ISMAIL RESIN (PRIVATE) LIMITED

SYSTEM OF CALIBRATION

IRL-SOP-CAL-09-L2 Effective Date: 15-09-2023 Review Date: 15-09-2025

Version – [1.0] Supersede: None

SYSTEM OF CALIBRATION

Reference:

ISO 9001:2015

Prepared By: Sign: ________________ Date:

Reviewed By: Sign: ________________ Date:

Approved By: Sign: ________________ Date:

DISTRIBUTION RECORD LIST:

S. NO DISTRIBUTED TO DATE

Page 1 of 6

� ISMAIL RESIN (PRIVATE) LIMITED

SYSTEM OF CALIBRATION

IRL-SOP-CAL-09-L2 Effective Date: 15-09-2023 Review Date: 15-09-2025

Version – [1.0] Supersede: None

CHANGE RECORD LIST:

Revision Date Amended by Description of Approved by

Change

1 PURPOSE

The purpose of this document is to establish a documented procedure to control, calibrate

and maintain the monitoring, measuring and testing equipments which are used in

verifying conformance of product/services to required specification.

This procedure defines the actions and responsibilities of maintenance department in

maintaining machines and equipments in good working condition.

2 SCOPE

Page 2 of 6

� ISMAIL RESIN (PRIVATE) LIMITED

SYSTEM OF CALIBRATION

IRL-SOP-CAL-09-L2 Effective Date: 15-09-2023 Review Date: 15-09-2025

Version – [1.0] Supersede: None

This procedure applies to the all machines and equipments which are used for measuring

the conformity of product/services.

3 ROLES AND RESPONSIBILITIES

Management Representative (MR) is responsible to ensure that the procedures is

followed effectively. Services department e.g Electrical , Mechanical and Lab is

responsible to ensure that all machines and equipments are calibrated and maintained in

proper working condition and maintenance and calibration is carried out as planned.

4 ABBRIVIATION DEFINITION

4.1 IRL = Ismail Resin (Private) Limited

4.2 ISO = International Organization for Standardization

4.3 SOP = Standard Operating Procedure

4.4 L2 = Level II Documents

4.5 QHSE = Quality, Health, Safety and Environment.

4.6 MR = Management Representative

4.7 CAL = Calibration

5 PROCEDURE

5.1 Calibration

5.1.1 All the equipment and instruments, which directly affect the quality of product/services

or process, are calibrated prior to their use and at regular intervals depending upon the

use of the equipment and nature of the equipment. Calibration plan identifies the

instruments for which calibration is required.

Page 3 of 6

� ISMAIL RESIN (PRIVATE) LIMITED

SYSTEM OF CALIBRATION

IRL-SOP-CAL-09-L2 Effective Date: 15-09-2023 Review Date: 15-09-2025

Version – [1.0] Supersede: None

5.1.2 Relevant department arranges to carry out calibration of the measuring, inspection and

testing equipment’s.

5.1.3 Top management review at suitable intervals and evaluate the effectiveness of calibrated

equipment used at facility. If any measuring equipment found to be out of order then its

maintenance is done first then calibrated for accuracy.

5.1.4 Original calibration certificates remain under custody of departmental head. Photocopies

of certificate will be kept by departmental QHSE coordinator for ready reference.

Any equipment which is reported by the external calibration agency to have abnormal

errors and not suitable for use is declared un-serviceable and labeled as “OUT OF

ORDER” and later on disposed off.

5.2 Frequency of calibration

5.2.1 The frequency of calibration depends upon the type of equipment and its usage. If the

equipment is not used for a long time it is calibrated / validated prior to use to eliminate

the traces of doubts, if any. The frequency of calibration is mentioned in equipment

calibration certificate issued by third party. On the basis of master list of equipment

calibration, departmental heads prepares and maintained calibration schedule.

5.2.2 Departmental head will arrange to conduct yearly internal calibration of critical

equipment and mark proper identification and calibration date conducted

5.2.3 In-house calibration stickers will be posted on all internally calibrated equipment should

be signed as approved by departmental head or person authorized by top management to

perform job.

5.3 Calibration Status

Status of calibration is identified with a suitable tag, label or sticker that shows when the

equipment was last calibrated, the next calibration due date, Identification number and

the authorized signature.

Page 4 of 6

� ISMAIL RESIN (PRIVATE) LIMITED

SYSTEM OF CALIBRATION

IRL-SOP-CAL-09-L2 Effective Date: 15-09-2023 Review Date: 15-09-2025

Version – [1.0] Supersede: None

5.3.1 Calibration Records

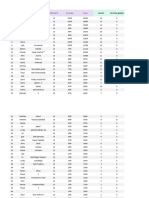

5.3.2 Relevant department supervisor maintain the master list of measuring equipment.

5.3.3 This list contains the following information:

5.3.4 Serial number

5.3.4 Identification number of equipment’s

5.3.5 Name of equipment’s

5.3.6 Calibration done by.

5.3.7 Calibration date and next due date

5.3.8 Remarks

5.3.9 The relevant department representative is responsible to maintain the calibration record.

If any equipment becomes "OUT OF ORDER", then relevant department representative

after verification declares the equipment as "OUT OF ORDER", and maintain the record.

Relevant department is responsible to maintain the calibration records. Master list of

calibration equipments is maintained by departmental respresentative.

5.4 Handling of equipment

The equipment are maintained, stored and handled in such a way as to ensure its

accuracy and fitness for use.

5.5 External calibration

5.5.1 External calibration agencies will be approved by top management for measuring

equipment and testing.

5.5.2 Departmental head make sure that after calibration of equipment from calibration

agency it is properly marked and placed on required location with date of calibration

and next due date on “Calibration Status Sticker”.

5.5.3 Top management ensure that the calibration agency has provided the calibration

certificate after calibration.

5.5.4 Departmental head is responsible to maintain record of certificates.

Page 5 of 6

� ISMAIL RESIN (PRIVATE) LIMITED

SYSTEM OF CALIBRATION

IRL-SOP-CAL-09-L2 Effective Date: 15-09-2023 Review Date: 15-09-2025

Version – [1.0] Supersede: None

5.6 Master equipment calibration

5.6.1 One master equipment will be calibrated and kept under custody of departmental head

for inhouse calibration.

5.6.2 Departmental head will arrange to conduct yearly calibration of master equipment and

mark proper identification and calibration date conducted.

5.7 Actions taken when any measuring equipment found to be working without

calibration.

5.7.1 If any equipment found without calibration then process department will inform to

relevant department.

5.7.2 Process department will evaluate its effect on product quality and increase product

testing if required.

5.7.3 Relevant department representative will arrange the internal/external calibration of

effected equipment.

6 RELATED DOCUMENTS:

6.1 Master list of Calibration Equipments IRL-CAL-F.9-1-L4

6.2 External Calibration Certificates

Page 6 of 6