide a comprehensive

Communicable Diseases (NCD) (3). In addition, model for identifying, evaluating, and prioritizing

based on the statistics published by the Iranian occupational health hazards in the North-

Center for Environmental and Occupational Azadegan (13) oil field in 2022. Another purpose

Health in 2009, one million and two hundred of this study was to simplify decision-making for

thousand people were covered by occupational the organization's senior management in deter-

medical examinations (4). mining the location of the budget allocated for

The International Labor Organization (ILO) re- remedial measures using clarifying and prioritiz-

port indicates that 60% of the world's workforce ing health risks.

is in developing countries. From 5% to 15% have

access to occupational health engineering services Methods

(5). Occupational accidents and illnesses generate

economic and human burdens. They have led to Ethical approval was obtained from Shahid Be-

serious concerns for the ILO and related organi- heshti University of Medical Sciences:

zations (6). One of the most important factors IR.SBMU.PHNS.REC.1401.051.

influencing the improvement of health and safety The NAZ oil field located 120 km southwest of

management is developing and implementing risk Ahvaz. The number of employed workers is 915,

assessment methods to ensure the achievement with an average age of 34.05±7.8 years. By ob-

of health and safety programs 7).Risk manage- serving the ethical principles, this study was con-

ment is legally required in some countries, such ducted according to the conceptual model (Fig.1).

as the United Kingdom and Singapore (8). To First, a team including managers and supervisors

minimize the potential conflict between work and of the units, including the Health, Safety and En-

family, implementing effective safety and health vironment manager, maintenance, operation, and

management systems, focusing on improving occupational health expert, implemented check-

workplace occupational health, can be beneficial lists and instructions presented by the Iranian

(9) . Environment and Occupational Health Center

Risk assessment focuses on workplace safety (IEOHC) to identify harmful health agents in the

(10). However, workers exposed to health haz- workplace (14). In the next step, to measure the

ards include physical, chemical, biological, ergo- harmful occupational health agents for the differ-

nomic, and psychological harmful agents. The oil ent company job groups, the instructions ap-

industry and its derivatives have a specific place proved by the Ministry of Health and Medical

in oil-producing countries. This industry's high Education (MHME) were used in Table 1. In the

number of workers necessitates further studies in next step, we combined Noise control priority

occupational health engineering services (11). On index (NCPI) (15, 16) and Comprehensive Oc-

the other hand, we should note that one of the cupational Health Risk Assessment (COHRA) (7)

main tasks of risk assessment as a management with two purposes and provided the Harmful

tool is simplifying the perception of subjects and Agent Risk Priority Index (HARPI). 1) Using

decisions. Therefore, the risk management pro- COHRA to determine each harmful agent’s

cess should select remedial actions with the de- weight factor and eliminate their unit (dimension)

sired impact, the assumed benefits at an accepta- to compare all agents' priorities (Table 2) 2) Us-

ble cost, and resource savings (12). In studies, ing NCPI to consider the parameters of exposure

many investigations have been done on health time and the number of workers exposed to pol-

risk assessment in both processing and non- lutants (Table 3).

processing industries. As a result, only some

Available at: http://ijph.tums.ac.ir 2158

Iran J Public Health, Vol. 52, No.10, Oct 2023, pp.2157-2168

Figure 1 shows the location of HARPI in the oc- exposure time or repetition. Nonetheless, re-

cupational health management process. Some searchers can now investigate all possible harmful

potentially harmful factors, like vibration, were work-related factors based on the proposed

excluded due to the lack of identification at the model.

initial stages or investigation because of limited

Fig.1: Conceptual risk Process management model

Eq.1: 𝑊𝐹𝑖 = √𝐸𝑅 × 𝐻𝑅

WFi: Weight factor

ER: Exposure rate

HR: Hazard rate

∑! "#$ &$ '$

Eq.2:𝐻𝐴𝑅𝑃𝐼 = 100 × "#$ ∑ ()

pi: Number of people exposed to pollutants

ti: Job group exposure time average (hr.)

P: People total number

T: Total exposure times

2159 Available at: http://ijph.tums.ac.ir

Askari et al.: Workplace Risk Factors Assessment in North-Azadegan Oil Field Based …

Table 1: Identified harmful agents, measurement methods and devices used

Agents Methods Devices

Noise OEL – NV–9505 CEL-450

Lighting OEL–L – 9507 TES-1339

EMFs OEL – R – 9506 Extech-480846

Ultraviolet ray Lutron UV-340 A

Infrared ray Hagner ECI 1-IR

Heat stress OEL-HC-9508 Casella-Microtherm

Analysis Posture OEL – E – 9509 Worksheet and related software’s

Volatile organic com- 2549 SKC Air lite pump - activated carbon 50/100 mg

pounds

NIOSH1

1501

Dust 0600 SKC Air Check pump – PVC2 filter

Acid 7909 SKC Air Check pump - quartz fiber filter,

MCEF3

OSHA4 ID 113

1 National Institute of Occupational Safety and Health, 2 Polyvinyl Chloride, 3Mixed Cellulose Membrane Filter,

4Occupational Safety and Health Administration

Table 2: ER and HR table for harmful agent’s weight factor calculation

Analysis Posture (3) Physical

electromagnetic

Infrared,

RULA & REBA

Agents

ROSA score

QEC score

Heat stress

Ultraviolet,

(WBGT)

Vibration

Lighting

Noise

E

fields

and

R

5 - Level S>75% E>100% OEL E < E >100% OEL E>100% OEL E > OEL

4 OEL

4 - Level 51%≤S≤75 AL<E≤100% - - 75%OEL<E≤100%O AL<E≤OE

3 % OEL EL L

3 S Level 41%≤S≤50 E≤ AL - AL<E≤100% 50%OEL<E≤75%O E ≤AL

≥5 2 % OEL EL

2 S<5 Level S≤40% - - E≤ AL 25%OEL<E≤50%O -

1 EL

1 - - - - E ≥ - E≤25%OEL -

OEL

E Chemicals

R Exposure rate to a single contaminant Mixed exposure rate with synergic effects

5 E>1 E>100% OEL

4 - 75%OEL<E≤100%OEL

3 - 50%OEL<E≤75%OEL

2 - 25%OEL<E≤50%OEL

1 E≤1 E≤25%OEL

H Physical and Ergonomics

R

5 Catastrophic: More than one death due to significant irreversible health or physiological effects, toxins affecting re-

Available at: http://ijph.tums.ac.ir 2160

Iran J Public Health, Vol. 52, No.10, Oct 2023, pp.2157-2168

production, life-threatening consequences, lack of light and loudness that pose a risk of an accident

4 Severe: death of one person, irreversible or debilitating health effects in one or more people, chronic progressive

complications such as hearing loss, pneumoconiosis, and obstructive pulmonary disease

3 Moderate: Reversible health effects with missed workdays such as musculoskeletal disorders, effects of vibration,

manual load carrying, physical effects of sunburn, heat stress, effects of the nervous system other than narcosis, non-

fatal airborne diseases, complications Ultraviolet, infrared, and electromagnetic fields

2 Minor: Reversible health effects, requires treatment without missed workday, bacterial food poisoning, sunburn, and

narcosis

1 Negligible: No effect on performance, reversible effects, requires first aid, minor muscle discomfort, and headache

H Chemicals

R

5 The carcinogenic, mutagenic, and teratogenic effects of the substance are known. Elements that ACGIH and IARC

classify in category A1 and group 1

4 Substances in ACCIH class A2. Group A2 in IRAC class, highly corrosive substances (0 ˂PH˂ 2 or 11.5 ˂PH˂ 14).

3 Substances that ACGIH has placed in class A3. Group B2 materials in IRAC classification. Corrosive substances (5

PH˂3 or 12 PH˂9) and respiratory sensitizers.

2 Substances with reversible effects on the skin, eyes, and mucous membranes, but their effects are not severe enough

to cause serious harm to humans. Substances that ACGIH has placed in the A4 class of carcinogens. Substances with

skin sensitivity and irritation effect.

1 Substances that have no known health effects and are not classified as toxic or harmful substances. Substances that

ACGIH has placed in class A5 carcinogens.

Table 3: Job groups identified based on human resource database analysis

Job groups Staff total num- Offices %%%%%%%

Exposure 𝒕"𝒎𝒆 Operational Exposure %%%%%%%

𝒕"𝒎𝒆

ber (hr) (hr)

HSE 99 19 14 80 10

Laboratory 12 2 8 10 5

Quality 6 2 12 4 5

Planning 2 2 12 0 0

Production 102 12 14 90 5

Logistic 171 11 14 160 5

Commercial 39 39 14 0 0

Security 275 25 8 250 5

Legal affairs 3 3 6 0 0

Management 4 4 6 0 0

Technology 15 15 8 0 0

Human Re- 7 7 10 0 0

source

Process 4 2 14 2 5

Maintenance 175 45 12 130 5

SUM 914 188 726

Physical agents * ,&$.

11111(𝑑𝐵) = 10 log[ ∑+$/* 10

Eq.3: 𝑆𝑃𝐿 *- ]

Noise +

We measured the Sound Pressure Level (SPL) n: Stations number

based on ISO 9612-2009 (E) and then calculated Lpi: Each stations SPL (dB)

the average SPL based on Eq.3 to determine the

noise-related ER (17).

2161 Available at: http://ijph.tums.ac.ir

Askari et al.: Workplace Risk Factors Assessment in North-Azadegan Oil Field Based …

Lighting workers breathing zone and the pollutant's syner-

To measure the average general light intensity in gistic effects by Eq.8,9 and 10, respectively(21) .

the operational areas, we selected certain stations Eq.8: 𝐶 =

("> 6 ": – 0> A 0:)

and measured the light intensity on the horizon B

and at workers' eye level. We used IES patterns Wf,b: Analyte found in the sample front and

to calculate the average light intensity in office back (Coconut shell charcoal)

areas, warehouses, and roofed locations. We Bf,b: Average media in the blank front and

measured light intensity in industrial and roofed back

areas after sunset, and then used Equation 4 to V: Air volume sample (1)

determine exposure to average light intensity C: Pollutant concentration (mg/m3)

(C*)*6D8E86⋯6DGEG)

(18). Eq.9: 𝑇𝐿𝑉 − 𝑇𝑊𝐴 = H 2I.

*

Eq.4:𝐸 (𝐴𝑣𝑔) = ) ∑+$/* 𝐸𝑖 × 𝑇𝑖 C* C8

Eq.10: 𝑇𝐿𝑉 − 𝑀𝑖𝑥𝑡𝑢𝑟𝑒 = )* + )8 + )+ ≤ 1

C+

Heat stress Dust

We used the Wet Bulb Globe Temperature The NIOSH 0600, was used, to measure the

(WBGT) index to calculate the ER to heat stress number of respirable particles, and to calculate

in the workplace (Eq.5and 6) (19). the concentration of respirable particulate

Eq.5: 𝑊𝐵𝐺𝑇𝑖 = (mg/m³) in the air volume sampled (1), utilizing

"01) 23456(8×"01) 4:5;<3+)6"01) >;;' Eq.11 (22).

? ("8A "*) – (08 A 0*)

*

Eq.6: 𝑊𝐵𝐺𝑇(𝐴𝑣𝑔) = ) ∑+$/* 𝑊𝐵𝐺𝑇𝑖 × 𝑇𝑖 Eq.11: 𝐶 = B

× 10K

W1,2: Tare weight of filter before and post-

Rays and EMF sampling (mg)

To determine the level of exposure to ultraviolet B1,2: Mean tare weight of blank filters and

and infrared rays, considering the region's climate post-sampling (mg)

and the large number of outdoor workers, we V: Volume as sampled at the nominal flow

measured their intensity at midday (11am to rate (1.7 L/min - 2.2 L/min)

1pm). Furthermore, we measured EMFs from

the sources we identified. The measurements Acids

were achieved using direct-reading devices, and During the initial investigation, it was discovered

the results were applied to calculate the rate of that acid was present only in the oil quality lab.

exposure for workers, based on the Eq.7. (20). The concentration of the substances in the tech-

* nician's breathing zone was measured using

Eq.7: 𝑅(𝐴𝑣𝑔) = ) ∑+$/* 𝑅𝑖 × 𝑇𝑖 NIOSH 7909 and OSHA ID 113. Equations 12

and 13 were used from related literature to calcu-

Analysis posture late the pollutant levels, which enabled us to de-

We used Rapid Upper Limb Assessment termine the concentration of each substance

(RULA), Rapid Entire Body Assessment (RE- (mg/m³) (22).

BA), Quick Exposure Check (QEC), and Rapid Eq.12: 𝐶 =

(C*×B*×#5 ) – (C-×B-)

× 𝐹𝑐

Office Strain Assessment (ROSA) to analyze pos- B

ture assessment (7). C0,1: Mean concentration, in mg/L, of anion

in the field blank test solutions and post-

Chemical agents sampling

Volatile Organic Compounds (VOCs) V: Air sample volume (1)

By NIOSH 2549, we made sure of VOCs. We V0,1: Field blank and sample test solutions

calculated the concentration of pollutants in the volume (mL)

Available at: http://ijph.tums.ac.ir 2162

Iran J Public Health, Vol. 52, No.10, Oct 2023, pp.2157-2168

Fd: Dilution factor for each sample test solu- quently differentiated into operational and office

tion categories, according to their respective job char-

Fc: Conversion factor to convert from anion acteristic (Table 3).

to acid concentration Due to the large volume of results, we have

Fc: 1.0284 for chloride shown the HARPI calculation for the HSE

Eq.13: 𝑚𝑔/𝑚3 = (Health, Safety, and Environment) job group as

(<L M4NMON4'35 )×(<L P4<&N3 Q;N)×(*.-K)× (RSTUVSWG XYZVW[) an example in Table 4.

(N$'3I ;> 4$I)× (<N 4N$\O') Table 5 shows the maximum and minimum

HARPI values calculated for the harmful agents

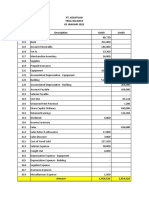

Due to the large volume of collected data, we identified in the offices and operational sectors.

have shown in Table 4 the calculations as an ex- Table 6 and Fig. 2, show the average of HARPI

ample for the HSE group. score for the all scope of the study to clarify the

factors with the highest risk and the budget prior-

Results ity allocation for corrective actions.

Upon reviewing the organization's database, we

recognized 14 job groups, which were subse-

Table 4: HARPI calculation for the HSE group

Harmful agents Operational Offices

ER HR Wfi HARPI ER HR Wfi HARPI

Noise 4 5 4.47 41.05 2 2 2 23.58

Lighting 5 5 5.00 45.91 1 2 1.41 16.62

EMFs 2 2 2.00 18.37 1 1 1 11.79

UV 5 3 3.87 35.08 NI1 NI NI NI

IR 2 3 2.45 22.50 NI NI NI NI

Heat stress 5 3 3.87 35.54 3 1 1.73 20.39

Analysis posture (3) 4 3 4.47 31.77 2 3 4.11 48.46

Benzene 4 5 4.47 451.52 NI NI NI NI

Toluene 1 3 1.73 15.89 NI NI NI NI

Ethyl benzene 1 3 1.73 15.89 NI NI NI NI

Xylene 1 3 1.73 15.89 NI NI NI NI

Synergic effect 1 5 2.24 20.57 NI NI NI NI

(BTEX)2

Sulfuric acid 1 4 2.00 18.37 NI NI NI NI

Hydrochloric acid 2 4 2.83 25.99 NI NI NI NI

Dust 2 1 2 18.37 NI NI NI NI

1No Identify, 2 Benzene, Toluene, Ethylbenzene, Xylenes

2163 Available at: http://ijph.tums.ac.ir

Askari et al.: Workplace Risk Factors Assessment in North-Azadegan Oil Field Based …

Table 5: Min and max HARPI calculated and related harmful agents for job groups

Job groups Operational Offices

HARPI min HARPI max HARPI min HARPI max

Agents Amount Agents Amount Agents Amount Agents Amount

HSE TEX1 15.89 Benzene 451.52 EMFs 11.79 AP 48.46

Laboratory TEX 1.19 Lighting 3.44 EMFs 0.71 AP 2.92

Quality TEX 0.48 Lighting 1.38 EMFs 1.06 AP 4.37

Planning - - - - EMFs 1.06 AP 4.37

Production TEX 10.72 EMFs 284.59 EMFs 7.47 AP 30.61

Logistic TEX 19.06 Lighting 55.10 EMFs 6.83 AP 28.06

Commercial - - - - EMFs 13.83 AP 56.84

Security TEX 29.79 Lighting 86.09 EMFs 6.65 AP 27.33

Legal affairs - - - - EMFs 0.80 AP 3.28

Management - - - - EMFs 1.42 AP 5.83

Technology - - - - EMFs 6.65 AP 27.33

Human Re- - - - - EMFs 4.34 AP 17.85

source

Process Toluene 0.07 Lighting 0.69 EMFs 0.71 AP 2.91

Maintenance Toluene 4.77 Lighting 44.77 EMFs 27.93 AP 114.77

1. Toluene, Ethylbenzene, Xylenes

Table 6: Average of calculated HARPI in all scope of study

Harmful agents ER HR Wfi HARPI

Noise 4 5 3.235 71.36

Lighting 5 5 3.205 70.66

EMFs 2 2 1.5 53.96

UV 5 3 1.91 36.90

IR 2 3 1.225 41.72

Heat stress 5 3 2.8 51.67

Analysis posture 4 3 3.785 74.85

Benzene 4 5 2.235 81.30

Toluene 1 3 0.865 10.25

Ethyl benzene 1 3 0.865 11.61

Xylene 1 3 0.865 11.61

Synergic effect 1 5 1.12 15.03

(BTEX)

Sulfuric acid 1 4 1 13.42

Hydrochloric acid 2 4 1.415 18.99

Dust 4 1 1 13.42

Available at: http://ijph.tums.ac.ir 2164

Iran J Public Health, Vol. 52, No.10, Oct 2023, pp.2157-2168

Fig. 2: Calculated HARPI in all scope of study

Discussion The priorities in the administrative and opera-

tional job groups are different. For the HSE

According to Anthony Giddens, we live in a civi- group, benzene, the production group, EMFs,

lization preoccupied with safety, thus emphasiz- and other groups, undesirable lighting has the

ing the concept of "risk." As a result, the risk ap- highest risk score, and exposure to TEX has the

pears as a pervasive and inescapable reality in lowest risk score (Table 5). In Jahangiri et al.'s

modernity. Risks to HSE abound, and the notion study (7), the risk of exposure to benzene was

of risk and risk-taking are increasingly preoccupy- moderate, and the risk of other chemical agents

ing people, governments, organizations, and sci- was low. In the present study, the risk of differ-

entists (23) . This study aimed to provide a com- ent chemical agents was medium and low, but

prehensive model that would detect, assess, and benzene was identified as the most dangerous

prioritize occupational health risks and thereby factor in the workplace. Based on other imple-

assist senior management in using the budget to mented research, benzene can cause cancer at

execute the necessary corrective measures in the low concentrations and a high-risk level (23).

NAZ oil field. The results revealed that among all This difference in the results is due to the data

administrative department employees of various analysis methods; in the study (7), risk prioritiza-

positions, the highest risk score was for ergo- tion was calculated based on risk levels frequen-

nomic risks due to workers' positions while cy. Still, in the proposed model, other influential

working. This finding was in agreement with an- factors such as exposure time, number of work-

other study (7). Moreover, among the harmful ers exposed, and exposure dose are considered.

factors identified for office workers in each job Table 6 and Fig. 2 reported that workers' ergo-

group, exposure to electromagnetic fields was nomic conditions were identified as a second pri-

determined as the factor with the lowest risk (Ta- ority.

ble 5). According to the WHO statistics, Safarian et al.

said musculoskeletal disorders are the second

2165 Available at: http://ijph.tums.ac.ir

Askari et al.: Workplace Risk Factors Assessment in North-Azadegan Oil Field Based …

most common work-related disease (24). Limitations

According to Anagha, one of the most important The workplace harmful factors are not limited to

causes of musculoskeletal disorders among those mentioned in the present study. Based on

workers is awkward posture (25). Recent state- the provided model, any known substance with

ments can confirm the results provided by our occupational exposure limits (OEL) can be eval-

proposed model. As mentioned, our proposed uated using Table 2. Among the five main cate-

model ranked noise as the third priority among gories of harmful factors in the workplace, psy-

the 14 harmful factors studied and as the first chological and biological factors require special-

factor among the physical agents. This result is ized methods and have a high cost for sampling

consistent with previous statements (Table 6 and and Paraclinical tests. The present study exam-

Fig. 2). ined the most common elements in the study

From a managerial point of view, risk acceptabil- scope as samples to present the current model.

ity is significant and of great importance (26).Risk

and risk assessments have a long history in Conclusion

making decisions, and human beings have always

sought to reduce the rate of exposure to dangers Among the employees of the administrative de-

(27). As a result, various risk assessment partment of all job groups, ergonomic risks due

approaches have many methods for each to people's posture while working has the highest

industry. Therefore, what is essential in adopting risk score and is the most critical risk for imple-

a risk assessment method is to simplify the menting corrective actions. For the HSE group,

decision-making in the risk management process benzene, the production group, EMFs, and other

and focus on a selection of the appropriate groups, undesirable lighting has the highest risk

corrective actions with the desired effect, score, and exposure to TEX has the lowest risk

assumed benefits at an acceptable cost, and score. In our proposed model, in addition to the

resource savings (12). For example, Multi-Criteria frequency of exposure, we used the most im-

Decision Making (MCDM) approaches provide portant factors affecting workers' health, includ-

risk assessment knowledge with their capability to ing exposure dose and duration of exposure, to

solve real-world problems with multiple, incon- determine the priority of risks. The significance

sistent, and discrepant criteria (28). and strength of the risk management approach

In our proposed model, in addition to the fre- reside in the fact that it consolidates diverse eval-

quency of exposure, we used the most important uation and discussion techniques, integrates them

factors affecting workers' health, including expo- into a whole, and supplies structure to the deci-

sure dose and duration of exposure, to determine sion-making process. The proposed model can

the priority of risks. The significance and strength prioritize measuring and evaluating the harmful

of the risk management approach reside in the agents of the workplaces based on the health risk

fact that it consolidates diverse evaluation and score (HARPI score) due to exposure to chemi-

discussion techniques, integrates them into a cals, physical factors, and analysis posture. By

whole, and supplies structure to the decision- developing the ER and HR table, this model can

making process (29). In Buckingham's theory, assess semi-quantitative risk in other fields, such

dimensionless parameters can be substituted for as the environment.

the main variables (30). In the present study, we

used a model (7), to eliminate the unit of parame- Journalism Ethics considerations

ters and another model (15) to influence the fac-

tors affecting health (duration and dose of expo- Ethical issues (Including plagiarism, informed

sure). consent, misconduct, data fabrication and/or fal-

sification, double publication and/or submission,

Available at: http://ijph.tums.ac.ir 2166

Iran J Public Health, Vol. 52, No.10, Oct 2023, pp.2157-2168

redundancy, etc.) have been completely observed 8. Gan SL (2019). Importance of hazard

by the authors. identification in risk management. Ind

Health,57 (3):281-2.

9. Malakoutikhah M, Karimi A, Hoseini M,et al

Acknowledgements (2017). Survey of the relationship between

musculoskeletal disorders and work-family

This work supported by the Health School, and conflict in one of the country's steel industry.

Neuroscience Research Center, Shahid Beheshti Journal of Occupational Hygiene Engineering, 4

University of Medical Sciences (No:32732 ). (1):10-7.

10. Gul M (2018). A review of occupational health

Conflicts of interest and safety risk assessment approaches based

on multi-criteria decision-making methods

There is no conflicts of interest and their fuzzy versions. Hum Ecol Risk Assess,

24 (7):1723-60.

11. Białas A (2016). Cost-benefits aspects in risk

References management. Polish Journal of Management

Studies, 14 (1):28-39.

1. Kulkarni SJ (2017). Safety and hazards in 12. Yarmohammadi H, Poursadeghiyan M, Shorabi

petroleum industries: research, studies and Y, et al (2016). Risk Assessment in a Wheat

surveys. Int J Emerg Trends Eng Res, 3 (1):31-4. Winnowing Factory Based on ET and BA

2. Kim EA, Kang SK (2013). Historical review of Method. Journal of Engineering and Applied

the List of Occupational Diseases Sciences, 11: 334-338.

recommended by the International Labour 13. Jahangiri M, Mostafavi A, Choobineh A, et al

organization (ILO). Ann Occup Environ Med, (2020). Development and validation of

25 (1):14. hoshra index for occupational safety and

3. Chaiklieng S, Suggaravetsiri P, Autrup H (2019). health risk assessment in hospitals. Shiraz E-

Risk assessment on benzene exposure among Medical Journal, 21 (6):e95357.

gasoline station workers. Int J Environ Res 14. Heyns S, Dekker K, Ker-Fox J, et al (2021).

Public Health,16(14):2545. COE 180701–Review The Current Sami

4. Tak S, Davis RR, Calvert GM (2009). Exposure Noise Exposure Limit And Conduct A Study

to hazardous workplace noise and use of On Vibration Oel In Relation To The Sami.

hearing protection devices among US Enterprises at the University of Pretoria,

workers—NHANES, 1999–2004. Am J Ind South African. Available from:

Med, 52 (5):358-71. https://mhsc.org.za/wp-

5. Halvani G, Fallah H, Barkhordari A, et al (2010). content/uploads/2021/07/Agenda-Item-

A Survey of causes of occupational accidents 8.2.1.-Draft-Final-Report-for-project-CoE-

at working place under protection of Yazd 180701.pdf

Social Security Organization in 2005. Iran 15. Askari A, Golmohammadi R, Alinia A, et al

Occupational Health, 7(3):22-9. (2021). Study the Impact of Acoustic Barrier

6. Leuenberger A, Farnham A, Azevedo S, et al on Noise Reduction of Generator Building,

(2019). Health impact assessment and health Case Study: North.Azadegan Oil Field. Journal

equity in sub-Saharan Africa: A scoping of Occupational Hygiene Engineering, 8 (3):50-8.

review. Environ Impact Assess Rev, 79 16. Askari A, Abadi ASS, Alinia A, et al (2021).

(2019):106288. Prioritizing and Providing Sound Pollution

7. Jahangiri M, Abaspour S, Derakhshan Jazari M, Control Strategies at the CPF of North

et al (2018). Development of comprehensive Azadegan Oilfield Project.Sound &

occupational health risk assessment Vibration,55 (4):329-341.

(COHRA) method: Case study in a 17. Monazzam MR, Golmohammadi R, Nourollahi

petrochemical industry. Journal of Occupational M, et al (2011). Assessment and control

Hygiene Engineering, 5 (3):53-62. design for steam vent noise in an oil refinery.

J Res Health Sci,11(1):14-9.

2167 Available at: http://ijph.tums.ac.ir

Askari et al.: Workplace Risk Factors Assessment in North-Azadegan Oil Field Based …

18. Abdullah KG, Bishop FS, Lubelski D, et al musculoskeletal disorders in office workers.

(2012). Radiation exposure to the spine Health Scope, 8(1):e68422.

surgeon in lumbar and thoracolumbar fusions 25. Majdabadi HA, khadri B, Pirposhteh EA, et al

with the use of an intraoperative computed (2022). Relationship between the status of

tomographic 3-dimensional imaging system. occupational health management and job

Spine (Phila Pa 1976) , 37 (17):E1074-E8. satisfaction among farmers: A health

19. Young MS (2002). Guide to Methodology in promotion approach. J Educ Health

Ergonomics: Designing for Human Use. 1st ed. Promot,11:390.

CRC Press. Florida, USA. 26. Dargahi A, Vosoughi Niri M, Zandian H, et al

20. Qutubuddin S, Hebbal S, Kumar A (2013). (2023). Determinants of Noncompliance with

Ergonomic risk assessment using postural Health Guidelines Related to COVID-19 in

analysis tools in a bus body building unit. Rev Ardebil, Iran Based on Network Analysis

Ind Eng Lett, 3 (8):10-20. Process. Health in Emergencies and Disasters

21. Schenk L, Hansson SO, Rudén C, et al (2008). Quarterly, 8 (2):133-144

Occupational exposure limits: A comparative 27. Khandan M, Vosoughi S, Azrah K, et al (2017).

study.Regul Toxicol Pharmacol,50(2):261-70. Decision making models and human factors:

22. Ashley K, O'Connor PF (2017). NIOSH manual TOPSIS and Ergonomic Behaviors

of analytical methods (NMAM), NIOSH, (TOPSISEB). Management Science Letters, 7

USA. Available from: (2):111–8.

https://stacks.cdc.gov/view/cdc/50253/cdc_50253 28. Wu HY, Tzeng GH, Chen YH (2009). A fuzzy

_DS1.pdf MCDM approach for evaluating banking

23. Lin YC, Lai CY, Chu CP (2021). Air pollution performance based on Balanced Scorecard.

diffusion simulation and seasonal spatial risk Expert Syst Appl, 36 (6):10135-47.

analysis for industrial areas. Environ Res, 29. Mahoney JF, Yeralan S (2019). Dimensional

194:110693. analysis. Procedia Manuf, 38 (2019):694-701.

24. Safarian MH, Rahmati-Najarkolaei F, 30. Cherniak O, Trishch R, Kim N, et al (2020).

Mortezapour A (2019). A comparison of the Quantitative assessment of working

effects of ergonomic, organization, and conditions in the workplace. Engineering

education interventions on reducing Management in Production and Services,12 (2):99-

106.

Available at: http://ijph.tums.ac.ir 2168

You might also like

- JG02 v1-0 10apr10 W507 Student Manual1 PDFDocument213 pagesJG02 v1-0 10apr10 W507 Student Manual1 PDFHerna S Hasugian100% (1)

- Introduction To Risk and FailuresDocument270 pagesIntroduction To Risk and FailuresEACOPNo ratings yet

- HSE Risk Assessment & Control FormDocument30 pagesHSE Risk Assessment & Control FormImam AliNo ratings yet

- 7 Principles For SuccessDocument13 pages7 Principles For Successigor_239934024No ratings yet

- Heat Stress Awareness GuideDocument22 pagesHeat Stress Awareness Guideqarz ShukoNo ratings yet

- Asbestos Micros PDFDocument8 pagesAsbestos Micros PDFigor_239934024No ratings yet

- Forklift HSDocument48 pagesForklift HSJOAQUIN DOMINGUEZ100% (1)

- HSE Manual Health Safety & Environmental Management SystemDocument226 pagesHSE Manual Health Safety & Environmental Management Systemthomas100% (1)

- Health Risk AssessmentDocument68 pagesHealth Risk Assessmentkarl_poor100% (4)

- HSE Definition and MoreDocument87 pagesHSE Definition and MoreRandy100% (1)

- Evaluation of Occupational Health Hazards Among Oil Industry Workers: A Case Study of Refinery WorkersDocument32 pagesEvaluation of Occupational Health Hazards Among Oil Industry Workers: A Case Study of Refinery WorkersNurhidayahNo ratings yet

- Risk Analysis and Control for Industrial Processes - Gas, Oil and Chemicals: A System Perspective for Assessing and Avoiding Low-Probability, High-Consequence EventsFrom EverandRisk Analysis and Control for Industrial Processes - Gas, Oil and Chemicals: A System Perspective for Assessing and Avoiding Low-Probability, High-Consequence EventsNo ratings yet

- Ladder of Customer LoyaltyDocument31 pagesLadder of Customer LoyaltyEshita Hajela100% (2)

- ICMM Good Practice Guidance On Occupational Health Risk AssessmentDocument68 pagesICMM Good Practice Guidance On Occupational Health Risk AssessmentSalim Vohra100% (1)

- Product Roadmap Guide by ProductPlanDocument68 pagesProduct Roadmap Guide by ProductPlananikbiswasNo ratings yet

- First Preboard ExamsDocument4 pagesFirst Preboard ExamsRandy PaderesNo ratings yet

- Basics of Occupational Safety and HealthDocument4 pagesBasics of Occupational Safety and HealthIOSRjournal100% (1)

- Heat Stress ManagementDocument52 pagesHeat Stress ManagementFazwan mohd nasir100% (1)

- Ansi A-1264-1 2007Document31 pagesAnsi A-1264-1 2007Yimmy Moreno100% (1)

- Work Health and Safety (WHS) Management Plan FOR: Insert Name HereDocument52 pagesWork Health and Safety (WHS) Management Plan FOR: Insert Name HereengrcabaneroNo ratings yet

- 12 M's To Successful EntrepreneurshipDocument3 pages12 M's To Successful EntrepreneurshipQueen Valle100% (4)

- RG 773Document94 pagesRG 773Sayed AbbasNo ratings yet

- Project Health, Safety and Environment Plan: DOC. NO.: 0304-GP-112 JOB NO.: 2011065Document46 pagesProject Health, Safety and Environment Plan: DOC. NO.: 0304-GP-112 JOB NO.: 2011065wilson mantilla100% (1)

- DOSH GL - Occupational - Noise PDFDocument67 pagesDOSH GL - Occupational - Noise PDFmichlsy11No ratings yet

- JSW Shoppe-A Unique Distribution Model For Branded Steel: Case PresentationDocument11 pagesJSW Shoppe-A Unique Distribution Model For Branded Steel: Case Presentationbaz chacko0% (1)

- Digital Marketing ProjectDocument55 pagesDigital Marketing Projectsarah IsharatNo ratings yet

- MBBcurrent 564548147990 2022-01-31 PDFDocument4 pagesMBBcurrent 564548147990 2022-01-31 PDFAdeela fazlinNo ratings yet

- Seguridad e HigieneDocument6 pagesSeguridad e HigieneJuan José Hernández TorresNo ratings yet

- Safety and Health at WorkDocument6 pagesSafety and Health at Workwisdha ghinaNo ratings yet

- Hazard Identification Using HiradcDocument8 pagesHazard Identification Using HiradcBucit SupriadiNo ratings yet

- Application of The Mond Fire Explosion IndexDocument17 pagesApplication of The Mond Fire Explosion IndexenviroNo ratings yet

- Evaluating OHS Systems Using Key Indicators (2017Document6 pagesEvaluating OHS Systems Using Key Indicators (2017Pipe GonzalezNo ratings yet

- The Comparing of Formaldehyde Risk Assessment in Histopathology Laboratories Staff by Using Three Methods Based On US-EPA Approaches in The West of IranDocument26 pagesThe Comparing of Formaldehyde Risk Assessment in Histopathology Laboratories Staff by Using Three Methods Based On US-EPA Approaches in The West of IranAnonymous tIwg2AyNo ratings yet

- SPE 86863 Health Risk Assessment in Oil and Gas Exploration: Siesmic WorkDocument6 pagesSPE 86863 Health Risk Assessment in Oil and Gas Exploration: Siesmic WorkWaleed Barakat MariaNo ratings yet

- ECONOMIC ImplicationDocument12 pagesECONOMIC ImplicationIdris Aji DaudaNo ratings yet

- Work Related Injuries and Associated Factors Among Small Scale Industry Workers of Mizan-Aman Town, Bench Maji Zone, Southwest EthiopiaDocument9 pagesWork Related Injuries and Associated Factors Among Small Scale Industry Workers of Mizan-Aman Town, Bench Maji Zone, Southwest EthiopiaaamichoNo ratings yet

- Arjun Kelompok 5Document9 pagesArjun Kelompok 5Arjun f2002No ratings yet

- IJPHSDocument9 pagesIJPHSMonabbirNo ratings yet

- Evaluating OHS systems using KPIsDocument17 pagesEvaluating OHS systems using KPIsWilisMilayantiNo ratings yet

- LSMR-19 Vol2010Document12 pagesLSMR-19 Vol2010Vivek SharmaNo ratings yet

- EVALUATION_OF_WORKPLACE_HARZARDS_IN_AN_ONSHORE_FACILITY_LOCATED_AT_OZORO_DELTA_S[1]Document8 pagesEVALUATION_OF_WORKPLACE_HARZARDS_IN_AN_ONSHORE_FACILITY_LOCATED_AT_OZORO_DELTA_S[1]Imonikosaye ToboreNo ratings yet

- Comparison of Risk Assessment Using HAZOP and ETBA Techniques: Case Study of A Gasoline Refinery Unit in IranDocument9 pagesComparison of Risk Assessment Using HAZOP and ETBA Techniques: Case Study of A Gasoline Refinery Unit in IranJacekNo ratings yet

- ICOHS 2017 Conference Paper Assesses Health RisksDocument11 pagesICOHS 2017 Conference Paper Assesses Health RisksJonas XoxaeNo ratings yet

- Health Risks of CPO Processing IndustryDocument14 pagesHealth Risks of CPO Processing IndustryDELOVELY SQUISHY TAGNo ratings yet

- HIA Guidance DocumentDocument60 pagesHIA Guidance DocumentNidia Ranah Azmi Lbs100% (1)

- Status of Occupational Safety and Health in Rice Milling FINALDocument27 pagesStatus of Occupational Safety and Health in Rice Milling FINALAyon80% (5)

- GestioneRischi HSE IngleseDocument52 pagesGestioneRischi HSE IngleseSalim Muftah100% (1)

- Safety and Health Index Development For FormulatedDocument8 pagesSafety and Health Index Development For FormulatedJesus Manuel Nuñez LopezNo ratings yet

- Occupational Health and Safety in Chemical Industries in Transitional EconomiesDocument3 pagesOccupational Health and Safety in Chemical Industries in Transitional EconomiesCerasela Daniela BNo ratings yet

- A9RF0C7Document7 pagesA9RF0C7nemoo80 nemoo90No ratings yet

- HiraDocument8 pagesHirarajmohapatraNo ratings yet

- 02.influence and Effect of Occupational Health and Safety On Employees Performance A Study of Afghanistan International BankDocument7 pages02.influence and Effect of Occupational Health and Safety On Employees Performance A Study of Afghanistan International BankAung Pyae Sone MaungNo ratings yet

- Health Risk Assessment in The Utility Area of Lubricant Production Limited Liability CompanyDocument12 pagesHealth Risk Assessment in The Utility Area of Lubricant Production Limited Liability CompanyAffan RifkiNo ratings yet

- Chemical Health Risk Assessment (CHRA) in A Wet Assay and Fire Assay Laboratory (WAFAL)Document12 pagesChemical Health Risk Assessment (CHRA) in A Wet Assay and Fire Assay Laboratory (WAFAL)Nikola RanđelovićNo ratings yet

- Accident Occurrence Among Scientific Laboratory Workers of The Public University in LebanonDocument8 pagesAccident Occurrence Among Scientific Laboratory Workers of The Public University in Lebanonlama charafeddineNo ratings yet

- Risk Assessment at The Cosmetic ProductDocument7 pagesRisk Assessment at The Cosmetic ProductKoukis PericlesNo ratings yet

- 2564-Article Text-17430-2-10-20231124 (1)Document14 pages2564-Article Text-17430-2-10-20231124 (1)Rhey PrimeNo ratings yet

- OHS Measures in Goldtree SLDocument26 pagesOHS Measures in Goldtree SLAbu Silvanus Mustapha MomohNo ratings yet

- Environmental Risk Assessment To Prevent Occupational Diseases in Industry 4.0 An IoT Based Model of Hydrocarbon Processing ComplexDocument11 pagesEnvironmental Risk Assessment To Prevent Occupational Diseases in Industry 4.0 An IoT Based Model of Hydrocarbon Processing ComplexragilpriyantoNo ratings yet

- Assessment of Occupational Safety Determinants in Finnish Agriculture and Commercial FishingDocument2 pagesAssessment of Occupational Safety Determinants in Finnish Agriculture and Commercial Fishingharsha thorNo ratings yet

- Protection of Workers Against Occupational HazardsDocument6 pagesProtection of Workers Against Occupational HazardsMagdelineJaneNo ratings yet

- Risk Assessment of Oxygen Plant by HAZOP and What If in Besat Hospital in SanandajDocument6 pagesRisk Assessment of Oxygen Plant by HAZOP and What If in Besat Hospital in SanandajDeepak KumarNo ratings yet

- 1 s2.0 S001393512101389X MainDocument5 pages1 s2.0 S001393512101389X MainYusril Ihza TachririNo ratings yet

- Identification of Occupational Health Hazards and Assessment of Intervention Strategies in Working Environment in Minna, Niger State, NigeriaDocument10 pagesIdentification of Occupational Health Hazards and Assessment of Intervention Strategies in Working Environment in Minna, Niger State, NigeriaEditor IJTSRDNo ratings yet

- 1 s2.0 S0169814118302737 MainDocument19 pages1 s2.0 S0169814118302737 Mainashish kumarNo ratings yet

- Implementation of Health and Safety Management System ToDocument10 pagesImplementation of Health and Safety Management System ToLesly GarciaNo ratings yet

- Safety Weighted Hazard Index (SWeHI) - A New, User-Friendly Tool For Swift Yet Comprehensive Hazard Identification and Safety EvDocument16 pagesSafety Weighted Hazard Index (SWeHI) - A New, User-Friendly Tool For Swift Yet Comprehensive Hazard Identification and Safety EvYusuf IskandarNo ratings yet

- Feasibility Study of Implementing Process Safety Management (PSM) Requirements in An Iranian Petrochemical CompanyDocument5 pagesFeasibility Study of Implementing Process Safety Management (PSM) Requirements in An Iranian Petrochemical CompanyFakHrey FaRzNo ratings yet

- Ergonomics Hazards and Musculoskeletal Disorders ADocument8 pagesErgonomics Hazards and Musculoskeletal Disorders ANik WanyNo ratings yet

- CPS Unit IDocument36 pagesCPS Unit I69 krishna AgrawalNo ratings yet

- 23 53 1 PB PDFDocument22 pages23 53 1 PB PDFNafiz FahimNo ratings yet

- Occupational Health and Safety Management System and Workplace Risk AssessmentDocument27 pagesOccupational Health and Safety Management System and Workplace Risk AssessmentSweety RoyNo ratings yet

- Occupational Health, Safety and Risk AnalysisDocument12 pagesOccupational Health, Safety and Risk AnalysisEka Setya Maulana CahyantoNo ratings yet

- Lesson 02 - Evaluating Hazard and Risks - Computer Systems Servicing NC IIDocument3 pagesLesson 02 - Evaluating Hazard and Risks - Computer Systems Servicing NC IINovelyn RabinoNo ratings yet

- Sample Research ProposalsDocument12 pagesSample Research ProposalsAnonymous yexoY5rhNo ratings yet

- Preventing Human Errors in Petrochemical PlantsDocument8 pagesPreventing Human Errors in Petrochemical Plants200Bimo Adiweno NotonegoroNo ratings yet

- Fpubh 10 898826Document9 pagesFpubh 10 898826Arul PrasaadNo ratings yet

- PRPOSALDocument7 pagesPRPOSALAhmedAhmedNo ratings yet

- Managing RiskDocument14 pagesManaging Riskroem1104No ratings yet

- Eng - HIRARC IN LABORATORY OF FOOD SAFETY AND QUALITYDocument12 pagesEng - HIRARC IN LABORATORY OF FOOD SAFETY AND QUALITYSyifaqiyatul KhasanahNo ratings yet

- Attribution of Radiation Health Effects and Inference of Radiation Risks: Considerations for Application of the IAEA Safety StandardsFrom EverandAttribution of Radiation Health Effects and Inference of Radiation Risks: Considerations for Application of the IAEA Safety StandardsNo ratings yet

- A Guide To Machinery & Equipment SafetyDocument24 pagesA Guide To Machinery & Equipment SafetyHaroonAbdulRahimNo ratings yet

- Fundamental Principle of H&SDocument221 pagesFundamental Principle of H&Sigor_239934024No ratings yet

- DOSH - Guidelines On OSH in The OfficeDocument29 pagesDOSH - Guidelines On OSH in The OfficeNur Fadhilah RosliNo ratings yet

- General Work PermitDocument2 pagesGeneral Work PermitAde Mazmur SilabanNo ratings yet

- Lifeline Harness Inspection GuideDocument7 pagesLifeline Harness Inspection GuideaustinrajaNo ratings yet

- Chemical and Laboratory Safety Guide: Environmental Health & Safety DivisionDocument215 pagesChemical and Laboratory Safety Guide: Environmental Health & Safety DivisionAswin MageshNo ratings yet

- Hirarc GuidelineDocument34 pagesHirarc Guidelinesawsheng59No ratings yet

- Wcms 346714Document59 pagesWcms 346714Beste Ardıç ArslanNo ratings yet

- Office Safety - 1Document28 pagesOffice Safety - 1igor_239934024No ratings yet

- OPTIKA B-382PLi-ALC Technical Datasheet ENDocument2 pagesOPTIKA B-382PLi-ALC Technical Datasheet ENigor_239934024No ratings yet

- 91 Germany GTZ ChemguideDocument96 pages91 Germany GTZ ChemguideLily Antonette AgustinNo ratings yet

- Alcotest 6820 Pi 9094088 en MasterDocument8 pagesAlcotest 6820 Pi 9094088 en Masterigor_239934024No ratings yet

- Install Agilent 6890 and 6850 GC DriverDocument11 pagesInstall Agilent 6890 and 6850 GC Driverigor_239934024No ratings yet

- Lifeline Harness Inspection GuideDocument7 pagesLifeline Harness Inspection GuideaustinrajaNo ratings yet

- Alcohol and Drug Detection BR 9107224 en MasterDocument28 pagesAlcohol and Drug Detection BR 9107224 en Masterigor_239934024No ratings yet

- Creating Strategic Advantages for NespressoDocument14 pagesCreating Strategic Advantages for NespressoAnkitpandya23No ratings yet

- Proj Mgmt. ReviewerDocument6 pagesProj Mgmt. ReviewerLuntian Amour JustoNo ratings yet

- B6 - Complete The Text and Reading ComprehensionDocument10 pagesB6 - Complete The Text and Reading ComprehensionAn NgoNo ratings yet

- Investment Analysis and Portfolio Management: Prof - Rajiv@cms - Ac.inDocument41 pagesInvestment Analysis and Portfolio Management: Prof - Rajiv@cms - Ac.inAshish kumar NairNo ratings yet

- Traditional Commerce V/s E-Commerce and Impact of Demonetization On E-CommerceDocument7 pagesTraditional Commerce V/s E-Commerce and Impact of Demonetization On E-CommerceAatif KhanNo ratings yet

- ST - Joseph's Degree & PG College Business Law Unit1Document14 pagesST - Joseph's Degree & PG College Business Law Unit1Saud Waheed KhanNo ratings yet

- Case 3 SolutionsDocument4 pagesCase 3 SolutionsNishtha Raheja100% (1)

- Sponsorship Letter - Green Cross IncorporatedDocument1 pageSponsorship Letter - Green Cross IncorporatedMary Joy Dela CruzNo ratings yet

- Services MarketingDocument5 pagesServices MarketingSharmaNo ratings yet

- InvoiceDocument1 pageInvoiceashish tripathiNo ratings yet

- FSA - Ch06 - Liquidity of Short-Term Assets Related Debt-Paying AbilityDocument46 pagesFSA - Ch06 - Liquidity of Short-Term Assets Related Debt-Paying AbilityAmine AbdesmadNo ratings yet

- Antoine Resume 52020Document2 pagesAntoine Resume 52020api-512211605No ratings yet

- Customer Satisfaction Towards Patanjali Ayurvedic ProductsDocument42 pagesCustomer Satisfaction Towards Patanjali Ayurvedic ProductsAnirudh Singh ChawdaNo ratings yet

- 1 - 20.09.2018 - Corriogendum 1aDocument1 page1 - 20.09.2018 - Corriogendum 1achtrpNo ratings yet

- 58 TQMDocument8 pages58 TQMWorld Of CreativityNo ratings yet

- ABB Drives Life Cycle ManagementDocument10 pagesABB Drives Life Cycle Managementjose guadalupe rodriguez rodriguezNo ratings yet

- List of Delisted Withholding Agents - Non-IndividualDocument11 pagesList of Delisted Withholding Agents - Non-IndividualGennelyn OdulioNo ratings yet

- IN Classguide en-GBDocument54 pagesIN Classguide en-GBcatalin9494No ratings yet

- Department of Collegiate and Technical Education: Government Polytechnic, KarwarDocument41 pagesDepartment of Collegiate and Technical Education: Government Polytechnic, Karwarmisba shaikhNo ratings yet

- Bulletin EQM 89 - 5SDocument40 pagesBulletin EQM 89 - 5SApurv BhattacharyaNo ratings yet

- Export Advance Payment - ApplicationDocument1 pageExport Advance Payment - ApplicationKumar SwamyNo ratings yet

- Kunci Jawaban Uts - Pengantar Akuntansi - s1 AkuntansiDocument18 pagesKunci Jawaban Uts - Pengantar Akuntansi - s1 AkuntansiAll AboutNo ratings yet

- Project PresentationDocument43 pagesProject PresentationDiptiNo ratings yet

![EVALUATION_OF_WORKPLACE_HARZARDS_IN_AN_ONSHORE_FACILITY_LOCATED_AT_OZORO_DELTA_S[1]](https://imgv2-1-f.scribdassets.com/img/document/725257591/149x198/64b5f18a63/1713723243?v=1)