Professional Documents

Culture Documents

Pressure Controlled Compressor V1.1 en

Uploaded by

Dharmesh ChanawalaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pressure Controlled Compressor V1.1 en

Uploaded by

Dharmesh ChanawalaCopyright:

Available Formats

Pressure_controlled_compressor_DE_2013Cover

SINAMICS G120: Pressure controlled

compressor

SINAMICS G120 from FW 4.4

Application June 2015

Applications & Tools

Answers for industry.

Siemens Industry Online Support

This article is taken from the Siemens Industry Online Support. The following link

takes you directly to the download page of this document:

http://support.automation.siemens.com/WW/view/en/77491582

Caution

The functions and solutions described in this article confine themselves to the

realization of the automation task predominantly. Please take into account

furthermore that corresponding protective measures have to be taken up in the

context of Industrial Security when connecting your equipment to other parts of the

plant, the enterprise network or the Internet. Further information can be found

under the Item-ID 50203404.

http://support.automation.siemens.com/WW/view/en/50203404

Siemens AG 2015 All rights reserved

Copyright

Pressure controlled compressor

2 V1.1, Item-ID: 77491582

s Introduction 1

Connection circuit

diagram 2

Script functionality 3

Description of the

parameterization 4

SINAMICS G120

Pressure controlled compressor Motor Staging circuit

5

diagram

SINAMICS G120 / G120P

Energy saving mode

CU240B-2, CU240E-2, CU230P-2 ab FW 4.4 using function blocks 6

Contact 7

Siemens AG 2015 All rights reserved

History 8

Copyright

Pressure controlled compressor

V1.1, Item-ID: 77491582 3

Warranty and liability

Warranty and liability

Note The Application Examples are not binding and do not claim to be complete

regarding the circuits shown, equipping and any eventuality. The Application

Examples do not represent customer-specific solutions. They are only intended

to provide support for typical applications. You are responsible for ensuring that

the described products are used correctly. These application examples do not

relieve you of the responsibility to use safe practices in application, installation,

operation and maintenance. When using these Application Examples, you

recognize that we cannot be made liable for any damage/claims beyond the

liability clause described. We reserve the right to make changes to these

Application Examples at any time without prior notice.

If there are any deviations between the recommendations provided in these

application examples and other Siemens publications – e.g. Catalogs – the

contents of the other documents have priority.

We do not accept any liability for the information contained in this document.

Any claims against us – based on whatever legal reason – resulting from the use of

the examples, information, programs, engineering and performance data etc.,

described in this Application Example shall be excluded. Such an exclusion shall

not apply in the case of mandatory liability, e.g. under the German Product Liability

Siemens AG 2015 All rights reserved

Act (“Produkthaftungsgesetz”), in case of intent, gross negligence, or injury of life,

body or health, guarantee for the quality of a product, fraudulent concealment of a

deficiency or breach of a condition which goes to the root of the contract

(“wesentliche Vertragspflichten”). The damages for a breach of a substantial

contractual obligation are, however, limited to the foreseeable damage, typical for

the type of contract, except in the event of intent or gross negligence or injury to

life, body or health. The above provisions do not imply a change of the burden of

proof to your detriment.

Copyright

Any form of duplication or distribution of these Application Examples or excerpts

hereof is prohibited without the expressed consent of Siemens Industry Sector.

Pressure controlled compressor

4 V1.1, Item-ID: 77491582

Table of contents

Table of contents

Warranty and liability................................................................................................... 4

1 Introduction ........................................................................................................ 7

2 Connection circuit diagram .............................................................................. 8

2.1 Control Unit CU240B-2 ......................................................................... 8

2.2 Control Unit CU240E-2 ....................................................................... 10

2.3 Control Unit CU230P-2 ....................................................................... 12

3 Script functionality .......................................................................................... 14

4 Description of the parameterization .............................................................. 15

4.1 Importing and executing the script ..................................................... 15

4.2 Parameterization sequence ............................................................... 16

4.2.1 Verifying of online status .................................................................... 16

4.2.2 CU module interrogation .................................................................... 17

4.2.3 Power module interrogation ............................................................... 18

4.2.4 Query, scope of the parameterization ................................................ 18

4.2.5 Factory setting .................................................................................... 19

4.2.6 Quick commissioning ......................................................................... 19

4.2.7 Motor temperature sensing ................................................................ 20

4.2.8 Calculating the minimum speed ......................................................... 20

4.2.9 Pressure Control ................................................................................ 20

Siemens AG 2015 All rights reserved

Applications ........................................................................................ 20

Pre-connecting the PID controller ...................................................... 20

CU240B-2: .......................................................................................... 21

Sensor with voltage output ................................................................. 21

Sensor with current output 0 … 20mA ............................................... 21

Sensor with current output 4 … 20mA ............................................... 21

CU240E-2, CU230P-2 ........................................................................ 21

Sensor with voltage output ................................................................. 21

Sensor with current output 0 … 20mA ............................................... 21

Copyright

Sensor with current output 4 … 20mA ............................................... 21

Technology standardization ............................................................... 22

4.2.10 Technological unit .............................................................................. 22

4.2.11 Configuration of the PID controller ..................................................... 22

4.2.12 Query - starting behaviour .................................................................. 22

4.2.13 Automatic restart ................................................................................ 23

4.2.14 Motor Staging (only CU230P-2) ......................................................... 23

4.2.15 Hibernation Mode (only CU230P-2) ................................................... 23

4.2.16 Energy saving mode (only CU240B-2, CU240E-2) ............................ 24

4.2.17 Set point input .................................................................................... 26

One set point ...................................................................................... 26

Set point change (only CU230P-2) .................................................... 26

4.2.18 Automatic mode ................................................................................. 27

4.2.19 Manual mode (only CU240E-2 and CU230P-2) ................................. 27

4.2.20 Setting of the application identifier ..................................................... 27

4.2.21 Setting the time and the date (only CU230P-2) ................................. 28

4.2.22 Copying RAM to ROM ........................................................................ 28

4.2.23 Applying the script .............................................................................. 28

5 Motor Staging circuit diagram ........................................................................ 30

6 Energy saving mode using function blocks ................................................. 31

7 Contact.............................................................................................................. 32

8 History............................................................................................................... 32

Pressure controlled compressor

V1.1, Item-ID: 77491582 5

Table of contents

Siemens AG 2015 All rights reserved

Copyright

Pressure controlled compressor

6 V1.1, Item-ID: 77491582

1 Introduction

2.1 Control Unit CU240B-2

1 Introduction

Compressors and blowers compress the air e.g. the gases up to values

significantly above atmospheric pressure. The main applications are

1. Generation of compressed air for aeration in wastewater sites , pneumatic

controls , pneumatic transport for bulk goods , pneumatic compressed air for

industrial manufacturing devices, forming containers of glass or plastic (PET ),

breathing air (scuba diving , breathing apparatus for fire protection ) , medical

applications.

2. Separation of gases such as in air separation plants.

3. Compression of the refrigerant in refrigerators after the linden method for

freezers in household , commercial refrigeration , refrigerated counters in food

retail , industrial refrigeration equipment such as cold stores or refrigerated

ships , air conditioning systems for residential, commercial and industrial

purposes.

Increasingly, fixed speed compressors with storage tank are replaced by

compressors with variable speed drives, which are able to control the pressure

needed in a narrow frame. Energy-intensive over-compression with fixed speed

compressors and storage tank is avoided. High starting currents and starting

torques with repeated switching on and off are when using the variable speed

compressor drives are of the past.

Siemens AG 2015 All rights reserved

Copyright

Figure 1-1: Screw compressor for compressed air industrial applications

The following description is used to completely set the inverter parameters for the

"Pressure controlled compressor" application with up to 4 pumps. It includes a

standard connection circuit diagram for the control wiring, a script that can run in

the STARTER commissioning software, as well as additional functions, which are

used for subsequent parameterization.

Pressure controlled compressor

V1.1, Item-ID: 77491582 7

2 Connection circuit diagram

2.1 Control Unit CU240B-2

2 Connection circuit diagram

2.1 Control Unit CU240B-2

Siemens AG 2015 All rights reserved

Copyright

Fig. 2-1: Connection circuit diagram with SINAMICS G120 CU240B-2

Pressure controlled compressor

8 V1.1, Item-ID: 77491582

2 Connection circuit diagram

2.1 Control Unit CU240B-2

CU240B-2:

The terminal assignment for the subsequent parameterization is as follows:

DI0 – On/Off

DI2 – Fault acknowledgement

AI0+/- -Connection for the pressure sensor

PTC A/B – Connection for the temperature sensor of the compressor motor

DO0 – Drive signal, fault

Siemens AG 2015 All rights reserved

Copyright

Pressure controlled compressor

V1.1, Item-ID: 77491582 9

2 Connection circuit diagram

2.2 Control Unit CU240E-2

2.2 Control Unit CU240E-2

Siemens AG 2015 All rights reserved

Copyright

Fig. 2-2: Connection circuit diagram with SINAMICS G120 CU240E-2

Pressure controlled compressor

10 V1.1, Item-ID: 77491582

2 Connection circuit diagram

2.2 Control Unit CU240E-2

CU240E-2:

The terminal assignment for the subsequent parameterization is as follows:

DI0 – On/Off

DI2 – fault acknowledgement

DI3 – Increases the setpoint (MOP) in manual operation

DI4 = Reduces the setpoint (MOP) in manual operation

DI5 – Changes over between automatic operation (closed-loop temperature

control) and manual operation (open-loop controlled operation via MOP)

AI1+/- - Connection for the pressure sensor

PTC A/B – Connection for the temperature sensor of the compressor motor

DO0 – Drive signal, fault

DO1 – Drive signal, alarm

DO2 – Drive signal, operation

Siemens AG 2015 All rights reserved

Copyright

Pressure controlled compressor

V1.1, Item-ID: 77491582 11

2 Connection circuit diagram

2.3 Control Unit CU230P-2

2.3 Control Unit CU230P-2

Siemens AG 2015 All rights reserved

+

Copyright

Fig. 2-3: Connection circuit diagram with SINAMICS G120 CU230P-2

Pressure controlled compressor

12 V1.1, Item-ID: 77491582

2 Connection circuit diagram

2.3 Control Unit CU230P-2

CU230P-2:

The terminal assignment for the subsequent parameterization is as follows:

DI0 – On/Off

DI2 – fault acknowledgement

DI3 – Increases the setpoint (MOP) in manual operation

DI4 = Reduces the setpoint (MOP) in manual operation

DI5 – Changes over between automatic operation (closed-loop temperature

control) and manual operation (open-loop controlled operation via MOP)

AI1+/- - Connection for the pressure sensor

PTC A/B – Connection for the temperature sensor of the compressor motor

DO0 – Drive signal, fault / compressor 4 (with motor staging)

DO1 – Drive signal, alarm / compressor 3 (with motor staging)

DO2 – Drive signal, operation / compressor 2 (with motor staging)

Siemens AG 2015 All rights reserved

Copyright

Pressure controlled compressor

V1.1, Item-ID: 77491582 13

3 Script functionality

2.3 Control Unit CU230P-2

3 Script functionality

Check the CU module (CU240B-2, CU240E-2, CU230P-2)

and SW Version ( V4.4)

Select between complete parameterization or subsequent setpoint change

Factory setting

Quick commissioning

Motor temperature monitoring

Enter the minimum speed

Sensor selection incl. technological calibration (10V/20mA = xx.x bar)

Siemens AG 2015 All rights reserved

PID controller setting

Select automatic restart, yes/no

Select soft starting (PID controller enable is delayed), yes/no

Copyright

Select motor staging with presetting necessary parameters for compressors

(only CU230P-2)

Select Hibernation mode, (CU230P-2), Energy saving mode (CU240B-2,

CU240E-2) yes/no

A fixed setpoint or two setpoints alternating using timer 1 and 2

(input in bar)

BiCo wiring of the PID controller, the DI, DO

Automatic/manual operation (only CU240E-2, CU230P-2)

Execute the motor data identification in manual mode

Save date to ROM

Pressure controlled compressor

14 V1.1, Item-ID: 77491582

4 Description of the parameterization

4.1 Importing and executing the script

4 Description of the parameterization

4.1 Importing and executing the script

In order to be able to work with scripts, a script folder must first be created below

the CU module in STARTER. This is done by marking the CU module Select

Expert using the righthand mouse key Insert script folder

Siemens AG 2015 All rights reserved

Fig. 4-1: Importing the script folder

The scripts available as text file are inserted using the "ASCII Import" link.

Copyright

Fig. 4-2: Importing the script

When importing the script, the file manager opens with which the file to be run can

be selected. The imported scripts are saved in the directory structure of the project

in the Scripts folder.

Pressure controlled compressor

V1.1, Item-ID: 77491582 15

4 Description of the parameterization

4.2 Parameterization sequence

Fig. 4-3: Executing the script

Siemens AG 2015 All rights reserved

The script is started by selecting the script using the righthand mouse key and

selecting "Accept and execute". The further sequence of the script is controlled

using input screen forms, in which Yes/No prompts or value inputs are expected.

Note This script is only runnable in online mode, because a reset to factory setting and

a motor commissioning are included.

Copyright

4.2 Parameterization sequence

The parameterization that is carried out using the script is described in the

following. Most of the settings are carried out in the background, parameters shown

in bold ( ) require that users make the appropriate entries.

4.2.1 Verifying of online status

This script can only run in online operation as it includes a reset to the factory

setting (where the factory settings are restored) and motor commissioning.

Because of this the script tries to establish a connection to the CU if not already

online. If there is still no online connection a fault message is performed.

Pressure controlled compressor

16 V1.1, Item-ID: 77491582

4 Description of the parameterization

4.2 Parameterization sequence

Fig. 4-4: Message no connection to CU

4.2.2 CU module interrogation

The script is only coordinated to the functionality of the CU230P, CU240B-2 and

CU240E-2 control modules; other modules are rejected.

Siemens AG 2015 All rights reserved

Fig. 4-5: Message, incorrect CU module

Further, it is assumed that the module has a minimum firmware version of V4.4.

Copyright

Fig. 4-6: Message, incorrect firmware version

Both of these facts are queried in the background; if they are not fulfilled, then the

script is interrupted.

Pressure controlled compressor

V1.1, Item-ID: 77491582 17

4 Description of the parameterization

4.2 Parameterization sequence

4.2.3 Power module interrogation

The script is not released for power module PM330 and SINAMICS G120P Cabinet

drives.

Fig. 4-7: Message, prohibited power module

4.2.4 Query, scope of the parameterization

A selection can be made as to whether the complete parameterization is run

through or whether subsequently only set points and other inputs should be

changed.

Siemens AG 2015 All rights reserved

Copyright

Fig. 4-8: Selection screen form, scope of parameterization

CAUTION Make sure that no On-Signal at DI-0 is active!

To finish the parameterization successful, make sure that there is no On-signal at

DI-0.

Figure 4-9

In order that set points can be subsequently displayed and entered so that they are

correctly technologically scaled/normalized, the maximum pressure is entered in

p2900[0]. To identify the application macro, an identifier is entered into p2901[0].

Pressure controlled compressor

18 V1.1, Item-ID: 77491582

4 Description of the parameterization

4.2 Parameterization sequence

Using this identifier, the script can identify that a basic parameterization was

already performed.

Fig. 4-10: Message stating that the basic parameterization has not been performed

4.2.5 Factory setting

The parameterization using the script assumes that the inverter parameters are set

to the values of the factory setting. Because of this the fully parameterization can

only start, if factory setting is performed. In case of CU230P-2 DP the command

source is changed to Terminals after the factory setting has been done.

After that in a number of parameters settings will be done.

Parameter Value Comment

p0015 12 Macro drive unit

p0096 0 Application class

Siemens AG 2015 All rights reserved

p1110[0], [1] 1 Inhibit negative direction

p1030[0].4 1 Ramp-function generator always active

p1070[0] 0 Main setpoint

4.2.6 Quick commissioning

For the quick commissioning, a sensorless vector control is entered.

The user also has to select whether kW or hp values will be used in the application;

Copyright

after this, the system prompts you to enter the rated supply voltage, the rated

current, the rated power and rated frequency as well as the rated speed.

Depending on the motor standard the power factor or the efficiency factor will be

prompted. This completes the quick commissioning.

The Motor data identification is selected and becomes active with the first enable of

the drive.

Parameter Value Comment

p0205 1 Load duty cycle with low overload

p0300[0] 1 Induction Motor

p0100 0 IEC Motor (50Hz, SI Units)

1 NEMA Motor (60Hz, US Units)

2 NEMA Motor (60Hz, SI Units)

p0304[0] Input rated motor voltage

p0305[0] Input rated motor current

p0307[0] Input rated motor power

p0308[0], Rated motor power factor

p0309[0] or rated efficiency

p0310[0] Input rated motor frequency

p0311[0] Input rated motor speed

p1300[0] 20 Speed control encoderless

p3900[0] 3 Input rated motor freqency

p1900[0] 2 motor data identification

Pressure controlled compressor

V1.1, Item-ID: 77491582 19

4 Description of the parameterization

4.2 Parameterization sequence

4.2.7 Motor temperature sensing

The query allows you to select between either no sensor, PTC or KTY84. As a

result of the quick commissioning, the motor over temperature is specified; for

deviations, parameter p0604 can be changed.

Parameter Value Comment

p0601[0] 0 No sensor

1 PTC

2 KTY84

p0604[0] Enter alarm threshold, motor over temperature

4.2.8 Calculating the minimum speed

The minimum speed is either calculated from the process data "static delivery

head" and "zero delivery head" or is set to 20% of the maximum frequency. Other

values can be set.

Siemens AG 2015 All rights reserved

Parameter Value Comment

p1080[0] Enter a minimum speed

4.2.9 Pressure Control

At pressure Control the pump carries depending on the pressure in the pipe. The

control sense for the closed-loop pressure control is normal, i.e. with rising speed,

Copyright

the flow is rising and the pressure will rise.

Applications

For closed-loop pressure control, parameter p2901[0] is set temporary to a value of

2. Because of this the script identifies that the configuration is a closed-loop

pressure control.

Parameter Value Comment

p2901[0] 2 Identifier, not finished closed-loop pressure control

Pre-connecting the PID controller

A fixed set point is used as step-in for the PID controller.

Parameter Value Comment

p2253[0] r2224 Fixed set points are used

Actual value sensor setting

Option of selecting between sensors with a voltage output or a current output.

Pressure controlled compressor

20 V1.1, Item-ID: 77491582

4 Description of the parameterization

4.2 Parameterization sequence

Fig. 4-11: Selection screen form, actual value sensor

For sensors with a voltage output, the maximum voltage can also be entered,

which is then normalized (scaled) to 100% in the set point channel (e.g. sensors

with 5V output voltage are generally used).

CU240B-2:

Sensor with voltage output

Parameter Value Comment

p0756[0] 0 Voltage input, unipolar (0 … 10V)

Siemens AG 2015 All rights reserved

p0759[0] Enter the max. output voltage

Sensor with current output 0 … 20mA

Parameter Value Comment

p0756[0] 2 Current input, unipolar (0 … 20mA)

Sensor with current output 4 … 20mA

Parameter Value Comment

Copyright

p0756[0] 3 Current input, unipolar (4 … 20mA)

CU240E-2, CU230P-2

Sensor with voltage output

Parameter Value Comment

p0756[1] 0 Voltage input, unipolar (0 … 10V)

p0759[1] Enter the max. output voltage

Sensor with current output 0 … 20mA

Parameter Value Comment

p0756[1] 2 Current input, unipolar (0 … 20mA)

Sensor with current output 4 … 20mA

Parameter Value Comment

p0756[1] 3 Current input, unipolar (4 … 20mA)

Pressure controlled compressor

V1.1, Item-ID: 77491582 21

4 Description of the parameterization

4.2 Parameterization sequence

Technology standardization

The maximum pressure that can be measured in Bar must be entered to normalize

(scale) the technology values. The value must be saved in p2900[0]; the set points

refer to this value. An actual value smoothing of 100 ms is specified using

parameter p2265. The actual value is connected from analogue input AI1.

Parameter Value Comment

p2900[0] Enters the maximum pressure that can be

measured

p2265 0.1 Time constant, actual value filter

p2264 r755[0]/[1] Actual value from analogue input AI1

4.2.10 Technological unit

The technological unit P595 will be set to [bar]. The Reference quantity P596 from

the technological unit will be set to the same as maximum pressure p2900.

Parameter Value Comment

P595 3 [bar] Selecting technological units

P596 max. Reference quantity, technological units

pressure

Siemens AG 2015 All rights reserved

p2267 2 * max. Technology controller upper limit actual value

pressure

p2268 - 2 * max. Technology controller upper limit actual value

pressure

4.2.11 Configuration of the PID controller

Copyright

The PID controller is interconnected as main set point. The actual value is

connected from analogue input AI1. Fans are only operated with a positive

direction of rotation. This is the reason that the PID controller limiting is set from

0% to 100%. Three windows are opened one after the other to input the gain

factor, the integral time as well as the derivative action time.

Parameter Value Comment

p2200[0] 1 Enables the PID controller

p2251 0 Technology controller as main set point

p2297 p2291 Value, positive limit

p2298 p2292 Value, negative limit

p2280 Enter the proportional gain

p2285 Enter the integral time

p2274 Enter the differentiating time

4.2.12 Query - starting behaviour

A distinction can be made between immediately enabling the PID controller when

switching-on the drive and soft starting; in this case, the PID controller output is

opened using an up ramp that can be set.

Parameter Value Comment

Pressure controlled compressor

22 V1.1, Item-ID: 77491582

4 Description of the parameterization

4.2 Parameterization sequence

p2293 Technology controller, ramp-up/ramp-down time

in sec

4.2.13 Automatic restart

It is possible to select an automatic restart after power failure.

Parameter Value Comment

p1210 4 Restart after power failure

NOTE This value can only be changed in a status without faults, because of this an

automatic fault acknowledge is performed. If the fault message is still active a

warning message will appear and the script will go on without activating this

function.

4.2.14 Motor Staging (only CU230P-2)

Siemens AG 2015 All rights reserved

Using the Motor Staging function, when required up to three pumps can be

switched-in with a fixed speed in order to maintain the pressure. It is possible to

quickly set the Motor Staging function. You can chose between 1 to 3 auxiliary

motors. It is expected that all 3 Motors have the same size. The settings of the

Motor Staging are set to experience values. Depending on the particular customer

requirements, post-optimization is recommended.

Parameter Value Comment

Copyright

p2370 1 Enables Motor Staging

p2371 Motor Staging configuration

p2373 5.0% of p2900 Switch-on threshold, Motor Staging

p2374 5.0 Delay time, Motor Staging

p2375 5.0 Delay time, Destaging

p2376 15% of p2900 Override value, Motor Staging

p0732 r2379.0 Control auxiliary motor 1

p0731 r2379.1 Control auxiliary motor 2 (if configured)

p0730 r2379.2 Control auxiliary motor 3 (if configured)

4.2.15 Hibernation Mode (only CU230P-2)

The Hibernation Mode ensures that the inverter switches itself off if the actual value

is greater than the set point for a specific time. The PID controller also remains

active with the inverter switched-off. The delay time can be set as to how long the

pump operates at the minimum frequency before it is switched off. The restart

value is used to set the accuracy with which the inverter is switched-on again if the

actual value again drops below the set point. Low setting values in the range of

several percent result in a quite narrow switch-in bandwidth; high setting values in

the range greater than 10% mean that the level drops more before the drive is

switched-in again.

Pressure controlled compressor

V1.1, Item-ID: 77491582 23

4 Description of the parameterization

4.2 Parameterization sequence

NOTE The delay time of the Hibernation Mode must always be longer than the

destaging time of the possibly parameterized Motor Staging, as otherwise

malfunctions can occur.

Parameter Value Comment

p2398 1 Hibernation Mode activated

p2391[0] Enter the hibernation delay time

p2392 Enter the hibernation restart value

4.2.16 Energy saving mode (only CU240B-2, CU240E-2)

The Control Units CU240B-2 and CU240E-2 have no Hibernation mode. The

Energy saving mode is realized with the free function blocks. The connection of the

blocks is shown in chapter 6.

Parameter Wert Kommentar

p20236 r1114 LIM 1 input X

p20237 1 LIM 1 upper limit LU

Siemens AG 2015 All rights reserved

p20238 =p1080/p2000 LIM 1 lower limit LL

p20242 5 LIM 1 run-time group

p20243 2 LIM 1 run sequence

p20030[0] r20241 AND 0 input I0

p20030[1] 1 AND 0 input I1

p20030[2] 1 AND 0 input I2

p20030[3] 1 AND 0 input I3

p20032 5 AND 0 run-time group

Copyright

p20033 3 AND 0 run sequence

p20228 r2273 LIM 0 input X

p20229 LIM 0 upper limit LU

p20234 5 LIM 0 run-time group

p20235 4 LIM 0 run sequence

p20158 r20031 BI: PDE 0 input pulse I

p20159 PDE 0 pulse delay time in ms

p20161 5 PDE 0 run-time group

p20162 5 PDE 0 run sequence

p20163 r20232 PDE 1 input pulse I

p20164 PDE 1 pulse delay time in ms

p20166 5 PDE 1 run-time group

p20167 6 PDE 1 run sequence

p20188[0] r20160 RSR 0 inputs, Set S

p20188[1] r20165 RSR 0 inputs, Reset R

p20191 5 RSR 0 run-time group

p20192 7 RSR 0 run sequence

p20034[0] r722.0 AND 1 input I0

p20034[1] r20190 AND 1 input I1

p20034[2] 1 AND 1 input I2

p20034[3] 1 AND 1 input I3

p20036[0] 5 AND 1 run-time group

p20037[0] 8 AND 1 run sequence

p0840[0] r20035 On/Off (OFF1

Pressure controlled compressor

24 V1.1, Item-ID: 77491582

4 Description of the parameterization

4.2 Parameterization sequence

Siemens AG 2015 All rights reserved

Copyright

Pressure controlled compressor

V1.1, Item-ID: 77491582 25

4 Description of the parameterization

4.2 Parameterization sequence

4.2.17 Set point input

The set point is entered in bar. Due to the normalization (scaling) of the actual

value, the value is converted into a percentage and then entered as fixed set point.

If a value is entered, which is greater than the maximum possible actual value, then

value is rejected - and the input screen form is redisplayed. It is possible to select

between a fixed set point and a change between two set points. When selecting

two set points, a changeover is made using the two timers 1 and 2. If there is a gap

between the timers where no set point is active, the drive will be switched off in this

time.

One set point

Parameter Value Comment

p2201[0] Technology controller, fixed value 1

p2216 1 Fixed value direct selection

p840[0] r722.0 DI0 - Drive ON/OFF

p2220[0] 1 Fixed value selection, bit 0

Siemens AG 2015 All rights reserved

Set point change (only CU230P-2)

Parameter Value Comment

p2201[0] Technology controller, fixed value 1

p2202[0] Technology controller, fixed value 2

p2216 1 Fixed value direct selection

p8410[0] 1 Activation, weekday time switch 1

p8410[1] 1 Activation, weekday time switch 1

p8410[2] 1 Activation, weekday time switch 1

Copyright

p8410[3] 1 Activation, weekday time switch 1

p8410[4] 1 Activation, weekday time switch 1

p8410[5] 1 Activation, weekday time switch 1

p8410[6] 1 Activation, weekday time switch 1

p8420[0] 1 Activation, weekday time switch 2

p8420[1] 1 Activation, weekday time switch 2

p8420[2] 1 Activation, weekday time switch 2

p8420[3] 1 Activation, weekday time switch 2

p8420[4] 1 Activation, weekday time switch 2

p8420[5] 1 Activation, weekday time switch 2

p8420[6] 1 Activation, weekday time switch 2

p8411[0] Switch-on time, time switch - 1 hour

p8411[1] Switch-on time, time switch - 1 minute

p8412[0] Switch-off time, time switch - 1 hour

p8412[1] Switch-off time, time switch - 1 minute

p8421[0] Switch-on time, time switch - 2 hours

p8421[1] Switch-on time, time switch - 2 minutes

p8422[0] Switch-off time, time switch - 2 hours

p8422[1] Switch-off time, time switch - 2 minutes

p20030[0] r722.0 AND 0 Input, Input I0 – DI0

p20030[1] r2225.0 AND 0 Input, Input I1 – Fixed value active

p20030[2] 1 AND 0 Input, Input I2 – 1

p20030[3] 1 AND 0 Input, Input I3 – 1

p20032 5 AND 0 Run time group

Pressure controlled compressor

26 V1.1, Item-ID: 77491582

4 Description of the parameterization

4.2 Parameterization sequence

p840[0] r20031 On/Off1

p2220[0] r8413.0 Selection, fixed value 1 using time switch 1

p2221[0] r8423.0 Selection, fixed value 2 using time switch 2

4.2.18 Automatic mode

In the automatic mode, the fan is operated with closed-loop control using the PID

controller depending on the required control version; the set points are saved as

fixed set points. Depending on the selection, the drive operates with the

Hibernation Mode

Parameter Value Comment

p20030[0] r722.0 DI0 - AND 0 Input Drive on (time-dependent)

p2103[0] r722.2 DI2 - Fault acknowledgement

Only CU240E-2 and CU230P-2

p810 r722.5 DI5 - CDS0/1 changeover

p840[1] r722.0 DI0 - Drive On/Off

4.2.19 Manual mode (only CU240E-2 and CU230P-2)

Siemens AG 2015 All rights reserved

The drive can be switched over from the automatic into the manual mode using

DI5. In the manual mode, the PID controller is not operational, with DI3 and DI4,

the motorized potentiometer, which is used as set point source, is controlled either

higher or lower. The initial value of the motorized potentiometer is set to the

minimum frequency, the maximum value to the maximum frequency.

Parameter Value Comment

Copyright

p840[1] r722.0 DI0 - Drive ON/OFF

p2103[1] r722.2 DI2 - Fault acknowledgement

p1035[1] r722.3 DI3 - Set point, increase (raise)

p1036[1] r722.4 DI4 - Set point, decrease (lower)

p810 r722.5 DI5 - CDS0/1 changeover

p1070[1] r1050 Main set point MOP

p1038[1] p1080[0] Motorized potentiometer, minimum speed

p1037[1] p1082[0] Motorized potentiometer, maximum speed

p1040[1] p1080[0] Start speed, motorized potentiometer

4.2.20 Setting of the application identifier

The identifier of the application in p2901 identifier is completed as a sign of the

finished script. The application identifier is the addition of 2, the common identifier

of a pressure control and the already in p2901 existing identifier of the closed-loop

control type.

Parameter Value Comment

p2901[0] 152 closed-loop pressure control

Pressure controlled compressor

V1.1, Item-ID: 77491582 27

4 Description of the parameterization

4.2 Parameterization sequence

4.2.21 Setting the time and the date (only CU230P-2)

The internal real-time clock is set to the time and date of the PC.

Parameter Value Comment

p8400[0] RTC time, hour

p8400[1] RTC time, minute

p8400[2] RTC time, second

p8401[0] RTC date, day

p8401[1] RTC date, month

p8401[2] RTC date, year

Fig. 4-12: Message, system time was set

Siemens AG 2015 All rights reserved

4.2.22 Copying RAM to ROM

When parameterization has been completed, data is backed-up by copying from

RAM to ROM.

Copyright

Fig. 4-13: Message, save parameterization

4.2.23 Applying the script

After the complete parameterization has been performed, a message is displayed

indicating that the script has been successfully applied. This completes

parameterization.

A motor identification is activated for the first commissioning.

Now enable the drive in manual mod. You can also use a BOP or an IOP.

Pressure controlled compressor

28 V1.1, Item-ID: 77491582

4 Description of the parameterization

4.2 Parameterization sequence

Fig. 4-14: Application of the script

When the motor data identification is successfully done, the drive parameters will be saved

to ROM

Siemens AG 2015 All rights reserved

Copyright

Pressure controlled compressor

V1.1, Item-ID: 77491582 29

5 Motor Staging circuit diagram

4.2 Parameterization sequence

5 Motor Staging circuit diagram

(Only for CU230P-2)

Siemens AG 2015 All rights reserved

Fig. 5-1: Power wiring - inverter and fixed speed drives

Copyright

Fig. 5-2: Control wiring

Pressure controlled compressor

30 V1.1, Item-ID: 77491582

6 Energy saving mode using function blocks

4.2 Parameterization sequence

6 Energy saving mode using function blocks

Siemens AG 2015 All rights reserved

Copyright

Fig. 6-1: Interconnection free function blocks

Pressure controlled compressor

V1.1, Item-ID: 77491582 31

7 Contact

7 Contact

Siemens AG

Industry Sector

I DT MC PMA APC

Frauenauracher Straße 80

D - 91056 Erlangen

mailto: tech.team.motioncontrol@siemens.com

8 History

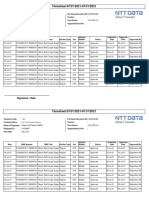

Table 8-1

Version Date Modifications

V1.0 09/2013 First version

V1.1 06/2015 PM330 interrogation and tested for FW V4.7.3

Siemens AG 2015 All rights reserved

Copyright

Pressure controlled compressor

32 V1.1, Item-ID: 77491582

You might also like

- Your UNIX Linux The Ultimate Guide 3rd Edition by Sumitabha Solution ManualDocument1 pageYour UNIX Linux The Ultimate Guide 3rd Edition by Sumitabha Solution ManualAasif Wani0% (1)

- SINAMICS S120 Connectivity To EtherNet/IPDocument40 pagesSINAMICS S120 Connectivity To EtherNet/IPCharoon SuriyawichitwongNo ratings yet

- SINAMICS G120 PN at S7-1200 DOCU V1d0 en PDFDocument63 pagesSINAMICS G120 PN at S7-1200 DOCU V1d0 en PDFGiacomo RossiNo ratings yet

- Simatic Converting Toolbox enDocument163 pagesSimatic Converting Toolbox enasolelpanchoNo ratings yet

- Sclconverter Doku v10 enDocument15 pagesSclconverter Doku v10 enu776287No ratings yet

- Solar enDocument23 pagesSolar enAynen JohnWaynenNo ratings yet

- Applications & Tools: 3-Point Stepper Control With PID - 3stepDocument54 pagesApplications & Tools: 3-Point Stepper Control With PID - 3stepDzinh TuongNo ratings yet

- Applications & ToolsDocument25 pagesApplications & Toolsnew2trackNo ratings yet

- Applications & Tools: PCS 7 Unit Template "Fermenter" Using The Example of The Chemical IndustryDocument54 pagesApplications & Tools: PCS 7 Unit Template "Fermenter" Using The Example of The Chemical IndustryElafanNo ratings yet

- PID Control With Gain Scheduling and PID TuningDocument42 pagesPID Control With Gain Scheduling and PID TuningIgor RokvicNo ratings yet

- Applications & Tools: Customizing Wincc ControlsDocument27 pagesApplications & Tools: Customizing Wincc ControlsRoyal BoardNo ratings yet

- Applikationen & Tools: Operator S Guide For An Acceptance Test With Sinucom NCDocument59 pagesApplikationen & Tools: Operator S Guide For An Acceptance Test With Sinucom NCVladimirAgeevNo ratings yet

- Sinamics s120 at s7-300400 Short-Doku v11 enDocument29 pagesSinamics s120 at s7-300400 Short-Doku v11 enKhaled OuniNo ratings yet

- Sinamics g120 at s7-300400-pn Doku v23 en PDFDocument67 pagesSinamics g120 at s7-300400-pn Doku v23 en PDFGlauco SantiagoNo ratings yet

- Calculation and Design of Fieldbus Segments in The PCS 7 Environment Using The SIMATIC Fieldbus CalculatorDocument33 pagesCalculation and Design of Fieldbus Segments in The PCS 7 Environment Using The SIMATIC Fieldbus CalculatorVipper80No ratings yet

- Sinapos Bloco PDFDocument91 pagesSinapos Bloco PDFcristian_ric_russo0% (1)

- SIMATIC S7-1200 - Sinamics Blocks TIA PortalDocument91 pagesSIMATIC S7-1200 - Sinamics Blocks TIA Portalantonio pedroNo ratings yet

- Modbus TCP Wizard DOC enDocument45 pagesModbus TCP Wizard DOC enJasson ChavezNo ratings yet

- Line Contactor Control Using The ON/OFF1 Command For Sinamics G120Document10 pagesLine Contactor Control Using The ON/OFF1 Command For Sinamics G120Hugo CruzNo ratings yet

- Creating User-defined Web Pages on S7-1200/S7-1500Document42 pagesCreating User-defined Web Pages on S7-1200/S7-1500Aguirre Castillo Jose de JesusNo ratings yet

- Wincc Copackcsharp enDocument39 pagesWincc Copackcsharp enWeiya WeiyaNo ratings yet

- Sinamics s120-dp at s7-300400 Doku v11 en PDFDocument107 pagesSinamics s120-dp at s7-300400 Doku v11 en PDFNam NguyễnNo ratings yet

- V20USS at S712001500 DOC V1d0 TIAV13SP1 enDocument40 pagesV20USS at S712001500 DOC V1d0 TIAV13SP1 enErdincNo ratings yet

- InfoPLC Net 67121011 S7-1500S Migration DOKU v30 enDocument32 pagesInfoPLC Net 67121011 S7-1500S Migration DOKU v30 endaniel rojasNo ratings yet

- SinamicsDocument68 pagesSinamicsBarack ObamaNo ratings yet

- g120 STD App2 enDocument34 pagesg120 STD App2 enYUSUF OZOGLUNo ratings yet

- Faceplate WinCC Valve enDocument35 pagesFaceplate WinCC Valve ensaba sabariNo ratings yet

- Safety With S7 1200FCPU V12 enDocument249 pagesSafety With S7 1200FCPU V12 enFelipe AcorsiNo ratings yet

- SIMIT Getting Started GuideDocument69 pagesSIMIT Getting Started GuideMateo QuispeNo ratings yet

- User Defined Diagnostics Doku v10 enDocument52 pagesUser Defined Diagnostics Doku v10 enLuis Felipe PeraltaNo ratings yet

- Using Simatic s7 Cpus As SNTP ServersDocument28 pagesUsing Simatic s7 Cpus As SNTP ServersOTOMASYON PLCNo ratings yet

- Connecting A SINAMICS G120 Drive To An S7-300/400 CPU in TIA PortalDocument59 pagesConnecting A SINAMICS G120 Drive To An S7-300/400 CPU in TIA PortalEdwin SaynesNo ratings yet

- Faceplates Instruction DOKU e PDFDocument114 pagesFaceplates Instruction DOKU e PDFluis.chuquimiaNo ratings yet

- s7 Opc Ua Redundancy enDocument41 pagess7 Opc Ua Redundancy enMohamed Ali RobbanaNo ratings yet

- Simple Web Server Examples for SIMATIC S7-1200/1500Document56 pagesSimple Web Server Examples for SIMATIC S7-1200/1500Carlos Jara AyalaNo ratings yet

- Winac at Tia Portal Doku v20 enDocument72 pagesWinac at Tia Portal Doku v20 endenisNo ratings yet

- SINAMICS G120 PN at S7-1200 DOCU V1d0 enDocument63 pagesSINAMICS G120 PN at S7-1200 DOCU V1d0 engerman_renkNo ratings yet

- Sinamics s120 DP at s7-300400 Docu v1d1 enDocument68 pagesSinamics s120 DP at s7-300400 Docu v1d1 enjoseNo ratings yet

- Sending SMS Messages With An S7 CPU Via The UMTS Router SCALANCE M873 M875Document32 pagesSending SMS Messages With An S7 CPU Via The UMTS Router SCALANCE M873 M875Siemens PlcNo ratings yet

- As Fe I 018 v10b Safety F POS eDocument32 pagesAs Fe I 018 v10b Safety F POS eesiek1974No ratings yet

- Operating Three-Phase Motors With Speeds Above The Rated SpeedDocument21 pagesOperating Three-Phase Motors With Speeds Above The Rated SpeedLaurentiuNo ratings yet

- Applications & Tools: Calculating Production Figures Using Wincc Standard FunctionsDocument33 pagesApplications & Tools: Calculating Production Figures Using Wincc Standard FunctionsJuan Enrique Nuñez TorresNo ratings yet

- SINAMICS G120 at S7-300400-PN DOKU v10 enDocument59 pagesSINAMICS G120 at S7-300400-PN DOKU v10 enanon_885892448No ratings yet

- Connecting A SINAMICS G120 Drive To An S7-300/400 CPU in TIA PortalDocument56 pagesConnecting A SINAMICS G120 Drive To An S7-300/400 CPU in TIA Portalcosmin1975No ratings yet

- Bibliothek Screens G120 enDocument26 pagesBibliothek Screens G120 enmsohaibkhalidNo ratings yet

- RF650M Remote DOKU V10 enDocument32 pagesRF650M Remote DOKU V10 enrocio.martinezNo ratings yet

- v20 at s7-1200 Uss v1d2 en PDFDocument41 pagesv20 at s7-1200 Uss v1d2 en PDFKhaled OuniNo ratings yet

- WINCC Runtime Professional S7-Graph Overview and PLC Code ViewerDocument35 pagesWINCC Runtime Professional S7-Graph Overview and PLC Code ViewerCarlos Octavio Gamarra LimaNo ratings yet

- Canopen Tutorial: Siemens Industry Online SupportDocument38 pagesCanopen Tutorial: Siemens Industry Online SupportHumberto MendozaNo ratings yet

- S7-1200 Ebmpapst DOKU v1d0 enDocument47 pagesS7-1200 Ebmpapst DOKU v1d0 enZenon nuñonca zapataNo ratings yet

- Config Idevice Standard DOCU V1d0 enDocument44 pagesConfig Idevice Standard DOCU V1d0 enAbel MogesNo ratings yet

- Programming Guideline DOCU v14 en PDFDocument109 pagesProgramming Guideline DOCU v14 en PDFcontroljotaNo ratings yet

- Recipes With S7-1200Document45 pagesRecipes With S7-1200Laurita Lucena GarcíaNo ratings yet

- Faceplates EngineeringExamples enDocument63 pagesFaceplates EngineeringExamples enjagadeesh.bammidiNo ratings yet

- Function Block To Control mm4 Via Profibus DP Docu v3 2 en PDFDocument12 pagesFunction Block To Control mm4 Via Profibus DP Docu v3 2 en PDFchuyen truongNo ratings yet

- Burner application example for TIA PortalDocument171 pagesBurner application example for TIA PortalErdincNo ratings yet

- WCP Faceplates Analogue enDocument79 pagesWCP Faceplates Analogue enchupoNo ratings yet

- WCP Faceplates Motor enDocument77 pagesWCP Faceplates Motor enchupoNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- Grade of ServiceDocument3 pagesGrade of ServiceShyam KrishnaNo ratings yet

- Reach Truck Neos II 25 MULTI AcDocument4 pagesReach Truck Neos II 25 MULTI AcBeyzaNo ratings yet

- Empowerment Tech MidtermDocument4 pagesEmpowerment Tech MidtermcocopitlabmixNo ratings yet

- Motivaciono PismoDocument2 pagesMotivaciono PismoOgnjen NestorovićNo ratings yet

- Cable Connection & Sealing of Sacrificial AnodesDocument5 pagesCable Connection & Sealing of Sacrificial AnodesmandiNo ratings yet

- Architectural Drawing TypesDocument28 pagesArchitectural Drawing TypesAr Ayoushika AbrolNo ratings yet

- Burj Khalifa's Structural DetailsDocument4 pagesBurj Khalifa's Structural DetailsA KNo ratings yet

- CABAWinDocument80 pagesCABAWinHoang AnhNo ratings yet

- Rating SheetDocument1 pageRating SheetJohn Dale EvangelioNo ratings yet

- Psepcor-E COURSE Coordination of Protections: P&E Center /0106 MOD00 - 02EDocument4 pagesPsepcor-E COURSE Coordination of Protections: P&E Center /0106 MOD00 - 02ECata CatalinNo ratings yet

- A Review of Mathematical Models in Economic Environmental ProblemsDocument37 pagesA Review of Mathematical Models in Economic Environmental ProblemsHo Nhat NamNo ratings yet

- Digital System Design FundamentalsDocument2 pagesDigital System Design FundamentalsRaut Amit DattatrayNo ratings yet

- Manual Montaje Mecanico Precision PlantingDocument173 pagesManual Montaje Mecanico Precision PlantingJose luis CeaNo ratings yet

- Cloud Computing CheatSheet ATech (Waqas Karim)Document1 pageCloud Computing CheatSheet ATech (Waqas Karim)bluegyiNo ratings yet

- Info Iec62271-203 (Ed1.0) en DDocument11 pagesInfo Iec62271-203 (Ed1.0) en DdvamseeramNo ratings yet

- SMC 6000a InstalareDocument106 pagesSMC 6000a Instalareaurel_c12-1No ratings yet

- 71.NCM-W NCM F Network Communicaiton ModulesDocument2 pages71.NCM-W NCM F Network Communicaiton ModulesGary JavierNo ratings yet

- B2B Marketing Chapter on Managing InnovationDocument23 pagesB2B Marketing Chapter on Managing InnovationSaurabh JainNo ratings yet

- Applications To Sizing Circuit Breakers (ANSI C37)Document22 pagesApplications To Sizing Circuit Breakers (ANSI C37)freddy riveraNo ratings yet

- Configure Selective QinQ in Huawei Switch - GPON SolutionDocument10 pagesConfigure Selective QinQ in Huawei Switch - GPON SolutionDinabilah AdaniNo ratings yet

- Cargo Aircraft Specifications GuideDocument18 pagesCargo Aircraft Specifications Guidearpitsingh06367% (3)

- Erosion and Erosion-Corrosion of Metals: A.V. LevyDocument12 pagesErosion and Erosion-Corrosion of Metals: A.V. LevyPritha GuptaNo ratings yet

- Kidde FM200Document116 pagesKidde FM200amechmar593583% (6)

- Modern Foundation Construction with Ground ScrewsDocument130 pagesModern Foundation Construction with Ground ScrewssaivigneshfacebookNo ratings yet

- 355 S DetectorDocument4 pages355 S DetectorFaizal ThelordImmortal100% (1)

- CSP Mill PresentationDocument14 pagesCSP Mill PresentationGHANESH MAHANTANo ratings yet

- Flow ThermDocument4 pagesFlow ThermDinesh KanaujiyaNo ratings yet

- Time Sheet - JulyDocument3 pagesTime Sheet - JulyraghuNo ratings yet

- Introduction to Transaction Processing Concepts and Concurrency ControlDocument65 pagesIntroduction to Transaction Processing Concepts and Concurrency ControlDeepak JhaNo ratings yet