Professional Documents

Culture Documents

01 General Information R900 Litronic LIEBHERR

01 General Information R900 Litronic LIEBHERR

Uploaded by

ashraf elsayed0 ratings0% found this document useful (0 votes)

22 views49 pagesLIEBHERR EXCAVATOR

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentLIEBHERR EXCAVATOR

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

22 views49 pages01 General Information R900 Litronic LIEBHERR

01 General Information R900 Litronic LIEBHERR

Uploaded by

ashraf elsayedLIEBHERR EXCAVATOR

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 49

SUBGROUP INDEX

1.01, Chart / Coming into Effect of Modifications

1.10. Safety Information

1.20. Conversion Factors

1.20.01 Tightening Torques

1.20.06 150 Tolerances

1.30. Torque values for UNC / UNF screws

1.40. Repair welding

1.50. Lubricants

Benennung/Description/Dénomination

LIEBHERR

DatumiEaion/Date

04.96

General Information

Typ

Mode!

Type

‘Abifiom/a parti de

BlarPage/Feuile

1.

Foreword

This manual has been prepared to provide you with technical information on the design and

construction of the various components which made up the LIEBHERR excavator.

It contains brief and precise descriptions, guidelines and drawings of adjustment procedures as well

as hydraulic and electrical schematics, and graphically depicted diagrams and sectionals to help you

with any repairs, which might become necessary on our hydraulic excavators,

We deliberately avoided full drawings and details of each repair stage, a practice often adopted in

workshop manuals of this kind, since only skilled mechanics already familiar with most repair work

described in this manual, shouid perform repair work. This manual is also intended to provide you

with information regarding certain adjustment values.

Instructions on_ maintenance is excluded from this manual, since it are covered in the individual

Operation and Maintenance Manual

Be sure to observe all accident prevention guidelines and adhere to all safety information before

and during any maintenance and / or repair procedure on the hydraulic excavator.

To perform tests and repairs listed in this manual, a complete set of standard tools, as well as special

tools and fixtures shown and listed, is necessary. Always observe utmost cleanliness and order.

No special emphasis is put on replacing sealing components, since it is taken for granted that all

removed seals, O-rings and gaskets are repiaced during the course of repair. Tighten any screw

connections, if no other values are given, to the required tightening torque.

Certain notes are used throughout this manual to emphasize important or critical instructions.

[JER This mark used in our descriptions denotes an important note or reminder, which

should be especially noted

This exclamation mark used in our descriptions denotes an important note or a

AA eminder of safety practices or directs attention to unsafe practices, which could pose

danger for the mechanic and / or the machine. if proper precautions are not taken.

This Service Manual has been issued by the Customer Service Department of LIEBHERR - FRANCE,

2, avenue J. REY 68000 COLMAR.

This manual will be updated regularly, as a registered holder of a Service Manual you will automa:

tically receive all revised and new pages according to the latest series status,

Some Service Information bulletins may also need to be filed in this Service Manual

This book may not be copied nor given to third persons without our approval!

We reserve the right to make changes

We trust that with this information contained in this manual and your cooperation we have taken

another step toward continuing improvement of service on our LIEBHERR hydraulic excavators.

LIEBHERR - FRANCE SA.

Explanation

In order to make it easy to find certain information or to remove and/or add pages in case of

changes or improvements, the following system has been established:

Page No.

Subgroup

Main group

7 10. 01

Hydraulic components

Var. displacement double pump (PVD

Page 01

The index for the main groups can be found on the index page.

The subgroups can be found on the index page in front of the main group. In addition, the

machines with serial numbers are listed on the index, which is valid for this subgroup.

In case of minor changes we will issue revised pages and update the date. If an already existent

sub group is completely revised, we will assign a new sub group number.

Anderungsmarke Artder Anderung Anderungseinlauf ab 5.Nr.

Modification mark Kind of modification Modified on machines from S.N.

Repére de modif. Nature de la modification Modifie & partir de n* de Serie

(a) Regler "GLD" ersetzt Regler "GLR" R922: Nr. 202, 210, 212 + 223,

Horsepower limiter "GLD" replaces "GLR" 225 + 245, 272 >

Régulateur "GLO" remplace regul. "GLR" | R932: Nr. 486, 498,511 541

651

R942: Nr. 333, 340, 347, 350, 354

360, 362 — 376, 449 --

(b) Bausatz “Power safety” serienmaBig eingebaut | R900, Nr. 192—

“Power safety” serially mounted R902 Nr. 2150—>

Fonetionnement de secours monté de série R912 Nr-2175-2

| R922: Nr. 380+

R932; Nr. 805—

R982; Nr. 542

iS) Einfahrung der Platine A1 von LBC R900: Nr. 101+

Mounting of print plate At (maker LBC) R902; Nr 44t—

Montage du circuit imprime Al de fabrication | R912: Nr.3472—+

LBC R922: Nr. 3558+

R932: Nr. 727->

| R942: Nr. 489+

(@) Hydraulikélstandsonde B14 R900: Nr. ~

Fabricat Honsberg ersetzt Fabrikat Bedia R902: Nr. 2001+

Hydraulic oil level transmitter 814 R92: Nr.2287

Model Honsberg replaces model Bedia R922: Nr. 103

Capteur de niveau / hulle hydraulique B14 R932; Nr. 550+

Le modéle Honsberg replace le modele Bedia__| R942: Nr. ~~

(e) Dieselmotor ausgerdstet mit Wasserfilter R902 Pea

“Fleetguard” R912 3388

Diesel engin fitted with "Fleetquard" water filter | R 922: 3527

‘Moteur Diesel equipe de filtre a eau “Fleetguard” | R932 3152, 3156, 3159

R942 3077 >

(f) Umstellung auf das Fahrerhaus Fabrikat "SIAC" | R 902: 2105-+

Mounting of the new driver's cab "SIAC’ R912 2617, 2646.--

Machine avec nouvelle cabine de fabrication R922: 331, 352

“Siac” R932; Nr.673,727—

R942: Nr. 485, 489->

a) Serienmassiger Einbau der Funktion R902: 3292+

“Druckzuschaltstufe Heben” R912: 3720->

Function "Pressure cut-in stage - lift boom" R922. 3642

serially mounted R932, 4001

Montage de serie de la fonction "commutation | R942: 4001.»

de pression en montee fleche"

‘Benennung/Description/Denomination, Ws R900 R942

Bee Liemcewe

Angaben iiber den =

Fam

Chart / Coming into Effect of Modifications | Depus

LIEBHERR

auf von Anderungen

Datum

Eaition 03.97 Entree en vigueur des modifications ae, 1.01.01

Anderungsmarke

Modification mark

Repére de modif.

Art der Anderung

Kind of modification

Nature de la modification

Anderungseinlauf

Modified on machines

Modifie a partir de

(hy) Druckschalter B30 hinfallig. Eingangssignal

"B30" an GLD ber Drucktaste $130 R902 Ne 3370. 3373, 3374, 3381,

Pressure switch B30 suppressed. Input signal -

"B30" to horsepower controller GLD given by | R912: Nr. 3660, 3993, 3700, 3708,

push button $130 3715, 3716, 3750, 3761, 3762,

Pressostat B30 supprimeé. Signal d’entrée "B30" 3764, 3769, 3771, 3772, 3784,

pour regulateur GLO donne par poussoir 130 3786 >

R922: Nr. 3636, 3650, 3653 3656+

R932: Nr. 3380, 3381, 3392, 3397,

3401 3406, 3411 —>

R942: Nr. 4005, 4026, 4047 —-4052,

4055 >

@ Bremsventile auf Fahrwerksmotoren mit

Anfahrdrosselbohrungen versehen R900: Nr-3065

Brake valves on travel motors fitted with t R902: Nr3291—>

bores for travel start .

Clapets de freinage sur moteurs de translation | R912: Nr. 3638

avec orifices calibres R922: Nr. 3616->

R932: Nr3311->

R942: Nr.3213—

(k) Rickschlagventil im Steuerkreis far die

Motorverstellung entfallt (in den Fahrmotoren)

Non return valve (in control line for travel motor

displacement is suppressed (in travel motor)

Suppression du clapet anti-retour (sur circutt de

‘commande de cylindree des moteurs) a interieur

des moteurs de translation

R900-R942 ~ 08,97»

1.01.01

Working with an excavator can be dangerous, it could result in injury or death if proper precautions are not

taken! WE URGE YOU TO READ THIS MANUAL CAREFULLY! This safety information is provided to operators and

maintenance mechanics to ensure the safe operation and maintenance of the excavator. Itis essential that you

read and familiarize yourself with this information, which explains safety requirements and precautions and

specific hazards of which you should be aware. This also applies to any personnel which might be working on,

the machine only occasionally, such as during set up or maintenance. It is essential that you read and familiarize

yourself with this information, which explains safety requirements and precautions and specific hazards of which

you should be aware

Careful adherence to these safety guidelines will permit safe operation and maintenance and potentially

prevent personal injury to yourself and others, and possible damage to the excavator

In addition to these instructions you must follow the safety regulations applicable to your work environment

and job site and any federal, state and local safety requirements

and federal highway regulations).

{A model excavators must also fallaw focal.

GENERAL SAFETY INFORMATION

Consult our employer or supervisor for specific

# Study the Operation and Maintenance Manual

belore operating or working on the excavator. safety equipment requirements and salety

Make sure that you have additional information regulations on the job site

for special attachments of your machine, read it Always tilt up the safety lever before leaving the

and understand it! operator's seat,

© Allow only authorized personnel to operate Do not carry tools, replacement parts or other

service or repair the excavator. Make sure to supplies while climbing on or off the excavator.

observe any minimum applicable age Never use the steering column, control levers or

requirement. joysticks as handhold

* Allow only properly trained personnel to Never jump off the excavator, climb on and off

‘operate or work on the excavator, make sure to the excavator using only the steps, rails and

clearly specify the person who is responsible for handles provided

set up, maintenance and repairs When climbing on or off the excavator, use both

'# Make sure the operator knows his responsibility hands for support and face the machine

regarding the observance of traffic regulations If needed, use the front window as an escape

and permit him to refuse any unsafe instructions hatch

given my a third person " Ch et '

tn no other guidelines are given, perform

© Any persons still in training should only operate maintenance ond repair uulizing the following

or work on the machine under the supervision precautions

and guidance of an experienced person

Park excavator on firm and level ground. Rest

@ Check and observe any person working or tne-attachment on the ground

operating the excavator periodicaily and

regularly, if they observe safety instructions and Place all control in neutral position and raise

guidelines given in the Operation and the safety lever.

Maintenance Manual Turn the engine off and remove the ignition

© Wear proper work clothing when operating or key.

LIEBHERR

Edition

working on the excavator. Rings, watches,

bracelets and loose clothing such as ties, scarves,

unbuttoned of unzipped shirts and jackels are

dangerous and could cause injury!

Wear proper safety equipment, such as safety

glasses, safety shoes, hard hats, work gloves,

rellector vests and ear protection.

Benennung/Descr gtionDenom nation

07.93

Safety Informations

Before working on the hydraulic circuit, move all

joysticks and pedals with the ignition key in

contact position to relieve the servo pressure

and the remaining pressures in the different

main circuits. In addition, relieve the pressure in

the hydraulic tank as described in the Operation

and Maintenance Manual

Typ

Médet

Tee

Page 1.10.01

Secure all loose parts on the excavator

Never operate the excavator without a

complete walk around inspection. Check if all

warning decals are on the machine and if they

are all legible

Observe all danger and safety guidelines

For certain special applications, the excavator

must be equipped with specific safety

equipment. Use the excavator only, if they are

installed and functioning properly

Never perform any changes, additions or

modifications on the machine, which could

influence the safety, without obtaining the

permission from the manufacturer. This also

applies to the installation and adjustment of

safely devices and safety valves as well as to

any welding on load carrying parts.

Do not install any equipment or attachments

made by other manufacturers or any which are

not specifically authorized by LIEBHERR for

installation without first obtaining the written

permission from LIEBHERR

LIEBHERR will issue any required technical

documentation for approved installations

CRUSHING AND BURN PREVENTION

Never work underneath the excavator unless it

is safely resting on the ground and / or is

properly biocked and supported

Never use damaged or insufficient wire ropes,

slings or chains.

Always wear gloves when handling wire ropes

Never reach into bores during attachment

installation or removal. Never align bores with

your fingers or hands. Use proper alignment

tools when installing, changing or servicing

attachments

Keep objects away from the radiator fan

Rotating fans will swirl and throw out objects,

which can become very dangerous and cause

severe injury to yourself and others.

Avoid contact with any components contai:

ning coolant. At or near operating tempe.

rature, the engine coolant is hot and under

pressure and could cause severe burns.

Check the coolant level only after the radiator

cap is cool enough to touch. Remove the

radiator cap slowly to relieve pressure

Do net allow your skin to come into contact

with hot oil or components containing hot oil

At or near operating temperature, engine and

hydraulic oil is hot and can be under pressure

Always wear safety glasses and protective

gloves when handling batteries. Keep sparks

or open flames away!

Never permit anyone to hand guide the bucket

or grapple into position

When working in the engine area, make sure

the top covers and side doors are properly

secured or closed with the appropriate

supports.

Never work underneath or on the excavator

unless itis properly blocked and supported.

FIRE AND EXPLOSION PREVENTION

Always turn off the engine while refueling the

excavator,

Never smoke or allow an open flame in

relueling areas or where batteries are being

charged, or where batteries or flammable

materials are stored

Always start the engine as described in the

‘Operation and Maintenance Manual.

Check the electrical system regularly and

frequently.

All defects, such as loose connections, burnt

oul fuses and bulbs, burnt or damaged cables

must be repaired immediately by an electrician

or especially trained personnel

Never store flammable fluids on the machine

except in storage tanks intended for the

excavator’ operation,

Inspect all components, lines, tubes and hoses

for oil and fuel leaks and / or damage.

Replace or repair any damaged components

immediately

Any oil, which escapes from leaks, can easily

cause a fire.

Be certain that all clamps, guards and heat

shields are installed. These components

prevent vibration, rubbing, chafing and heat

build-up. Install tie wraps to fasten hoses and

wires, as required

Cold start ether is extremely flammable. Use

ether only in ventilated areas and as directed.

Never use it near heat sources or open flames,

do not permit anybody to smoke.

Know the location of the excavator's fire

extinguisher and be familiar with its opera-

tion. Make sure you know your local fire

regulations and fire reporting procedures

1.10.01

MACHINE START UP SAFETY

Before excavator start up, perform a thorough

walk around inspection

Visually inspect the excavator, look for loose

bolts, cracks, wear, any leaks and any evidence

of vandalism,

Never start or operate an unsafe excavator.

Report all defects to your foreman or supervisor

and make sure they are corrected immediately

Make sure alt covers and doors are closed and

ocked and all warning decals are on the

machine

Make sure all windows, as well as inside and

outside mirrors are clean, and secure all doors

and windows to prevent any unintentional

movement

Be certain that the area surrounding the

excavator is free of other personnel, and that no

‘one is working on or under the excavator before

starting the engine.

Aller entering the cab, adjust the operator's

seat and controls, the inside and outside mirror,

the armrests and fasten and adjust the seat belt

Be certain that all controls can be reached

comfortably

All noise protection devices on the machine

must be functional during operation,

ENGINE START UP AND OPERATING SAFETY

atu

LIEBHERR

Before start up, check if all indicator lights and

instruments are functioning properly, place al

controls in neutral position and tlt the safety

lever up,

Before starting the engine, alert any nearby

personnel that the excavator is being started by

sounding the horn.

Start the machine only when seated in the

‘operator's seat, and with the seat belt fastened

{if nstalled)

If you have no other instructions, start the

engine as outlined in the Operation and Mainte-

nance Manual

Henennung Descrpton/Denamination

n 07.93

Safety Informations

Tilt the safety lever down and check alll indi

cators, gauges, warning devices and controls for

their proper indication

Start and operate the engine only in a well

ventilated area. If necessary, open doors and

windows

Warm up the engine and hydraulic system to

operating temperatures. Low engine and

hydraulic oil temperatures can cause the exca-

vator to be unresponsive.

Check that all attachment functions are

operating properly.

Move the excavator slowly into an open area

and check ail travel functions for their proper

‘operation, check travel and swing brakes, the

steering function as well as the turn signals and

ights

MACHINE OPERATING SAFETY

Familiarize yourself with job site rules. Be infor

med about traffic and hand signals and safety

signs. Ask who is responsible for signaling.

Check your surrounding for any obstacles in the

working and movement range, check the load

carrying capacity of the terrain, and secure the

job site Lo shield it from any public highway

traffic

Always keep a sale distance from overhangs,

walls, drop offs, and unstable ground.

Be alert of changing weather conditions, bad or

insufficient visibility and of changing ground

conditions

Be alert for utility lines, check the location of

underground cables, gas and water lines, and

work especially careful in that vicinity. If

necessary andi or if required, call local autho-

rities to mark the location.

Keep sufficient distance to electrical lines. When

working in the vicinity of high voltage electrical

lines, keep proper distance to assure that the

attachment does not come close to the lines

DANGER! You must inform yourself about safe

distances,

act

Type

ah

From

Deus

are

Feat

1.10.02

In case you do touch a high voltage line by

accident, proceed as follows:

do not leave the machine,

= move the machine, if possible, from the

danger zone until you obtain sufficient

distance,

- warn any personnel in the vicinity not to

come close to the excavator and not to

touchit,

~ instruct or initiate that someone turns off

the voltage

Do not leave the machine until you are

absolutely sure that voltage in the line,

which had been touched or damaged, has

been turned off!

Before moving the machine, make sure that

the attachments and equipment is secured

properly to avoid accidents.

When traveling on public roads or highways,

make sure to observe trallic regulations, and

make sure that the machine meets federal ang

local public highway standards,

Always turn on the lights if visibility is bad or if

you are still working during dusk

Never allow other personnel on the excavator

Operate the excavator only while seated and

with the seat bell fastened, if installed,

Report any problems or needed repairs to your

foreman or supervisor and make sure they are

corrected immediately,

Do not move the excavator until you are

certain that no one is endangered by moving

the excavator

On machines without negative brakes check

the brake system before starting to work, as

outlined in the Operation and Maintenance

Manual.

Never leave the operator's seat while the

machine is still moving

Never leave the machine unattended, with the

engine running,

When moving the excavator, keep the upper-

carriage in lengthwise direction and keep the

load as close as possible to the ground

Prevent any working movements, which could

tip the machine over If the excavator begins to

tip or slip on a grade, immediately lower the

attachment and load to the ground and turn

the excavator facing downhill

Hf possible, always operate the excavator with

the attachment positioned uphill or downhill,

never sideways

Always travel slowly on rough or slippery

ground and on slopes

Always travel downhill at permissible speed, so

you don't loose control over the machine. The

engine must run at nominal speed, use only

the foot pedals to brake and slow down the

machine

Never shift during down hill travel, always shift

toa lower gear before traveling downhill

Never load over an occupied truck. Request

that the driver leave the cab, even if a rock

protection is installed,

For demolition work, clearing, crane

operation, etc. always use the appropriate

protection device designed for this specific

application

If operating in visually obstructed terrain or

whenever necessary, have another person

guide you. Always have only one person signal

you.

Allow only experienced persons to attach loads

or to guide operators. The guide must be

visible by the operator and / or must be in voice

contact with him,

Depending on the attachment combination, it

is possible for the bucket teeth to hit the cab,

the cab protection or the boom cylinders. Be

very careful when the bucket teeth get in this

range to prevent any damage

MACHINE PARKING SAFETY

Park the excavator only on firm and level

ground

Ifit becomes necessary Lo park the machine on.

2 grade, properly block and secure it with

wedges.

Lock the uppercarriage with the lock pin.

Lower the attachments to the ground and

anchor the bucket lightly in the ground.

Bring all operating levers in neutral position

and engage the travel and swing brakes.

Turn the engine off as outlined in the

Operation and Maintenance Manual and raise

the safety lever before you leave the

operator's seat.

Lock the machine, remove all keys and secure

the excavator against vandalism and unautho-

rized use.

1.10.02

MACHINE TRANSPORTING SAFETY

LIEBHERR

Datum

ation

Use only suitable transporting and lifting

devices with sufficient capacity

Park the machine on firm and level ground and

block the chains or wheels

If necessary, remove part of the attachments

during transport

When loading the machine on a flatbed trailer

or railroad car, be sure that the loading ramp

incline is less than 30” and covered with wooden

planks to prevent skidding,

Remove all mud, snow or ice from track

components before moving up the ramp.

Before loading, secure the uppercarriage with

the undercarriage with the lock pin

Align the machine with the fading ramp.

Attach the manual contro! levers to the foot

pedals for sensitive control

Have another person guide and signal the

operator.

Have blocks or wedges ready to block the

machine, if necessary, to prevent the machine

from rolling backwards.

Retract the attachment as far 2s possible and

lower the attachment as close as possible to the

loading surface and carefully drive up the ramp.

and onto the flat bed trailer

When the excavator is on the trailer, release the

uppercarriage lock pin, turn the uppercarriage

back and lower the attachment.

If the backhoe attachment is attached, tilt the

stick and bucket in and relock the upper-

carriage

Carefully secure the uppercarriage and other

parts with chains, wedges and blocks to prevent

slipping

Release the hydraulic pressure, remove the

ignition key, raise the safety lever, close and lock

the cab and close and secure all other doors and

leave the machine

Carefully check out the transport route. Make

sure that width, height and weight allowances

are within the permitted limits

sencrnungibescrition Denomination

07.93

Check that there is enough clearance under:

neath ail bridges, underpasses, utility lines, and

in tunnels.

During the unloading procedure, proceed with

the same care and caution as during the loading

procedure Remove all chains and wedges. Start

the engine as outlined in the Operation and

Maintenance Manual. Carefully drive off the

loading platform Keep the attachment as close

a8 possible to the ground level. Have another

person guide and signal you.

MACHINE TOWING SAFETY

Safety Informations

Observe the correct procedure: check the index

in your Operation and Maintenance manual and

refer to the appropriate section : “Towing the

Excavator"

Only tow the excavator if absolutely necessary,

for example to remove it for repairs from a

dangerous job site

Be sure all towing and pulling devices such as

cables, hooks, and couplers are safe and

adequate

Make sure that the cable or the towing rod are

strong enough and are routed around the

center of the undercarriage or to the towing

hook on the undercarriage, which is designated

for this purpose. Be aware that any damage to

the machine caused by towing is never covered

by the manufacturer's warranty

Never allow anyone to stand near the cable

when pulling or towing the excavator.

Keep the cable tight and free of kinks.

Engage travel slowly, and do not jerk. With a

slack cable, the sudden impact of the load being

towed could snap and break

During the towing procedure, keep within the

required transport position, permissible speed

and distance

After the towing procedure is completed, return

the machine to its previous state

Proceed as outlined in the Operation and

Maintenance Manual when putting the

excavator back inservice

ab

beau

Tat

Peg

Fete

1.10.03

MACHINE MAINTENANCE SAFETY

The machine may not be made unsafe when,

performing maintenance work. Never attempt

maintenance procedures or repairs you do not

understand

Check the Operator's and Maintenance

Manual for service and maintenance intervals,

Make sure you use only appropriate tools for

all maintenance work

Refer to your Operator's and Maintenance

Manual to see, who 's authorized to perform

certain repairs. The operator should only

perform the daily / weekly maintenance

procedures

The remaining work may only be performed by

especially trained personnel

Use only replacement parts corresponding to

the technical requirements specified by the

manufacturer. This is assured by using only

original Liebherr replacement parts.

Always wear proper work clothing when

maintaining the excavator. Certain work may

only be performed with a hard hat, safety

shoes, safety glasses and gloves.

During maintenance, do not allow unautho-

rized personnel to enter the maintenance

Secure the maintenance area, as necessary.

Inform the operator before any special or

maintenance work. Make sure he knows the

person, who is in charge of the work.

If not otherwise noted in the Operation and

Maintenance Manual, always make sure the

excavator is parked on firm an level ground

and the engine is turned off

During maintenance and service work, make

sure you always retighten any loosened screw

connections!

If iL 1s necessary to disconnect or remove any

safety devices during set up, maintenance or

repair, make sure that after completion of

repairs, the safety devices are reinstalled and

checked for proper function

Before any maintenance work and especially

when working under the machine, make sure a

“Do not operate’ tag is attached to the starter

switch. Remove the ignition key

Before any repairs or maintenance work, clean

any oil, fuel and / or cleaning substances from

any fittings and connections

Don't use any harsh cleaners and use only lint

free cloths.

Use only nonflammabie cleaning fluids to

clean the machine

Any welding, torch or grinding work on the

machine must be explicitly authorized. Before

any using a welder, torch or grinder, clean off

any dust and dirt and remove any flammable

materials from the surrounding area. Make

sure the areas sufficiently ventilated

Danger of Fire and Explosion!

Before cleaning the machine with water or

steam (high pressure cleaning) or other

cleaning fluids, make sure that all openings,

which , for safety and/ or functioning reasons

should not be exposed to water / steam/

cleaners, are covered and / or masked off

Especially sensitive are electrical motors,

control boxes and plug connectors.

Make sure that the temperature sensors of the

fire alarm and extinguishers system do not

come in contact with the hot cleaning fluids,

which could trigger the fire extinguishing

system.

Remove all coverings and masking material

after completing the cleaning procedure.

Then check all fuel lines, engine oil lines and

hydraulic oil lines for leaks, loose connections,

chafing and / or damage. Fix any problems

immediately.

Never employ aggressive cleaning agent or

high pressure cleaning apparatus (water or

steam) during the two first months following

machine delivery or repainting

Observe all product safety guidelines when

handling oils, grease, and other chemical

substances

Make sure service fluids and replacement parts

are disposed of properly and in an environ:

mentally sound manner

When using hot service fluids, be very careful

(They can cause severe burns and injury!)

Operate combustion motors and {uel operated

heaters only in well ventilated areas. Before

operating these unils, check ventilation.

n addition, always follow applicable local

regulations.

Never try to lift heavy parts. Use appropriate

lifting devices with sufficient load carrying

capacity. When replacing or repairing parts or

components,make sure they are mounted very

carefully on lifting devices, to prevent any

possible danger. Use only suitable and

technically sound tifting devices, make sure

that lifting tackle, wire cables, etc. has

adequate load carrying capacity

Never position yourself, walk or work

underneath suspended loads.

Never use damaged lifting devices, or devices

which are not sufficient to carry the load

Always wear gloves when handling wire

cables

1.10.03

LIEBHERR

eit

Ask only experienced personnel to attach loads

and guide and s.gnal the crane operator. The

guide must be within the visibility range of the

‘operator and / or must be in direct voice contact

with the operator.

When working overhead, use appropriate and

safe ladders, scaffo'ding or other working plat-

forms designated for that purpose.

Never step on parts or components on the

machine when maintaining or repairing items

overhead

When working high above ground, make sure

you are fitted with ropes and appropriate safety

devices which will prevent a possible fail

Always keep handles, steps, railings, platforms

and ladders free of dirt, snow and ice!

When working on the attachments, for example

when replacing the bucket teeth, makes sure

the attachment is supported properly Never use

metal on metal support!

Never work underneath the machine if it is

raised or propped up with the attachment. The

undercarriage must be supported with wooden

blocks and supports.

Always support the raised machine in such a way

that any shifting to the weight change will not

influence the stability. Do not support the

machine with metal on metal support,

Only qualified, especially trained personnel may

work on travel gear, brake and steering systems.

IF it becomes necessary that the machine must

be repaired on a grade, block the chains with

wedges and secure the uppercarriage to the

undercarriage with the lock pin.

Only qualified, especially trained personnel may

work on the hydraulic system.

Never check for leaks with your bare hands,

always wear gloves. Fluid escaping from a small

hole can have enough force to penetrate the

skin.

Never loosen or remove lines or fittings before

the attachment has been lowered to the ground

and the engine has been tured off, Then turn

the ignition key to contact position, move all

servo controls (joysticks and foot pedals) in both

direction to release pressures. Then release the

tank pressure as outlined in this Operation and

Maintenance Manual

Check all lines, hoses and screw connections

regularly for leaks and externally visible

damage. Fix any damage immediately

BenennungyDescription/Deneminatior

n 07.93

Safety Informations

Oil sescaping from fittings etc. can cause serious

Injury and fires,

Before any repairs, always relieve pressures

before opening up any system sections and

pressure lines (hydraulic lines and air pressure

lines)

Always route and install hydraulic and air

pressure lines properly. Do not interchange the

connections, The length and quality of hoses

must match specifications and requirements

Change all hydraulic hoses in specified or

appropriate time intervals, even though no

damage or detects are visible

Always disconnect the battery cable before

working on the electrical system or before any

arc welding on the machine. Always disconnect

the negative (-) cable first and reconnect it last

Check the electrical system regularly.

Make sure that any problems, such as loose

connections, burnt out fuses and bulbs, scorched

or chafed cables are fixed immediately by an

electrician or qualified personnel

Use only Original fuses with the specified

amperage. Never use a different size or stronger

fuse than the original fuse.

(On machines with electrical medium or high

woitage systems:

If there is any problem with the electrical

energy supply, turn the machine off

immediately.

~ Any work on the electrical system may only be

performed by a qualified electrician or

qualified personnel under the guidance and

supervision of an electrician, according to

electro - technical regulations

If any work 1s required on any parts which carry

current, use a second person to turn off the

main battery switch, if necessary. Rope the work

area off with a red and white safety rope or

chain, and set up warning signs. Use only

insulated tools.

When working on medium and high voltage

components, shut off the voltage and connect

the supply cable to the ground and ground the

components, such as the condensor, with a

grounding rod

Check all disconnected parts if they are truly free

of current, ground them and close them olf

quickly. Insulate any close-by, current carrying

parts.

Pressure

Length

Volume

Torque

Weigth

Temperature:

bar

inches

feet

liter

liter

liter

gallons

cm

m3

Kpm

‘im

felbs

flbs

kg

metrt

metr.t

Ibs

Ibs

Conversion factors

x 145 =

x 03937 -

x 3937 =

x 3937 =

x 25.40 =

x 3048 =

x 2642 =

x 2413 =

x 1.057 =

x 3.785 =

x 06102 =

x 13079 =

x 723 =

x 7375 =

x 138 =

x 1.358 =

x 2.2046 =

x 1102 =

x 2208.6 =

x 4536 =

x o00asa .

Degree C x 1.8 plus 32 = Degree Fahrenheit,

Degree

O degree Celsius = 32 degree Fahrenheit

F minus 32 devided by 18 = Degree Celsius,

Pst

inches

inches

inches

gallons

pints

quarts

liter

cubicinen

cubic yard

flbs

fulbs

Kom

Nm.

Ibs

Shortt

bs

ka

Metzic ton

100 degree Celsius = 212 degree F

LIEBHERR

DatumieaionDave

10.90

Senennung/Descvaton/Dénom ination

Conversion factors

lye.

Type

Abitromia parti ce

BiatwrageFeulle

1.20.00

Torque values for nuts and bolts with standard (coarse) metric thread or fine metric thread

This chart provides the standard torque values for nuts and bolts, This torque chart should be used unless a

specific torque is givenin the manual

The torque values and conversions are approximate (rounded up or down) and apply to nuts and bolts

without additional treatment (not lubricated)

NOTE: The torque value for treated (cadmium plated) or lubricated nuts and bolts is (approx) 20% less of

the values shown in the charts (1 Nm x 0.7375 = ftibs)

EXEMPLE : The torque shown in the chart is 50 Nm (37 ft-lbs)

50 Nm (37 Fibs) less 20% = 40 Nm (30 ft Ibs)

Stondord metre thread Fine metre thread

| Tightening | Tightening Tightening | Tightening

ottsize | Grade | force | torque | Boitsize | Grade | ore | torque

fain | Maint Fain | Mginnm

3500 ad

ma iO a

ér00 S

e400 ei

ms | S300 bs i |

10300 a

9000 vos

m6 13300 88

- 13100 17,0 |

m7 13300 #9

23a00 330

~ “76500 25,0 88 18100 27

wa 220, 370 | ext 133 | deseo) a

des00 | aso 13 | 300 °

1 as) 23600 0

i M91 183 | 33600, 38

| of 8

ae | 26000 a a8 30500 7

wo 163 | 38800, 70 | toxt 3 aa a

Bs | doo aro 33 $3500 36

+—~s5 | 28500 sa

| M10 x 1,25 109 41500 | 79

133 | tee00 3

aa) 38500 a0 as | «3000 96

m2 163 | e600 || 180 Przxtas] 183 | Baooo 8

| 133 | eeo00 | t00 13 | Sano0 tes

88 40500 | 92

maxis | 188 e000 33

3 #009 133

88 ~ "53000 140,0 88 58000 150

wa 163 | 73000 | 2080 Panaxaas| 139 | Beano 20

133 | $3000 | 3860 33 | 180000 38

LIEBHERR we ‘Sub group index’

DaunFanonba Tightening torques

1.20.01

Standard metic thread Fine metic thread

; ;

| Tightening | Tightening Tightening | Tightening

Bottsize | Grade | force | “torque | Gottsize | Grade | tore | “torque

faints | Bgl dim aint | Maint

33] 72000 | ris 3317000 | 230

me | 108 | 106000 | 3100 Jmmexts | 108 | sieo00 | Bao

123 | {24000 | 3700 123 | {38000 | 390

ea | 91000 | 300 ee | 106000 | 30

mia | 103 | 123000 | «430, | mmexas | 109 | ts2000 | ao

123 | Stoo. | sia 123 | 77000 | Seo

88 17000 430 88 134000 480

mao | 103 | t0000 | Gan | waoxts | 103 | 1000 | bao

123 | tsio00 | 50 123 | daanoo | 800

as 146000 | seo ea | 166000 | a0

22 198 | oso. | 30 | maaxts | 108 | d5e000 | 40

123 | aso | 870 123 | 275000 | so70

ea | vea000 | 740 es | 200000 | 830

mea | 103 | 233000 | sae | aweaxas | 183 | 3as000

128 20000 | 1240 | 129 333000

~ 88 189000

maax2 | 103 | dy0000

123 | 313000

38 | 221000 | 1700 ae | 2se000 |

mer | 138 | aiso0n | 1350 | warns | 103 | Sevo00

133 | 310000 | 1850, 123 | 230000

T 88 245000

M27x2 10.9 350000

123 | cdo

—) 8 | 270000 | 3500 ea | 323000

mao | 103 | 3asooo | 2100, | mwoxas | 105 | abco00

123 | #0000 | 2500 23 | $3800

T &3 | 309000

maox2 | 103. | dapoo0

| 125 | S15000

88 335000 2000 \ 88 396000

133 168 | ago | 3800 J maaxas | 163. | Ses000

| 129 560000 3400 12.9 659000

a2 | 309000

waax2 | 103 | aaoo00

| 123 | S1S000

- 88 395000 2600 8B 475000

mas | 103 | e000 | 5700 | awexts | 108 | 677000

123_| eso000 | 4300 123 | 32000

es | «25000 |

| wsexa | 108. | braa00

} 12.9 710000

| 88 475000 | 3400 BB 562000,

mao | 103 | e700 favo, | magxns | 108 | soroco |

125 | 790000 | Se00 [tes | 837000

a2 | 510000

w3axa | 103. | jzo0e0

123 | 0000

Tightening torques for straight male stud coupling -LB=standard version SB = heavy duty version

Straight male couplings = GE (R = inch, M™= metric)

Connections with conical and Connections with

cylindrical sealing edge eolastic seal ring

| Tightening torque Tightening torque

type | tendsice FE | oe | tmcadsice | NY

Mork MorR

LB _

Ge6-im | Mtoxi 2 20 [Gee tied | Mi0xt at 70

GE6-LR R18" 2 20 | GE6-LR-ed R18" cal 10

“eim |wrxis 3 29_| Gee Med |Mi2xi5 | ca? 20

GEB-IR Ria ca 4 29 [Geeited [Rie 2 | 20

GEid-uM | Mtaxts | aa 39 [GE0-iMed| miaxts | cad 29

GE10-LR R14 - a4 39 | GE10-tRed | R 1/4 ca.2 20

GE12-LM Vv [ae 59 | GE 12 iM-ed| 16x15 a3 29

GE12-LR R38" ca. 6 $9 | GE12 LR-ed | R 3/8" ca 4 39

GE15-IM | Mi18x1,5 a7 69 | GE 15-LM-ed | M 18x 1,5 ca.4 i

“Geis-ia PRI eT 708 | GE1S-iR-ed [RUZ ae

GE1S-IM | M22x15 | ca. “i108 GE1E Lw-ed [M22x13 | ca6

GE 18-LR R12" att 108 | GE 18-LR-ed | R 1/2" ca. 6

GE 22-LM M16x1,5 als | 128] GE 22-LM-ed | M 26x 1,5 a7

GE2-IR [Ra a6 157[ GE 27-tR-ed [RA <9

GE2-IM | M33x2 2 216 | GE%e UNved | 26x15 | ca 12

GE 28-1LR RI a. 27 265 | GE26-LR-ed | RI Ta 14

“GE35- IM xd [ea 36 353, | Ge35-Uvved| Ma?x1,5 | ca 20

Ge35-1R | RIWA

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- TM 5 3805 258 24 1Document538 pagesTM 5 3805 258 24 1ashraf elsayedNo ratings yet

- W5A-580TransmissionControlSystem 1998Document12 pagesW5A-580TransmissionControlSystem 1998ashraf elsayedNo ratings yet

- 03 Technical Data R900 LitronicDocument57 pages03 Technical Data R900 Litronicashraf elsayedNo ratings yet

- 07 - Hydraulic - Components R900 LitronicDocument260 pages07 - Hydraulic - Components R900 Litronicashraf elsayedNo ratings yet

- 08 - Electrical - System R900 LitronicDocument129 pages08 - Electrical - System R900 Litronicashraf elsayedNo ratings yet

- 06 - Hydraulic - System R900 LitronicDocument197 pages06 - Hydraulic - System R900 Litronicashraf elsayedNo ratings yet

- Air Compressor - Old Products Volvo BM Volvo 860 - 861 - Brake Wheel Brake 777partsDocument2 pagesAir Compressor - Old Products Volvo BM Volvo 860 - 861 - Brake Wheel Brake 777partsashraf elsayedNo ratings yet

- Air-Pressure Governor Tillv NR - 57290 - Old Products Volvo BM Volvo 860 - 861 - Brake Wheel Brake 777partsDocument3 pagesAir-Pressure Governor Tillv NR - 57290 - Old Products Volvo BM Volvo 860 - 861 - Brake Wheel Brake 777partsashraf elsayedNo ratings yet

- Hydraulic Excavator John Deere Model 230Lcr NSN 3805-01-463-0804 AND Model 230Lcrd With Rock Drill NSN 3805-01-463-0806Document1,113 pagesHydraulic Excavator John Deere Model 230Lcr NSN 3805-01-463-0804 AND Model 230Lcrd With Rock Drill NSN 3805-01-463-0806ashraf elsayedNo ratings yet

- Bogie-Wheel Brake - Old Products Volvo BM Volvo 860 - 861 - Brake Wheel Brake 777partsDocument3 pagesBogie-Wheel Brake - Old Products Volvo BM Volvo 860 - 861 - Brake Wheel Brake 777partsashraf elsayedNo ratings yet

- Wheel Equipment, Trailer - Old Products Volvo BM Volvo 860 - 861 - Power Transmission Hydrostatic D Rive 777partsDocument2 pagesWheel Equipment, Trailer - Old Products Volvo BM Volvo 860 - 861 - Power Transmission Hydrostatic D Rive 777partsashraf elsayedNo ratings yet

- Brake System - Old Products Volvo BM Volvo 860 - 861 - Brake Wheel Brake 777partsDocument2 pagesBrake System - Old Products Volvo BM Volvo 860 - 861 - Brake Wheel Brake 777partsashraf elsayedNo ratings yet

- Alternator CatalogueDocument29 pagesAlternator Catalogueashraf elsayedNo ratings yet

- Adjusting Lever - Old Products Volvo BM Volvo 860 - 861 - Brake Whe El Brake 777partsDocument1 pageAdjusting Lever - Old Products Volvo BM Volvo 860 - 861 - Brake Whe El Brake 777partsashraf elsayedNo ratings yet

- Differential Lock Tillv NR - 59094 - Old Products Volvo BM Volvo 860 - 861 - Power Transmission Hydrostatic Drive 777partsDocument2 pagesDifferential Lock Tillv NR - 59094 - Old Products Volvo BM Volvo 860 - 861 - Power Transmission Hydrostatic Drive 777partsashraf elsayedNo ratings yet

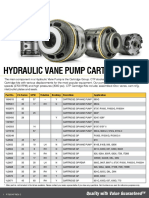

- Hydraulic Vane Pump Cartridges: Quality With Value GuaranteedDocument3 pagesHydraulic Vane Pump Cartridges: Quality With Value Guaranteedashraf elsayedNo ratings yet

- Controls For Reduction Gear - Old Products Volvo BM Volvo 860 - 861 - Power Transmission Gearbox, Manual 777partsDocument2 pagesControls For Reduction Gear - Old Products Volvo BM Volvo 860 - 861 - Power Transmission Gearbox, Manual 777partsashraf elsayedNo ratings yet

- Controls For Differential Lock - Old Products Volvo BM Volvo 860 - 861 - Power Transmission Transmission, Hydraulic Control 777partsDocument2 pagesControls For Differential Lock - Old Products Volvo BM Volvo 860 - 861 - Power Transmission Transmission, Hydraulic Control 777partsashraf elsayedNo ratings yet

- Wheel Equipment, Trailer - Old Products Volvo BM Volvo 860 - 861 - Power Transmission Hydrostatic Drive 777partsDocument3 pagesWheel Equipment, Trailer - Old Products Volvo BM Volvo 860 - 861 - Power Transmission Hydrostatic Drive 777partsashraf elsayedNo ratings yet

- Drive Axle Shafts and Drive Axle Tubes - Old Products Volvo BM Volvo 860 - 861 - Power Transmission Transmission, Hydraulic Control 777partsDocument2 pagesDrive Axle Shafts and Drive Axle Tubes - Old Products Volvo BM Volvo 860 - 861 - Power Transmission Transmission, Hydraulic Control 777partsashraf elsayedNo ratings yet

- Ets Rexroth Standard Parts Stocking ListDocument1 pageEts Rexroth Standard Parts Stocking Listashraf elsayedNo ratings yet

- Controls For High and Low Ranges - Old Products Volvo BM Volvo 860 - 861 - Power Transmission Clutch, Torque Converter 777partsDocument2 pagesControls For High and Low Ranges - Old Products Volvo BM Volvo 860 - 861 - Power Transmission Clutch, Torque Converter 777partsashraf elsayedNo ratings yet

- 1 Systems OperationDocument34 pages1 Systems Operationashraf elsayedNo ratings yet

- Clutches, Gears and Shafts - Old Products Volvo BM Volvo 860 - 861 - Power Transmission Clutch, Torque Converter 777partsDocument4 pagesClutches, Gears and Shafts - Old Products Volvo BM Volvo 860 - 861 - Power Transmission Clutch, Torque Converter 777partsashraf elsayedNo ratings yet

- Gauges: Quality With Value GuaranteedDocument6 pagesGauges: Quality With Value Guaranteedashraf elsayedNo ratings yet

- Elec SystemDocument4 pagesElec Systemashraf elsayedNo ratings yet

- Sun Coast Product CatalogDocument39 pagesSun Coast Product Catalogashraf elsayedNo ratings yet

- Bce Katalog 2022 Metin ConvertDocument58 pagesBce Katalog 2022 Metin Convertashraf elsayedNo ratings yet

- A List of Oil and Fuel Filters and How To Change The Fuel Filters On A Caterpillar 3208the Mounting ofDocument6 pagesA List of Oil and Fuel Filters and How To Change The Fuel Filters On A Caterpillar 3208the Mounting ofashraf elsayedNo ratings yet

- JLG Lull Skytrak Power Train CatalogDocument38 pagesJLG Lull Skytrak Power Train Catalogashraf elsayedNo ratings yet