Professional Documents

Culture Documents

LT 01 Fis-Em-Plus-Mit-Fisa F Sen Aip v1

LT 01 Fis-Em-Plus-Mit-Fisa F Sen Aip v1

Uploaded by

HOANG KHANH SONOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LT 01 Fis-Em-Plus-Mit-Fisa F Sen Aip v1

LT 01 Fis-Em-Plus-Mit-Fisa F Sen Aip v1

Uploaded by

HOANG KHANH SONCopyright:

Available Formats

Loads

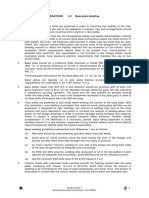

Injection system FIS EM Plus with threaded rod FIS A resp. RG M

Permissible loads of a single anchor1) 2) in normal concrete of strength class C20/25.

For the design the complete current assessment ETA-17/0979 has to be considered.

Cracked concrete Non-cracked concrete

Material/ Effective Minimum Maximum Permissible tension (Nperm) and shear loads (Vperm); Permissible tension (Nperm) and shear loads (Vperm);

surface3) anchorage member installation- minimum spacing (smin) and edge distances (cmin) minimum spacing (smin) and edge distances (cmin)

depth thickness torque with reduced loads with reduced loads

hef hmin Tinst,max Nperm4) Vperm4) smin4) cmin4) Nperm4) Vperm4) smin4) cmin4)

Type [mm] [mm] [Nm] [kN] [kN] [mm] [mm] [kN] [kN] [mm] [mm]

FIS A M 8 5.8 60 100 10 5.4 6.3 40 40 9.0 6.3 40 40

5.8 80 110 10 7.2 6.3 40 40 9.0 6.3 40 40

5.8 160 190 10 9.0 6.3 40 40 9.0 6.3 40 40

R-70 60 100 10 5.4 6.0 40 40 9.9 6.0 40 40

R-70 80 110 10 7.2 6.0 40 40 9.9 6.0 40 40

R-70 160 190 10 9.9 6.0 40 40 9.9 6.0 40 40

FIS A M 10 5.8 60 100 20 6.7 9.7 45 45 10.9 9.7 45 45

5.8 90 120 20 10.1 9.7 45 45 13.8 9.7 45 45

5.8 200 230 20 13.8 9.7 45 45 13.8 9.7 45 45

R-70 60 100 20 6.7 9.2 45 45 10.9 9.2 45 45

R-70 90 120 20 10.1 9.2 45 45 15.7 9.2 45 45

R-70 200 230 20 15.7 9.2 45 45 15.7 9.2 45 45

FIS A M 12 5.8 70 100 40 9.6 14.3 55 45 13.7 14.3 55 45

5.8 110 140 40 17.8 14.3 55 45 20.5 14.3 55 45

5.8 240 270 40 20.5 14.3 55 45 20.5 14.3 55 45

R-70 70 100 40 9.6 13.7 55 45 13.7 13.7 55 45

R-70 110 140 40 17.8 13.7 55 45 22.5 13.7 55 45

R-70 240 270 40 22.5 13.7 55 45 22.5 13.7 55 45

FIS A M 16 5.8 80 120 60 11.7 23.5 65 50 16.8 26.9 65 50

5.8 125 170 60 22.9 26.9 65 50 32.7 26.9 65 50

5.8 320 360 60 37.6 26.9 65 50 37.6 26.9 65 50

R-70 80 120 60 11.7 23.5 65 50 16.8 25.2 65 50

R-70 125 170 60 22.9 25.2 65 50 32.7 25.2 65 50

R-70 320 360 60 42.0 25.2 65 50 42.0 25.2 65 50

FIS A M 20 5.8 90 140 120 14.0 28.0 85 55 20.0 40.0 85 55

5.8 170 220 120 36.3 42.3 85 55 51.9 42.3 85 55

5.8 400 450 120 58.6 42.3 85 55 58.6 42.3 85 55

R-70 90 140 120 14.0 28.0 85 55 20.0 39.4 85 55

R-70 170 220 120 36.3 39.4 85 55 51.9 39.4 85 55

R-70 400 450 120 65.7 39.4 85 55 65.7 39.4 85 55

FIS A M 24 5.8 96 160 150 15.4 30.8 105 60 22.0 44.1 105 60

5.8 210 270 150 49.9 60.6 105 60 71.3 60.6 105 60

5.8 480 540 150 84.3 60.6 105 60 84.3 60.6 105 60

R-70 96 160 150 15.4 30.8 105 60 22.0 44.1 105 60

R-70 210 270 150 49.9 56.8 105 60 71.3 56.8 105 60

R-70 480 540 150 94.3 56.8 105 60 97.3 56.8 105 60

FIS A M 30 5.8 120 190 300 21.6 43.1 140 80 30.8 61.6 140 80

5.8 280 350 300 76.8 96.0 140 80 109.8 96.0 140 80

5.8 600 670 300 133.8 96.0 140 80 133.8 96.0 140 80

R-70 120 190 300 21.6 43.1 140 80 30.8 61.6 140 80

R-70 280 350 300 76.8 90.2 140 80 109.8 90.2 140 80

R-70 600 670 300 150.1 90.2 140 80 150.1 90.2 140 80

1)

Design according to EN 1992-4:2018 (for static resp. quasi-static loads). The partial safety factors for material resistance as regulated in the ETA as well as a partial safety factor for load

actions of γL = 1.4 are considered. As a single anchor counts e.g. an anchor with a spacing s ≥ 3 x hef and an edge distance c ≥ 1.5 x hef. Accurate data see ETA.

2)

The specified loads are valid for anchorages in dry and damp concrete. For temperatures in the anchoring substrate up to 50 °C (resp. short term up to 72 °C). Drill hole cleaning as per

specification in the ETA. The factor Ψsus for sustained load was taken into account with 1.0.

3)

Further steel grades, versions and technical data see ETA, e.g. for dry internal conditions, galvanised steel (gvz); for damp interiors and for outdoor use, stainless steel (R).

4)

In the case of combinations of tension and shear loads, bending moments with reduced or minimum spacing and edge distances (anchor groups), the design must be carried out in

accordance with the provisions of the complete ETA and the provisions of the EN 1992-4:2018. We recommend using our anchor design software C-FIX.

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- ASME International Steam Tables For Industrial UseDocument290 pagesASME International Steam Tables For Industrial UseOscar Hoyos100% (7)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Chapitre 16 - Consoles CourtesDocument27 pagesChapitre 16 - Consoles CourtesOussama FaridNo ratings yet

- Detailing Considerations Design Guide 7 - bk745 PDFDocument5 pagesDetailing Considerations Design Guide 7 - bk745 PDFFunkNo ratings yet

- How Does The Concentration of Copper Sulphate Affect The Voltage Produced by A Voltaic Cell?Document5 pagesHow Does The Concentration of Copper Sulphate Affect The Voltage Produced by A Voltaic Cell?gitikaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- Geometria 3°Document142 pagesGeometria 3°hector100% (1)

- Chapitre 5 Dynamique Fluide RéelDocument29 pagesChapitre 5 Dynamique Fluide RéelNowe AhmadeNo ratings yet

- 01 - DM II - CRCH - Tarea Prob #1 y 2 - 1 Semestre 2021Document19 pages01 - DM II - CRCH - Tarea Prob #1 y 2 - 1 Semestre 2021Bratt ArangoNo ratings yet

- IM-7000 ManualUsuario Part1Document268 pagesIM-7000 ManualUsuario Part1Jorge HuertaNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- 0001 - POLYFOAM Super (Gen) 09-30.11.2020Document1 page0001 - POLYFOAM Super (Gen) 09-30.11.2020Meeran MohamedNo ratings yet

- CDN SuperTitan Tower Section of CatalogueDocument56 pagesCDN SuperTitan Tower Section of CatalogueMeeran MohamedNo ratings yet

- Civil V Sem Sa-I Ce 6501Document16 pagesCivil V Sem Sa-I Ce 6501Meeran MohamedNo ratings yet

- Kalzip Walkway Systems: Maximum Safety Due To Collective Protection!Document4 pagesKalzip Walkway Systems: Maximum Safety Due To Collective Protection!Meeran MohamedNo ratings yet

- Structural AnalysisDocument55 pagesStructural AnalysisMeeran MohamedNo ratings yet

- எனனடடய யயயசடனகள Professional ஆக இரககயவணடய அவசசயம இலடல. Just a common man's ideas ..Document1 pageஎனனடடய யயயசடனகள Professional ஆக இரககயவணடய அவசசயம இலடல. Just a common man's ideas ..Meeran MohamedNo ratings yet

- Non Destructive Testing Methods Destructive Testing Methods Destructive Testing MethodsDocument32 pagesNon Destructive Testing Methods Destructive Testing Methods Destructive Testing MethodsMACLIN JOHN VASANTH KNo ratings yet

- FUERZA Evaluación de La FuerzaDocument101 pagesFUERZA Evaluación de La FuerzaalbertoviaNo ratings yet

- Ud01 - Los GasesDocument21 pagesUd01 - Los GasesJorge Vázquez NuñoNo ratings yet

- MaterialesDocument20 pagesMaterialesTANIA DE LOS ANGELES CASTELLANOSNo ratings yet

- Acfrogb9meunsj Bqhgad4tjprfkaiqpsghbnzstrompbmuvz3m5jjjbwethlgvuqn2vdljovbwv 4sg6o8lcscc0eo55rkb9smxukdhyszzxcahjusvqt 3m5cz7gp2xnfalrjk OckhgllcvntDocument2 pagesAcfrogb9meunsj Bqhgad4tjprfkaiqpsghbnzstrompbmuvz3m5jjjbwethlgvuqn2vdljovbwv 4sg6o8lcscc0eo55rkb9smxukdhyszzxcahjusvqt 3m5cz7gp2xnfalrjk OckhgllcvntYuvraj SinghNo ratings yet

- Tarea SonidoDocument3 pagesTarea SonidoERIN NATALIA GOMEZ FELIXNo ratings yet

- Lista de Óptica 2Document2 pagesLista de Óptica 2Cefas AlmeidaNo ratings yet

- Calculo de Velocidad de Un MecanismoDocument8 pagesCalculo de Velocidad de Un Mecanismoangelica saucedaNo ratings yet

- Plan Esp. Industrial Mencion Telematica 4° 22-23Document16 pagesPlan Esp. Industrial Mencion Telematica 4° 22-23JesusObrero EvaluacionNo ratings yet

- Eléctrico Panorama: Agencia de Regulación Y Control de Energía Y Recursos Naturales No RenovablesDocument54 pagesEléctrico Panorama: Agencia de Regulación Y Control de Energía Y Recursos Naturales No RenovablesStalin OñaNo ratings yet

- Guía 4 - Circuitos IIDocument6 pagesGuía 4 - Circuitos IICarlos GirónNo ratings yet

- Chap I TreviDocument12 pagesChap I Trevidz filmNo ratings yet

- Chapitre - 2 - Les - Suites - de - Nombres - R - Elles (6) - 2Document18 pagesChapitre - 2 - Les - Suites - de - Nombres - R - Elles (6) - 2Ka TiaNo ratings yet

- Phase Equilibria With ExcelDocument3 pagesPhase Equilibria With ExcelFarizal PaneNo ratings yet

- GuiaDocument12 pagesGuiaMELENDEZ HERNANDEZ MONICA GUADALUPENo ratings yet

- Mass, Inertia, Weight & CM Exercise-PureDocument10 pagesMass, Inertia, Weight & CM Exercise-Puremaatla monkgeNo ratings yet

- 8106 Machine LayoutDocument1 page8106 Machine LayoutSantosh SamalNo ratings yet

- CIE 140 Road Lighting CalcsDocument37 pagesCIE 140 Road Lighting CalcsJ Gomez WilliamNo ratings yet

- The Seismic Response of Structural Outrigger SysteDocument9 pagesThe Seismic Response of Structural Outrigger SysteAbir DuttaNo ratings yet

- Cbse Class Xii Physics Investigatory ProjectDocument21 pagesCbse Class Xii Physics Investigatory ProjectKunmun Meher100% (1)

- MTES2092M - e Learning 03-1Document2 pagesMTES2092M - e Learning 03-1Vanessa KasiNo ratings yet

- Matrices in Data ScienceDocument118 pagesMatrices in Data Scienceramlal18ramNo ratings yet