Professional Documents

Culture Documents

ACSR Curlew STRINGING and WELDING

ACSR Curlew STRINGING and WELDING

Uploaded by

carlos.figueiredo0 ratings0% found this document useful (0 votes)

15 views12 pagesOriginal Title

ACSR-curlew-STRINGING-and-WELDING

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views12 pagesACSR Curlew STRINGING and WELDING

ACSR Curlew STRINGING and WELDING

Uploaded by

carlos.figueiredoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 12

VEIKI-VNL

ELECTRIC LARGE LABORATORIES Ltd. No.11812/VNL

EVIL Bi

enero TESTING LABORATORY Page 1 of 10

TYPE TEST REPORT

Test object: Aluminium Conductor Steel Rainforced (ACSR Cardinal)

Designation: ACSR Cardinal

Manufacturer: EMTAKABLO SANAYI ve TICARET AS.

Istasyon Mah. Ibisaga Cad. No: 4 Tuzla Istanbul

TURKIYE

Tested for: EMTA KABLO SANAYI ve TICARET AS.

Date of tests: 18" March 2021 — 19 March 2021

Project ID: NAL-10/2021

Order/Contract: PO: KYS-FRM95 Rev.00, 08.02.2021

Test specification: EN 50182:2001 Conductors for overhead lines round wire concentric lay

stranded conductors

‘Tests performed: = Stringing test

= Welding of aluminium wires test

Test results: ‘The test object fulfilled the relevant requirements of the standard.

‘This document has been issued by VEIKI-VNL Electric Large Laboratories Ltd. Testing Laboratory in accordance with

above mentioned test specification.

‘This document applies only to the test object. The responsibility for conformity of any product having the same

designations with that tested rests with the Manufacturer

‘This document comprises 11 pages in total (10 numbered pages,! page of conductor datasheet)

Gergely Gal ‘Norbert Menyhért aldzs Varga

22" March 2021 responsible for the test supervised by head of laboratory

VEIRI-VNL Lids an independent company, member of Short-cicuit Testing Liaison (STL).

Copyright: Only integral reproduction of this document is permitted without written permission of VEIKI-VNL Lid.

Electronic copies of this document may be available and have status of “for information only”. The sealed and

bound version of the document is the only valid version.

1158 Budapest, Vasgolyé u. 2-4., HUNGARY Pr

E-mail: VEIK|-info@dekra.com bl ¢ Hi

Phone: +36-1-417 3157 avasasva618

wow.vnl.hu See

‘VEIKI-VNL

Yu 7 ELECTRIC LARGE LABORATORIES Ltd. nes Hah De

TESTING LABORATORY beet

TEST CERTIFICATES OR REPORTS ISSUED BY VEIKI-VNL

ELECTRIC LARGE LABORATORIES LTD. AS TESTING LABORATORY

1 STL Type Test Certificates of ... Performance

VEIKI-VNL asa STL Member organization with ts own testing laboratories (Member Laboratories) is entitled to issue

STL Type Test Cerificate of..Performance ifthe product to be tested is inside the STL scope, all STL rules are fulfilled

and the proven tests fully comply with the applicable TEC Standard and the corresponding STL Guide.

About STL

The Short-Cireuit Testing Liaison (STL) provides a forum for voluntary international collaboration between testing

organisations. The basic aim isthe harmonised application of IEC and Regional/National Standards for type testing

of electrical high-voltage power equipment, and unified evaluation then presentation (reporting) of the test results

Certificates

STL asa collaboration does not itself issue Certificates. Each STL Member issuing a STL Type Test Certificate is

responsible for the validity and contents of that Cerificate. A STL Type Test Certificate is issued by STL Members

based on tests performed by a STL Member Laboratory within their accredited scope to ISOMEC 17025.

A detailed description of Certificate documents is available at wnw.st-liaison.org.

STL Guides

AULSTL Members pledge that, when testing for certification to a Standard in respect of which an STL Guide has been

issued, they wil test only in accordance with the agreed interpretation of the Standard as given in the STL Guide. In

‘addition, the STL Members have agreed to present STL Type Test Certificates in the form given in the STL General

Guide. For further information contact us or visit the STL website at www.stl-liaisonore.

2 Type Test Report / Certificate

‘Type Test Report provides the verification of the rated characteristics ofthe equipment as assigned by the manufacturer,

by means of the performance of the appropriate (type) tests specified by the standard. This reporvcertificate can be issued

ifthe test object is completely prepared for testing, test circumstances and results fully comply with one or more (type)

tests or test series defined by the applicable standard and all drawings serving the identification of the sample was

submitted prior testing and approved by the laboratory. In case of special request Type Test Certificate can be issued

Which is equal in status, meaning and content requirement of the Type Test Report

3. Prototype Test Report

Prototype tests are required to verify the suitability ofthe materials and method of manufacture for composite insulators

defined by relevant ANSI standards.

4 Design Test Report

According to IEC standard: The design tests are intended to verify the suitability ofthe design, materials and method of

‘manufacture (technology) of composite insulators.

According o ANSI standard: The design tests are intended to verify the insulators electrical and mechanical

characteristics that depend on is size and shape.

5 Test Report

‘Test report is issued in all cases not listed above, eg,

+ Test(s) were carried out according to instructions of the Client or Technical Specification,

+ The test sample, test circumstances, required test parameters and evaluation method of the results do not or partially

‘comply with the prescriptions of the standard.

‘The submitted technical documents and drawings are not suitable forthe clear identification of the tested object.

‘Tests and test series were carried out according to the standard, but the test object failed,

AS Important notice

Reports and Certificates are issued usually in minimum two original copies. These sealed and bound copies are the original.

epors, Electronic reports in pdf format may be available and shall be considered as “for information only” In case of

doubt with respect to the authenticity of the electronic version, please ask forthe original sealed and bound version or

Send the entire electronic report to us for checking its authenticity. Please send this request to our e-mail address: VEIKIL

info@dekra.com

Vv VEIKI-VNL

Sra ELECTRIC LARGE LABORATORIES Ltd.

oe TESTING LABORATORY

11812/VNL

Page 3 of 10

Ratings/characteristics assigned by the manufacturer:

Test object:

Designation:

Manufacturer:

Structure:

Core:

Layer 1

Layer 2:

Layer 3:

Layer 4

Cross sectional are:

Nominal diameter:

Rated Tensile Strength (RTS):

Modulus of elasticity

Nominal conductor mass without grease:

DC resistance at 20°C:

Aluminium Conductor Steel Rainforced

ACSR CARDINAL

EMTA KABLO SANAYI ve TICARET A.S.

1* 93.38 mm

6* 03.38 mm

12 * @3.38 mm

18 x @3.38 mm

24x 93.38 mm

347.3 mm’

30.42 mm

149.7 KN

61.6 GPa

1834 kg/km

0.0596 O/km

Steel wire

Steel wire

Aluminium wire

Aluminium wire

Aluminium wire

The tests were carried out in accordance with the following standards:

EN 50182:2001 Conductors for overhead lines - Round wire concentric lay stranded

conductors

Requirements of manufacturer or purchaser:

List of manufacturer's drawings for identification of the test object:

Conductor Data Sheet and test specification ACSR CARDINAL (1 page)

Present at the test in charge of manufacturer or purchaser:

VEIKI-VNL

ELECTRIC LARGE LABORATORIES Ltd.

TESTING LABORATORY

No.11812/VNL

Page 4 of 10

TESTS PERFORMED ON THE TEST OBJECT

No. | Description Relevant clauses of the standard

1_| Stringing test EN 50182: 2001 Clause 6.4.9, Annex E

2 | Welding of aluminium wires EN 50182: 2001 Clause 6.5.3

DESCRIPTION OF THE TEST

1. Stringing test

1.1. Test method and parameters

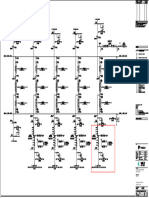

Stringing test was carried out according to EN 50182:2001 Clause 6.4.9 and Annex E as shown in

Figure 1. The drum was installed on a drum holder which was regulated by an automatic controlled

tensioner. The drum was placed 15 m apart from the tensioner. The drum number and the details of

the drum is shown on Photo 1. The force of the pulling was measured with a load cell placed at the

grip. The pilot cable and the tested conductor was connected together with a swivel. The tension was

maintained at 29.94 KN (20% RTS). The test arrangement is shown in Figure | and Photos 3-6.

1 Woven grip

2 Pilot cable

23 Drum holder

4 Tensioner

5 Block

8 Pulling winch

Stringing test arrangement

1.2. Test results

During and after the test, deformation or looseness on the outer layer did not occurred on the

conductor; therefore the conductor met the requirement of the standard for stringing test.

Surface condition of the conductor and position of the individual wires in the outer layer after the test

are shown in Photo 7.

2.Welding of aluminium wires

2.1. Test method and parameters

‘The manufacturer shall demonstrate to the purchaser that the method used for jointing aluminium

wires meets the strength requirements of the relevant standard. The straightened wire shall be installed

in a suitable tensile testing machine. The load shall be applied gradually with a rate of separation of

the jaws not less than 25 mm/min and not greater than 100 mm/min, The rate of separation of the

jaws was 60 mm/min during the test.

The type of the joints were cold presser welded joints

(NL VEIKI-VNL

Vv cy ELECTRIC LARGE LABORATORIES Ltd. No.11812/VNL

Se TESTING LABORATORY Page 5 of 10

2.2. Test results

Table 1: Breaking strength values of the welded aluminium wires

Wire Diameter ‘Cross. A. Tensile force Tensile stress

[mm] _ [mm?] [kN] [N/mm?]

Welded wire [3.398 9.063 1.4872 164.1

Welded wire2 [3.396 9.052 1.4955 165.2

Welded wire3 [3.399 9.069) 1.4803 163.2

Welded wired | 3.401 9.079 15436 170.0

Welded wires | 3.408 9.116 15142 166.1

Welded wireé | 3.400 9.076 1.5588 1718

Welded wire 7 3.407 9.112 1.5709 1724

Welded wires [3.406 9.104 1.5248 167.5

Welded wire9 | 3.400 9.072 1.5298 168.6

Welded wire 10 [ 3.394 9.041 13478 1712

The measured tensile stress values are greater than the specified value of 130 N/mm* therefore the

welded aluminium wires met the requirements of the standard.

Uncertainty of measurements

Tensile force measurement: + 1%

The uncertainty values given in this report are the standard deviation values multiplied by k=2.

Measurement uncertainty was estimated according to the method described in the EA-4/02 document.

Measuring devices used for the tests:

Designation Manufacturer Type SIN:

Load cell A. GmbH AGK-1031/2018 1605453

Instrument AS.T. GmbH AE 703 2016502840

Digital micrometer Mitutoyo MDC-258X 63115246

‘Tensile test machine (SO kN) Métisz-Q Kft. ZD10-90 263/1111/DSZ

Extensometer VEIKI-VNL Ltd. LVDT 2/2014

VEIKI-VNL.

ELECTRIC LARGE LABORATORIES Ltd. N MEIN

TESTING LABORATORY pear

PHOTOS

Drum placed into the drum holder

Photo 2

Label and markings on the surface of the Drum

WU VEIKI-VNL

Vv ELECTRIC LARGE LABORATORIES Ltd. No.l Be bale

Ete TESTING LABORATORY Page To

Photo 3

Stringing test arrangement

Photo 4

Pulling swivel, “Socks” and “Bug” used for stringing test

VEIKI-VNL

ELECTRIC LARGE LABORATORIES Ltd.

TESTING LABORATORY

No.11812/VNL

Page 8 of 10

Photo 5

Load cell placed into the test circuit and the measured load during the test

The block device used for the stringing test

VEIKLVNL

ELECTRIC LARGE LABORATORIES Ltd. No.11812/VNL

TESTING LABORATORY Page 10 of 10

VIE

KT

Photo 9

‘Test arrangement of the tensile test on welded aluminium wires

Aluminum strand

Number Diameter

Steet strand{for ACSR only)

Ahm

Steel

Minumum breaking strength ny

Standard weight

Modulus of elasticity

[Coefficient of linear expansion 193 + 10%

Second

Lay ratio and Direction of lay [Alum To Toh

Steel

3

oe

eo

-

2

=

o

%

o

vo

3s

a

/

S

$

eo

5

3

a

Ss

0

2.000

mm*mm*mm 1950 * 900 * 950 (1110)

kg 3.668,

inium

kg ais

[Grease weight Ace. To BS EN 50182 2001* | kykm (+/-%20)

Alum:

[Grease ype

Diameter

Uimate tensile strength

{Conductivity at 20°C

ALUMINUM

WIRE

[Diemerer

[Ultimate tensile strength

Stress at 1% extension

Elongation in 250 mm

STEEL CORE,

Falvanizing weight of coating

[EMTA KABLO SANAYIVETICARETAAS.

Istsyon Manas age Cadden Net 34540 Tua —lsanbul

Tl(-0) 216 44 605 /Fx 20216 46 «399

salesBemtacondto com wre amtaccadicton.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- OpEx Budget TemplateDocument5 pagesOpEx Budget Templatecarlos.figueiredoNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Estudo de Layout em Uma Distribuidora de Água Mineral: 1 IntroduçãoDocument10 pagesEstudo de Layout em Uma Distribuidora de Água Mineral: 1 Introduçãocarlos.figueiredoNo ratings yet

- CCG-Utility-Pole-Brochure-Web-r3 FiberDocument36 pagesCCG-Utility-Pole-Brochure-Web-r3 Fibercarlos.figueiredoNo ratings yet

- TCB18 Final Report Elec AppendixDocument100 pagesTCB18 Final Report Elec Appendixcarlos.figueiredoNo ratings yet

- Gabriel-Marcal-Barroso CapexDocument97 pagesGabriel-Marcal-Barroso Capexcarlos.figueiredoNo ratings yet

- CapEx Budgeting Template V2Document5 pagesCapEx Budgeting Template V2carlos.figueiredoNo ratings yet

- Pir TRP A4 0118 001 - 4fa23-53216e64 PDFDocument7 pagesPir TRP A4 0118 001 - 4fa23-53216e64 PDFcarlos.figueiredoNo ratings yet

- Copper Clad Aluminum CCA Cables-6002212Document5 pagesCopper Clad Aluminum CCA Cables-6002212carlos.figueiredoNo ratings yet

- 645480Document52 pages645480carlos.figueiredoNo ratings yet

- Pir - TRP - A4 - 0119 - 001 - 245cd-53216e64 Data Sheet Trafo 230Kv PDFDocument3 pagesPir - TRP - A4 - 0119 - 001 - 245cd-53216e64 Data Sheet Trafo 230Kv PDFcarlos.figueiredoNo ratings yet

- Seu Futuro e A Eletronica Vol.2Document158 pagesSeu Futuro e A Eletronica Vol.2carlos.figueiredoNo ratings yet

- Seu Futuro e A Eletronica Vol.3Document157 pagesSeu Futuro e A Eletronica Vol.3carlos.figueiredoNo ratings yet

- XXV Snptee Seminário Nacional de Produção E Transmissão de Energia Elétrica 10 A 13 de Novembro de 2019 Belo Horizonte - MG 3993 GSE/23Document9 pagesXXV Snptee Seminário Nacional de Produção E Transmissão de Energia Elétrica 10 A 13 de Novembro de 2019 Belo Horizonte - MG 3993 GSE/23carlos.figueiredoNo ratings yet

- Cno - Ele - A1 - 0001 - 001 - 7b851-547c9447 Unifilar 550Document1 pageCno - Ele - A1 - 0001 - 001 - 7b851-547c9447 Unifilar 550carlos.figueiredoNo ratings yet

- Luminaria Globe Sem Painel Foto 4m de AlturaDocument1 pageLuminaria Globe Sem Painel Foto 4m de Alturacarlos.figueiredoNo ratings yet

- CP Coelt 2017 2 01Document54 pagesCP Coelt 2017 2 01carlos.figueiredoNo ratings yet

- Mez3 Set Ric Ric Eps A4 0100 - 006 01Document200 pagesMez3 Set Ric Ric Eps A4 0100 - 006 01carlos.figueiredoNo ratings yet

- Planilha FinalDocument3 pagesPlanilha Finalcarlos.figueiredoNo ratings yet

- B.3562-00 Esquema Ligação 24 Elem 19HR-640Document1 pageB.3562-00 Esquema Ligação 24 Elem 19HR-640carlos.figueiredoNo ratings yet

- Proposta - Contrato Se23.1128-01 - Se Appa 138 KVDocument5 pagesProposta - Contrato Se23.1128-01 - Se Appa 138 KVcarlos.figueiredoNo ratings yet

- Acsr Ibis and Pelican Type Test ReportDocument10 pagesAcsr Ibis and Pelican Type Test Reportcarlos.figueiredoNo ratings yet

- Mez3 Set Ric Ric Eps A4 0100 - 005 01Document226 pagesMez3 Set Ric Ric Eps A4 0100 - 005 01carlos.figueiredoNo ratings yet

- Certificate - 71 100868 ALUKAFLEX Extern 1 - CompressedDocument2 pagesCertificate - 71 100868 ALUKAFLEX Extern 1 - Compressedcarlos.figueiredoNo ratings yet

- 795 Arquivo Licitacaoeletronica 054 2019 4Document7 pages795 Arquivo Licitacaoeletronica 054 2019 4carlos.figueiredoNo ratings yet

- Projeto Executivo Eletrico-SubestacaoDocument49 pagesProjeto Executivo Eletrico-Subestacaocarlos.figueiredoNo ratings yet

- Report Routine Test Ibis CableDocument5 pagesReport Routine Test Ibis Cablecarlos.figueiredoNo ratings yet