Professional Documents

Culture Documents

35140953826

Uploaded by

thomasnafCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

35140953826

Uploaded by

thomasnafCopyright:

Available Formats

British standard whitworth thread chart pdf

British standard for metric threads. Whitworth thread specifications. What is british standard thread.

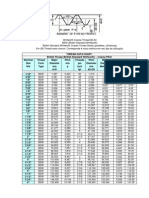

BSW 55 Degree Threads SIZE TPI EXTERNAL INTERNAL DRILL SIZE DRILL SIZE BSW 55 MAJORS MINORS CLEARANCE HOLE TAPPED HOLE INCH MM INCH MM INCH MM INCH MM 1/16 60 0.0620 1.59 0.0410 1.05 1.99 3/32 48 0.0940 2.38 0.0670 1.70 2.67 1/8 40 0.1250 3.18 0.0930 2.36 9/64 3.57 # 38 5/32 32 0.1560 3.97 0.1160

2.95 11/64 4.37 1/8 3/16 24 0.1870 4.75 0.1340 3.40 13/64 5.16 # 27 7/32 24 0.2190 5.60 0.1660 4.22 15/64 5.95 # 19 1/4 20 0.2500 6.35 0.1860 4.72 17/64 6.75 # 9 5/16 18 0.3120 7.92 0.2410 6.12 21/64 8.33 1/4 3/8 16 0.3750 9.53 0.2950 7.49 25/64 9.92 5/16 7/16 14 0.4370 11.10 0.3460 8.79 29/64 11.51 U 1/2 12 0.5000 12.70 0.3930 9.98 17/32

13.49 27/64 9/16 12 0.5630 14.29 0.4560 11.58 19/32 15.08 15/32 5/8 11 0.6250 15.88 0.5090 12.93 21/32 16.67 17/32 11/16 11 0.6880 17.48 0.5710 14.50 17.75 3/4 10 0.7500 19.05 0.6220 15.80 25/32 19.84 21/32 13/16 10 0.8130 20.65 0.6840 17.37 21.00 7/8 9 0.8750 22.23 0.7330 18.62 29/32 23.02 49/64 15/16 9 0.9380 23.83 0.7950 20.19

24.00 1 8 1.0000 25.40 0.8400 21.34 1 1/16 26.99 7/8 1 1/8 7 1.1250 28.58 0.9420 23.93 1 3/16 30.16 1 1 1/4 7 1.2500 31.75 1.0670 27.10 1 5/16 33.34 1 7/16 1 3/8 6 1.3750 34.93 1.1620 29.51 1 7/16 36.51 1 7/32 1 1/2 6 1.5000 38.10 1.2870 32.69 1 9/16 39.69 1 11/32 1 5/8 5 1.6250 41.28 1.3690 34.77 41.50 1 3/4 5 1.7500 44.45 1.4940 37.95

45.00 1 7/8 4.5 1.8750 47.63 1.5910 40.40 48.00 2 4.5 2.0000 50.80 1.7150 43.57 51.00 2 1/4 4 To bookmark this page you need to Sign in Not yet registered? Register for free BSW is an imperial-unit-based screw thread standard, devised and specified by Joseph Whitworth in 1841 and later adopted as a British Standard. It was the

world’s first national screw thread standard, and is the basis for many other standards, such as BSF, BSP, BSCon, and BSCopper.

British Standard Fine (BSF) is a screw thread form, as a fine-pitch alternative to British Standard Whitworth (BSW) thread.

It was used for steel bolts and nuts on much British machinery, including cars, prior to adoption of Unified, and later Metric, standards. For highly stressed conditions, especially in motorcycles, a finer thread, British Standard Cycle (BSC), was used as well. Tolerances should be considered when designing products. Values related to drilling and

tapping can differ significantly depending on factors such as operating temperature and material. Optimas are a full-service supply chain and manufacturing solutions provider. Before you design your next product or make updates to an existing product, consider partnering with Optimas to take advantage of our many capabilities. The Whitworth

thread was the world's first national screw thread standard devised and specified by Joseph Whitworth in 1841. Until then, the only standardization was what little had been done by individual people and companies. Some of the companies' in-house standards spreading a bit within their industries. Whitworth's new standard specified a 55° thread

angle and a thread depth of 0.640327p and a radius of 0.137329p. Where p is the pitch. The thread pitch increases with the diameter in steps specified on a chart. The Whitworth thread system was later to be adopted as a British Standard to become British Standard Whitworth (BSW). An example of the use of the Whitworth thread is the Royal

Navy's Crimean War gunboats. These are the first instance of mass-production techniques being applied to marine engineering. The following quotation from the obituary from The Times of 24 January 1887 to Sir Joseph Whitworth (1803–1887) shows. The British Standard Fine (BSF) standard has the same thread angle as the BSW but has a finer

thread pitch and smaller thread depth. This is more like the modern "mechanical" screw and was used for fine machinery and steel bolts.

The British Standard Cycle (BSC) standard which replaced the Cycle Engineers' Institute (CEI) standard was used on British bicycles and motorcycles.

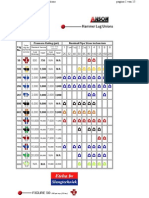

It uses a thread angle of 60° compared to the Whitworth 55° and very fine thread pitches. British Standard Pipe Parallel Thread, with sealant compound,(parallel, cylindrical), external = G. The flank angle is 55°.NominalDiameterMajorDiameterInchMajorDiametermmMinor DiamterNutmmTappingDrill SizemmTPIPitchmmG

1/16"0.3047.7226.8436.561280.907G 1/8"0.3839.7288.8488.565280.907G 1/4"0.51813.15711.89011.445191.337G 3/8"0.65616.66215.39514.950191.337G 1/2"0.82520.95519.17218.633141.814G 5/8"0.90222.91121.12820.587141.814G 3/4"1.04126.44124.65824.120141.814G 7/8"1.18930.20128.41827.877141.814G

1"1.30933.24930.93130.292112.309G 1 1/8"1.49237.89735.57934.939112.309G 1 1/4"1.65041.91039.59238.953112.309G 1 3/8"1.74544.32342.00541.365112.309G 1 1/2"1.88247.80345.48544.846112.309G 1 5/8"2.08252.88350.56649.926112.309G 1 3/4"2.11653.74651.42850.788112.309G 1 7/8"2.24456.99854.68154.041112.309G

2"2.34759.61457.29656.657112.309G 2 1/4"2.58765.71062.75263.392112.309G 2 1/2"2.96075.18473.39172.227112.309G 2 3/4"3.21081.53478.57679.216112.309G 3"3.46087.88486.28984.927112.309G 3 1/2"3.950100.33097.37298.012112.309G 4"4.450113.030111.733110.073112.309G 4 1/2"4.950125.730122.772123.412112.309G

5"5.450138.430137.332135.473112.309G 5 1/2"5.950151.130148.172148.812112.309G 6"6.450163.830162.732160.873112.309

You might also like

- British Standard Whitworth - Wikipedia, The Free EncyclopediaDocument2 pagesBritish Standard Whitworth - Wikipedia, The Free EncyclopediaIvan DuncanNo ratings yet

- BRITISH THREAD PITCH BSWDocument1 pageBRITISH THREAD PITCH BSWhisaj4uNo ratings yet

- Thread Specifications GuideDocument30 pagesThread Specifications GuidesoparlNo ratings yet

- A Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersFrom EverandA Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersRating: 3.5 out of 5 stars3.5/5 (19)

- BS 3799Document28 pagesBS 3799Nigel FiresNo ratings yet

- Off-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderFrom EverandOff-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderRating: 5 out of 5 stars5/5 (2)

- Tabale de ParafusoDocument54 pagesTabale de ParafusoSilas MendesNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- BSP ThreadsDocument3 pagesBSP ThreadssatphoenixNo ratings yet

- BS 3799 1974 Specification For Steel Pipe Fittings, Screwed and Socket-Welding For The Petroleum IndustryDocument26 pagesBS 3799 1974 Specification For Steel Pipe Fittings, Screwed and Socket-Welding For The Petroleum Industrycaleshu100% (2)

- Screwcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsFrom EverandScrewcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsNo ratings yet

- Technical Data: Section 7 BritishDocument1 pageTechnical Data: Section 7 BritishUrip S. SetyadjiNo ratings yet

- Brittle Fracture in Steel StructuresFrom EverandBrittle Fracture in Steel StructuresG.M. BoydNo ratings yet

- F BSW-Thread-ChartDocument3 pagesF BSW-Thread-Chartsergio_daq100% (2)

- Section 10 Useful Information: British Screw ThreadsDocument1 pageSection 10 Useful Information: British Screw ThreadsrefaeNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- SprocketsDocument38 pagesSprocketssurachsNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Engineering Thread DataDocument26 pagesEngineering Thread DataJaveed A. KhanNo ratings yet

- Identifying Threads Identifying Threads: How To Use The CaliperDocument6 pagesIdentifying Threads Identifying Threads: How To Use The CaliperkyletgerberNo ratings yet

- InformationDocument38 pagesInformationashoksiva100% (1)

- Tapping Drill IS 10952Document6 pagesTapping Drill IS 10952George ThomasNo ratings yet

- BS 4395 Part-1Document28 pagesBS 4395 Part-1kunjal_radiaNo ratings yet

- The Evolution of Screw ThreadsDocument3 pagesThe Evolution of Screw ThreadsanukrithikaNo ratings yet

- Bs 4395 1 1969Document37 pagesBs 4395 1 1969galind0100% (1)

- Bolts TechnicalData PDFDocument48 pagesBolts TechnicalData PDFAnonymous smFxIR07No ratings yet

- Thread DataDocument13 pagesThread DataajujkNo ratings yet

- BRITISH THREAD DATA CHARTSDocument6 pagesBRITISH THREAD DATA CHARTSVishnuGKNo ratings yet

- Machine Screw ThreadsDocument2 pagesMachine Screw ThreadsMoaed KanbarNo ratings yet

- Bs 3600Document12 pagesBs 3600Lucian ChituNo ratings yet

- Nuts and BoltsDocument58 pagesNuts and Boltsbruteforce2000100% (2)

- Power Generation Boiler Tubes GuideDocument12 pagesPower Generation Boiler Tubes GuidewalitedisonNo ratings yet

- UNC Thread Specifications ANSI B1.1 StandardDocument2 pagesUNC Thread Specifications ANSI B1.1 Standardgmascini9893No ratings yet

- Spanner Jaw SizesDocument7 pagesSpanner Jaw SizesSHIVANo ratings yet

- 03 Wire Rope Strand TerminationsDocument20 pages03 Wire Rope Strand Terminationsoluomo1No ratings yet

- ISO metric screw thread standards and profilesDocument18 pagesISO metric screw thread standards and profilesKalai KjNo ratings yet

- BS 3410 1961 WashersDocument20 pagesBS 3410 1961 WashersAndy TaylorNo ratings yet

- Threads - Metric ISO 724Document5 pagesThreads - Metric ISO 724sathishNo ratings yet

- BS 46-1-1958 (Keys & Keyways)Document36 pagesBS 46-1-1958 (Keys & Keyways)Cinmon100% (2)

- Rosca BSW-BSFDocument1 pageRosca BSW-BSFRafaSegadesNo ratings yet

- Trainees Digest: Picking Up The Thread From The CARTOON atDocument2 pagesTrainees Digest: Picking Up The Thread From The CARTOON atSaiful IslamNo ratings yet

- Tool HoldersDocument35 pagesTool HoldersCarlos Santos Ramirez MarañonNo ratings yet

- Understanding - Unbrako Fasteners (Technical Brochure)Document48 pagesUnderstanding - Unbrako Fasteners (Technical Brochure)pavan_jssatebNo ratings yet

- General information on hose fitting part numbers, thread types and dimensionsDocument6 pagesGeneral information on hose fitting part numbers, thread types and dimensionsFelix RanillaNo ratings yet

- SCI - P324 - The Use of Tension Control Bolts Grade SIOT in Friction Grip ConnectionsDocument84 pagesSCI - P324 - The Use of Tension Control Bolts Grade SIOT in Friction Grip ConnectionsLathesh JanarthananNo ratings yet

- QS-03-Steel-Reinforcement-rev-05Document104 pagesQS-03-Steel-Reinforcement-rev-05Crisanto EncilanNo ratings yet

- BCSA - P50-09 Typical Welding Procedure Specifications For Structural Steelwork - Welding BookDocument0 pagesBCSA - P50-09 Typical Welding Procedure Specifications For Structural Steelwork - Welding BookDifa Liu100% (1)

- Hamerlug Unions (Anson)Document15 pagesHamerlug Unions (Anson)Leonardo ViannaNo ratings yet

- BS 919-2-2007 Screw Gauge Limits and Tolerances - Part 2 Specification For Gauges For Screw Threads of Whitworth and B.A. FormsDocument42 pagesBS 919-2-2007 Screw Gauge Limits and Tolerances - Part 2 Specification For Gauges For Screw Threads of Whitworth and B.A. FormsAshwanth Ramesh100% (1)

- ARAB BOLTS IMPORTER & EXPORTER OF ALL TYPE FASTENERSDocument80 pagesARAB BOLTS IMPORTER & EXPORTER OF ALL TYPE FASTENERSZahid Iqbal100% (2)

- CATÁLOGO IsomeltMini.D4 PUR - EN - LRDocument2 pagesCATÁLOGO IsomeltMini.D4 PUR - EN - LRCaio OliveiraNo ratings yet

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10016-2Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10016-2farshid KarpasandNo ratings yet

- Introduction To Press Tool DesignDocument118 pagesIntroduction To Press Tool DesignPrashant AmbadekarNo ratings yet

- Wuhan Jianheng Metal Technology CO - LTD 20201015Document20 pagesWuhan Jianheng Metal Technology CO - LTD 20201015梁庆民No ratings yet

- Jase 202112 24 6 0009Document9 pagesJase 202112 24 6 0009sarathNo ratings yet

- CX Tds 2322s EngDocument5 pagesCX Tds 2322s EngKeiwer SuárezNo ratings yet

- Amercoat 383HDocument4 pagesAmercoat 383Humn_mlkNo ratings yet

- Estimates LesDocument28 pagesEstimates LesDon France PascoNo ratings yet

- Mech 204 Takehome Exam 1 of 2020Document2 pagesMech 204 Takehome Exam 1 of 2020Manuel Tikongyin WundengbaNo ratings yet

- RAB Monopole 30M Jabar Area OkkDocument2 pagesRAB Monopole 30M Jabar Area OkkAsep ZamhajiNo ratings yet

- First SolarDocument12 pagesFirst SolarSathya PriyaNo ratings yet

- Stanley William Hayter's New Ways of GravureDocument1 pageStanley William Hayter's New Ways of GravuremaxfilmNo ratings yet

- Tds Dexseal (En)Document2 pagesTds Dexseal (En)Phuong The NguyenNo ratings yet

- Crawler-Mounted-Feeder-Breaker Brochure NA Imperial DigitalDocument2 pagesCrawler-Mounted-Feeder-Breaker Brochure NA Imperial DigitalAxk QueryNo ratings yet

- Rate Analsis Chapter No. 15 (Sheet Pilling)Document16 pagesRate Analsis Chapter No. 15 (Sheet Pilling)M HAFEEZ RAJANo ratings yet

- Wiper BladeDocument3 pagesWiper Bladeghyd artiagaNo ratings yet

- PET For CSD Bottles - Jade PET Resin ChinaDocument2 pagesPET For CSD Bottles - Jade PET Resin ChinaEudy CardozoNo ratings yet

- Schindler Escalator 9700AE - Handrail MaintenanceDocument9 pagesSchindler Escalator 9700AE - Handrail MaintenanceHùng VĩNo ratings yet

- Astm B479 19Document3 pagesAstm B479 19mohamedsamireldeep70No ratings yet

- Competence Overview - New Candidates - BMSDocument19 pagesCompetence Overview - New Candidates - BMSJose DiazNo ratings yet

- E - Catalogue - TAKSU KL - Symphony of Souls - CIMB Artober 2023 - CompressedDocument47 pagesE - Catalogue - TAKSU KL - Symphony of Souls - CIMB Artober 2023 - CompressedDiego WalbergNo ratings yet

- Industrial Parks Guid: Where... Manufacturing MattersDocument48 pagesIndustrial Parks Guid: Where... Manufacturing MattersIbtissam BenayadaNo ratings yet

- Garbage Disposal 5Document7 pagesGarbage Disposal 5John cris SalangsangNo ratings yet

- PAC Metal Roofing Wall and Trim Catalog 2023Document48 pagesPAC Metal Roofing Wall and Trim Catalog 2023THIS IS AWESOMENo ratings yet

- Jayco Plummer Blocks CataloguesDocument45 pagesJayco Plummer Blocks CataloguesInamMuradNo ratings yet

- Working Procedure For Pipes and GatesDocument29 pagesWorking Procedure For Pipes and GatesAdvance Hydro Power Works Pvt. Ltd.No ratings yet

- Denso SeaShield Series 100Document4 pagesDenso SeaShield Series 100Danny RusnaldyNo ratings yet

- PLEXCONCIL Ordinary Members 2022-23Document45 pagesPLEXCONCIL Ordinary Members 2022-23uma maheshwariNo ratings yet

- RM operation SOPsDocument3 pagesRM operation SOPsAlaa MaherNo ratings yet

- Specification For Precast Concrete WorksDocument39 pagesSpecification For Precast Concrete Worksm.nurhishammNo ratings yet