Professional Documents

Culture Documents

Abstract and Literature Surveys

Abstract and Literature Surveys

Uploaded by

Jagdish annaya0 ratings0% found this document useful (0 votes)

7 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views3 pagesAbstract and Literature Surveys

Abstract and Literature Surveys

Uploaded by

Jagdish annayaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

ABSTRACT

This project focuses on utilizing numerical simulation techniques, particularly

through PROSPER software, to investigate and compare various gas lift valve

designs and operating conditions. Gas lift valves playa critical role in

enhancing reservoir pressure and facilitating fluid flow from the reservoir to

the surface. Gas lift valves are essential components in artificial lift systems

which helps in the removal of fluids, including water and gas, from the

reservoir. Continuous gas lift is a technology used by injecting a highly

compressed gas to decrease the density of fluid column hence provide an

additional lifting energy to increase the production performance of an oil well.

Understanding the behavior and efficiency of these valves is crucial for

maximizing production rates and minimizing operational costs.

PROSPER software is one of the most important packages of the IPM

simulator. The PROSPER simulator is used to model all wells individually

using actual PVT data of the deviation survey, down-hole completion,

geothermal gradient, and average heat capacities. The model is constructed

and matched with the real data and thereby the best fluid and well production

correlations are selected. Then, the constructed model is used to determine

the optimum gas injection rate of the well. Finally, sensitivity analysis tests

are performed to simulate and investigate the effect of other parameters to

have a real impact in optimized gas lift process. The investigated parameters

include injection gas composition, water cut, well-head pressure, and tubing

roughness.

LITERATURE SURVEY

Mayo et al. (1936) used the Lagrange multiplier approach with each of the

gas-lift performance curves modeled using second-order polynomials.

Bahadori et al. (2001) and Denney (2002) have used nodal analysis to

generate the gas-lift performance curve of a single-well based on actual

pressure and temperature surveys along with a suitable multi-phase flow

correlation. Although the model has been established well, the single-well

configuration, considered in isolation of other wells, is not a field gas-tift

optimization solution.

Nishikiori et al. (2002) presented the application of more standard non-linear

optimization procedures for the gas-lift optimization problem. A first-order

quasi-Newton method was developed. This is known to present super-linear

convergence ata starting point close to the optimal solution.

Vazquez and Hernandez (2005) examined a single-well case to determine

the injection depth, pressure and the amount of gas injection. A more

accurate well model, based on mass, energy and momentum balance, was

proposed and the results were reported as being more accurate and therefore

better suited for field-wide simulation studies, than the standard nodal

approach. However, no results were reported for a field-wide application.

Bahadori and Zeidani (2006) indicated that the use of compositional models

over simple black oil models is also recommended practice for better

accuracy.

Rashid et al. (2012) presented a survey for methods and techniques

developed for the solution of the continuous gas-lift optimization problem.

You might also like

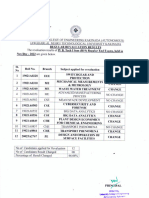

- Result For II B.Tech I Sem (R20) Supplementary Examinations Held in January 2024Document7 pagesResult For II B.Tech I Sem (R20) Supplementary Examinations Held in January 2024Jagdish annayaNo ratings yet

- Dibutyl Phthalate: Cautionary Response InformationDocument2 pagesDibutyl Phthalate: Cautionary Response InformationJagdish annayaNo ratings yet

- Results For IV B.Tech I Semester (R16) Supplementary Examinations Held in December-2023Document4 pagesResults For IV B.Tech I Semester (R16) Supplementary Examinations Held in December-2023Jagdish annayaNo ratings yet

- AIML Projectswise DocumentsDocument1 pageAIML Projectswise DocumentsJagdish annayaNo ratings yet

- Project Report 18021A2708 (1) - CompressedDocument63 pagesProject Report 18021A2708 (1) - CompressedJagdish annayaNo ratings yet

- CamScanner 10-21-2020 19.16.42 - RemovedDocument2 pagesCamScanner 10-21-2020 19.16.42 - RemovedJagdish annayaNo ratings yet

- Water Flooding Development Technology and Enhanced Oil Recovery in Oil FieldDocument3 pagesWater Flooding Development Technology and Enhanced Oil Recovery in Oil FieldJagdish annayaNo ratings yet

- II B.Tech PE PCE Heat transferUNIT V EVAPORATION (Recovered)Document20 pagesII B.Tech PE PCE Heat transferUNIT V EVAPORATION (Recovered)Jagdish annayaNo ratings yet

- Task 5Document2 pagesTask 5Jagdish annayaNo ratings yet

- InternshipDocument1 pageInternshipJagdish annayaNo ratings yet

- Banner-KSS - 16.11.2023Document1 pageBanner-KSS - 16.11.2023Jagdish annayaNo ratings yet

- Environmental Control in Petroleum EnginDocument3 pagesEnvironmental Control in Petroleum EnginJagdish annayaNo ratings yet

- Hse Mid-2 AnswersDocument9 pagesHse Mid-2 AnswersJagdish annayaNo ratings yet

- Noc20 Ch31 Assignment Week 6Document1 pageNoc20 Ch31 Assignment Week 6Jagdish annayaNo ratings yet

- Circular On Yuva SamwadDocument1 pageCircular On Yuva SamwadJagdish annayaNo ratings yet

- IV B.tech I Sem (R19) Regular Exams Dec - 2022 Revaluation ResultsDocument1 pageIV B.tech I Sem (R19) Regular Exams Dec - 2022 Revaluation ResultsJagdish annayaNo ratings yet

- Vapor Recovery UnitsDocument13 pagesVapor Recovery UnitsJagdish annayaNo ratings yet

- Govt CSP Report by AKASH (3EDITED)Document55 pagesGovt CSP Report by AKASH (3EDITED)Jagdish annayaNo ratings yet

- Member Certificate For 5338643Document1 pageMember Certificate For 5338643Jagdish annayaNo ratings yet

- 7.1.15. Human Values and Professional EthicsDocument5 pages7.1.15. Human Values and Professional EthicsJagdish annayaNo ratings yet

- Withheld Result of IV B.Tech II Semester (R19) Regular Examinatins Held in Feb-2023Document1 pageWithheld Result of IV B.Tech II Semester (R19) Regular Examinatins Held in Feb-2023Jagdish annayaNo ratings yet

- Certificate For 963404155Document1 pageCertificate For 963404155Jagdish annayaNo ratings yet

- Proceedings: Eighteenth Wo Kshop Geothermal Reservoir EngineeringDocument9 pagesProceedings: Eighteenth Wo Kshop Geothermal Reservoir EngineeringJagdish annayaNo ratings yet

- Final Thorax Disease GhfykuukiDocument48 pagesFinal Thorax Disease GhfykuukiJagdish annayaNo ratings yet

- Water Influx 1Document50 pagesWater Influx 1Jagdish annayaNo ratings yet

- PTRL5005 2016 Group30 FinalReport GOSP PDFDocument89 pagesPTRL5005 2016 Group30 FinalReport GOSP PDFJagdish annayaNo ratings yet

- r19 Ai Unit IV Chapter 1Document19 pagesr19 Ai Unit IV Chapter 1Jagdish annayaNo ratings yet

- SPE JNTUK Student Chapter Quiz Competition 1Document3 pagesSPE JNTUK Student Chapter Quiz Competition 1Jagdish annayaNo ratings yet

- 1 s2.0 S0920410519308332 MainDocument14 pages1 s2.0 S0920410519308332 MainJagdish annayaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)