Professional Documents

Culture Documents

QC-FM-089-02 Internal Self Audit Checklist

Uploaded by

Janice LeeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QC-FM-089-02 Internal Self Audit Checklist

Uploaded by

Janice LeeCopyright:

Available Formats

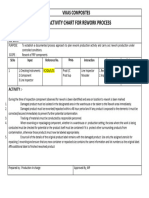

OTC COSMETIC INDUSTRIES SDN BHD

Doc No. : QC-FM-089

INTERNAL SELF AUDIT Rev. : 02

CHECKLIST Date : 25th January 2023

Date of audit : ________________

Department / Section Audited: _______________

PARTICULARS COMPLY COMMENTS

YES NO

1.0 PERSONNEL

- All personnel are properly attired

- All safety equipment is used correctly

- There are no significant language barriers between

supervisors and operators

- The employees are capable of reading and

understanding all company documents used in

the production of the products

- All injuries are immediately reported to the

employee's supervisor

- No jewelry and cosmetics are worn

2.0 MANUFACTURING PREMISES

- There is adequate lighting

- There is adequate ventilation

- There are adequate screens and controls to

prevent infestation

- Physical separation exists for operations requiring

dust collection, solvent control and temperature

and humidity control

- There are adequate personnel washing, locker,

and toilet facilities.

- There is adequate space provided for the

placement of equipment and materials in the

following areas:

(a) Receiving and sampling, storage of raw

materials

(b) In-process and production operations and

materials

(c) Storage areas for containers, packaging

materials, quarantined material, and released

final product.

(d) QC laboratory operations, equipment, retain

samples and records

QC-FM-089 (Rev 02) Page 1 of 7

OTC COSMETIC INDUSTRIES SDN BHD

PARTICULARS COMPLY COMMENTS

YES NO

3.0 RECEIVING AND STORAGE

- Receiving records for raw materials or components

include

(a) Name of component or material

(b) Manufacturer or supplier

(c) Receiving date

(d) Manufacturer's lot number

(e) Quantity received

(f) Control or purchase number

(g) A stock rotation policy is in place

(h) Proper storage conditions are used for all

the materials

(i) All the raw materials and components are

properly labelled

(j) There is a receiving procedure that is followed

and a list of personnel authorized to receive

items

- Raw materials and components are labelled,

sampled, and placed in quarantine according to

written procedures; only authorized personnel

have access to the quarantine areas

- There are written procedures that indicate how

rejected materials or components are handled

4.0 IDENTIFICATION

- Each component or raw material is identified

- Each component or raw material has a purchase

order or control number that, when cross-checked

to the receiving records, will identify the

(a) product

(b) supplier

(c) quantity received

(d) purchase or control number

(e) date of receipt

- Q.C labels are complete and affixed to each

container, as appropriate

- Accurate inventory records are kept for all

approved components and raw materials

QC-FM-089 (Rev 02) Page 2 of 7

OTC COSMETIC INDUSTRIES SDN BHD

PARTICULARS COMPLY COMMENTS

YES NO

5.0 EQUIPMENT

- There are no mechanical parts that come in

contact with the product that will react, add to,

be absorptive, or adversely affect the identity,

strength, quality or purity of the product

- The equipment is constructed in such a manner

that lubricants or coolants required for the

operation of the equipment may be used without

becoming incorporated into the product

- The equipment is constructed or located in such

a manner as to permit necessary cleaning,

adjustments and maintenance

- The equipment is constructed or located in such

a manner as to exclude possible contamination

from previous as well as current production

operation

- The equipment is thoroughly cleaned before use

and identified to indicate that it is ready for use

- The equipment is of suitable capacity and

accuracy for use in the intended measuring,

weighing or blending operations

- The weighing equipment is properly calibrated

- Utensils and in-process containers are constructed

in such a manner as to permit thorough cleaning

- Responsible supervisors or QC inspectors

approve the equipment and areas prior to the

start of production or packaging operations

- Responsible supervisors or QC inspectors are

present while the equipment is in operation

6.0 PRODUCTION

- Each critical step in the production process is

performed by a responsible individual, and

checked by a second responsible individual

- The automatic, mechanical or electronic

equipment used in the processing is routinely

checked and documented by responsible

individuals

- There is record to show that adequate

blending time was used, providing a uniform

compound prior to further processing

QC-FM-089 (Rev 02) Page 3 of 7

OTC COSMETIC INDUSTRIES SDN BHD

PARTICULARS COMPLY COMMENTS

YES NO

- There is adequate documentation to show that in-

process samples were collected and tested as

per the batch records

- The determination of actual yield has been

calculated and recorded on the batch records

- Fully competent and responsible personnel check

the actual yield against the theoretical yield of

each batch or lot

- The formulation and processing areas are manned

by competent responsible individuals who are

trained in the procedures required to prevent

cross-contamination

- Weighing operations are carefully supervised and

require two signatures on all weighing steps

- There are documented cleaning schedules for the

equipment and areas used in production

- There is documentation to show that the cleaning

of the equipment and the areas used for

production are adequate to prevent cross-

contamination

- Approved cleaning compounds are used for the

cleaning of all equipment used in the production

- Product containers are not left open or

unattended

in the production areas for any length of time

- All areas, equipment and containers will be

completely labelled at all times to identify fully

and accurately their

(a) batch or lot number

(b) contents

(c) stage of processing

- All previous identification labels have been

removed

- The batch or lot is handled in such a manner as

to prevent the cross-contamination of the material

with any other material

- All in-process containers are labelled for use and

labels are removed prior to reuse

QC-FM-089 (Rev 02) Page 4 of 7

OTC COSMETIC INDUSTRIES SDN BHD

PARTICULARS COMPLY COMMENTS

YES NO

7.0 PACKAGING AND LABELLING OF PRODUCT

- There are documented specifications for all

containers, closures, cartons and component parts

- Only approved containers, closures, cartons,

and component parts are used in the packaging

operations

- The containers provide adequate protection for

the product from deterioration or contamination

- There is adequate storage space and inventory

control of all packaging materials prior to use

- Packaging and labelling operations are adequately

controlled to assure that only those products that

have met all the QC specifications and have been

released will be packaged and labelled

- There is adequate physical separation of the

packaging and labelling lines

8.0 WAREHOUSING

- Finished products are stored under sanitary

conditions and adhere to "First In First Out"

procedures

- The shipping and storage areas are maintained

under proper temperature and humidity

conditions

- Stock rotation is used to prevent outdating of

products and to avoid product deterioration

- An approved rodenticide and insecticide program

is in place

- The warehouse area is maintained in a clean and

orderly manner and is secured at all times

9.0 QUALITY CONTROL LABORATORY

- There are written specifications for all raw

materials used in the production.

- The laboratory is staffed with competent,

responsible personnel and equipped with the

appropriate instruments necessary to test raw

materials, in-process samples, and final product

in a scientific and accurate manner

QC-FM-089 (Rev 02) Page 5 of 7

OTC COSMETIC INDUSTRIES SDN BHD

PARTICULARS COMPLY COMMENTS

YES NO

- Representative samples are collected from the

production operation and retained until the

product is released

- Specifications for final product testing and release

are documented

- Documentations exists for all outside laboratory

testing

- A calibration program exists that checks the

reliability, accuracy and precision of laboratory

instruments

- There are procedures for the acceptance or

rejection of raw materials, in-process samples and

final product

- There are complete records of all laboratory tests

performed, including dates and signatures of the

individuals completing the assays, and the

individuals who verified the assays for accuracy

- There are procedures for retain samples

- Stability studies have been performed on all

products

- There are no errors in the laboratory records; and

all test failures have been investigated and

recorded

10. DOCUMENTATION

- All specifications, procedures and policies are

available and properly stored

- Each document is current, approved and subject to

periodic review

- There is a proper change control mechanism

- There is a proper distribution procedures to

preclude the use of out-dated documents

- All documents are effectively controlled by all

departmental heads

QC-FM-089 (Rev 02) Page 6 of 7

OTC COSMETIC INDUSTRIES SDN BHD

PARTICULARS COMPLY COMMENTS

YES NO

11. QC/QA RESPONSIBILITES

- There is proper documentation for the handling of

all returned products

- If the material is to be destroyed, it will be

documented and destroyed by two competent

individuals under the supervision of the QC Dept.

- A customer complaint system is in place and will

be utilized to track all product complaints and to

take all product complaints and to take the

appropriate corrective action.

- There is a recall procedure and documentation

for all products involved in recalls

- All batch records and packaging and labelling

records will be reviewed by Quality Assurance

prior to the final release of the product for

shipping

- There is a central file where all distribution

records are maintained

- There is a documented GMP and SOP training

program for all employees

QC-FM-089 (Rev 02) Page 7 of 7

You might also like

- Check List HACCPDocument76 pagesCheck List HACCPAnba Tablet0% (1)

- Quality System Procedure: Introduction:-ResponsibilityDocument3 pagesQuality System Procedure: Introduction:-ResponsibilityPeracha EngineeringNo ratings yet

- Incoming Inspection SOPDocument5 pagesIncoming Inspection SOPBPG ServiceNo ratings yet

- Line Clearence Ravi 17oct14Document31 pagesLine Clearence Ravi 17oct14pooja singhNo ratings yet

- Procedure For ProductionDocument7 pagesProcedure For ProductionSharif Khan100% (1)

- Preveration Material ProcedureDocument6 pagesPreveration Material ProcedureSafety Naravisi BatamNo ratings yet

- (PRPS) ListDocument9 pages(PRPS) ListDeepak MoreNo ratings yet

- QC's SOP - REV 1 FLOW CHARTDocument8 pagesQC's SOP - REV 1 FLOW CHARTDavid SeeNo ratings yet

- New DOC DocumentDocument5 pagesNew DOC DocumentHazrat AminNo ratings yet

- Procedure For ProductionDocument7 pagesProcedure For ProductionTuan Anh100% (1)

- QC's SOPDocument11 pagesQC's SOPDavid SeeNo ratings yet

- Cosmetic Guideline.Document4 pagesCosmetic Guideline.Alice SamonteNo ratings yet

- Brand Protection and Left Over Product Handling ProcedureDocument3 pagesBrand Protection and Left Over Product Handling ProcedureSharif OmarNo ratings yet

- 03 - Good Manufacturing Practices - Guidelines For The Manufacturer of Cosmetic ProductsDocument21 pages03 - Good Manufacturing Practices - Guidelines For The Manufacturer of Cosmetic Productssilverfox7No ratings yet

- Hl-Non-Electrical Fcca Outline (Cn-En) - 07 - Nov - 2013 v1.0Document13 pagesHl-Non-Electrical Fcca Outline (Cn-En) - 07 - Nov - 2013 v1.0Rebeca TorresNo ratings yet

- 1.procedure For Incoming Material. Customer Products (6 Files Merged)Document16 pages1.procedure For Incoming Material. Customer Products (6 Files Merged)Valentine GaneshNo ratings yet

- SafetyDocument4 pagesSafetyHazrat AminNo ratings yet

- Validation of Pharmaceutical PackagingDocument28 pagesValidation of Pharmaceutical PackagingNaheed Malik100% (3)

- GMPDocument5 pagesGMPharwinderpanditNo ratings yet

- Productie Discreta - ManufacturingDocument3 pagesProductie Discreta - ManufacturingMazareanu GheorghitaNo ratings yet

- GMP Guidelines For ManufacturersDocument23 pagesGMP Guidelines For Manufacturerssiltanmuket88No ratings yet

- Bizmanualz AS9100 Rev C Policies and Procedures SampleDocument8 pagesBizmanualz AS9100 Rev C Policies and Procedures SampleHoang TanNo ratings yet

- Bizmanualz AS9100 Rev C Policies and Procedures SampleDocument8 pagesBizmanualz AS9100 Rev C Policies and Procedures SampleHoang TanNo ratings yet

- Definitions of Each of The 20 Tools of Process ControlDocument2 pagesDefinitions of Each of The 20 Tools of Process Control88No1FanNo ratings yet

- Aseptic Filler and Packaging Validation G - 005 - V1Document24 pagesAseptic Filler and Packaging Validation G - 005 - V1aaro_oraal100% (1)

- Good Manufacturing Practice or GMPDocument10 pagesGood Manufacturing Practice or GMPMuhammad Masoom AkhtarNo ratings yet

- Method Statement of Split AC Units InstallationDocument12 pagesMethod Statement of Split AC Units InstallationMomen Ayassrh100% (1)

- Quality Control Manual: Function and ObjectiveDocument6 pagesQuality Control Manual: Function and ObjectivechandraNo ratings yet

- Standard Operating Procedure For Rejected Items and ReturnsDocument4 pagesStandard Operating Procedure For Rejected Items and ReturnsMarichelle Palo100% (3)

- I-Plast Presentation - Handling Control IdentificationDocument18 pagesI-Plast Presentation - Handling Control IdentificationchoirsdocNo ratings yet

- "Thai Union Group Packaging Safety & Hygiene Requirements" (Version 2.0 - February 2018)Document21 pages"Thai Union Group Packaging Safety & Hygiene Requirements" (Version 2.0 - February 2018)Md Kamruzzaman MonirNo ratings yet

- Focus On Cgmps & Fda Inspections: WelcomeDocument40 pagesFocus On Cgmps & Fda Inspections: WelcomeYahia MasriNo ratings yet

- Audit Checklist For Production AreaDocument2 pagesAudit Checklist For Production AreaPrince Moni100% (3)

- Dokumen - Tips - NB CPD Ag 03 004 FPC Check ListDocument4 pagesDokumen - Tips - NB CPD Ag 03 004 FPC Check ListTaha HusNo ratings yet

- WI-H-003 Inspection and Acceptance Work Instruction Rev ADocument8 pagesWI-H-003 Inspection and Acceptance Work Instruction Rev AAnil Chowadary Anil ChowadaryNo ratings yet

- Assignment On CGMPDocument19 pagesAssignment On CGMPRajesh Nayak50% (2)

- P Qms 21 Procedure For PreservationDocument4 pagesP Qms 21 Procedure For PreservationAdipramono PutraNo ratings yet

- Draft GMP For Ayurveda Ravindra PrakashDocument28 pagesDraft GMP For Ayurveda Ravindra Prakashreflectprakash3610No ratings yet

- 2 Job Procedure For IMIRDocument6 pages2 Job Procedure For IMIRShubham ShuklaNo ratings yet

- Method of Statement Material Handling, Preservation and StorageDocument8 pagesMethod of Statement Material Handling, Preservation and StoragefazalrehmanNo ratings yet

- Validation of EquipmentDocument31 pagesValidation of Equipmentjyothisahadevan100% (4)

- CGMP Training Suntara Cosmetics Pvt. LTD.: Prepared By: Pratham ConsultantsDocument76 pagesCGMP Training Suntara Cosmetics Pvt. LTD.: Prepared By: Pratham Consultantsmrugeshj100% (1)

- 5.7 - Non-Conforming Material & Product Control Procedure.Document1 page5.7 - Non-Conforming Material & Product Control Procedure.Md.Akidul Islam AkidNo ratings yet

- Final Exame NumanDocument16 pagesFinal Exame NumanMayson BaliNo ratings yet

- CGMP On CosmeticsDocument12 pagesCGMP On CosmeticsMiguel LigasNo ratings yet

- GMP TrainingDocument14 pagesGMP TrainingPrince MoniNo ratings yet

- Finished ProductDocument4 pagesFinished ProductDilip ChaudharyNo ratings yet

- Foreign Materials Control PRPDocument4 pagesForeign Materials Control PRPPoulami DeNo ratings yet

- Current Good Manufacturing PracticesDocument24 pagesCurrent Good Manufacturing PracticesChinenye AkwueNo ratings yet

- Designation: Assistant Manager - Production Reporting To: Senior Manager - ProductionDocument5 pagesDesignation: Assistant Manager - Production Reporting To: Senior Manager - Productionvishal9patel-63No ratings yet

- Sop For Good Manufacturing Practices: Written by Verified by Function Name Signature DateDocument17 pagesSop For Good Manufacturing Practices: Written by Verified by Function Name Signature DateSreelakshmi RakeshNo ratings yet

- Amf-P-19 Procedure For ReworkDocument1 pageAmf-P-19 Procedure For Reworkgangadhar.patilNo ratings yet

- Method Statement For CCTV System Testing & CommissioningDocument12 pagesMethod Statement For CCTV System Testing & CommissioningAhmed GamalNo ratings yet

- Aka GMP Audit FormDocument8 pagesAka GMP Audit FormAlpian BosixNo ratings yet

- Self Appraisal Check ListDocument48 pagesSelf Appraisal Check ListDilip.V.PancholiNo ratings yet

- SOP For Control of Cross ContaminationDocument5 pagesSOP For Control of Cross ContaminationAli Ausat100% (5)

- PP13 00 y QNQ Gam 044 0 PDFDocument20 pagesPP13 00 y QNQ Gam 044 0 PDFRıdvan UyarNo ratings yet

- Vesda System Method StatementDocument6 pagesVesda System Method Statementsanthilal100% (2)

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- D3 Quick Reference Guide, Sept 09Document11 pagesD3 Quick Reference Guide, Sept 09Arnoldo FelixNo ratings yet

- Calsetfer PDFDocument2 pagesCalsetfer PDFMadalina Cioroiu-AndronescuNo ratings yet

- ISPE Blend and Content Uniformity GuidanceDocument26 pagesISPE Blend and Content Uniformity GuidanceRui PiresNo ratings yet

- Inserto Torch PositivoDocument22 pagesInserto Torch PositivoMayra LaraNo ratings yet

- Senior Scientist Molecular Biology in Albany NY Resume Jamie RusconiDocument3 pagesSenior Scientist Molecular Biology in Albany NY Resume Jamie RusconiJamieRusconiNo ratings yet

- 340 Operators ManualDocument274 pages340 Operators ManualAlvaro Restrepo GarciaNo ratings yet

- Milliplex - Analyte QuarterlyDocument40 pagesMilliplex - Analyte QuarterlyFrancisco SiirNo ratings yet

- (Biochem) Lab1Document7 pages(Biochem) Lab1Bảo NgọcNo ratings yet

- Covid-19 RT-PCR Test Report & Certification: Certificate IssuedDocument1 pageCovid-19 RT-PCR Test Report & Certification: Certificate IssuedJerome OliverosNo ratings yet

- Labtium Schedule Services 2010Document34 pagesLabtium Schedule Services 2010MuhammadFaisal100% (1)

- ALS Geochemistry Service Schedule 2013 - USDDocument44 pagesALS Geochemistry Service Schedule 2013 - USDlarv00970% (1)

- SOP For Chromogenic End Point MethodDocument27 pagesSOP For Chromogenic End Point MethodAli RazaNo ratings yet

- Qualification of Quality Control LaboratoriesDocument14 pagesQualification of Quality Control Laboratoriesltsophie100% (1)

- InTech-Analytical Method ValidationDocument19 pagesInTech-Analytical Method ValidationIordache SorinNo ratings yet

- Heliyon: Amira F. El-Yazbi, Karin M. Guirguis, Mona M. Bedair, Tarek S. BelalDocument10 pagesHeliyon: Amira F. El-Yazbi, Karin M. Guirguis, Mona M. Bedair, Tarek S. BelalWentySafitriNo ratings yet

- Technical Guide For The Elaboration of Monographs EDQMDocument72 pagesTechnical Guide For The Elaboration of Monographs EDQMppiccoliniNo ratings yet

- Fujirebio Lumipulse g600 BrosuraDocument4 pagesFujirebio Lumipulse g600 Brosura陈未免No ratings yet

- Autoimmunity Reviews: R. Tozzoli, M. Bagnasco, D. Giavarina, N. BizzaroDocument7 pagesAutoimmunity Reviews: R. Tozzoli, M. Bagnasco, D. Giavarina, N. BizzaroMohamed KhalidNo ratings yet

- Standard Operating Procedure: Biosystems Ba400Document5 pagesStandard Operating Procedure: Biosystems Ba400Mohamad QinaoiNo ratings yet

- DNSDocument7 pagesDNSainakmliaNo ratings yet

- Diacon N: (Assayed Universal Control Serum Normal)Document1 pageDiacon N: (Assayed Universal Control Serum Normal)Khadhraoui JamelNo ratings yet

- Antibiotic AssaysDocument12 pagesAntibiotic AssaysKhushbu RathodNo ratings yet

- DPlus OMV321 Quick Guide EN (2020 - 08 - 19 20 - 34 - 39 UTC)Document12 pagesDPlus OMV321 Quick Guide EN (2020 - 08 - 19 20 - 34 - 39 UTC)Arnoldo FelixNo ratings yet

- QC 1 Assay ManualDocument52 pagesQC 1 Assay ManualKevin DacatimbangNo ratings yet

- Methodology Research Design: Table 1. Amount of Garlic Extract Present in The Alternative DisinfectantDocument14 pagesMethodology Research Design: Table 1. Amount of Garlic Extract Present in The Alternative DisinfectantPaopao MacalaladNo ratings yet

- KB-03-006 Folin Ciocalteau BookDocument11 pagesKB-03-006 Folin Ciocalteau BookNaye VillalónNo ratings yet

- Effects of 46 Dyes On Population Growth of Freshwater Green Alga Se-Eksfrum CapricornutumDocument8 pagesEffects of 46 Dyes On Population Growth of Freshwater Green Alga Se-Eksfrum Capricornutummozierlan100% (1)

- Cobas e 411 AnalyzerDocument10 pagesCobas e 411 AnalyzerAfsana N.ANo ratings yet

- WHO CSDT SampleDocument120 pagesWHO CSDT SampleYen-Yee Lim JacqNo ratings yet

- STA Compact - Operator's ManualDocument418 pagesSTA Compact - Operator's ManualИлья ЛебедевNo ratings yet