Professional Documents

Culture Documents

Work Method Statement For Afam III Flow Meter Installation

Uploaded by

ISAAC0 ratings0% found this document useful (0 votes)

23 views2 pagesOriginal Title

Work Method Statement for Afam III Flow Meter Installation

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views2 pagesWork Method Statement For Afam III Flow Meter Installation

Uploaded by

ISAACCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

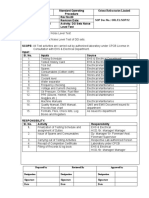

WORK METHOD STATEMENT FOR AFAM III FLOW METER

INSTALLATION

TASK STEPS

1. Raise PTW/JHA and sign.

2. Carryout site inspection of the pipeline to be cut and the environment.

3. Gas Testing of the area.

4. Installation of flow meter.

5. Installation of Pressure and Temperature transmitters( EMERSON TRANSMITTERS)

6. Installation of the junction box on a junction box stand.

7. Installation of instrument cables from pressure thermocouple to the junction box.

8. Installation of cables from the junction box to control room.

9. Installation of FLOW COMPUTER, POWER PACK AND RITAL RACK at the control room.

10. Configuration.

11. Pre-commissioning and Commissioning.

12. Housekeeping.

13. Close PTW and work order in SAP.

14. Demobilize.

TOOLS/EQUIPMENTS AND MATERIALS

1. Gas Detectors.

2. Spirit Level.

3. Rags.

4. Copper Hammer.

5. W.D 40.

6. Lifting Aid/A frame.

7. Mechanical and Instrument Tool Boxes.

8. Multimeters.

9. Insulation and Resistance Testers(Negger Testers).

10. Earth Tester.

11. Cables and Installation accessories.

12. Drilling Machine.

13. Expansion Bolts and Accessories.

14. Climping Tools.

PPE & SAFETY EQUIPMENTS REQUIRED

1. Caution Tape.

2. Rubber Hand Gloves.

3. Rubber boots/ Insulated Safety Boots.

4. First Aid Box.

5. Fire Extinguishers.

6. Stretcher.

7. Eye Goggles.

8. Coverall.

You might also like

- Essentials of Oil and Gas Utilities: Process Design, Equipment, and OperationsFrom EverandEssentials of Oil and Gas Utilities: Process Design, Equipment, and OperationsRating: 4.5 out of 5 stars4.5/5 (4)

- Construction Method of Statement: Submitted By: Mega Air EnterprisesDocument12 pagesConstruction Method of Statement: Submitted By: Mega Air Enterprisesallen bernabeNo ratings yet

- Fire Fighting Pumping Systems at Industrial FacilitiesFrom EverandFire Fighting Pumping Systems at Industrial FacilitiesRating: 4.5 out of 5 stars4.5/5 (3)

- Air-Con Installation Method StatementDocument2 pagesAir-Con Installation Method StatementMohamad Hafiz50% (2)

- Personnel Protection and Safety Equipment for the Oil and Gas IndustriesFrom EverandPersonnel Protection and Safety Equipment for the Oil and Gas IndustriesRating: 5 out of 5 stars5/5 (3)

- DOCUMENTS OBTAIN CERTIFICATIONDocument3 pagesDOCUMENTS OBTAIN CERTIFICATIONOkky Agassy FirmansyahNo ratings yet

- Electrical Engineering Technology - Higher National Diploma (HND)Document19 pagesElectrical Engineering Technology - Higher National Diploma (HND)Chibueze EzeokaforNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Apv Valves Da3plus Atex GBDocument48 pagesApv Valves Da3plus Atex GBSimon MinneNo ratings yet

- SID-MS-06 - Pipeline Erection & HydrotestingDocument3 pagesSID-MS-06 - Pipeline Erection & Hydrotestingcnanda89No ratings yet

- Replacement of Bad Pipe and Gate Valve Methd StatmDocument10 pagesReplacement of Bad Pipe and Gate Valve Methd StatmOdejobi OloladeNo ratings yet

- ITP New Pressure VesselDocument2 pagesITP New Pressure Vesselyosafateden60% (5)

- 2.1 Method of Statement - Installation of Aircon Diffuser and Sensors - Comments 4 Sep 2023Document1 page2.1 Method of Statement - Installation of Aircon Diffuser and Sensors - Comments 4 Sep 2023Suresh NaiduNo ratings yet

- List DokumenDocument2 pagesList DokumenInddraa Firmansyah D'cubaaNo ratings yet

- Job Hazard AnalysisDocument45 pagesJob Hazard Analysisuchechris05_2387211875% (4)

- GTU Diploma Electrical Engineering Installation MaintenanceDocument4 pagesGTU Diploma Electrical Engineering Installation MaintenanceJêx SÕlänki67% (15)

- OISD Check List - 1Document5 pagesOISD Check List - 1Pinjala AnoopNo ratings yet

- Well Testing Recommended PracticesDocument40 pagesWell Testing Recommended Practicessajithv78100% (1)

- JP Jo Interview QuestionsDocument10 pagesJP Jo Interview QuestionsMuhammad MehboobNo ratings yet

- Daily Site Inspection List - ExampleDocument3 pagesDaily Site Inspection List - ExampleSeNNinhA031No ratings yet

- CSPC-F-COL-13B Camarines Sur Polytechnic CollegesDocument3 pagesCSPC-F-COL-13B Camarines Sur Polytechnic CollegesPrincess NobleNo ratings yet

- AMSA36Document66 pagesAMSA36Btwins123100% (2)

- Installation and Testing of Fire Sprinkler SystemDocument7 pagesInstallation and Testing of Fire Sprinkler SystemMossad SamyNo ratings yet

- Appendix 7 - Wellsite Well Test Equipment Preparation ChecklistDocument6 pagesAppendix 7 - Wellsite Well Test Equipment Preparation Checklistsergiopuyo9184100% (3)

- Instrumentation and ControlDocument13 pagesInstrumentation and ControlEvans HopeNo ratings yet

- SMP - Flame ScannerDocument4 pagesSMP - Flame ScannerPragneshNo ratings yet

- Permit To Work Format - Ramzan Sugar Mills Limited (RSML)Document2 pagesPermit To Work Format - Ramzan Sugar Mills Limited (RSML)cuteboom1122No ratings yet

- SOP-08 Thermocouple - DTC CalibrationDocument9 pagesSOP-08 Thermocouple - DTC CalibrationPandu BirumakovelaNo ratings yet

- Engine Officers Familiarization and Handover Checklist: Alta Shipping Llc. Safety Management System Manual 6Document3 pagesEngine Officers Familiarization and Handover Checklist: Alta Shipping Llc. Safety Management System Manual 6Jacinto Eduardo Quiñonez100% (1)

- Kano Racks Methd StatementDocument8 pagesKano Racks Methd StatementOdejobi OloladeNo ratings yet

- Service and Maintain DomRAC UnitsDocument1 pageService and Maintain DomRAC UnitsGen FuNo ratings yet

- Construction Site Inspection Check List ALMCDocument2 pagesConstruction Site Inspection Check List ALMCAmeerHamzaWarraichNo ratings yet

- Cable Tray InstallationDocument6 pagesCable Tray InstallationsbpathiNo ratings yet

- Revised - MosDocument15 pagesRevised - MosNadeesha BandaraNo ratings yet

- Method of StatementDocument5 pagesMethod of StatementPari Rajendran100% (1)

- apv-valves-sv1-atex-gbDocument42 pagesapv-valves-sv1-atex-gbKim HenyeonNo ratings yet

- 005 (Method Statement For Installation and Inspection of Clean Agent system-FM 200Document4 pages005 (Method Statement For Installation and Inspection of Clean Agent system-FM 200Wahid HusainNo ratings yet

- Weldolet Methd StatementDocument8 pagesWeldolet Methd StatementOdejobi OloladeNo ratings yet

- Job Safety Analysis for Hydro-TestingDocument1 pageJob Safety Analysis for Hydro-TestingZeyad RezkNo ratings yet

- Method of StatementDocument6 pagesMethod of StatementPari Rajendran100% (1)

- SOP Stack Emission of DG SetsDocument2 pagesSOP Stack Emission of DG SetsPandu BirumakovelaNo ratings yet

- Precomm. & Comm. Safety EssentialsDocument3 pagesPrecomm. & Comm. Safety Essentialsmudatha100% (2)

- Butterfly Valve JMDocument4 pagesButterfly Valve JMMohd A IshakNo ratings yet

- SOP Noise Testing of DG SetsDocument2 pagesSOP Noise Testing of DG SetsPandu Birumakovela100% (1)

- Method Statement Format (CDRIHBIBSG and Silo DC Pipe Line Cleaning by Hydrojetting MOSDocument11 pagesMethod Statement Format (CDRIHBIBSG and Silo DC Pipe Line Cleaning by Hydrojetting MOSPrem Preetham Dsouza100% (1)

- Method Statement: System: Air Condition & VentilationDocument4 pagesMethod Statement: System: Air Condition & VentilationSamantha HarveyNo ratings yet

- Electrofusion WeldingDocument11 pagesElectrofusion WeldingZuberYousufNo ratings yet

- Safe Flare SystemDocument113 pagesSafe Flare SystemMostafa Sharaf100% (5)

- CP Training Maual-Module 8-Field Measurement and Testing of CP Sys...Document38 pagesCP Training Maual-Module 8-Field Measurement and Testing of CP Sys...Emre Erdem100% (1)

- Chiller CarrierDocument70 pagesChiller CarrierJavier OmarNo ratings yet

- 6-Weekly Site Safety Inspection ChecklistDocument6 pages6-Weekly Site Safety Inspection ChecklistZeeshan AbbasiNo ratings yet

- Well Testing Systems: Norsok StandardDocument40 pagesWell Testing Systems: Norsok StandardBoris Zaslichko100% (1)

- SND Spray Nozzle Desuperheater-Installation Maintenance ManualDocument16 pagesSND Spray Nozzle Desuperheater-Installation Maintenance ManualShameer Majeed100% (1)

- SS Piping Method StatementDocument10 pagesSS Piping Method StatementNishar BalkavadeNo ratings yet

- EM-I Lab Manual 28.10.08 LatestDocument82 pagesEM-I Lab Manual 28.10.08 Latestjoe2509100% (6)

- Wa0008.Document61 pagesWa0008.Praveen SingupurapuNo ratings yet

- Lamp, Switch & Socket Installation MethodDocument2 pagesLamp, Switch & Socket Installation MethodVõ Khắc GhiNo ratings yet

- 10.2.2 PCS Phosphate's New 4500 STPD Sulfuric Acid Plant in AuroraDocument20 pages10.2.2 PCS Phosphate's New 4500 STPD Sulfuric Acid Plant in AuroraCarlosNo ratings yet

- 4.1g Quality AuditReportDocument9 pages4.1g Quality AuditReportISAACNo ratings yet

- ACFrOgAV186TvKd1V yBTox7rsdqh2nyi6cbv8WEssR8orWkn0KJwwuDNiKeyETskv88BbbmQzl2mdHVEf2OD9X4enp5D0zhNZ8 9Zvx1yz-gT7u12qXJ-kOheTJgycEWLCPBMvus 4cfb5l7dBnDocument2 pagesACFrOgAV186TvKd1V yBTox7rsdqh2nyi6cbv8WEssR8orWkn0KJwwuDNiKeyETskv88BbbmQzl2mdHVEf2OD9X4enp5D0zhNZ8 9Zvx1yz-gT7u12qXJ-kOheTJgycEWLCPBMvus 4cfb5l7dBnISAACNo ratings yet

- Method Statement For InstallationDocument32 pagesMethod Statement For Installationbharathks641No ratings yet

- Halliburton Supplier GuideDocument16 pagesHalliburton Supplier GuideISAACNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisFrom EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisNo ratings yet

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesFrom EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesRating: 4 out of 5 stars4/5 (2)

- Risk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesFrom EverandRisk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesNo ratings yet

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- Biostratigraphic and Geological Significance of Planktonic ForaminiferaFrom EverandBiostratigraphic and Geological Significance of Planktonic ForaminiferaRating: 4 out of 5 stars4/5 (5)

- Pipeline Integrity: Management and Risk EvaluationFrom EverandPipeline Integrity: Management and Risk EvaluationRating: 4.5 out of 5 stars4.5/5 (6)

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)

- Essentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesFrom EverandEssentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesRating: 5 out of 5 stars5/5 (5)