Professional Documents

Culture Documents

1,3-Butylene Glycol - MSDS

Uploaded by

Ashok MauryaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1,3-Butylene Glycol - MSDS

Uploaded by

Ashok MauryaCopyright:

Available Formats

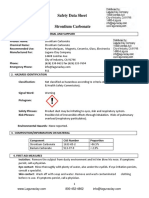

GODAVARI BIOREFINERIES LIMITED

MATERIAL SAFETY DATA SHEET

1,3-BUTYLENE GLYCOL

1. PRODUCT AND COMPANY IDENTIFICATION

PRODUCT : 1,3-Butylene glycol

MSDS number : Revision 2013 1 GHS

Amended date : 20.07.2013

Substance Name : 1,3 Butylene Glycol

EC Number : 203 – 529 - 7

CAS Number : 107 - 88 - 0

Molecular weight : 90.12

Chemical formula : C4H10O2

1 .2 Identified uses

1.2.1 Identified Uses : For Cosmetic Use Only

1 .3 Supplier & Manufacturer identification

MANUFACTURER LOCATION CONTACT DETAILS

Godavari Biorefineries Ltd. Sakarwadi, Mail: sangle@somaiya.com

Somaiya Bhavan, Stn.: Kanhegoan, Emergency no: +91 22 22048272

45/47, M.G.Road, Kopargoan, Fax: 0091 22 22047297

Fort, Mumbai 400 001, Maharashtra

India.

1 .4 Indian Emergency Number +91 22 22048272

2. HAZARDS IDENTIFICATION

Other Hazards: The substance does not meet the criteria for PBT / vPvB

according to REACH, Annex XIII

MATERIAL SAFETY DATA SHEET (1,3-Butylene glycol)

3. COMPOSITION /INFORMATION ON INGREDIENTS

Chemical Characterization : 1,3 Butylene Glycol

Components CAS-No EC-No. Percent %

1,3 Butylene Glycol 107-88-0 203-529-7 > 99.0

4. FIRST AID MEASURES

General Information

Remove contaminated, soaked clothing immediately and dispose of safely. First

aider needs to protect himself.

Inhalation

Keep at rest. Aerate with fresh air. When symptoms persist or in all cases of doubt

seek medical advice.

Skin

Wash off immediately with plenty of water. When symptoms persist or in all cases

of doubt seek medical advice

Eyes

Rinse immediately with plenty of water, also under the eyelids, for at least 15

minutes. Remove contact lenses.

Immediate medical attention is required.

Ingestion

Call a physician immediately. Do not induce vomiting without medical advice.

Main symptoms

Cough.

Special hazard

Lung irritation.

Notes to physician (Main symptoms)

Treat symptomatically. If ingested, irrigate the stomach using activated

charcoal.

MATERIAL SAFETY DATA SHEET (1,3-Butylene glycol)

5. FIREFIGHTING MEASURES

Suitable extinguishing media

Foam, Dry chemical, Carbon dioxide (CO2), water spray

Extinguishing media which must not be used for safety reasons

Do not use a solid water stream as it may scatter and spread fire***

Special exposure hazards arising from the substance or preparation itself, its

combustion products, or released gases

Under conditions giving incomplete combustion, hazardous gases produced

may consist of Carbon monoxide

Carbon dioxide (CO2)

Combustion gases of organic materials must in principle be graded as inhalation

poisons***

Vapors are heavier than air and may spread along floors

Special protective equipment for fire fighters

Fire fighter protection should include a self-contained breathing apparatus

(NIOSH-approved or EN 133) and full fire-fighting turn out gear.

Environmental precautions

Dike and collect water used to fight fire. Water run-off can cause environmental

damage.

Other Information

Cool containers / tanks with water spray.

Keep people away from and upwind of fire

6. ACIDENTAL RELEASE MEASURES

Personal precautions

Avoid contact with skin and eyes. Avoid breathing vapors or mists. Keep people

away from and upwind of spill/leak. Ensure adequate ventilation, especially in

confined areas. Keep away from heat and sources of ignition.

For emergency responders: Personal protections see section 8.

MATERIAL SAFETY DATA SHEET (1,3-Butylene glycol)

Environmental precautions

Prevent further leakage or spillage. Do not discharge product into the aquatic

environment without pretreatment (biological treatment plant).

Methods for containment

Stop the flow of material, if possible without risk. Dike spilled material, where this

is possible.

Methods for cleaning up

Soak up with inert absorbent material. Keep in suitable, closed containers for

disposal. If liquid has been spilt in large quantities clean up promptly by scoop or

vacuum. Dispose of in accordance with local regulations. Take necessary action

to avoid static electricity discharge (which might cause ignition of organic

vapors).

Additional information

Consult trained personnel. Consider the information for "Personal Protection" in

chapter 8 of this Safety Data Sheet***

7. HANDLING AND STORAGE

Handling

Hygiene measures

Avoid contact with skin, eyes and clothing. Wash hands before breaks and

immediately after handling the product.

Provide sufficient air exchange and/or exhaust in work rooms.

Advice on safe handling

Avoid contact with skin, eyes and clothing. Wash hands before breaks and

immediately after handling the product.

Provide sufficient air exchange and/or exhaust in work rooms.

Incompatible products

Keep away from: Strong oxidizing agents

Protection - fire and explosion:

Keep away from sources of ignition - No smoking. Vapours are heavier than air

and may spread along floors. Take necessary action to avoid static electricity

discharge. In case of fire, emergency cooling with water spray should be

available

MATERIAL SAFETY DATA SHEET (1,3-Butylene glycol)

Reduce the release of the substance or mixture to the environment See Section

8: Environmental exposure controls

Temperature class

T2

Storage

Material storage

Keep containers tightly closed in a cool, well-ventilated place. Handle and

open container with care. Keep at temperatures between 15 and 27 °C (60 and

80 °F).

Incompatible products

Keep away from: Strong oxidizing agents

8. EXPOSURE CONTROLS/PERSONAL PROTECTION

DNEL & PNEC

1,3-Butylene glycol (Butane-1,3-diol), CAS: 107-88-0

General population ***

DN (M) EL - long-term exposure - systemic effects - Oral 25-mg/kg bw/day

Environment ***

PNEC aqua - freshwater 0.85 mg/l

PNEC aqua - marine water 0.085 mg/l

PNEC aqua - intermittent releases 2 mg/l

PNEC STP 10 mg/l

PNEC sediment - freshwater 1.78 mg/kg

PNEC sediment - marine water 0.178 mg/l

PNEC soil 0.13 mg/kg

Engineering measures

General or dilution ventilation is frequently insufficient as the sole means of

controlling employee exposure. Local ventilation is usually preferred. Explosion-

proof equipment (for example fans, switches, and grounded ducts) should be

used in mechanical ventilation systems.

Personal protective equipment

MATERIAL SAFETY DATA SHEET (1,3-Butylene glycol)

General advice

Avoid contact with skin, eyes and clothing. Do not breathe vapors or spray mist.

Ensure that eyewash stations and safety showers are close to the workstation

location.

Hygiene measures

When using, do not eat, drink or smoke. Take off all contaminated clothing

immediately. Wash hands before breaks and immediately after handling the

product.

Eye protection

Tightly fitting safety goggles. In addition to goggles, wear a face shield if there is

a reasonable chance for splash to the face.

Equipment should conform to EN 166

Skin protection

Impervious clothing. Wear face-shield and protective suit for abnormal

processing problems.

Hand protection

Wear protective gloves. Recommendations are listed below. Other protective

material may be used, depending on the situation, if adequate degradation

and permeation data is available. If other chemicals are used in conjunction

with this chemical, material selection should be based on protection for all

chemicals present.

Chemicals resistant gloves

Suitable material : Nitrile-rubber

Evaluation : according to EN 374: level 6

Material thickness : approx. 0.55 mm

Break through time : approx. 360 min

Suitable material : Polyvinyl Chloride/ Nitrile rubber

Evaluation : according to EN 374: level 3

Material thickness : approx. 0.9 mm

Break through time : approx. 360 min

The times listed are suggested by measurements taken at 22 °C and constant

contact. Temperatures raised by warmed substances, body heat, etc. and a

weakening of the effective layer thickness caused by expansion can lead to a

significantly shorter breakthrough time. In case of doubt contact the gloves'

MATERIAL SAFETY DATA SHEET (1,3-Butylene glycol)

manufacturer. A 1.5-times increase / decrease in the layer thickness doubles /

halves the breakthrough time. This data only applies to the pure substance.

Transferred to mixtures of substances, these figures should only be taken as an

aid to orientation.

Environmental exposure controls

If possible use in closed systems. If leakage cannot be prevented, the substance

needs to be suck off at the emersion point, if possible without danger. Observe

the exposure limits, clean exhaust air if needed. If recycling is not practicable,

dispose of in compliance with local regulations. Inform the responsible

authorities in case of leakage into the atmosphere, or of entry into waterways,

soil or drains.

Environmental Precautions

Should not be released into the environment

9. PHYSICAL AND CHEMICAL PROPERTIES

9.1 Information on basic physical and chemical properties

Appearance

a) Physical state Liquid

b) Colour Colourless

c) Odour Weak

d) Molecular Weight 90.12

e) Molecular Formula C4H10O2

f) Flash point 115 °C (method: ISO 2719)

g) Auto-ignition temperature 410 °C (Method: DIN 51794)

h) Lower explosion limit 1.9 VOL %

i) Upper explosion limit 12.6 VOL %

j) Melting point/range -57 °C

k) Boiling point/range 209 °C @1013 hPa

l) Refractive index 1.440 @ 20 °C

m) Viscosity 131.8 mPa*s @ 20 °C (Method: DIN

51562-Dynamic)

n) pH 6.1 (500 g/l in water @ 20 °C (68 °F))

o) Water solubility Miscible, OECD 105

p) log Pow -0.9 (measured), OECD 117

q) Vapour density 3.2 (Air = 1) @ 20 °C (68 °F)

r) Surface tension 72.6 mN/m (1 g/l @ 20°C), OECD

115

MATERIAL SAFETY DATA SHEET (1,3-Butylene glycol)

Vapour Pressure

Values [hPa] @0 C @0 F

<1 20 68

1.8 50 122

Density

Values [g/cm3] @0 C @0 F Method

1,0035 20 68 DIN51757

Remark

Hygroscopic.

10. STABILITY AND REACTIVITY

Chemical Stability

Stable under recommended storage conditions

Conditions to avoid

Avoid contact with heat, sparks, open flame and static discharge. Avoid any

source of ignition

Incompatible Materials

Keep away from: Strong oxidizing agents

Hazardous decomposition products

No decomposition if stored and applied as directed

11.TOXICOLOGICAL INFORMATION

Principle Routes of Exposure Inhalation, Eye contact, Skin contact, Ingestion

1,3-Butylene glycol (Butane-1,3-diol) (107-88-0)

Routes of Exposure Endpoint Values Species Method

Oral LD50 22800 mg/kg rat, male

Inhalative LC0 290 mg/m³ rat, male OECD 403

Irritation and corrosion

(Butane-1,3-diol) (107-88-0)

Target Organ Effects Species Result Method

Skin rabbit No skin irritation

MATERIAL SAFETY DATA SHEET (1,3-Butylene glycol)

Eyes rabbit Mild eye irritation

Sensitization

(Butane-1,3-diol) (107-88-0)

Target Organ Effects Species Evaluation Method

Skin Human experience not sensitizing Patch-test

Subacute, subchronic and prolonged toxicity

(Butane-1,3-diol) (107-88-0)

Type Dose Species Method

Chronic toxicity NOAEL: 5000 rat, male/female Oral two-year

mg/kg/d

Carcinogenicity, Mutagenicity, Reproductive toxicity

(Butane-1,3-diol) (107-88-0)

Type Dose Species Evaluation Method

Mutagenicity Rat, Negative In vivo

male/female

Reproductive Toxicity LOAEL 12000 Rat Oral

mg/kg/d

Reproductive Toxicity NOAEL 5000 Rat Oral

mg/kg/d

Developmental Toxicity NOAEL 2500 Rat Oral Maternal

mg/kg/d toxicity

Developmental Toxicity NOAEL 12000 Rat Oral Teratogenicity

mg/kg/d

Developmental Toxicity LOAEL 5000 Rat Oral Fetal toxicity

mg/kg/d

Developmental Toxicity NOAEL 2500 Rat Oral Fetal toxicity

mg/kg/d

Carcinogenicity NOAEL 5000 Rat Oral

Mg/kg/d

Main symptoms

Cough.

Note

Handle in accordance with good industrial hygiene and safety practice

12. ECOLOGICAL INFORMATION

Acute aquatic toxicity

MATERIAL SAFETY DATA SHEET (1,3-Butylene glycol)

1,3-Butylene glycol (Butane-1,3-diol) (107-88-0)

Species Exposure Time Dose Method

Daphnia magna (Water flea) 48H EC50: > 1000 mg/l OECD202

Desmodesmus subspicatus 72H EC50: > 1070 mg/l OECD201

(growth period)

Oryzias latipes (Medaka) 96H LC50: > 100 mg/l OECD203

Activated sludge (bacteriae) 3H EC20: > 100 mg/l OECD 209

Long term toxicity

Type Species Dose Method

Reproductive toxicity Daphnia magna (Water flea) EC50: > 85 mg/l/21d OECD 202

Biodegradation

81 % (29 d), activated sludge (domestic) aerobic, non-adapted, OECD

301 B.

PBT and vPvB assessment

This substance is not considered to be persistent, bioaccumulating nor toxic

(PBT), nor very persistent nor very bioaccumulating (vPvB)

Note

Avoid release to the environment

13. DISPOSAL CONSIDERATIONS

Product Information

Disposal required in compliance with all waste management related state and

local regulations. The choice of the appropriate method of disposal depends on

the product composition by the time of disposal as well as the local statutes and

possibilities for disposal.

Uncleaned empty packaging

Contaminated packaging should be emptied as far as possible and after

appropriate cleansing may be taken for reuse.

14. TRANSPORT INFORMATION

ADR/RID

UN/ID No.

MATERIAL SAFETY DATA SHEET (1,3-Butylene glycol)

Proper Shipping Name 1,3 Butylene Glycol

Hazard Class

Subsidiary Risk

Classification Code

Packing group

Environmentally hazardous no

Tunnel Restriction Code

Hazard Label(s)

Hazard Number

ADNR

ADNR Container and Tanker

UN/ID No.

Proper Shipping Name 1,3 Butylene Glycol

Hazard Class

Subsidiary Risk

Classification Code

Packing group

Environmentally hazardous

Hazard Labels

ICAO/IATA Non restricted

IMDG

UN/ID No.

Proper Shipping Name 1,3 Butylene Glycol

Hazard Class

Subsidiary Risk

Packing group

Marine pollutant

Hazard Labels

EMS Code

15. REGULATORY INFORMATION

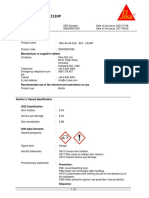

GHS & CLP

Based on present data no classification and labelling is required according to

Directive 1272/2008/EC and its amendments (CLP Regulation, GHS). (See

chapter 2)

MATERIAL SAFETY DATA SHEET (1,3-Butylene glycol)

International Inventories

Listed on the chemical inventories of the following countries or qualifies for an

exemption:

Australia (AICS)

Canada (DSL)

China (IECSC)

Europe (EINECS)

Japan (ENCS)

Japan (ISHL)

Korea (KECI)

New Zealand (NZIoC)

Philippines (PICCS)

United States (TSCA)***

16. OTHER INFORMATION

Other Information:

• Observe national and local legal requirements

Changes against the previous version are marked by ***

Training advice

Make sure that employees are aware of the hazards / risks as detailed on this

Safety Data Sheet. When wearing a breathing apparatus, the need for

appropriate training needs to be considered

Sources of key data used to compile the datasheet

Information contained in this safety data sheet is based on data from public

sources deemed valid or acceptable. The absence of data elements required

by ANSI or 1907/2006/EC indicates that no data meeting these requirements is

available***

Abbreviation and Acronym:

ADR = Accord européen sur le transport des marchandises dangereuses par

Route (European Agreement

concerning the International Carriage of Dangerous Goods by Road)

CAS = Chemical Abstracts Service (division of the American Chemical Society)

CLP = Classification, Labelling and Packaging

DNEL = Derived No Effect Level

EINECS = European Inventory of Existing Commercial Chemical Substances

GHS = Globally Harmonized System of Classification and Labelling of Chemicals

MATERIAL SAFETY DATA SHEET (1,3-Butylene glycol)

IATA = International Air Transport Association

IBC Code = International Code for the Construction and Equipment of Ships

Carrying Dangerous Chemicals in Bulk

(IMO)

ICAO = International Civil Aviation Organization

IMDG = International Maritime Code for Dangerous Goods

LC50 = Lethal Concentration

LD50 = Lethal Dose

LOAEC = Low Observed Adverse Effect Concentration

LOAEL = Low Observed Adverse Effect Level

LOEL = Low Observed Effect Level

MEST = Mouse Ear Swelling Test

NOAEC = No Observed Adverse Effect Concentration

NOAEL = No Observed Adverse Effect Level

NOEC = No Observed Effect Concentration

NOEL = No Observed Effect Level

PBT = Persistent, Bioaccumulative and Toxic

PNEC = Predicted No Effect Concentration

RCR = Risk Characterization Ratio

RID = Règlement international concernant le transport des marchandises

dangereuses par chemin de fer (Regulations Concerning the International

Transport of Dangerous Goods by Rail)

R-Phrases = Risk Phrases

S-Phrases = Safety Phrases

STOT RE = Specific Target Organ Toxicity Repeated Exposure

STOT SE = Specific Target Organ Toxicity Single Exposure

STP = Sewage Treatment Plant

vPvB = very Persistent and very Bioaccumulative***

The information in this safety data sheet is based on data and samples

provided. The sheet was written to the best of our ability and according to the

state of knowledge at that time. The safety data sheet only constitutes a

guideline for the safe handling, use, consumption, storage, transport and

disposal of the substances/preparations/mixtures mentioned under point 1. New

safety data sheets are written from time to time. Only the most recent versions

may be used. Old versions must be destroyed. Unless indicated otherwise word

for word on the safety data sheet, the information does not apply to

substances/preparations/mixtures in purer form, mixed with other substances or

in processes.

MATERIAL SAFETY DATA SHEET (1,3-Butylene glycol)

The safety data sheet offers no quality specification for the

substances/preparations/mixtures in question. Compliance with the instructions

in this safety data sheet does not release the user from the obligation to take all

measures dictated by common sense, regulations and recommendations or

which are necessary and/or useful based on the real applicable circumstances.

GBL does not guarantee the accuracy or exhaustiveness of the information

provided.

MATERIAL SAFETY DATA SHEET (1,3-Butylene glycol)

You might also like

- AZG 368 Aluminum - Zirconium Tetrachlorohydrex-Gly, USPDocument6 pagesAZG 368 Aluminum - Zirconium Tetrachlorohydrex-Gly, USPZi LiNo ratings yet

- Butyl Acrylate (Cas 141-32-2) MSDSDocument6 pagesButyl Acrylate (Cas 141-32-2) MSDSfdt895thNo ratings yet

- Material Safety Data Sheet: Polyethylene TerephthalateDocument4 pagesMaterial Safety Data Sheet: Polyethylene Terephthalatesaeful anwarNo ratings yet

- MSDS PLA-Crystal-Clear EN 07122018Document6 pagesMSDS PLA-Crystal-Clear EN 07122018AngelNo ratings yet

- 1,4-Butylene Glycol - 2023 - February - 02 - CB4452184 - Any - Any1Document9 pages1,4-Butylene Glycol - 2023 - February - 02 - CB4452184 - Any - Any1Someone elseNo ratings yet

- Melina 30 - MSDSDocument7 pagesMelina 30 - MSDSBeryl FernandesNo ratings yet

- Corena S2 P68Document7 pagesCorena S2 P68Beryl FernandesNo ratings yet

- Safety Data Sheet for Nitobond SBRDocument7 pagesSafety Data Sheet for Nitobond SBRusman khalidNo ratings yet

- AntifreezeDocument12 pagesAntifreezeArdyas Wisnu BaskoroNo ratings yet

- Safety Data Sheet Nitobond Ar: Revision Date: 09/06/2015 Revision: 3aDocument7 pagesSafety Data Sheet Nitobond Ar: Revision Date: 09/06/2015 Revision: 3afaisal nadeemNo ratings yet

- 10.SDS-Nitofill-UR63-IndiaDocument16 pages10.SDS-Nitofill-UR63-IndiaVajbayee elangovanNo ratings yet

- Corena S2 P150Document7 pagesCorena S2 P150Beryl FernandesNo ratings yet

- Resina Ceramica CoppsDocument12 pagesResina Ceramica CoppsAlex SuarezNo ratings yet

- 6300-Weber - Kol SRK Safety Data Sheet: Saint-Gobain Weber Yapi Kim. San. Ve Tic. A.SDocument10 pages6300-Weber - Kol SRK Safety Data Sheet: Saint-Gobain Weber Yapi Kim. San. Ve Tic. A.SGökhan PanpaNo ratings yet

- Fisa Tehnica Alcool Etilic 2019-EnglezaDocument7 pagesFisa Tehnica Alcool Etilic 2019-EnglezaMADALINA LAZARNo ratings yet

- modified starch MSDSDocument5 pagesmodified starch MSDSdewi.mizobataNo ratings yet

- Corena S3 R 32Document7 pagesCorena S3 R 32Beryl Fernandes0% (1)

- Argina X40 - MSDSDocument7 pagesArgina X40 - MSDSBeryl FernandesNo ratings yet

- Corena S3 R 46Document7 pagesCorena S3 R 46Beryl FernandesNo ratings yet

- Corena S2 P100Document7 pagesCorena S2 P100Beryl FernandesNo ratings yet

- SRB-Universal Transmission Oil MSDSDocument7 pagesSRB-Universal Transmission Oil MSDSBen WigginsNo ratings yet

- Safety Data Sheet: Tokyo Chemical Industry Co., LTDDocument5 pagesSafety Data Sheet: Tokyo Chemical Industry Co., LTDJonny DenNo ratings yet

- Gadinia AL30 - MSDSDocument6 pagesGadinia AL30 - MSDSBeryl FernandesNo ratings yet

- En AuDocument10 pagesEn AumajidhajnasrNo ratings yet

- Safety-Data-Sheet Nonoilen EN 18022021 FFNDocument7 pagesSafety-Data-Sheet Nonoilen EN 18022021 FFNAngelNo ratings yet

- Omala S2 G 68Document7 pagesOmala S2 G 68Beryl FernandesNo ratings yet

- SP179 Hand SanitiserDocument7 pagesSP179 Hand SanitiserJohn GeddesNo ratings yet

- Naterol N70 MSDSDocument9 pagesNaterol N70 MSDSMohammed IsmailNo ratings yet

- Safety Data Sheet Blend of Polyalkylene Glycol and AdditivesDocument6 pagesSafety Data Sheet Blend of Polyalkylene Glycol and AdditivesmelvinkuriNo ratings yet

- Cedar Fiber: Safety Data SheetDocument5 pagesCedar Fiber: Safety Data SheetmikeNo ratings yet

- 2-Ethylhexanol: 2-Ethylhexanol Safety Data SheetDocument8 pages2-Ethylhexanol: 2-Ethylhexanol Safety Data SheetmishaNo ratings yet

- Safety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/UndertakingDocument13 pagesSafety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/Undertakingayman emmadNo ratings yet

- Acetic AnhydrideDocument5 pagesAcetic AnhydrideChern YuanNo ratings yet

- Baymer 23BC005i - MSDSDocument16 pagesBaymer 23BC005i - MSDSjosira6121No ratings yet

- Product Identification and Manufacture Information.: Msds-1Document4 pagesProduct Identification and Manufacture Information.: Msds-1hse indacoNo ratings yet

- SDS Nitobond AR May 2013Document6 pagesSDS Nitobond AR May 2013Muhammad Haris KhattakNo ratings yet

- Di-Tert-Butyl Dicarbonate (Cas 24424-99-5) MSDSDocument6 pagesDi-Tert-Butyl Dicarbonate (Cas 24424-99-5) MSDS4edcqweNo ratings yet

- Strontium CarbonateDocument7 pagesStrontium Carbonatetrishala shahiNo ratings yet

- MSDS - Shell Madrela - Compressor OilDocument7 pagesMSDS - Shell Madrela - Compressor OilAnonymous LfeGI2hMNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument10 pagesSafety Data Sheet: 1. Identificationthehoang12310No ratings yet

- Sherwin Williams Internal Sprays SDSDocument9 pagesSherwin Williams Internal Sprays SDSJoe de Tracy GouldNo ratings yet

- En AuDocument10 pagesEn AuÖzlem YılmazNo ratings yet

- Safety Data Sheet for Mono Propylene GlycolDocument7 pagesSafety Data Sheet for Mono Propylene GlycolSACO QCNo ratings yet

- Lithium Hydroxide MonohydrateDocument6 pagesLithium Hydroxide MonohydratemeimeiliuNo ratings yet

- Safety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/UndertakingDocument8 pagesSafety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/UndertakingAung SilalaNo ratings yet

- Gadus S5 U130D 2Document8 pagesGadus S5 U130D 2Beryl FernandesNo ratings yet

- Premise 200 SC Termiticide PDF 37kbDocument8 pagesPremise 200 SC Termiticide PDF 37kbMYUTILITYNo ratings yet

- Gadinia 30 - MSDSDocument7 pagesGadinia 30 - MSDSBeryl FernandesNo ratings yet

- Propylene Glycol 2000Document8 pagesPropylene Glycol 2000Sechaba NobleNo ratings yet

- Naterol 70 MSDSDocument8 pagesNaterol 70 MSDSMohammed IsmailNo ratings yet

- Msds - Alcohol GelDocument5 pagesMsds - Alcohol Gelnita susiawatiNo ratings yet

- IC 1190msdsDocument8 pagesIC 1190msdsBNo ratings yet

- MSDS Acetaldehyde SolutionDocument7 pagesMSDS Acetaldehyde Solutionhi thereNo ratings yet

- 2 Aminoterephthalic AcidDocument9 pages2 Aminoterephthalic AcidLila AdelNo ratings yet

- MSDS Al2O3Document7 pagesMSDS Al2O3Mas BagusNo ratings yet

- TYRIN-200Document10 pagesTYRIN-200Nicol AlejandraNo ratings yet

- Self-Cleaning Materials and Surfaces: A Nanotechnology ApproachFrom EverandSelf-Cleaning Materials and Surfaces: A Nanotechnology ApproachWalid A. DaoudRating: 5 out of 5 stars5/5 (1)

- Cleaning and disinfection of food factories: a practical guideFrom EverandCleaning and disinfection of food factories: a practical guideNo ratings yet

- Georgia Pest Management Handbook: 2021 Home and Garden EditionFrom EverandGeorgia Pest Management Handbook: 2021 Home and Garden EditionEmily CabreraNo ratings yet

- Antil 141Document10 pagesAntil 141Ashok MauryaNo ratings yet

- Ajidew NL-50 - SDS - enDocument4 pagesAjidew NL-50 - SDS - enAshok MauryaNo ratings yet

- 4 ButylresorcinolDocument6 pages4 ButylresorcinolAshok MauryaNo ratings yet

- RDS - AMP Ultra PC 2000Document17 pagesRDS - AMP Ultra PC 2000Ashok MauryaNo ratings yet

- DM HSD GU99 SSW2 - Technical Guideline On Safety Signs at WorkDocument30 pagesDM HSD GU99 SSW2 - Technical Guideline On Safety Signs at WorkNatalie BlackmoreNo ratings yet

- MSDS ThievesDocument11 pagesMSDS ThievesATOMY KESEHATANNo ratings yet

- PPAP 4th EdDocument11 pagesPPAP 4th EdEd Ri0% (1)

- MSDS - Sikafloor 291 Comp. CDocument7 pagesMSDS - Sikafloor 291 Comp. CGabriel GabeNo ratings yet

- Flowtain SDSDocument7 pagesFlowtain SDSCernei Eduard RaduNo ratings yet

- SDS - Stikwel 469L-LVDocument7 pagesSDS - Stikwel 469L-LVmonik manuelNo ratings yet

- Sblreddye PDFDocument8 pagesSblreddye PDFRonald Figo Torres EcheNo ratings yet

- ECOLAB CIP SDS - LiquidCipCleaner - VirtuePlus - EcolabDocument10 pagesECOLAB CIP SDS - LiquidCipCleaner - VirtuePlus - EcolabLas Vegas Global ServicesNo ratings yet

- Sika Grout 212 215 212hp - MsdsDocument9 pagesSika Grout 212 215 212hp - MsdsPeralatan Divisi3No ratings yet

- Manufacturer MSDS - Caffeine Anhydrous Ex Hebei Guanxiang - 01.01.2020Document9 pagesManufacturer MSDS - Caffeine Anhydrous Ex Hebei Guanxiang - 01.01.2020ricardoNo ratings yet

- A7XN-RC-85-SP-0022-R3 External PaintingDocument46 pagesA7XN-RC-85-SP-0022-R3 External PaintingAriel InsaurraldeNo ratings yet

- Taiba Cococharcoal MSDSDocument8 pagesTaiba Cococharcoal MSDSHarapan AronNo ratings yet

- Antimussol UDF LiqDocument10 pagesAntimussol UDF Liqraju_hosssenNo ratings yet

- Safety Data Sheet: According To 1907/2006/EC, Article 31Document6 pagesSafety Data Sheet: According To 1907/2006/EC, Article 31Özlem YılmazNo ratings yet

- Urea MSDS AbfDocument9 pagesUrea MSDS AbfPKNo ratings yet

- Safety Data Sheet for ELASTAN KC 6565/3 C-B Polymeric MDIDocument12 pagesSafety Data Sheet for ELASTAN KC 6565/3 C-B Polymeric MDIwahyuniNo ratings yet

- Pomoclean TRDS SDSDocument3 pagesPomoclean TRDS SDSgurinder pal singhNo ratings yet

- Safety Data Sheet for LGMT 2 LubricantDocument7 pagesSafety Data Sheet for LGMT 2 LubricantJonathan Aguilar CortésNo ratings yet

- Carburetor Cleaner-MSDSDocument9 pagesCarburetor Cleaner-MSDSJONATHAN CASTRONo ratings yet

- MSDS-Etidronic AcidDocument7 pagesMSDS-Etidronic Acidherbi naturalsNo ratings yet

- Safety Data Sheet: 1. Chemical Product and Company IdentificationDocument6 pagesSafety Data Sheet: 1. Chemical Product and Company IdentificationNguyễn Thị ThúyNo ratings yet

- SDS Gta 733Document12 pagesSDS Gta 733harlendri STNo ratings yet

- K-37 Septic Tank Treatment SDSDocument7 pagesK-37 Septic Tank Treatment SDSRicardo AlvaradoNo ratings yet

- SDS US - Crystal Clean 142 Mineral Spirits (915876) Revision Date 2-11-15Document7 pagesSDS US - Crystal Clean 142 Mineral Spirits (915876) Revision Date 2-11-15ashadeofdarknessNo ratings yet

- MSDS Makeup Solvent Jet Print Best CodeDocument19 pagesMSDS Makeup Solvent Jet Print Best CodeHSE PT. MASNo ratings yet

- Rittal Safety Data Sheet Cooling Medium For Recooling (CH 5 2956Document15 pagesRittal Safety Data Sheet Cooling Medium For Recooling (CH 5 2956Chung NguyenNo ratings yet

- GHS SDS - E - SikaGrout - 212 HP - 2014Document8 pagesGHS SDS - E - SikaGrout - 212 HP - 20144919404No ratings yet

- Corrosion Inhibitor Safety Data SheetDocument6 pagesCorrosion Inhibitor Safety Data SheetLIZNo ratings yet

- Safety Data Sheet: Intertherm 50 AluminiumDocument14 pagesSafety Data Sheet: Intertherm 50 AluminiumHari Shewa DR1No ratings yet

- Safety Data Sheet: Chimassorb 2020 FDLDocument9 pagesSafety Data Sheet: Chimassorb 2020 FDLWing ZenandNo ratings yet