Professional Documents

Culture Documents

Amf-P-19 Procedure For Rework

Uploaded by

gangadhar.patilOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Amf-P-19 Procedure For Rework

Uploaded by

gangadhar.patilCopyright:

Available Formats

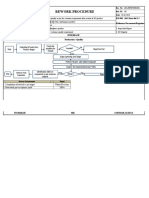

VIKAS COMPOSITES

TITLE : ACTIVITY CHART FOR REWORK PROCESS

REF. NO. :

REV. NO. :

REV DATE :

PURPOSE: To establish a documented process approach to plan rework production activity and carry out rework production under

controlled conditions.

SCOPE : Rework of FRP components

SLNo Input Reference No. Resp. Interaction Out put Reference

1 1.Checking Instruments VC/QA/L/01 Prod I/C Line Inspector 1.Rework component VC/QA/F/02

2.Component Prod Sup Moulder 2.Inspection report

3.Line inspector

ACTIVITY :-

During the time of inspection component observed for rework is been identified and area or location to rework is been marked

1. Damaged product must be isolated in the designated area in the warehouse or be taken to the Rework area immediately.

2. Damaged product must be reworked/repacked within a 48 hour period and if any product is exposed to the elements it must be

corrected/secured immediately to prevent further potential contamination.

3. Tracking of materials must be conducted by responsible personnel.

4. When reworking or repackaging component, whether in a warehouse or production setting, the area where the work is being

conducted must be checked for potential or the product itself must be contained if it is protect other surrounding products from

contamination, otherwise those products must now be labeled appropriately.

5. Ensure all of the details of the original product label remains with the damaged product. Use only the assigned utensils for

repacking / reworking and ensure that any new container or repacked size contains the same information and lot numbers as the original label.

Affix additional label to finished reworked product

Prepared by : Production In charge Approved By; MP

You might also like

- SOP For Change OverDocument6 pagesSOP For Change OverJayesh Meharwal100% (3)

- Standard Operating Procedure General Rework Procedure: Pranjal Projects (P) LTDDocument1 pageStandard Operating Procedure General Rework Procedure: Pranjal Projects (P) LTDvekas bhatia100% (3)

- Installation QualificationDocument17 pagesInstallation Qualificationtrinath16198067% (6)

- Ultratech India LTD Technical Specification Revision: P0 Air Shower Page 1 of 6Document6 pagesUltratech India LTD Technical Specification Revision: P0 Air Shower Page 1 of 6MUNINo ratings yet

- QMS 065 Manufacturing Rework Procedure SampleDocument5 pagesQMS 065 Manufacturing Rework Procedure Sampleevil genius100% (1)

- Procedure For Control of Non-Conforming ProductsDocument4 pagesProcedure For Control of Non-Conforming Productsmatrixmaze100% (3)

- Sop of Tablet & CApsuleDocument2 pagesSop of Tablet & CApsuleZeyad A AbdullahNo ratings yet

- Standard Operating Procedure For Rejected Items and ReturnsDocument4 pagesStandard Operating Procedure For Rejected Items and ReturnsMarichelle Palo100% (3)

- Procedure Recall ProductDocument3 pagesProcedure Recall ProductLinda Setya WatiNo ratings yet

- QMS 065 SampleDocument6 pagesQMS 065 SamplebaluchakpNo ratings yet

- Audit Report EXAMPLE 1Document3 pagesAudit Report EXAMPLE 1Thomas G. NimmerNo ratings yet

- QP003 Control of Nonconforming ProductDocument2 pagesQP003 Control of Nonconforming ProductsotoyeNo ratings yet

- SOP For ReworkDocument2 pagesSOP For Reworkabc75% (4)

- General Rework ProcedureDocument1 pageGeneral Rework ProcedureLuke BilisNo ratings yet

- QMS 055 SampleDocument8 pagesQMS 055 SampleMostafa FawzyNo ratings yet

- Production Environment Rev - A PDFDocument2 pagesProduction Environment Rev - A PDFMohamed RafeeNo ratings yet

- A Control of Nonconforming Material: Document Number Revision Title Rev DateDocument3 pagesA Control of Nonconforming Material: Document Number Revision Title Rev DateImam MansyurNo ratings yet

- 7) Changeover SOPDocument3 pages7) Changeover SOPVYAPAR INDIANo ratings yet

- DRP001-OUF-STA-MTS-L-000-030-O1 - WMS Pickling and Passivation PDFDocument36 pagesDRP001-OUF-STA-MTS-L-000-030-O1 - WMS Pickling and Passivation PDFrodman823No ratings yet

- Procedure For ProductionDocument7 pagesProcedure For ProductionSharif Khan100% (1)

- QC-FM-089-02 Internal Self Audit ChecklistDocument7 pagesQC-FM-089-02 Internal Self Audit ChecklistJanice LeeNo ratings yet

- 11.1.0 Traceability ProcedureDocument5 pages11.1.0 Traceability ProcedureZed100% (1)

- Covid-19 Post Lockdown Production Restart & Part Readiness ChecklistDocument9 pagesCovid-19 Post Lockdown Production Restart & Part Readiness ChecklistSanjay KumarNo ratings yet

- Covid-19 Post Lockdown Production Restart & Part Readiness ChecklistDocument9 pagesCovid-19 Post Lockdown Production Restart & Part Readiness ChecklistSanjay KumarNo ratings yet

- Hold Time Study Protocol OF Cleaned Manufacturing Equipment Awaiting For UseDocument11 pagesHold Time Study Protocol OF Cleaned Manufacturing Equipment Awaiting For Usegopusankar100% (5)

- Procedure For ProductionDocument7 pagesProcedure For ProductionTuan Anh100% (1)

- Procedure Recall ProductDocument3 pagesProcedure Recall ProductLinda Setya WatiNo ratings yet

- Procedure Recall ProductDocument3 pagesProcedure Recall ProductLinda Setya Wati100% (2)

- Level 2 m200 Pahu Qa-Qc ChecksDocument10 pagesLevel 2 m200 Pahu Qa-Qc ChecksAnurag KumbhareNo ratings yet

- Pilot Plant Scale-Up TechniqueDocument27 pagesPilot Plant Scale-Up TechniqueVidvendu GuptaNo ratings yet

- Control Sample SOP - SOP For Control Sample ManagementDocument10 pagesControl Sample SOP - SOP For Control Sample ManagementdaribeefaNo ratings yet

- SOP For Changeovers Carried Out in Manufacturing and Packing AreaDocument2 pagesSOP For Changeovers Carried Out in Manufacturing and Packing Areareflectprakash3610No ratings yet

- Summary of Cleaning ValidationDocument90 pagesSummary of Cleaning ValidationSadanand Gundare100% (2)

- QMS 055 SampleDocument8 pagesQMS 055 Samplebaluchakp100% (1)

- Batch Releas ProcedureDocument4 pagesBatch Releas ProcedureSolomon Gamanuel100% (1)

- ASEAN TMHS GMP Training Chapter 4 Annex 8 SOP On Cleaning of Equipment and Acce PDFDocument3 pagesASEAN TMHS GMP Training Chapter 4 Annex 8 SOP On Cleaning of Equipment and Acce PDFAnuradha yadavNo ratings yet

- PT Eco Laundry Hijau Ind - CAP 1.2Document25 pagesPT Eco Laundry Hijau Ind - CAP 1.2Tika Nur Laili L HiperkesNo ratings yet

- ASEAN TMHS GMP Training Chapter 9 Annex 4 Sample SOP On Product Recalls1Document4 pagesASEAN TMHS GMP Training Chapter 9 Annex 4 Sample SOP On Product Recalls1Uli OktariaNo ratings yet

- Aseptic Filler and Packaging Validation G - 005 - V1Document24 pagesAseptic Filler and Packaging Validation G - 005 - V1aaro_oraal100% (1)

- 4100F-QAS-151 (Supplier Quality Assurance Manual)Document35 pages4100F-QAS-151 (Supplier Quality Assurance Manual)Sanjay KumarNo ratings yet

- Incoming Inspection SOPDocument5 pagesIncoming Inspection SOPBPG ServiceNo ratings yet

- 2 Job Procedure For IMIRDocument6 pages2 Job Procedure For IMIRShubham ShuklaNo ratings yet

- Sop Eyewash Station InspectionDocument7 pagesSop Eyewash Station InspectionSathya SeelanNo ratings yet

- Evidence PlanDocument11 pagesEvidence PlanJestoni CenizaNo ratings yet

- ACMV Hirac - Mcintyre Prep Room 2Document13 pagesACMV Hirac - Mcintyre Prep Room 2NethiyaaRajendranNo ratings yet

- Line Clearence Ravi 17oct14Document31 pagesLine Clearence Ravi 17oct14pooja singhNo ratings yet

- WI-H-003 Inspection and Acceptance Work Instruction Rev ADocument8 pagesWI-H-003 Inspection and Acceptance Work Instruction Rev AAnil Chowadary Anil ChowadaryNo ratings yet

- Quality Control Manual: Function and ObjectiveDocument6 pagesQuality Control Manual: Function and ObjectivechandraNo ratings yet

- Production Management of Change (Pmoc) New /modified Equipment Safety ChecklistDocument4 pagesProduction Management of Change (Pmoc) New /modified Equipment Safety Checklistwiss gaderNo ratings yet

- # Observations Corrective Actions: Manufacturing ControlsDocument4 pages# Observations Corrective Actions: Manufacturing ControlsMasthan GMNo ratings yet

- F AP 1 Stock in TradeDocument10 pagesF AP 1 Stock in TradeAung Zaw HtweNo ratings yet

- Rework Process FlowDocument6 pagesRework Process FlowIsaac Samuel100% (1)

- Corrective Action Report (8D Report) : Discipline 1: Use Team ApproachDocument12 pagesCorrective Action Report (8D Report) : Discipline 1: Use Team ApproachWilmer EnarioNo ratings yet

- Prod - Product - Supervisor RDocument2 pagesProd - Product - Supervisor RSrihari Babu PeddiNo ratings yet

- Cold Forging Process For The Manufacturing of Nuts&boltDocument35 pagesCold Forging Process For The Manufacturing of Nuts&boltaseemk1No ratings yet

- QC's SOPDocument11 pagesQC's SOPDavid See100% (1)

- Issuing, Handling, Revision of Batch File and Final Release of Finished Products For Sale and Distribution 07Document18 pagesIssuing, Handling, Revision of Batch File and Final Release of Finished Products For Sale and Distribution 07ibrahimgomaaNo ratings yet

- Practical Guide To Production Planning & Control [Revised Edition]From EverandPractical Guide To Production Planning & Control [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- The Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsFrom EverandThe Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsNo ratings yet

- Amf-P-21 Procedure For Problem SolvingDocument2 pagesAmf-P-21 Procedure For Problem Solvinggangadhar.patilNo ratings yet

- Amf-P-20 Procedure For Repair ProcedureDocument2 pagesAmf-P-20 Procedure For Repair Proceduregangadhar.patilNo ratings yet

- Amf-P-11 Procedure For Design and DevelopmentDocument1 pageAmf-P-11 Procedure For Design and Developmentgangadhar.patilNo ratings yet

- Amf-P-10 Procedure For Engineering SpecificationDocument2 pagesAmf-P-10 Procedure For Engineering Specificationgangadhar.patilNo ratings yet

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-2-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)