Professional Documents

Culture Documents

ASTM C1622-10 Standard Specification For Cold-Weather Admixture Systems

Uploaded by

benedick barquinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASTM C1622-10 Standard Specification For Cold-Weather Admixture Systems

Uploaded by

benedick barquinCopyright:

Available Formats

Designation: C1622/C1622M − 10 (Reapproved 2016)´1

Standard Specification for

Cold-Weather Admixture Systems1

This standard is issued under the fixed designation C1622/C1622M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε1 NOTE—Editorially corrected ASTM designation references in October 2016.

1. Scope* system shall be used independently of the other. Combining

1.1 This specification covers cold-weather admixture sys- values from the two systems may result in non-conformance

tems to be added to hydraulic-cement concrete when the with the standard.

temperature of the concrete immediately after placement will 1.5 The text of this standard references notes and footnotes,

be as low as -5.0 °C [23.0 °F] prior to the time of initial set. which provide explanatory material. These notes and footnotes

1.2 This specification stipulates tests of the cold-weather (excluding those in tables and figures) shall not be considered

admixture system with suitable materials as described in 11.1 as requirements of the standard.

– 11.3 or with materials proposed for specific work (See 11.5). 1.6 The following precautionary caveat pertains to the test

Unless otherwise requested by the purchaser, tests shall be methods portion, Sections 11 – 18, of this specification. This

made using suitable concreting materials as described in 11.1 – standard does not purport to address all of the safety concerns,

11.3. if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health

NOTE 1—Whenever practicable, tests should be made using the

concreting materials, the mixture proportions, and batching sequence

practices and determine the applicability of regulatory limita-

proposed for the specific work (See 11.5) because the time of setting, tions prior to use. WARNING—Fresh hydraulic cementitious

compressive strength gain, and other properties may vary. mixtures are caustic and may cause chemical burns to skin and

1.3 This specification provides three levels of testing. tissue upon prolonged exposure.2

1.3.1 Level 1—During the initial approval stage, proof of

2. Referenced Documents

compliance with the performance requirements defined in

Table 1 demonstrates that the cold-weather admixture system 2.1 ASTM Standards:3

meets the requirements of this specification. Uniformity and C33/C33M Specification for Concrete Aggregates

equivalence tests (See Section 6) shall be carried out to provide C39/C39M Test Method for Compressive Strength of Cylin-

results against which later comparisons can be made. drical Concrete Specimens

1.3.2 Level 2—Limited retesting is described in 5.2, 5.2.1, C125 Terminology Relating to Concrete and Concrete Ag-

and 5.2.2. Proof of compliance with the requirements of Table gregates

1 demonstrates conformity of the admixture system with the C136/C136M Test Method for Sieve Analysis of Fine and

--`,`,,``,`,`,````,,,,`,,,,```,`-`-`,,`,,`,`,,`---

requirements of this specification. Coarse Aggregates

1.3.3 Level 3—For acceptance of a lot or for measuring C138/C138M Test Method for Density (Unit Weight), Yield,

uniformity within or between lots, when specified by the and Air Content (Gravimetric) of Concrete

purchaser, uniformity and equivalence tests (See Section 6) C143/C143M Test Method for Slump of Hydraulic-Cement

shall be used. Concrete

C150/C150M Specification for Portland Cement

1.4 The values stated in either SI units or inch-pound units

C157/C157M Test Method for Length Change of Hardened

are to be regarded separately as standard. Within the text, the

Hydraulic-Cement Mortar and Concrete

inch-pound units are shown in brackets. The values stated in

C183/C183M Practice for Sampling and the Amount of

each system may not be exact equivalents; therefore, each

Testing of Hydraulic Cement

1 2

This specification is under the jurisdiction of ASTM Committee C09 on Section on Safety Precautions, Manual of Aggregates and Concrete Testing,

Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee Annual Book of ASTM Standards Vol. 04.02.

3

C09.23 on Chemical Admixtures. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2016. Published October 2016. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2005. Last previous edition approved in 2010 as C1622/C1622M-10. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/C1622_C1622M-10R16E01. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

Copyright ASTM International

Provided by IHS Markit under license with ASTM

1Licensee=North-South Commuter Railway Extension (NSCR-EX)/8285720001, User=Lea

No reproduction or networking permitted without license from IHS Not for Resale, 11/12/2021 00:19:38 MST

C1622/C1622M − 10 (2016)´1

TABLE 1 Performance Requirements 3.2 Definitions of Terms Specific to This Standard:

for Cold-Weather AdmixtureA 3.2.1 cold-weather admixture system, n—an admixture or

Time of Initial Setting,

maximum % of controlB

200 group of admixtures that depresses the freezing point of mixing

water and increases the hydration rate of cement in concrete.

Compressive Strength.

minimum % of controlC

3.2.2 control concrete mixture, n—a concrete mixture with-

7 daysD 40 out the cold-weather admixture system.

28 days 80

90 days 90

3.2.3 dummy concrete specimen, n—additional concrete

specimen instrumented with a temperature sensing device to

Length Change, Maximum Shrinkage estimate the temperature of test concrete specimens.

(alternative requirements)E

Percent of ControlB 135 3.2.4 replicate concrete specimen, n—additional time-of-

Increase over control, percentage points 0.010 setting specimen exposed to the same temperature regimen as

Relative Durability Factor, the test concrete specimen.

Minimum % of controlF 80 3.2.5 test concrete mixture, n—a concrete mixture with the

A

B

The values in the table include allowance for normal variation in test results cold weather admixture system.

As an example, in the case of initial time of setting, if the control mixture has a set

time of 4.0 hrs, the test specimens can have a set time up to 8.0 hrs. For length

change, if the control specimen shrinks X units, the test specimen is allowed to 4. Apparatus

shrink up to 1.35X.

C

The compressive strength of the concrete containing the cold-weather admixture 4.1 Low Temperature Environment—A chamber of sufficient

shall not be less than 90 % of that attained at the previous test age. The objective size to subject the test specimens to the specified low tempera-

of this limit is to require that the compressive strength of the cold-weather

admixture concrete shall not decrease with age.

ture and that allows access for laboratory personnel to conduct

D

Because the test specimens will be cool and damp for the 7d compressive test, appropriate tests. The chamber or chambers shall be capable of

it will be necessary to use unbonded caps as described in Practice cooling numerous specimens from their initial temperature to

C1231/C1231M.

E

Alternative requirements, see 17.1.2: Percent of control applies when shrinkage -5.0 6 1 °C [23.0 6 2.0 °F] within the specified elapsed time

of control concrete is 0.030 % or greater; the increase over control limit applies and maintain them at that temperature for the specified time

when shrinkage of control concrete is 0.030 % or less. period.

F

This requirement is applicable only when the cold-weather admixture is to be

used in air-entrained concrete that may be exposed to freezing and thawing while 4.2 Temperature Measuring Equipment—The temperature

wet.

measuring equipment shall be capable of measuring and

recording the temperature at the center of the dummy speci-

mens to 6 1.0 °C [6 2.0 °F] at least every 1⁄2 h for 7 days.

C192/C192M Practice for Making and Curing Concrete Test

Specimens in the Laboratory 4.3 Tools—Molds and tools for preparing test specimens as

C231/C231M Test Method for Air Content of Freshly Mixed described in Practice C192/C192M. Molds shall have lids to

Concrete by the Pressure Method provide for sealed conditions.

C260/C260M Specification for Air-Entraining Admixtures

for Concrete 5. General Requirements

C403/C403M Test Method for Time of Setting of Concrete 5.1 For initial compliance with this specification, the con-

Mixtures by Penetration Resistance crete shall be tested with the cold-weather admixture system

C494/C494M Specification for Chemical Admixtures for for conformance with the requirements in Table 1.

Concrete

5.2 The purchaser is permitted to require limited retesting to

C666/C666M Test Method for Resistance of Concrete to

confirm current compliance of the admixture system to speci-

Rapid Freezing and Thawing

fication requirements. The limited retesting includes measure-

C1064/C1064M Test Method for Temperature of Freshly

ments of physical and performance properties of the admixture

Mixed Hydraulic-Cement Concrete

system as described in 5.2.1 and 5.2.2.

C1231/C1231M Practice for Use of Unbonded Caps in

5.2.1 The physical properties retesting consists of unifor-

Determination of Compressive Strength of Hardened Cy-

mity and equivalence tests of the admixture system for infrared

lindrical Concrete Specimens

absorption spectrum and relative density.

D1193 Specification for Reagent Water

5.2.2 The performance properties retesting consists of time

2.2 American Concrete Institute Standard:4

of initial setting and compressive strength of concrete at 7 and

ACI 211.1 Practice for Selecting Proportions for Normal,

28 days. Purchasers having special requirements are permitted

Heavyweight, and Mass Concrete

to require additional tests.

3. Terminology 5.3 At the request of the purchaser, the manufacturer shall

3.1 Definitions: state in writing that the admixture system supplied for use in

3.1.1 For definitions of terms used in this specification, refer the work is equivalent in all essential respects, including

to Terminology C125. concentration, to the admixture system tested under this

specification.

4

Available from American Concrete Institute (ACI), P.O. Box 9094, Farmington 5.4 At the request of the purchaser, the manufacturer shall

Hills, MI 48333-9094, http://www.aci-int.org. state in writing the chloride content of the admixture system.

--`,`,,``,`,`,````,,,,`,,,,```,`-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS Markit under license with ASTM

2Licensee=North-South Commuter Railway Extension (NSCR-EX)/8285720001, User=Lea

No reproduction or networking permitted without license from IHS Not for Resale, 11/12/2021 00:19:38 MST

C1622/C1622M − 10 (2016)´1

5.5 Tests for uniformity and equivalence, as indicated in 9.3 For the purpose of this specification, it is recognized that

Section 6, shall be made on the initial sample and the results samples will be taken for two reasons:

retained for reference and comparison with the results of 9.3.1 Compliance Tests—A sample taken for evaluating

samples taken elsewhere within the lot or subsequent lots of compliance of a source or lot of cold-weather admixture

admixture supplied to the work. system shall meet the applicable requirements of this specifi-

cation. Samples used to determine conformance with this

6. Uniformity and Equivalence Tests specification shall be composites of grab samples taken from

6.1 When specified by the purchaser, the uniformity of a lot, different locations so that the composite sample will be

or equivalence of multiple lots from the same source shall be representative of the lot.

established by the following requirements: 9.3.2 Uniformity and Equivalence Tests—When specified by

6.1.1 Infrared Analysis—The absorption spectra of the ini- the purchaser, a sample taken for evaluating the uniformity of

tial sample and the test sample, obtained as specified in Section a single lot or equivalence of multiple lots from one source

18, shall exhibit the same pattern of absorption bands in terms shall be tested as provided in Section 6. When uniformity of a

of frequency and intensity. single lot is being determined, grab samples shall be used.

6.1.2 Relative Density (Liquid Admixture)—When tested as When uniformity of multiple lots from the same source is being

specified in Section 18, the relative density (specific gravity) of determined, composite samples from individual lots shall be

subsequent test samples shall not differ from the relative used.

density of the initial sample by more than 10 % of the 9.4 Liquid Admixtures—Liquid admixtures shall be agitated

difference between the relative density of the initial sample and immediately prior to sampling. Grab samples taken for quality

reagent water at the same temperature. Reagent water conform- or uniformity tests shall represent a unit shipment or a single

ing to Specification D1193, Type III or IV, and prepared by production lot. Each grab sample shall be at least 1 L [1 qt]. At

distillation, ion exchange, reverse osmosis, or a combination of least three grab samples of equal portions shall be taken.

these procedures, is acceptable (See Note 2). Composite samples shall be prepared by mixing the grab

6.2 When the nature of the admixture system or analytical samples and the resultant mixture shall provide at least 3 L [3

capability of the purchaser make these procedures unsuitable, qt] for compliance tests. Grab samples shall be taken from

other requirements for uniformity and equivalence from lot to different locations distributed throughout the quantity to be

lot or within a lot shall be established by agreement between represented.

9.4.1 Admixtures in bulk storage tanks shall be sampled

--`,`,,``,`,`,````,,,,`,,,,```,`-`-`,,`,,`,`,,`---

the purchaser and the manufacturer.

equally from the upper, intermediate, and lower levels by

NOTE 2—Oven drying methods are not appropriate for measuring the means of drain cocks in the sides of the tanks or a weighted

oven-dried residue content for cold-weather admixture system because sampling bottle fitted with a stopper that can be removed after

water, present in the form of bound water of hydration, is released slowly

upon drying, and can often lead to highly variable results. Relative density the bottle is lowered to the desired depth.

is an acceptable indication of lot-to-lot uniformity. 9.4.2 Samples shall be stored in impermeable containers

that are resistant to attack by the admixture.

7. Packaging and Marking 9.5 Nonliquid Admixtures—Grab samples taken for compli-

7.1 When the cold-weather admixture system is delivered in ance or uniformity tests shall be at least 1kg [2 lb]. At least four

packages or containers, the proprietary name of the individual grab samples of equal portions shall be taken from not more

admixtures in the system, the designation of this specification, than 2 Mg [2 tons] of admixture. Prepare composite samples by

and the net mass or volume shall be plainly marked thereon. mixing the grab samples and sampling the resultant mixture to

Similar information shall be provided in the shipping informa- provide at least 2.5 kg [5 lb] for the composite sample. Take

tion accompanying packages or bulk shipments of admixture. grab samples from different locations distributed throughout

the quantity to be represented.

8. Storage 9.5.1 Obtain samples of packaged admixtures by means of a

8.1 Store the cold-weather admixture system to permit easy sampler as described in Practice C183/C183M.

access for proper inspection and identification of each 9.5.2 Samples shall be stored in moisture-proof, airtight

shipment, and in a suitable building that will protect the containers.

admixture from moisture absorption if it is a dry admixture or 9.6 Mix samples before testing to ensure uniformity. When

from freezing if it is a liquid admixture. recommended by the manufacturer, dissolve the entire sample

of non-liquid admixture in water prior to testing.

9. Sampling and Testing

9.1 Every facility shall be provided to the purchaser for 10. Rejection

sampling and inspection, either at the point of manufacture or 10.1 For initial compliance testing, the purchaser is permit-

at the site of the work, as specified by the purchaser. ted to reject the cold-weather admixture system if it fails to

9.2 Samples shall be either “grab” or “composite” samples meet any of the requirements of this specification.

as specified by this specification. A grab sample is one obtained 10.2 For the initial retesting, the purchaser is permitted to

in a single operation. A composite sample is one obtained by reject the admixture if it fails to meet any of the requirements

combining three or more grab samples. of Section 6 and applicable parts of Table 1, as defined in 5.2.2.

Copyright ASTM International

Provided by IHS Markit under license with ASTM

3Licensee=North-South Commuter Railway Extension (NSCR-EX)/8285720001, User=Lea

No reproduction or networking permitted without license from IHS Not for Resale, 11/12/2021 00:19:38 MST

C1622/C1622M − 10 (2016)´1

10.3 If, after completion of tests, an admixture has been 11.3.4 Perform sieve analyses on the coarse aggregate

stored at the point of manufacture for more than 6 months prior prepared in 11.3.3.1 by Test Method C136/C136M. Discard

to shipment, or an admixture has been in local storage in the any prepared quantity of aggregate that deviates from the

hands of a vendor for more than 6 months, it shall be retested specified percent passing by more than the amount shown in

before use when requested by the purchaser and is permitted to column 3 below.

be rejected if it fails to conform to this specification. Sieve Specification C33/ Maximum Variation

C33M, from Percent Passing

10.4 Packages and containers varying more than 5 % from No. 57

the specified mass or volume are permitted to be rejected. If the Percent Passing by

average mass or volume of 50 packages taken at random is less Mass

37.5 mm (1 1⁄2 in.) 100 0.0

than that specified, the entire shipment is permitted to be 25.0 mm (1 in.) 95 to 100 1.0

rejected. 12.5 mm (1⁄2 in.) 25 to 60 4.0

4.75 mm (No. 4) 0 to 10 4.0

10.5 When the admixture is for a specific use in non-air- 2.36 mm (No. 8) 0 to 5 1.0

entrained concrete, it is permitted to be rejected if the test 11.4 Air-Entraining Admixture—Except when tests are

concrete containing it has an air content greater than 3.5 % at made in accordance with 11.5 using an air-entraining admix-

the dosage used to meet this specification. When the admixture ture proposed for specific work, the air-entraining admixture

is to be used in air-entrained concrete, it is permitted to be used in the concrete mixtures specified in Section 12 shall be

rejected if the test concrete containing it has an air content a material such that, when used to entrain the specified amount

greater than 7.5 % at the dosage used to meet this specification. of air in the concrete mixture, will give concrete of satisfactory

resistance to freezing and thawing. The air-entraining admix-

11. Materials ture shall conform to Specification C260/C260M.

11.1 Concrete Not for Specific Use—The materials in 11.2 – 11.5 Concrete for Specific Use—The materials in this sec-

11.4 are for compliance testing using a concrete mixture not for tion are for specific use, such as for testing the cold-weather

a specific use. admixture system in simulated job concrete mixtures. To test

11.2 Cementitious Materials—The cementitious materials the cold-weather admixture system for use in specific work, the

shall be a Type I or Type II portland cement conforming to cementitious materials, aggregates (See 11.3), other chemical

Specification C150/C150M, or a blend of two or more of these admixtures, and air-entraining admixture used shall be repre-

cements from different sources. sentative of those used in the work. Add the cold-weather

admixture system in the same manner and at the same time

11.3 Aggregates—Except when tests are made in accor- during the batching and mixing sequence as it will be added on

dance with 11.4 using the aggregates for a specific use, the fine the job. Proportion the concrete mixture to be similar to that

and coarse aggregates used in any series of tests shall come used in the work. If the maximum size of coarse aggregate in

from single lots of materials that conform to the requirement of the job concrete is greater than 25.0 mm [1 in.], screen the

Specification C33/C33M, except that the grading shall conform fresh concrete over a 25.0 mm (1 in.) sieve prior to fabricating

to the following requirements: the specimens to be tested.

11.3.1 Fine Aggregate Grading:

Sieve Percent Passing by Mass 12. Proportioning Concrete Mixtures

4.75 mm (No. 4) 100

1.18 mm (No. 16) 65 to 75

12.1 Preparation and Batching—Prepare all materials and

300 µm (No. 50) 12 to 20 make all weighing as prescribed in Practice C192/C192M.

150 µm (No. 100) 2 to 5 Prepare all materials so that the test concrete temperature, at

11.3.2 Coarse Aggregate Grading—The coarse aggregate the time of specimen casting, shall be 14 6 2 °C [57 6 3 °F].

grading shall meet the Size 57 grading requirements of Prepare all control concrete materials according to 14.6.2.

Specification C33/C33M. Take care in loading and delivery to 12.2 Proportions—Concrete mixtures not for specific uses

avoid segregation. shall be proportioned using ACI 211.1 (See Note 4). After

11.3.3 Coarse aggregate used for control concrete and test evaluation of trial mixtures, aggregate proportions shall be

concrete shall be essentially the same. Provide sufficient coarse adjusted as needed to obtain workable, cohesive mixtures with

aggregate for the control concrete, the test concrete, and for the correct yield. Unless otherwise specified, the cold-weather

grading analysis. admixture system shall be added with the second increment of

11.3.3.1 Prepare required quantities of coarse aggregate mixing water added to the mixer.

(See Note 3) as follows: Fill tared containers, one for sieve 12.2.1 The cementitious materials content shall be 357 6 3

analysis, one for a batch of control concrete, and one for a kg/m3 [600 6 5 lb/yd3 ].

batch of test concrete, to the required mass from the aggregate 12.2.2 For the first trial mixture, refer to the table on volume

stockpile. Accomplish this by placing equal quantities into of coarse aggregate in ACI 211.1 for guidance on amount of

each container, successively, and repeat the procedure until all coarse aggregate to use for the fineness modulus of the fine

the containers have their required mass. aggregate being used.

--`,`,,``,`,`,````,,,,`,,,,```,`-`-`,,`,,`,`,

NOTE 3—Refer to the section on Sampling Aggregates in the Manual of NOTE 4—Values in the referenced table of ACI 211.1 are intended to

Aggregate and Concrete Testing for guidance on sampling from stock- ensure workable mixtures with the least favorable combinations of

piles. aggregates used. It is suggested, therefore, that for a closer approximation

Copyright ASTM International

Provided by IHS Markit under license with ASTM

4Licensee=North-South Commuter Railway Extension (NSCR-EX)/8285720001, User=Lea

No reproduction or networking permitted without license from IHS Not for Resale, 11/12/2021 00:19:38 MST

C1622/C1622M − 10 (2016)´1

of the proportions required for this test, the volume of coarse aggregate (in 14. Test and Properties of Freshly Mixed Concrete

the dry-rodded condition) per unit volume of concrete selected from ACI

211.1 be increased by about 0.07 for the first trial mixture. 14.1 Samples of freshly mixed concrete from at least three

12.2.3 The target air content of air-entrained concrete shall separate batches for each control and test concrete mixture

be 6 %. shall be tested according to 14.2 – 14.6.

12.2.4 Adjust the water content to obtain a slump of 150 6 14.2 Slump—Test Method C143/C143M.

15 mm [6 6 1⁄2 in.]. 14.3 Density—Test Method C138/C138M

The workability of the control concrete mixture shall be

suitable for consolidation by hand rodding and the concrete 14.4 Air Content—Test Method C231/C231M.

mixture shall have the lowest water content possible. Achieve 14.5 Temperature of Freshly Mixed Concrete—Test Method

these conditions by final adjustment in the amount of fine C1064/C1064M.

aggregate or in the amount of total aggregate, or both, while

maintaining yield and slump. 14.6 Time of Initial Setting—Test Method C403/C403M

with the following exceptions:

12.3 Specimens—Prepare concrete mixtures with and with- 14.6.1 Quantity of mortar used in each container for deter-

out the cold-weather admixture system. Control concrete mining initial setting shall not exceed 5.7 L [350 in.3].

specimens shall be cured in above-freezing conditions and test

14.6.2 Control Concrete: Condition concrete ingredients at

concrete specimens in below-freezing conditions as specified

20 to 25 °C [68 to 77 °F] prior to mixing. Mix the concrete,

in Section 14 and Section 16. Add the cold-weather admixture

prepare test specimens, and measure penetration resistance at

system in a manner recommended by the manufacturer and in

this temperature. Make the initial penetration measurement 3 to

an amount necessary to comply with Table 1.

4 h after initial contact of the cement with the water.

12.4 Non-Air-Entrained Concrete—When the cold-weather 14.6.3 Test Concrete: Measurements are made in a low-

admixture system is to be tested in non-air-entrained concrete, temperature environment. Unless otherwise specified, make the

the air content of both the control and test mixtures shall be initial penetration measurement 3 to 5 h after initial contact of

3.5 % or less, and the difference between the air contents of the the cement with the water. Prepare three specimens: one for

two mixtures shall not exceed 1.0 percentage point. If measuring setting time at low temperature; a dummy specimen

necessary, air-entraining admixture shall be added to the for measuring temperature history; and a replicate specimen for

control mixture to achieve the same air content as the test verifying that freezing did not occur. Place the specimens into

concrete. Tests for freezing and thawing are not required. the low temperature environment within 40 min after the start

12.5 Air-Entrained Concrete—When the cold-weather ad- of mixing. The temperature at the center of the specimen shall

mixture system is to be tested in air-entrained concrete, the reach -5 6 1 °C [23 6 2 °F] not sooner than 6 h and not later

air-entraining admixture shall be added to the control concrete than 8 h after placement into the cold temperature environment

and, if necessary, to the test concrete mixtures in sufficient (See Note 6). Record the initial temperature of the dummy

amounts to produce air contents of 6 6 1.5 % when measured specimen, its temperature history every 1⁄2 h while in the

according to Test Method C231/C231M. The difference be- low-temperature environment, and the time required to cool it

tween the air content of the control concrete mixture and that from its initial temperature to the required temperature range.

of the test concrete mixture shall not exceed 0.5 percentage NOTE 6—It may be desirable to use a series of baths, each at a different

point. Tests for freezing and thawing are required. temperature, for cooling specimens to target temperature within the

specified period.

13. Mixing 14.6.3.1 To make certain that the test specimen did not

13.1 Machine mix the concrete as prescribed in Practice freeze during the test, a replicate specimen (See Table 2) shall

C192/C192M. be removed from the low-temperature room and placed at 20 to

NOTE 5—Tests in Sections 14 – 18 are based on arbitrary stipulations, 25 °C [68 to 77 °F] at the time the test specimen reaches initial

which make possible highly standardized testing in the laboratory, and are setting. Penetration readings shall be made on the replicate

not intended to simulate actual job conditions. specimen every 15 min for 2 h. If the penetration resistance

TABLE 2 Minimum Number of Specimens for each test.

Tests Test Specimens Dummy Specimens Batches per test age Total Specimens

Test

Ages Control Test Control Test Control Test Control Test

A

Setting 1 2 – 1B 3 3 3 9C

Compressive

3 2 2 1 3 3 18 19

Strength

Freezing and

1 2 2 – – 3 3 6 6

Thawing

Length

1 1 1 – – 3 3 3 3

Change

A

See 14.6.

B

For measurement of the thermal history of each batch of test concrete.

C

Includes one replicate specimen per batch of test concrete.

--`,`,,``,`,`,````,,,,`,,,,```,`-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS Markit under license with ASTM

5Licensee=North-South Commuter Railway Extension (NSCR-EX)/8285720001, User=Lea

No reproduction or networking permitted without license from IHS Not for Resale, 11/12/2021 00:19:38 MST

C1622/C1622M − 10 (2016)´1

continues to increase, the test specimen is considered not to 16. Test Specimens for Hardened Concrete

have frozen. Conversely, if a decrease in penetration resistance

16.1 Number of Specimens—The minimum number of

is observed during the 2 h period, the test specimen is

specimens and the number of test ages are shown in Table 2.

considered to have frozen and the admixture system fails to

meet this specification. The results of this testing of the 16.2 Types of Specimens—Specimens made from control

replicate specimen, including the thermal history of the dummy concrete and test concrete shall be prepared in accordance with

specimen recorded every 1⁄2 h, shall be included in the final the following:

report. 16.2.1 Compressive Strength—Make specimens in accor-

14.6.4 Calculate the average time of initial setting from the dance with Practice C192/C192M. Specimen size shall be 100-

results of each batch of concrete. Calculate relative initial by 200-mm [4- by 8-in.] cylinders to facilitate adequate

setting time by dividing the average time of initial setting of the cooling rates using readily available cooling equipment. All

test concrete by the average time of initial setting of the control specimens shall be cured in a sealed condition.

concrete and multiplying by 100.

NOTE 8—Typically, plastic cylindrical molds are sealed with plastic

14.7 Water-Cementitious Materials Ratio and Water Con- caps. Alternately, a plastic bag may be placed over the top of a mold and

tent: held snugly to the side of the mold with a rubber band.

14.7.1 Determine the water-cementitious materials ratio of 16.2.1.1 Control Concrete: Specimens shall be stored in a

concrete as follows: Determine the amount of total water in the 23 6 2 °C [73.5 6 3.5 °F] environment within 40 min of initial

batch as the mass of water added to the batch, water occurring contact of cement and water until time of testing.

as free moisture on the aggregates, and water introduced by the 16.2.1.2 Test Concrete: Specimens shall be stored in the

admixtures. Determine the water-cementitious materials ratio low-temperature curing environment within 40 min after the

as the mass of the total water divided by the mass of the start of mixing. Specimens shall be exposed to the same

cementitious materials. Calculate the volume of concrete from environment as the time of setting specimens as specified in

the total batch quantities and density in accordance with Test 14.6.3. Use the dummy specimen to record the maximum

Method C138/C138M. Determine the water content as the initial starting temperature of one batch of test specimens, their

mass of total water divided by the volume of the concrete temperature history while in the low-temperature environment,

batch. Determine the cementitious materials content as mass of and the time required to cool the test specimens to the required

cementitious materials divided by the volume of the concrete temperature range. Test concrete specimens shall be stored in a

batch. sealed condition so that their internal temperatures are main-

14.7.2 Calculate the relative water content of the test tained at -5 6 1 °C [23 6 2 °F] until an age of 7 days from

concrete as follows: Divide the average water content of all initial contact of cement and water. After 7 days, cure the test

batches of test concrete by the average water content of all concrete in accordance with Practice C192/C192M until the

batches of the control concrete and multiply the quotient by 28-day test. After 28 days, cure the remaining test specimens at

100. not less than 95 % relative humidity until time of test. The

thermal history of the dummy specimen shall be included in the

15. Preparation of Test Specimens test report.

16.2.2 Resistance to Freezing and Thawing—Concrete

15.1 Make sufficient number of specimens representing

specimens shall be prisms made in accordance with Practice

each test from at least three separate batches. The minimum

--`,`,,``,`,`,````,,,,`,,,,```,`-`-`,,`,,`,`,,`---

C192/C192M, and having dimensions in accordance with Test

numbers of specimens are shown in Table 2 (See Note 7). It is

Method C666/C666M. Make one set of two specimens from

permitted to complete specimen fabrication in one, two, or

each batch of the control concrete and one set of two specimens

three days of mixing provided control concrete specimens are

from each batch of the test concrete. The air content of each

made each day.

mixture shall be as specified in 12.4 and 12.5. The control and

NOTE 7—It is recommended that more than the minimum number of test concrete specimens shall be cured in accordance with

specimens be prepared so that replacements are available in case some Practice C192/C192M. Test the specimens in accordance with

specimens are faulty. Test Method C666/C666M, Procedure A, unless specified

15.2 Manifestly Faulty Specimens—Visually examine each otherwise.

test specimen before testing and discard any specimen found to 16.2.3 Length Change—Concrete specimens shall be made

be manifestly faulty. Visually examine each test specimen after in accordance with Test Method C157/C157M, except for the

testing and discard any test result associated with a specimen following curing conditions. Make one specimen from each

found to be manifestly faulty. If there are not enough replace- batch of the control concrete and one specimen from each

ment specimens to provide at least two valid results for each batch of the test concrete. Remove the molds at 24 h and store

test, the entire test shall be disregarded and repeated. The test all specimens in lime-saturated water at 23.0 6 1.0 °C [73.5 6

report shall be the average of the individual test results of the 2.0 °F] until age of 28 days. At 28 days, remove all specimens

specimens tested or, in the event that one specimen or one from water bath and store in accordance with the air storage

result has been discarded, it shall be the average of the procedure in Test Method C157/C157M for an additional 28

remaining test specimens. days.

Copyright ASTM International

Provided by IHS Markit under license with ASTM

6Licensee=North-South Commuter Railway Extension (NSCR-EX)/8285720001, User=Lea

No reproduction or networking permitted without license from IHS Not for Resale, 11/12/2021 00:19:38 MST

C1622/C1622M − 10 (2016)´1

17. Tests on Hardened Concrete concrete shrinkage shall be not more than 0.010 percentage

points greater than the control concrete.

17.1 Compressive Strength—Test in accordance with Test

Method C39/C39M at 7, 28 and 90 days. For the 7-day tests, NOTE 10—Since the specific effects produced by a cold-weather

admixture system may vary with the properties of other ingredients of the

the test concrete specimens shall be moved from the low- concrete, results of length change tests using aggregates of such a nature

temperature environment to a 23 6 2 °C [73.5 6 3.5 °F] that the shrinkage on drying is low may not accurately indicate relative

environment for no less than 2 h and no more than 4 h before performance to be expected with other aggregates having properties such

testing (See Note 9). The test concrete specimens shall be as to produce concrete of high shrinkage on drying.

spaced at least 50 mm [2 in.] apart during this warming period. 18. Uniformity and Equivalence Tests

Record the temperature history of the dummy specimen from

18.1 Perform the infrared analysis and relative density

the time of removal from the low-temperature environment

(specific gravity) procedures in accordance with Specification

until testing. Compute the average compressive strength from

C494/C494M Section on Uniformity and Equivalence Tests.

the separate batches of test concrete and control concrete.

Divide the average strength of the test concrete by the average 19. Report

strength of the control concrete at each test age and multiply by 19.1 Report the following:

100 to obtain relative strength. Report the results to the nearest 19.1.1 Results of tests specified in Section 14 and Sections

1 %. 16 – 18 and the relevant specification requirements, with which

NOTE 9—The intent is to have the center of the test concrete specimens

they are compared,

at 4 and 7 °C [40 to 45 °F] at the time of testing to avoid possible influence 19.1.2 Brand name, manufacturer’s name, lot number, and

of ice crystals inside the specimens. the quantity represented by the sample of cold-weather admix-

ture system under test,

17.1.1 Resistance to Freezing and Thawing—Comparison

19.1.3 Brand name, manufacturer’s name and specification

of the test concrete with the control concrete shall be made in

conformance for air entraining admixture and any other ad-

accordance with Test Method C666/C666M, Procedure A,

mixtures used,

unless specified otherwise. Calculate the relative durability

19.1.4 Brand name, manufacturer’s name, type, and speci-

factor in accordance with Specification C260/C260M, where fication conformance for cementitious materials used,

DF is the durability factor of the control concrete. 19.1.5 Producer’s name, description, and specification con-

17.1.2 Length Change—Measure the initial length at 28 formance for fine and coarse aggregates,

days within 5 min of removing the specimen from curing 19.1.6 Data on concrete mixtures used, including amounts

water. After 28 days of air drying, determine the length in and dosages of admixtures, cementitious materials content,

accordance with Test Method C157/C157M. The drying water-cementitious materials ratios, water content, ratio of fine

shrinkage is the length change during the 28-day drying period, to coarse aggregates, slumps, total air contents, initial setting

based on the initial length at the time of removal of the times, and temperature history of the dummy specimens stored

specimen from the curing water, expressed as a percentage of at low-temperature conditions.

the initial length to the nearest 0.001 %. Calculate the relative 19.1.7 In the event that some of the tests have been waived,

shrinkage by dividing the average shrinkage of the test the circumstances under which such action was taken shall be

concrete by the average shrinkage of the control concrete and stated.

multiplying by 100. If the shrinkage of the control concrete

after 28 days is 0.030 % or greater, the relative shrinkage of the 20. Keywords

test concrete shall not exceed 135 %. If the shrinkage of the 20.1 chemical admixture; cold-weather admixture; con-

control concrete at 28 days is less than 0.030 %, the test crete; performance requirements

--`,`,,``,`,`,````,,,,`,,,,```,`-`-`,,`,,`,`,,`---

SUMMARY OF CHANGES

Committee C09 has identified the location of selected changes to this specification since the last issue,

C1622/C1622M-10, that may impact the use of this specification. (October 1, 2016)

(1) Editorially revised 2.1, 9.5.1, 11.2, 11.3, 11.3.2, 11.3.4,

11.4, 12.5, 14.4, and 17.1.1.

Copyright ASTM International

Provided by IHS Markit under license with ASTM

7Licensee=North-South Commuter Railway Extension (NSCR-EX)/8285720001, User=Lea

No reproduction or networking permitted without license from IHS Not for Resale, 11/12/2021 00:19:38 MST

C1622/C1622M − 10 (2016)´1

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the Copyright Clearance Center, 222

Rosewood Drive, Danvers, MA 01923, Tel: (978) 646-2600; http://www.copyright.com/

--`,`,,``,`,`,````,,,,`,,,,```,`-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS Markit under license with ASTM

8Licensee=North-South Commuter Railway Extension (NSCR-EX)/8285720001, User=Lea

No reproduction or networking permitted without license from IHS Not for Resale, 11/12/2021 00:19:38 MST

You might also like

- C 1017 - C 1017M - 98 - QzewmtctotgDocument9 pagesC 1017 - C 1017M - 98 - Qzewmtctotgruddy sniderNo ratings yet

- Chemical Admixtures For ConcreteDocument10 pagesChemical Admixtures For ConcreteSMR STPNo ratings yet

- Astm SPDocument15 pagesAstm SPMadhavi Latha KasulanatiNo ratings yet

- ASTM C494-C49M-05aDocument10 pagesASTM C494-C49M-05aKidist MollaNo ratings yet

- ASTM C494-13 (Aditivos para Concreto) PDFDocument10 pagesASTM C494-13 (Aditivos para Concreto) PDFAnonymous SBjNS7Gw0qNo ratings yet

- Chemical Admixtures For Use in Producing Flowing ConcreteDocument9 pagesChemical Admixtures For Use in Producing Flowing ConcreteJesús Luis Arce GuillermoNo ratings yet

- Chemical Admixtures For ConcreteDocument10 pagesChemical Admixtures For ConcreteEligio Antonio CerdaNo ratings yet

- Chemical Admixtures For ConcreteDocument15 pagesChemical Admixtures For ConcreteKMNo ratings yet

- Chemical Admixtures For ConcreteDocument10 pagesChemical Admixtures For ConcreteChavier ManguanaNo ratings yet

- ASTM - C1107-99 Packaged Dry Hydraulic-Cement Grout (Nonshrink)Document4 pagesASTM - C1107-99 Packaged Dry Hydraulic-Cement Grout (Nonshrink)조남현No ratings yet

- ASTM C1017 - Chemical Admixtures For Use in Producing Flowing ConcreteDocument9 pagesASTM C1017 - Chemical Admixtures For Use in Producing Flowing Concretesugi zhuangNo ratings yet

- Astm C1107-08Document5 pagesAstm C1107-08LydiaNo ratings yet

- Astm C 1107 - C 1107M - 11 PDFDocument5 pagesAstm C 1107 - C 1107M - 11 PDFkishor150688100% (2)

- Packaged Dry, Hydraulic-Cement Grout (Nonshrink) : Standard Specification ForDocument5 pagesPackaged Dry, Hydraulic-Cement Grout (Nonshrink) : Standard Specification FormickyfelixNo ratings yet

- Chemical Admixtures For Use in Producing Flowing ConcreteDocument9 pagesChemical Admixtures For Use in Producing Flowing Concretemohammed ;arasnehNo ratings yet

- Astm C1107 C11021M 09Document2 pagesAstm C1107 C11021M 09Raul Ibarra MartinezNo ratings yet

- Astm c1017Document9 pagesAstm c1017Monserrat100% (1)

- ASTM C403-16 Time of Setting of Concrete Mixtures by Penetration ResistanceDocument7 pagesASTM C403-16 Time of Setting of Concrete Mixtures by Penetration ResistanceRajnikanth Gedhada50% (4)

- Astm C-494 PDFDocument9 pagesAstm C-494 PDFvelmurug_bala100% (5)

- Astm C1107Document6 pagesAstm C1107Anny Villegas100% (2)

- Astm C 403-2016Document7 pagesAstm C 403-2016Mohammed Ali0% (1)

- Astm C 403Document7 pagesAstm C 403elygq0% (1)

- C 932 - 03 PDFDocument5 pagesC 932 - 03 PDFTarek FennicheNo ratings yet

- ASTM C231-17 Standard Test Method For Air Content of Freshly Mixed Concrete by The Pressure MethodDocument9 pagesASTM C231-17 Standard Test Method For Air Content of Freshly Mixed Concrete by The Pressure MethodAdam Jones0% (1)

- Astm C881 C881M-15Document6 pagesAstm C881 C881M-15Sergio VianaNo ratings yet

- ASTM C494 (Admixtures)Document10 pagesASTM C494 (Admixtures)Ali ArsalanNo ratings yet

- ASTM D2137 11 - Standard Test Methods For Rubber Property-Brittleness Point of Flexible Polymers and Coated FabricsDocument7 pagesASTM D2137 11 - Standard Test Methods For Rubber Property-Brittleness Point of Flexible Polymers and Coated FabricsAndre SpirimNo ratings yet

- Astm C143 C143MDocument4 pagesAstm C143 C143MhavalNo ratings yet

- Astm C 1201-09Document4 pagesAstm C 1201-09kishor150688No ratings yet

- ASTM C882C882M-13aDocument4 pagesASTM C882C882M-13aPensil TeknikNo ratings yet

- Scaling Resistance of Concrete Surfaces Exposed To Deicing ChemicalsDocument3 pagesScaling Resistance of Concrete Surfaces Exposed To Deicing ChemicalsSherif MohamedNo ratings yet

- C672C672M 12 Scaling Resistance of Concrete Surfaces Exposed ToDocument3 pagesC672C672M 12 Scaling Resistance of Concrete Surfaces Exposed ToJamman Shahid ShiblyNo ratings yet

- Astm C942-15Document3 pagesAstm C942-15adolfo camayoNo ratings yet

- Astm F3007 - 13Document4 pagesAstm F3007 - 13Sofia YuliNo ratings yet

- Resistance of Concrete To Rapid Freezing and Thawing: Standard Test Method ForDocument6 pagesResistance of Concrete To Rapid Freezing and Thawing: Standard Test Method FormaribelNo ratings yet

- C31 C31M 03aDocument5 pagesC31 C31M 03aJesus Luis Arce GuillermoNo ratings yet

- Astm D 573 - 2004Document6 pagesAstm D 573 - 2004leoardoNo ratings yet

- 10-C1262 10 Standard Test Method ForDocument5 pages10-C1262 10 Standard Test Method ForAlireza AzarioonNo ratings yet

- Astm C403-99 PDFDocument6 pagesAstm C403-99 PDFJoel Josué Vargas BarturénNo ratings yet

- ASTM C1017-13 Standard Specification For Chemical Admixtures For Use in Producing Flowing ConcreteDocument9 pagesASTM C1017-13 Standard Specification For Chemical Admixtures For Use in Producing Flowing Concretebenedick barquinNo ratings yet

- Sampling Freshly Mixed Concrete: Standard Practice ForDocument3 pagesSampling Freshly Mixed Concrete: Standard Practice ForBiltek TekNo ratings yet

- Gypsum Keene's Cement: Standard Specification ForDocument3 pagesGypsum Keene's Cement: Standard Specification Fordiego rodriguezNo ratings yet

- Astm C172 C172M 14Document1 pageAstm C172 C172M 14jaafar abdullahNo ratings yet

- Aashto T209-12Document15 pagesAashto T209-12Emran BanatNo ratings yet

- Astm C94-C94MDocument15 pagesAstm C94-C94MRomeo Ramos MéndezNo ratings yet

- C672-12 Scalling Resistance of Concrete Surfaces Exposed To Deicing Chemicals.13104Document3 pagesC672-12 Scalling Resistance of Concrete Surfaces Exposed To Deicing Chemicals.13104Kartika Setia RiniNo ratings yet

- Astm C 1107Document5 pagesAstm C 1107Adán Vera Go100% (1)

- Calorimeter C 1679 PDFDocument14 pagesCalorimeter C 1679 PDFPablocastilloHNo ratings yet

- Time of Setting of Concrete Mixtures by Penetration ResistanceDocument6 pagesTime of Setting of Concrete Mixtures by Penetration ResistanceJuan Carlos Fernandez LoveraNo ratings yet

- Astm c-192 PDFDocument8 pagesAstm c-192 PDFProbo100% (2)

- Astm D2041-D2041M - 11Document4 pagesAstm D2041-D2041M - 11Black Goku100% (1)

- D573-04 Standard Test Method For Rubber-Deterioration in An Air Oven PDFDocument6 pagesD573-04 Standard Test Method For Rubber-Deterioration in An Air Oven PDFรอคนบนฟ้า ส่งใครมาให้ สักคน100% (1)

- Astm C232Document3 pagesAstm C232mirvahid HOSSiNiNo ratings yet

- Astm C494Document4 pagesAstm C494OmphaNo ratings yet

- Compressive Strength of Grouts For Preplaced-Aggregate Concrete in The LaboratoryDocument3 pagesCompressive Strength of Grouts For Preplaced-Aggregate Concrete in The LaboratoryEmman Cosme Gumanit Virtudazo100% (3)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- High-Yield-Strength, Quenched and Tempered Alloy Steel Plate, Suitable For WeldingDocument3 pagesHigh-Yield-Strength, Quenched and Tempered Alloy Steel Plate, Suitable For Weldingbenedick barquinNo ratings yet

- Rope-Lay-Stranded Copper Conductors Having Concentric-Stranded Members, For Electrical ConductorsDocument5 pagesRope-Lay-Stranded Copper Conductors Having Concentric-Stranded Members, For Electrical Conductorsbenedick barquinNo ratings yet

- Aluminum Bronze Sheet, Strip, and Rolled Bar: Standard Specification ForDocument4 pagesAluminum Bronze Sheet, Strip, and Rolled Bar: Standard Specification Forbenedick barquinNo ratings yet

- ASTM C979-05 Standard Specification For Pigments For Integrally Colored ConcreteDocument5 pagesASTM C979-05 Standard Specification For Pigments For Integrally Colored Concretebenedick barquinNo ratings yet

- Subject Spec - Number Title Spec. NameDocument2 pagesSubject Spec - Number Title Spec. Namebenedick barquinNo ratings yet

- ASTM C1017-13 Standard Specification For Chemical Admixtures For Use in Producing Flowing ConcreteDocument9 pagesASTM C1017-13 Standard Specification For Chemical Admixtures For Use in Producing Flowing Concretebenedick barquinNo ratings yet

- ASTM C1582-17 Standard Specification For Admixtures To Inhibit Chloride-Induced Corrosion of Reinforcing Steel in ConcreteDocument10 pagesASTM C1582-17 Standard Specification For Admixtures To Inhibit Chloride-Induced Corrosion of Reinforcing Steel in Concretebenedick barquinNo ratings yet

- ASTM D4959-07 Standard Test Method For Determination of Water (Moisture) Content of Soil by Direct HeatingDocument3 pagesASTM D4959-07 Standard Test Method For Determination of Water (Moisture) Content of Soil by Direct Heatingbenedick barquinNo ratings yet

- ASTM D648-18 Standard Test Method For Deflection Temperature of Plastics Under Flexural Load in The Edgewise PositionDocument6 pagesASTM D648-18 Standard Test Method For Deflection Temperature of Plastics Under Flexural Load in The Edgewise Positionbenedick barquinNo ratings yet

- ASTM D256-23 Standard Test Methods For Determining The Izod Pendulum Impact Resistance of PlasticsDocument11 pagesASTM D256-23 Standard Test Methods For Determining The Izod Pendulum Impact Resistance of Plasticsbenedick barquinNo ratings yet

- PNS49 2020Document20 pagesPNS49 2020benedick barquin100% (2)

- Color, Solubility, and Complex Ion Equilibria of Nickel (11) Species in Aqueous SolutionDocument2 pagesColor, Solubility, and Complex Ion Equilibria of Nickel (11) Species in Aqueous SolutionManuel OrihuelaNo ratings yet

- 2012 Form 5 (Paper 3)Document6 pages2012 Form 5 (Paper 3)Nieda IbrahimNo ratings yet

- UV VIS CaffeineDocument15 pagesUV VIS CaffeineTinuviele EsguerraNo ratings yet

- Lai BinglinDocument22 pagesLai BinglinNicholas Chin Yong LekNo ratings yet

- Chemistry Sample Syllabus 2 Id 1029717v1Document13 pagesChemistry Sample Syllabus 2 Id 1029717v1Wong Weng SiongNo ratings yet

- Block 2BBCCT 107Document44 pagesBlock 2BBCCT 107robinNo ratings yet

- Road Liner ThermoplasticDocument2 pagesRoad Liner ThermoplasticDuc NguyenNo ratings yet

- Magnetic Terms and UnitsDocument3 pagesMagnetic Terms and UnitsDeepak Choudhary DCNo ratings yet

- Metabolism Exam 2 - GIFT - Spring 2016Document9 pagesMetabolism Exam 2 - GIFT - Spring 2016shafa_nathani100% (2)

- Efficient Biosorption of Cadmium by Eucalyptus Globulus Fruit Biomass Using ProcessDocument12 pagesEfficient Biosorption of Cadmium by Eucalyptus Globulus Fruit Biomass Using ProcessRabialtu SulihahNo ratings yet

- Formula Writing - CambridgeDocument5 pagesFormula Writing - CambridgeQusai Saify100% (3)

- Heat Exchanger Selection GuideDocument2 pagesHeat Exchanger Selection GuiderodrigoperezsimoneNo ratings yet

- Eca ChangeoverDocument61 pagesEca ChangeoverVijai Singh100% (1)

- Crystal Field Theory IIDocument2 pagesCrystal Field Theory IIabhay j bavishiNo ratings yet

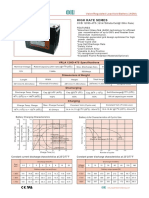

- High Rate Series: CCB 12HD-475Document1 pageHigh Rate Series: CCB 12HD-475orunmila123No ratings yet

- Protein MetabolismDocument6 pagesProtein MetabolismGeline Dela RosaNo ratings yet

- European Steel and Alloy Grades: HDT560F (1.0959)Document2 pagesEuropean Steel and Alloy Grades: HDT560F (1.0959)farshid KarpasandNo ratings yet

- Estimate For Water SupplyDocument2 pagesEstimate For Water SupplyAbdulsamad RacmanNo ratings yet

- Ceramic XrayDocument9 pagesCeramic XrayFandi MarcelloNo ratings yet

- Bituminous TestsDocument23 pagesBituminous TestsikreddyNo ratings yet

- Structure-Property Relationships of Flexible Polyurethane FoamsDocument10 pagesStructure-Property Relationships of Flexible Polyurethane Foamstoiec hocNo ratings yet

- Enzymes: Biology Matters G.C.E. 'O' Level (2 Edition) : Textbook AnswersDocument2 pagesEnzymes: Biology Matters G.C.E. 'O' Level (2 Edition) : Textbook Answerslee40% (5)

- Lecture 1 Surface and Interfacial PhenomenaDocument26 pagesLecture 1 Surface and Interfacial Phenomenabattal eduNo ratings yet

- Mixing TimeDocument7 pagesMixing TimeakoNo ratings yet

- Nanoformulation of Curcuma Longa Root Extract and Evaluation of Its Dissolution PotentialDocument9 pagesNanoformulation of Curcuma Longa Root Extract and Evaluation of Its Dissolution Potentialmuhammad adnan ayubNo ratings yet

- Chloride MohrDocument2 pagesChloride MohrVaibhav KrNo ratings yet

- Determination of Water Potential in A Plant PartDocument3 pagesDetermination of Water Potential in A Plant PartMishti2No ratings yet

- Topic 4: Classification, Properties and Applications of S.G. and C.G.Iron S.G.IRONDocument11 pagesTopic 4: Classification, Properties and Applications of S.G. and C.G.Iron S.G.IRONsandeep kumarNo ratings yet

- Acid SlurryDocument8 pagesAcid SlurryVinod GoelNo ratings yet