Professional Documents

Culture Documents

Attachment - 1 - SOP On Core Sample Testing

Uploaded by

NVLNNAGEOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Attachment - 1 - SOP On Core Sample Testing

Uploaded by

NVLNNAGECopyright:

Available Formats

SOP for Core Sample Test to cross verify the concrete strength

(1) Introduction: Generally, the core sample test to cross verify the concrete strength is done wherein

there in any doubt arises about the normal representative corresponding cube strength tests at

various stipulated intervals or in case the corresponding cube tests fail to deliver the desired/

expected minimum strength. However, interpretation of “Core Sample Test” results and equate

the same as equivalent to the corresponding cube test results are very tricky and more of them

than not gives false representation to the concrete strength as this is very much dependent on

many factors. With this outset, this SOP (Standard Operating Procedure) is made to have a common

conclusion on the factors, affecting the core sample test results & corresponding methodologies

to be adopted to mitigate the same as per as practicable along-with outlining the acceptance

criteria.

(2) Sample Preparation: The specimen shall be sawn perpendicular to its longitudinal axis. The

intended load bearing surfaces shall be prepared either by trimming or by capping to improve the

contact with loading machine. Cutting and trimming shall be carried out in such a way that

structural changes of the test specimen are avoided.

Method of End Surface Preparation

a) Trimming: Trimming with a masonry or diamond saw is preferred.

b) Capping

i. Capping with Calcium Aluminate Cement Mortar: It should be done as per clause

7.3.2 IS 516 (Part 4):2018

ii. Capping with Sulphur Mixture Method: It should be done as per clause 7.4 IS 516

(Part 4):2018

➢ Cores should be tested in saturated condition. For the saturated condition, soak in water at 27±3°C

for a minimum of 40 hours and maximum up to 48 hours before testing.

At the time of testing cores shall be in wet condition but all excess surface grit and water should be

removed by wiping off.

(3) Factors affecting the core strength:

Determination of the actual strength of a concrete in a structure is not easy as it is dependent on

the history curing and the adequacy of compaction of concrete. After carrying out many sample

tests, various advanced engineering journals have pointed out that the core strength reduces with

the increase in aspect ratio (length/ diameter), the reduction in core diameter, the presence of

reinforcing steel, the incorporation of gravel in concrete, the increase in core moisture content,

the drilling perpendicular to casting direction, the reduction in concrete strength, the presence of

micro-fissures, elastic modulus, wrong or no application of reliable strength correction factors etc.

Sensitivity: Internal (C3)

(a) Place of drilling of core: Generally, the in-place strength of concrete at the top of member as cast

is less than the strength at the bottom.

(b) Micro-cracking: Micro-cracks can be present if the core is drilled from a region of the structure that

has been subjected to stress resulting from applied load or restraint of imposed deformation.

Rough handling of core samples may also cause micro-cracks.

(c) Curing: Curing period and curing temperature both affect the strength. In mass concrete,

differential moisture and temperature within the member can give variation in results of cores

taken from outer face and inner mass. Inner mass can have lower compressive strength due to high

initial temperature. Similarly for non-continuous curing, the moisture gradient between surface

and inner mass can result in different strengths in concrete, i.e., lower strength in cores along face

due to less curing and higher strength within the inner mass due to availability of moisture for

continuous curing.

(d) Compaction: Entrapped air in the concrete due to poor compaction or bleeding can reduce the

strength. As the extent of poor compaction or bleeding can vary within the member, visual

inspection of cores is essential to see if there is the presence of voids or honeycombs in the core

samples. The extent of non-compaction and/or bleeding can be assessed by the ultrasonic pulse

velocity testing as per IS 516 (part 5/ section 1).

(e) Moisture Content: Moisture condition of cores also affects the strength. Dried core samples give

about 5 to 10% more strength than saturated samples.

Notes:

(i) The overall average effect of factors mentioned at (a) to (e) and other minor factors like coring

direction, etc., is that the core test is generally 85 to 90 percent of corresponding cube strength

and the same has been considered in the acceptance criteria for core given in IS 456. However,

if cracks are observed in the core, the core should not be tested or if cracking is observed during

testing from failure pattern or from load machine displacement curve, the core results can be

discarded.

(ii) The effect of diameter is considered in the correction factors at cl 8.4. 2(IS 516). While there is

consensus that difference between 100 mm and 150 mm diameter cores are negligible, there

is Less agreement concerning smaller diameter cores. The analysis of large number of cores by

various investigators indicated that the strength of 50 mm diameter cores was on an average 6

percent less than the strength of 100 mm diameter cores. In other tests, the average strength

of 60 mm diameter cores was Less by about 7 percent (for cores with average strength of 30-

32 N/mm2). As the strength increases, the difference reduces. The scatter in results of 60 mm

diameter cores is also found to be more. Therefore, when core diameter is less than 100mm,

more number of cores will give better assessment.

Sensitivity: Internal (C3)

Factors to be considered prior to the “Core Sample” test:

(i) The application of latest version of reference code (British/American Concrete Institute/

European Standard Specimen/ Japanese Standard/ Concrete society/IS 456 or IS 516 (Pt.4)

etc.

(ii) Nos. of specimen to be taken- Normally at least 3 specimen are taken & the average values

are reported.

(iii) Location of the core samples are taken- The element should at least be cured for 14 days

for determining early strength, or fully cured for 28 days.

(iv) The rate of load application i.e., 14 N/mm^2/min (cl 8.2 – IS-516) as recommended by most

codes.

(v) The specific aspect ratios (l/d) after trim/capping the samples

(vi) The location/ layer of the sample specimens are taken- Core specimens for compression

tests should preferably not contain reinforcing bars. These may be located before drilling

the core using a pachometer or cover meter. Also, avoid cutting sections containing

conduit, ductwork, or prestressing tendons.

(vii) Visual inspection to be carried out to detect any visual flaws/ honeycomb etc.

(viii) Detection of any micro-cracks through eddy pulse echo tests/UPV machine or any other

acceptable methods

(ix) Methods of handling the core samples. The sample should be placed in a wooden box with

thermocol all around it to avoid collision among the sample and collision with the peripheral

wall.

(x) Interpretation of core sample specimen results through applying appropriate correction

factors

(xi) A complete result sheet with description of methodologies followed throughout the

experiments (End-to-End)

(xii) Direction of drilling.

(xiii) End condition and capping.

(xiv) Reinforcement

(xv) Characteristics of concrete

(xvi) Size of sample

(xvii) The test length of core shall not contain concrete from top 15 percent to 20 percent depth

as top part of the core may not contain uniform distribution of aggregates (maximum up to

60 mm). In case of cores which are not across full depth of member, about 10 percent to

15 percent portion of the bottom side of core may be trimmed off as the portion near to

the broken end may contain some micro cracks/fractures.

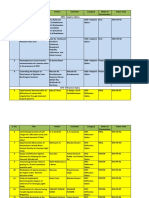

4. Measurement and Calculation:

Sensitivity: Internal (C3)

➢ The ratio of diameter to the nominal maximum size of aggregate shall be greater than 3.

➢ The core diameter shall be 100 mm to 150 mm (±10 mm) as per clause 5.5 of IS 516 (Part 4):2018

➢ l/d ratio for the sample should be greater than 2

➢ For l/d smaller than 2, the test value of compressive strength should be corrected as per formula:

F = 0.11N + 0.78

where,

F = correction factor

N = Length/Diameter ratio

For correction factor for core having diameter less than 100mm.

Diameter of core in mm (no. of cores ≥3) Correction Factor

75±5 1.03

<70 1.06

➢ The equivalent cube strength of concrete shall be determined by multiplying the corrected cylinder

strength by 5/4.

Core Diameter – Take three pairs of measurements at right angles, at the half and quarter points of the

length of the core to an accuracy of ±0.01 mm. Determine the average diameter (dm)

Core Length – Measure the maximum and minimum lengths after completion of the end preparation in

accordance with Cl-7 IS -516(excluding capping material) to an accuracy of ±0.01 mm. Determine the

average length.

Mass – Each specimen shall be weighed as received and/or saturated, as specified. The mass shall be

recorded to the nearest 0.1 percentage of the mass of the specimen.

Density – The density of each specimen shall be determined as received and/or saturated, as specified, in

accordance with IS 516 (Part 2/Sec 1)

Sensitivity: Internal (C3)

Acceptance criteria of core test results:

The acceptance criteria for the core test results shall be as given hereunder.

(a) As the specified compressive strength is generally cube strength, the

results of cores are also expressed in terms of equivalent cube strength.

Accordingly, the acceptance criteria of core test results should also be

correlated to acceptance criteria of cube tests.

Acceptance criteria of Cube test as per IS-456:2000 & Amendment No. 4-

May 2013

1. When the number of samples is only 1[concrete volume = 1 to 5 cum]

Then, minimum requirement: (fck+4) N/mm2 of sample.

2. When the number of samples is less than 4 (i.e., 2,3) [concrete volume

= 6 to 30 cum]

• The requirement of minimum individual test = (fck-2) N/mm2

• The mean of samples = (fck+4) N/mm2

3. Mean of group of 4 non-overlapping consecutive test results in N/mm2

• fck+0.825*standard deviation, or

• (fck+3) N/mm2, whichever is greater.

➢ Individual test result in N/mm2 is greater than or equal to (fck-3)

N/mm2

(b) Acceptance criteria of cube tests in the Indian Standards and other

International Standards are based on statistical analysis technique. The

confidence level considered in the Indian Standard is 95 percent (that is,

95 percent probability that 95 percent of the results will be more than fck

with minimum 30 samples).

(c) For acceptance of concrete based on limited in-situ testing, little lower

confidence level is acceptable. Generally, 75 percent confidence level (75

percent probability of 95 percent results) is considered.

(d) Acceptance of core test results is generally required for two purposes as

mentioned below, particularly for new construction. For existing

structures, the requirement is generally to assess the grade or strength of

concrete in place:

(i) Acceptance for structural adequacy; and

(ii) Contractual acceptance for conformance to specification.

Sensitivity: Internal (C3)

Sensitivity: Internal (C3)

(e) If average of equivalent cube strength of minimum three cores is more

than 0.85 times the specified cube strength and no individual core has

equivalent cube strength less than 0.75 times to specified cube strength,

the core test results are considered satisfactory.

(f) The present procedure of IS 456 suggests that a minimum of three cores or

in case where one set of cube samples (set of 4 consecutive sample) has

failed to be considered. The specified strength will be considered as

characteristic strength.

(g) For overall assessment requirement or where large number of cube sets

(each set consisting of 4 consecutive samples) have failed say 2 consecutive

sets or 3 scattered sets have failed (for the same grade/class of concrete)

within a batch to be assessed, minimum 10 cores will be tested.

Notes:

(1) Detecting outliers in test results: Outlier con be detected by inspection of

load- machine displacement curves or using statistical tests. Out of every

10 cores tested. one core test result con be outlier.

(2) Where the requirements of procedure have been met, the concrete can be

said to be meeting requirements of specification of IS 456. But where, 10

or more than 10 cores are taken but the results do not meet the criteria

but results of average of cores from all the individual members tested have

strength more than 0.85 times the specified values and no individual core

has strength less than 0.75 times the specified strength, the concrete in the

particular batch or member may be accepted for structural adequacy and

contractual acceptance/ penalties/deduction may be decided as per

contract provisions by the project authorities.

(3) In case of any doubt or if it appears to have significant uncertainty in core

sample specimen results, any other alternative tests such as NDT or any

other equivalent test may be conducted with mutual consent.

Report:

The following but not the least information’s shall be included in the report on

each test specimen:

a) Identification mark

b) Date of test

c) Age of specimen (if known/supplied)

d) Maximum nominal size of aggregate (if known/supplied)

Sensitivity: Internal (C3)

Sensitivity: Internal (C3)

e) Curing conditions, including date of manufacture of specimen in the field

(if known/supplied)

f) Density of specimen (after end surface preparation) and dry density (prior

to capping). The density of a core may be determined by weighing it and

dividing it by the volume calculated from average diameter and Iength.

Wet density to be reported, if specifically asked

g) Method used for preparation of specimen: cutting/grinding/capping etc.

h) Dimensions of specimen (diameter and length (after preparation)

i) Cross-sectional area

j) Maximum load

k) Measured compressive strength

I) Corrected compressive strength

m) Corrected cylinder strength

n) Equivalent cube strength; and

Appearance of fractured faces of concrete (satisfactory/unsatisfactory) and, type of fracture,

if these are unusual.

Note: It is recommended that the tests are to be conducted at NABL accredited laboratory &

given the complexity & % of uncertainty, the whole process right from taking the sample till

laboratory tests along-with the analysis of test results prior conclusion is recommended to be

supervised by civil SME & his/her team.

Sensitivity: Internal (C3)

Sensitivity: Internal (C3)

You might also like

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- 5.4) Job Procedure - Concrete Core CuttingDocument6 pages5.4) Job Procedure - Concrete Core CuttingDeepak Kumar MallickNo ratings yet

- CORE TESTING FOR CONCRETE STRENGTHDocument13 pagesCORE TESTING FOR CONCRETE STRENGTHvempadareddyNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Testing Concrete CoresDocument7 pagesTesting Concrete CoresvigneshwarimahamuniNo ratings yet

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- Astm C 393Document4 pagesAstm C 393Arash Aghagol0% (1)

- Concrete Core TestDocument5 pagesConcrete Core Testtaruc jose royNo ratings yet

- C 651Document4 pagesC 651Asep TheaNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Astm C 393 - 00Document4 pagesAstm C 393 - 00AlexandreNo ratings yet

- Astm D 1002Document5 pagesAstm D 1002Aisya IbrahimNo ratings yet

- Astm C-42Document8 pagesAstm C-42thescubatater100% (3)

- Determination of The Compressive Strength of Concrete Hollow BlocksDocument54 pagesDetermination of The Compressive Strength of Concrete Hollow BlocksChrissaNo ratings yet

- Method For Determining The Unconfined Compressive Strength of Intact Rock Core Specimens SCT39Document4 pagesMethod For Determining The Unconfined Compressive Strength of Intact Rock Core Specimens SCT39Deepak Kumar MallickNo ratings yet

- FULLTEXT01Document8 pagesFULLTEXT01balamuruganNo ratings yet

- Flexural Strength of ConcreteDocument3 pagesFlexural Strength of ConcretevikasNo ratings yet

- C1604C1604MDocument5 pagesC1604C1604MJorge Luis Arevalo Lopez100% (1)

- Astm c131 06 LaavDocument4 pagesAstm c131 06 LaavRasya FiezaNo ratings yet

- CIP35 - Testing Compressive Strength of ConcreteDocument2 pagesCIP35 - Testing Compressive Strength of ConcreteGerardo BeckerNo ratings yet

- ASTM (Los Angeles Test)Document4 pagesASTM (Los Angeles Test)Efri DwiyantoNo ratings yet

- Splitting Tensile Strength of Intact Rock Core Specimens: Standard Test Method ForDocument4 pagesSplitting Tensile Strength of Intact Rock Core Specimens: Standard Test Method ForWalter German KrauseNo ratings yet

- Comparing Bond Strength of Steel Reinforcing Bars To Concrete Using Beam-End SpecimensDocument4 pagesComparing Bond Strength of Steel Reinforcing Bars To Concrete Using Beam-End SpecimensJosé Ramón Gutierrez100% (1)

- Sampling and Testing Concrete Masonry UnitsDocument10 pagesSampling and Testing Concrete Masonry UnitsRegenir Macedo AlvesNo ratings yet

- Reconfirmation Notice: AS 1012.3.4-1998 (Reconfirmed) 2014-10-24Document9 pagesReconfirmation Notice: AS 1012.3.4-1998 (Reconfirmed) 2014-10-24heyh jdjNo ratings yet

- Astm C273-00Document4 pagesAstm C273-00Arash AghagolNo ratings yet

- 1 s2.0 S0020740306001846 MainDocument15 pages1 s2.0 S0020740306001846 Mainisraaahmed12No ratings yet

- Rebound Number of Hardened Concrete: Standard Test Method ForDocument3 pagesRebound Number of Hardened Concrete: Standard Test Method ForSNOWTOOSNo ratings yet

- Wsdot Fop For Aashto T 23: 1. ScopeDocument10 pagesWsdot Fop For Aashto T 23: 1. ScopeEinstein JeboneNo ratings yet

- Evaluating Concrete Structures and Reinforcement SamplesDocument3 pagesEvaluating Concrete Structures and Reinforcement SamplesBoris GalindoNo ratings yet

- ''C496.142250 Splitting Tensile Strength of ConcreteDocument5 pages''C496.142250 Splitting Tensile Strength of ConcreteAbu Bakar Muzamil ButtNo ratings yet

- Astm C131 - 2006Document4 pagesAstm C131 - 2006Jessica FarrugiaNo ratings yet

- Astm C-496Document5 pagesAstm C-496Carlos R Martinez100% (2)

- Core Test PDFDocument8 pagesCore Test PDFprince aNo ratings yet

- Steel Strips Sheaths For Pre-Stressing TendonsDocument8 pagesSteel Strips Sheaths For Pre-Stressing TendonsAbdullahNo ratings yet

- Astm C341Document4 pagesAstm C341GUO LEINo ratings yet

- Comparison of Core and Cube Compressive Strength of Hardened ConcreteDocument5 pagesComparison of Core and Cube Compressive Strength of Hardened ConcreteRajmonda RamaNo ratings yet

- Work Methode of Rebound Hammer and Core DrillDocument17 pagesWork Methode of Rebound Hammer and Core DrillAdolf TambunanNo ratings yet

- Testing Concrete CoresDocument7 pagesTesting Concrete Coresjafary007No ratings yet

- Astm C131Document4 pagesAstm C131Devi Suryono ArselorNo ratings yet

- C426 Contraccion Bloques 2010Document6 pagesC426 Contraccion Bloques 2010Javier MendezNo ratings yet

- Is 5816 Splitting Tesile Strength of Concrete-Method of Test.182112830Document11 pagesIs 5816 Splitting Tesile Strength of Concrete-Method of Test.182112830shinjinkuroNo ratings yet

- Mechanical Tests for Evaluating Bond Strength of Repointing MortarsDocument20 pagesMechanical Tests for Evaluating Bond Strength of Repointing Mortarsrajeshji_000No ratings yet

- CIP 35 - Testing Compressive Strength of ConcreteDocument7 pagesCIP 35 - Testing Compressive Strength of ConcretesudhakarmnNo ratings yet

- Method Statement For Pile Integrity Test ProcedureDocument3 pagesMethod Statement For Pile Integrity Test ProcedureDharma Pratap Lamgade100% (1)

- C 174 - C 174M - 97 Qze3nc9dmtc0tq - PDFDocument2 pagesC 174 - C 174M - 97 Qze3nc9dmtc0tq - PDFMarceloNo ratings yet

- API 1104 2014 EditionDocument17 pagesAPI 1104 2014 EditionekkyNo ratings yet

- D994Document4 pagesD994smanoj354No ratings yet

- 26.05.2021-METHOD STATEMENT - VERTICAL LOAD TEST by Anchor MethodDocument16 pages26.05.2021-METHOD STATEMENT - VERTICAL LOAD TEST by Anchor MethodpdksubudhiNo ratings yet

- Standard Test Method For Measuring Thickness of Concrete Elements Using Drilled Concrete Cores1Document3 pagesStandard Test Method For Measuring Thickness of Concrete Elements Using Drilled Concrete Cores1Lupita RamirezNo ratings yet

- Riveted Cold Form Steel Stru Articles TestDocument161 pagesRiveted Cold Form Steel Stru Articles TestroldoguidoNo ratings yet

- Final Long Paper FIB2014Document12 pagesFinal Long Paper FIB2014Matheus L. G. MarquesiNo ratings yet

- Norma TestDocument3 pagesNorma TestIvan Huilcapaz MoraNo ratings yet

- Engineering Fracture Mechanics: Z.X. Chen, L.H. Qian, S.J. ZhuDocument9 pagesEngineering Fracture Mechanics: Z.X. Chen, L.H. Qian, S.J. ZhuMustafa MoussaouiNo ratings yet

- Split Tensile Strength of ConcreteDocument9 pagesSplit Tensile Strength of Concreteabhineet srivastavaNo ratings yet

- Splitting Tensile Strength of Cylindrical Concrete SpecimensDocument5 pagesSplitting Tensile Strength of Cylindrical Concrete Specimenssayra chavezNo ratings yet

- Use of Unbonded Caps in Determination of Compressive Strength of Hardened Concrete CylindersDocument4 pagesUse of Unbonded Caps in Determination of Compressive Strength of Hardened Concrete CylindersYENCEINo ratings yet

- Uia03 - FullDocument12 pagesUia03 - Fullali_naghedifarNo ratings yet

- Thesis Presentation HollyDocument41 pagesThesis Presentation HollyОльга Владимировна МинаковаNo ratings yet

- Department of Mechanical EngineeringDocument4 pagesDepartment of Mechanical EngineeringAriff Muhaimin AhmadNo ratings yet

- SBBSBDocument130 pagesSBBSBRam KumarNo ratings yet

- Ansys Fracture TutorialDocument55 pagesAnsys Fracture Tutorialavenasha100% (2)

- SupportsDocument6 pagesSupportsDana GuerreroNo ratings yet

- Sluice Valve ChampersDocument34 pagesSluice Valve ChampersWessam NourNo ratings yet

- Cells and BatteriesDocument3 pagesCells and BatteriesmelissaNo ratings yet

- ANSI-ASNT CP-105 (2016 Edition)Document129 pagesANSI-ASNT CP-105 (2016 Edition)aun.muhd2100% (1)

- 09 Endurica Beutler Rubber Boot SealDocument11 pages09 Endurica Beutler Rubber Boot SealSrashmiNo ratings yet

- Properties of Concrete For Use in Eurocode 2Document59 pagesProperties of Concrete For Use in Eurocode 2oqusousNo ratings yet

- Finite Element Analysis of The Flow Path of Food 3D Printing NozzleDocument6 pagesFinite Element Analysis of The Flow Path of Food 3D Printing NozzleChethan GowdaNo ratings yet

- Gravimetric Determination of Condensable Components: Group StandardDocument6 pagesGravimetric Determination of Condensable Components: Group Standardthiagomcasimiro100% (1)

- Cyclic Pile Load Test On Large Diameter Piles, A Case Study PDFDocument5 pagesCyclic Pile Load Test On Large Diameter Piles, A Case Study PDFhardik sorathiyaNo ratings yet

- Combined Stresses Mohr's CircleDocument11 pagesCombined Stresses Mohr's Circleواجد کمپیوٹرزNo ratings yet

- TDS BS Epoxy 614Document2 pagesTDS BS Epoxy 614Rock RulzNo ratings yet

- Journal of Food Engineering: Vanessa A. Fernandes, Alejandro J. Müller, Aleida J. SandovalDocument12 pagesJournal of Food Engineering: Vanessa A. Fernandes, Alejandro J. Müller, Aleida J. SandovalExon Omar AnticonaNo ratings yet

- Aquasomes 140317093622 Phpapp01 PDFDocument26 pagesAquasomes 140317093622 Phpapp01 PDFDRx Sonali TareiNo ratings yet

- Physical Science 10th Edition Tillery Solutions ManualDocument9 pagesPhysical Science 10th Edition Tillery Solutions Manualthoabangt69100% (27)

- Electron Gain Enthalpy - The Energy Required to Add an ElectronDocument4 pagesElectron Gain Enthalpy - The Energy Required to Add an ElectronAshish YadavNo ratings yet

- SoiTech Pile Foundation Settlement CalculationDocument1 pageSoiTech Pile Foundation Settlement CalculationJohn Iván Nivia OsorioNo ratings yet

- Project Report. Composite Materials Used On Aircraft WingsDocument15 pagesProject Report. Composite Materials Used On Aircraft WingsYalew MekonnenNo ratings yet

- 9A01301 Mechanics of SolidsDocument4 pages9A01301 Mechanics of SolidssivabharathamurthyNo ratings yet

- Introduction As FoundryDocument10 pagesIntroduction As FoundrySunil BajpaiNo ratings yet

- Engineering Plastic Properties and Processing GuidelinesDocument28 pagesEngineering Plastic Properties and Processing GuidelinesSamuel Berger VeltenNo ratings yet

- 661 Assignment LUSASDocument8 pages661 Assignment LUSASNaqiyatul MiskaNo ratings yet

- Austenitic Alloy Hardness ConversionDocument1 pageAustenitic Alloy Hardness ConversiongoggerNo ratings yet

- 1.heat Tint Poses Corrosion Hazard in Stainless SteelDocument3 pages1.heat Tint Poses Corrosion Hazard in Stainless SteelTree TaweeNo ratings yet

- Process Line Sizing Task and Solution PDFDocument4 pagesProcess Line Sizing Task and Solution PDFKamalNo ratings yet

- Lecon 1Document52 pagesLecon 1Radu SNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNo ratings yet

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- Summary of Neil Postman's Amusing Ourselves to DeathFrom EverandSummary of Neil Postman's Amusing Ourselves to DeathRating: 4 out of 5 stars4/5 (2)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansRating: 4.5 out of 5 stars4.5/5 (21)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetFrom EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetRating: 4.5 out of 5 stars4.5/5 (10)

- Cable Supported Bridges: Concept and DesignFrom EverandCable Supported Bridges: Concept and DesignRating: 5 out of 5 stars5/5 (1)

- The Finite Element Method: Linear Static and Dynamic Finite Element AnalysisFrom EverandThe Finite Element Method: Linear Static and Dynamic Finite Element AnalysisRating: 5 out of 5 stars5/5 (3)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeFrom EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeRating: 4.5 out of 5 stars4.5/5 (59)

- Methodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaFrom EverandMethodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaNo ratings yet

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingFrom EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingNo ratings yet

- Transportation Engineering: Theory, Practice, and ModelingFrom EverandTransportation Engineering: Theory, Practice, and ModelingNo ratings yet

- Pile Design and Construction Rules of ThumbFrom EverandPile Design and Construction Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (15)

- Introducing Structures: A Textbook for Students of Civil and Structural Engineering, Building and ArchitectureFrom EverandIntroducing Structures: A Textbook for Students of Civil and Structural Engineering, Building and ArchitectureRating: 4.5 out of 5 stars4.5/5 (11)

- Principles of Forensic Engineering Applied to Industrial AccidentsFrom EverandPrinciples of Forensic Engineering Applied to Industrial AccidentsNo ratings yet

- Professional Surveyors and Real Property Descriptions: Composition, Construction, and ComprehensionFrom EverandProfessional Surveyors and Real Property Descriptions: Composition, Construction, and ComprehensionNo ratings yet