Professional Documents

Culture Documents

R ATFF Handouts

Uploaded by

marlonpejante981Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

R ATFF Handouts

Uploaded by

marlonpejante981Copyright:

Available Formats

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC.

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – BASIC TRAINING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 1

Contents

PAGE

01 Introduction 02

02 Organize and train fire parties

Composition and allocation of personnel to fire parties 04

Strategies and tactics for control of fires in various parts of 06

the ship

Preparation of contingency plans 09

03 Control fire-fighting operations aboard ships

Use of water for fire extinguishing, the effect on ship stability, 13

precautions and corrective procedures

Fire fighting involving dangerous goods 13

Investigate and compile reports on incidents involving

04 fire

Assessment of cause of incidents involving fire 22

Inspect and service fire-detection and fire- extinguishing

05 systems and equipment

Requirements for statutory and classifications surveys 28

Fire detection and extinguishing systems and equipment 29

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 2

01 COURSE INTRODUCTION

Mandatory minimum requirements for training in advanced fire fighting

1. Seafarers designated to control fire-fighting operations shall have successfully completed advanced

training in techniques for fighting fire, with particular emphasis on organization, tactics and

command, in accordance with the provisions of section A-VI/3, paragraphs 1 to 4 of the STCW

Code and shall meet the standard of competence specified therein.

2. Where training in advanced fire fighting is not included in the qualifications for the certificate to be

issued, a certificate of proficiency shall be issued indicating that the holder has attended a course of

training in advanced fire fighting.

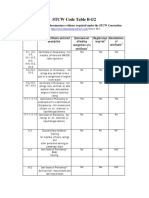

Section A-VI/3

Mandatory minimum requirements for the issue of certificates of advanced fire fighting

Standard of competence

1. Seafarers designated to control fire-fighting operations shall have successfully completed

advanced training in techniques for fighting fire, with particular emphasis on organization,

tactics and command, and shall be required to demonstrate competence to undertake the

tasks, duties and responsibilities listed in column 1 of table A-VI/3.

2. The level of knowledge and understanding of the subjects listed in column 2 of table A-VI/3

shall be sufficient for the effective control of fire-fighting operations on board ship*.

3. Training and experience to achieve the necessary level of theoretical knowledge,

understanding and proficiency shall take account of the guidance given in part B of this Code.

4. Every candidate for certification shall be required to provide evidence of having achieved the

required standard of competence, in accordance with the methods for demonstrating

competence and the criteria for evaluating competence tabulated in columns 3 and 4 of table

A-VI/3.

5. Seafarers qualified in accordance with paragraph 4 in advanced fire fighting shall be required,

every five years, to provide evidence of having maintained the required standards of

competence to undertake the tasks, duties and responsibilities listed in column 1 of table A-

VI/3.

6. Parties may accept onboard training and experience for maintaining the required standard of

competence of table A-VI/3, in the following areas:

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 3

.1 Control fire-fighting operations aboard ships;

.1.1 fire-fighting procedures at sea and in port, with particular emphasis on

organization, tactics and command;

.1.2 communication and coordination during fire-fighting operations;

.1.3 ventilation control, including smoke extraction;

.1.4 control of fuel and electrical systems;

.1.5 fire-fighting process hazards (dry distillation, chemical reactions, boiler

uptake, fires);

.1.6 fire precautions and hazards associated with the storage and handling of

materials;

.1.7 management and control of injured persons; and

.1.8 procedures for coordination with shore-based fire fighters.

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 4

02

Introduction

ORGANIZE AND TRAIN

FIRE PARTIES

The organisational response takes place depending on the situation of the fire whether it is

extinguished or not. In most cases, the Officer of the Watch gives a status report to the captain before

the latter takes the command and control of the situation.

The fire-fighting organisation during which the captain is in command of the situation, and properly

uses the available resources at his disposal. There are different emergency groups ready to respond,

using the fighting procedures to fight the fire.

COMPOSITION AND ALLOCATION OF PERSONNEL TO FIRE PARTIES

1. Emergency teams

The emergency teams are teams of crew located at the muster station. They will perform designated

tasks in an organisational manner to cope with the fire. The number of emergency groups varies with

the type and size of the ship and also the number of the crew. In large cruise ships, with 100 crew

members and more, there are four emergency teams to cope with ship emergency, namely, the

bridge team, the attack team, the continuous run ship and the emergency stand-by team. Meanwhile,

in cargo ships, there are also four emergency teams, but structured in a different way. Nevertheless,

the key element is that one team has to lead the others; this is always the bridge team. Another one

will fight the fire, another will help the others to conduct their designated tasks and prepare

evacuation, and the last one, the engine room team, is in charge of the engine room.

2. The bridge team

The bridge team, as its name indicates, is located on the bridge or at an alternative site if necessary

(cf. Chapter 2). It is also called operational command team in some ships (Norway Committee of

Investigation, 1991) because of its commanding position during the emergency. Led by the master,

this team is intended to lead and co-ordinate all efforts and keeps a detailed timed record of events in

case of a shipboard fire. Based on the information from the other teams, it shall co-ordinate the entire

fire fighting operation. It should normally consist of at least the master, the officer of watch and the

helmsman (Stranding, 1986). However, in passenger ships with a large crew, this team is reinforced

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 5

by other personnel to help in the co-ordination of the emergency. In the author’s opinion, due to the

importance of the assigned task of this team, the officer of watch and the helmsman should be

particularly chosen because of their special qualification. Table 1 provides an example of a typical

bridge team.

3. The attack team

The attack team, as its name indicates, is intended to attack, more precisely to fight the fire under the

direction of the bridge team. Both Nazzaro (1980) and Standring (1986) mention that this team should

be led by the chief mate. This is reasonable because the chief mate is the second in command

onboard a ship. Therefore, he normally has to act as on scene command in a fire emergency because

of his special knowledge of the crew and the ship equipment. However, it is vital that he should have

good knowledge of firefighting. The attack team is normally composed of ten crewmembers in a

typical emergency organisation (Standring, 1986). However, the number mostly depends on the size

of the crew and type of the ship.

4. The support team

The support team is normally assigned to support the attack team when the latter is performing its

tasks in a fire fighting operation. It is usually intended to provide extra manpower by helping the

members of the attack team to get equipped and by fetching equipment and breathing apparatus

(Standring, 1986). In the vicinity of the fire, the support team has to establish a staging area, which is

a smoke free area that is protected from the fire. Supplies of, inter allia, hose nozzles, axes and spare

cylinders for breathing apparatus should be brought to this area by the support team (Nazzaro, 1980).

Apart from the tasks mentioned above, Skipp (1985) also identifies the following:

- Providing first aid to injured persons

- Preparing lifeboats and life rafts for evacuation

- Recharging self contained breathing apparatus cylinders

- Conducting security patrols

- Providing boundary cooling.

5. Engine room team

This team is located in the engine room team station, normally led by the chief engineer. It may also

be called the Technical Department in some ships (Norway Committee of Investigation, 1991). Its task

is to control the technical, mechanical and electrical devices that are needed to support the

emergency response and to maintain and provide maximum readiness to engines and auxiliaries in

the engine room. In practice, such tasks are to control the operation of the emergency pumps and

generator and react promptly but safely to the command from the bridge. Moreover, it should also

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 6

advise the bridge if the emergency has any adverse effect on the equipment and suggest alternative

actions to remedy the deficiencies to the equipment.

STRATEGIES AND TACTICS FOR CONTROL OF FIRES IN VARIOUS PARTS OF

THE SHIP

Fire fighting strategy for cargo ships -Safety training and awareness

Fire is a constant hazard at sea. It results in more total losses of ships than any other form of

casualty. Almost all fires are the result of negligence or carelessness.

Fighting a fire on board ship may amount to a life or death struggle; to enter into such a conflict

unprepared and unarmed is to invite failure. The 'armaments' or equipment available have been

described. Now comes the matter of being prepared.

A basic strategy should be followed in all fire fighting situations. This will involve four distinct aspects,

which are locating, informing, containing and finally extinguishing a fire.

A fire may be located by detection devices fitted in the various spaces in a ship or simply by smelling

or seeing smoke. Alert personnel, whether on watch or not, should always be conscious of the danger

of fire and the signs which indicate it.

Certain areas are more liable to outbreaks of fire and these should be regularly visited or checked

upon. Once detected the presence of a fire must be made known quickly to as many people as

possible. It is essential therefore that the bridge is informed of the location and extent of the fire. A

small fire might reasonably be immediately tackled by the finder but attempts should be made whilst

fighting the fire to attract attention. Shouting 'Fire', banging on bulkheads, deliberately setting off

equipment alarms in the vicinity, all are possible means of attracting attention. Anyone finding a fire

must decide whether to fight it immediately or whether to leave it and inform others first. The more

people who know of a fire the greater the efforts that can be brought to bear upon it. If in doubt—

inform! Ships are built to contain fires in the space where they begin.

Fire resisting bulkheads and decks are positioned at appropriate distances in order to limit the spread

of fire, and it remains for fire fighting personnel to ensure that these barriers are secure whilst

attempting to fight the fire. All doors and openings should be closed, all ventilation and exhaust fans

stopped, and flammable material isolated from the space. It should be remembered that a fire exists

in three dimensions and therefore has six sides, so it must be contained on six sides. A small fire can

usually be easily extinguished but it can also quickly become a big fire, so the fire extinguishing must

be rapid if it is to be effective. Fire fighting strategy will vary according to the location of the fire. The

various areas and their particular problems will now be examined.

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 7

Accommodation

The accommodation areas will be made up almost exclusively of Class A material requiring the use of

water or soda-acid type extinguishers. Electrical circuits however should be isolated before directing

quantities of water into an accommodation area. AH ventilation and exhaust fans must be stopped

and fire flaps closed. If hoses are employed a water spray should be used in order to achieve the

maximum cooling effect. The accommodation will no doubt fill with smoke and therefore breathing

apparatus should be available.

The galley area presents a somewhat different fire hazard. Here Class B materials, such as cooking

oil, fat or grease, will be present requiring the use of foam, dry powder or carbon dioxide

extinguishers. A fire blanket quickly spread over burning cooking utensils could extinguish a

potentially dangerous fire.

Machinery spaces

Machinery space fires will involve mainly Class B material requiring the use of foam type

extinguishers. Only the smallest of fires should be tackled with hand extinguishers. The alarm should

be quickly given and the bridge informed. The ventilation fans should be stopped and fire flaps closed.

Any oil tanks close to the fire should be closed off and kept cool by hosing with water.

Foam-making equipment should be used on the fire and foam spread over the tank tops and bilges.

Water spray can also be used to cool the surroundings of the fire, but a water jet should not be used

in the machinery space since it will move any burning oil around and subsequently spread the fire.

Only if the situation becomes hopeless should the space be evacuated and gas flooding used. The

machinery space contains most of the fire fighting equipment as well as the propulsion machinery. If it

is vacated then control of the situation is lost to a 'one-shot' attempt at gas flooding.

If evacuation is decided upon all personnel must be made aware of the decision. The space must

then be completely sealed against the entry or exit of air and all oil supplies isolated at the tank

valves. When all these matters have been attended to, the flooding gas can be admitted and, if the

surrounding bulkheads hold to contain the fire, it will quickly go out. Cooling of the boundary

bulkheads should continue from outside the space whilst flooding is taking place.

When the extinguished fire has been left long enough to cool down the space can be re-entered. This

should be done from the tunnel, if there is one, or the lowest point remote from the seat of the fire.

Engineers wearing breathing apparatus may now enter, taking water spray hoses with them to cool

down any hot surfaces. Cooling and smoke dispersal are the first priorities to provide an atmosphere

in which others can operate and gradually bring the machinery back into service. Where a machinery

space fire involves electrical equipment then only dry powder or carbon dioxide extinguishers can be

used until the equipment is isolated.

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 8

Cargo spaces

Where a fire occurs in a cargo hold with a smoke detection and carbon dioxide flooding system fitted,

the procedure is straightforward and has already been described. It is essential to ensure before

flooding that all air entry and exit points are closed by fire dampers and all fans are stopped.

Oil tankers with their cargo tanks full or empty present a potentially serious fire hazard, A fire

occurring in a cargo tank will doubtless lead to an explosion or an explosion will lead to fire. The rapid

use of foam making equipment, the cooling of surrounding areas and the isolation of the fire should

immediately take place.

The prevention of fire and explosion conditions is the main prerequisite with oil tankers. With

reference to hydrocarbon vapours, such as those present in oil tanks, the diagram shown in Figure

13.15 should be considered. The relative proportions of hydrocarbon vapour and oxygen necessary

for a fire or explosion are shown. By keeping the tank atmosphere outside of the flammable limits, no

fire or explosion can occur. It is usual practice to inert the tank atmosphere by displacing the oxygen

with an inert gas and thus effectively prevent a fire or explosion. The inert gas producing systems

have already been described.

Training and awareness

Where is the nearest fire extinguisher? What type is it? How is it operated? At any position in the ship

these questions should be asked and answered. Knowing how to operate any extinguisher just by

looking at it will indicate some degree of training and an awareness of the fire defences.

Fire drills are often referred to as 'Board of Trade Sports', but they merit a more sober attitude than

they receive. Practices are useful and should be seriously undertaken. Equipment should be tried and

tested to ensure that it works and is ready when needed. Regular maintenance should take place on

extinguishers, fire pumps, hydrants, hoses, etc. All engineers should be familiar with recharging and

overhauling extinguishers and those in charge should make sure it is regularly done. The statutory

surveys do much to ensure that equipment is ready for use but the one year period between leaves a

lot of time for neglect.

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 9

PREPARATION OF CONTINGENCY PLANS

Planning, preparedness and training

The system and plans will be of little value if the personnel who are to use them are not made familiar

with them. Responsibility should be assigned for each emergency system, and it should be incumbent

on the company that all relevant officers and crew members should understand, be trained in and be

capable of operating the emergency systems, such as fixed fire extinguishing systems, emergency

generator, emergency steering, fire pumps, etc.

Successful management of an emergency or marine crisis situation depends on the ability of the

shipboard personnel, the company, and external emergency coordinating authorities to muster

sufficient resources in the right positions quickly.

An important goal of planning, preparedness and training programmes should be to increase

awareness of safety and environmental issues.

Training should be at regular intervals and, in particular, be provided to shipboard personnel

transferred to new assignments.

Records of all emergency drills and exercises conducted ashore and on board should be maintained

and be available for verification. The drills and exercises should be evaluated as an aid to determining

the effectiveness of documented procedures and identifying system improvements.

When developing plans for drills and exercises, a distinction should be made between full-scale drills

involving all the parties that may be involved in a major incident and exercises limited to the ship

and/or the company.

Feedback is essential for refining emergency response plans and emergency preparedness based on

the lessons learned from previous exercises, accident investigations or real emergencies, and

provides an avenue for continuous improvement. Feedback should ensure that the company, as well

as the ship, is prepared to respond to shipboard emergencies

In conclusion, as a minimum, provide information on the procedures, programmes or activities

developed in order to:

familiarize shipboard personnel with the provisions of the system and plans;

provide training for shipboard personnel about the system and plans, in particular for

personnel transferred to new assignments;

schedule regular drills and exercises to prepare shipboard personnel to deal with potential

shipboard emergency situations;

coordinate the shipboard personnel and the company's actions effectively, and include and

take note of the aid which could be provided by external emergency coordinating authorities;

and

prepare a workable feedback system.

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 10

Response actions

In an emergency, the best course of action to protect the personnel, ship, marine environment and

cargo requires careful consideration and prior planning. Standards for shipboard procedures to

protect personnel, stabilize conditions and minimize environmental damage when an incident occurs

should therefore be developed.

In this context reference is made to the guidelines already developed by the Organization, which

contain information to provide a starting point and to assist personnel in the preparation of plans for

individual ships.

The variety of plans to be incorporated in the system should be simple documents which outline

procedures different from those used for daily routine operations. With normal operational procedures

very difficult problems can be handled, but an emergency situation, whether on the ship at sea or in a

port, can extend those involved beyond their normal capabilities.

In order to keep the plans held by ship and shore identical, and to reduce possible confusion in an

emergency as to who is responsible for which action, plans should make clear whether the action

should be taken by shipboard personnel or shoreside personnel.

Taking these particulars into consideration, the module "Response actions" should comprise main

groupings of emergency shipboard situations.

Potential emergency situations should be identified in the plans, including, but not limited to, the

following main groups of emergency:

.1 fire;

.2 damage to the ship;

.3 pollution;

.4 unlawful acts threatening the safety of the ship and the security of its passengers and crew;

.5 personnel accidents;

.6 cargo-related accidents; and

.7 emergency assistance to other ships.

In order to give the company the necessary flexibility for identifying, describing and responding to

further shipboard emergency situations, more specific types of emergency should be included in the

main groups.

The above-mentioned main groups can be further subdivided to cover the majority of shipboard

emergencies. The detailed response actions should be formulated so as to set in motion the

necessary steps to limit the consequence of the emergency and the escalation of damage following,

for example, a collision or grounding.

The company should identify all possible situations where shipboard contingency planning would be

required relative to the operational requirements, ship's type, equipment and trade. The company

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 11

should consider which shipboard contingency plans should be reviewed and/or updated whenever

changing trade patterns.

In all cases priority should be given to actions which protect life, the marine environment and property,

in that order. This means that "initial actions" which are common for all ships, regardless of their type

and the cargoes carried, should be fully taken into account when formulating "subsequent response"

procedures.

The planning of subsequent response actions should include information relating to the individual ship

and its cargo, and provide advice and data to assist the shipboard personnel. Examples of such

information are listed below:

Information on:

the number of persons aboard; and

the cargo carried (e.g. dangerous goods, etc.);

Steps to initiate external response:

.1 search and rescue coordination;

.2 buoyancy, strength and stability calculations;

.3 engagement of salvors/rescue towage;

.4 lightering capacity; and

.5 external clean-up resources;

Ship drift characteristics; and

General information:

.1 cooperation with national and port authorities; and

.2 public relations.

Although shipboard personnel should be familiar with the plan, ease of reference is an important

element in compiling and using an effective plan. Allowance must be made for quick and easy access

to essential information under stressful conditions. Appendices 3 and 4 show a detailed picture of the

sequence of priorities for "initial actions" in an emergency situation and their link with the "subsequent

response".

Reporting procedures

A ship involved in an emergency situation, or in a marine pollution incident will have to communicate

with the appropriate ship interest contacts and coastal State or port contacts. Therefore the system

must specify in appropriate detail the procedures for making the initial report to the parties concerned.

This module should take care of the following:

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 12

Every effort should be made to assure that information regarding:

.1 ship interest contacts;

.2 coastal State contacts; and

.3 port contacts,

for reporting emergencies are part of the system and are regularly updated.

The establishment and maintenance of rapid and reliable 24-hour communication lines between the

ship in danger and emergency control centre(s), company's main office and national authorities (RCC,

points of contact), is important.

Those managing response operations on board and services assisting ashore should keep each other

mutually informed of the situation.

Details such as telephone, telex and telefax numbers must be routinely updated to take account of

personnel changes. Clear guidance should also be provided regarding the preferred means of

communication.

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 13

03 CONTROL FIRE FIGHTING

OPERATIONS ABOARD

SHIPS

USE OF WATER FOR FIRE EXTINGUISHING, THE EFFECT OF SHIP STABILITY,

PRECAUTIONS AND CORRECTIVE PROCEDURES

Flooding aboard a ship can create compartments with free surface. This can affect the stability of the

ship. Flooding can be caused by fire fighting as well as breaches in the hull. Putting fires out by a fire

hose can add weight high in the ship and create free surface. Both of these will cause a rise in the

center of gravity, smaller righting arms and less overall stability.

SS Normandie, 1942 This ship caught fire in New York City harbor while being converted from a

luxury passenger liner to a troop transport to support the war effort. The resulting firefighting efforts

from off-hull led to massive weight additions high on the upper decks and large free-surfaces inside

the ship. After the fire was extinguished, the ship capsized in calm water pier side as a result of the

negative stability introduced by the free-surface and vertical weight shift. This would have been

avoided had the ship been de-watered following the fire.

FIRE FIGHTING INVOLVING DANGEROUS GOODS

Be prepared

Preventing a fire from occurring is the most important part of a shipboard safety programme.

However, once a fire has started, a well-trained crew is the best defence for bringing the fire under

control. Given the complexity of extinguishing a fire involving dangerous goods, it is essential that the

advice in this Guide be incorporated into the ship's training regime so that the crew will be able to

respond to a fire casualty in a timely and effective manner.

This Guide should be integrated into a Safety Management System (SMS). Procedures contained in

the shipboard emergency plan should be tailored to the individual ship.

The fire-fighting procedures within the EmS SCHEDULES are different for "on deck" and "under deck"

stowage. For specific ship types (e.g. hatchless container ships) or cargo holds (e.g. open vehicle

decks of ferries), these two procedures have to be assigned specifically to the individual ship.

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 14

Given the toxic nature of some of the dangerous goods involved, accommodation spaces should be

protected from fire and smoke as far as possible (e.g. water spray). Therefore, the ventilation systems

for working and living spaces should be shut off, closed and secured to reduce the possibility of

vapours, dusts and gases penetrating these spaces. In some instances, it may be necessary to turn

the ship's accommodation spaces upwind, if possible.

The safety of fire-fighting personnel is most important. Use of appropriate protective clothing (i.e. a

firefighter's outfit when dealing with a fire) and self-contained breathing apparatus, to protect skin and

lungs from toxic and/or corrosive liquids, vapours, dusts and gases, is essential. This equipment

should be suitable for each individual member of the fire-fighting team, as working with such

equipment requires a high level of fitness and training. It should be kept in mind that even a weak

acute illness may interfere with a crew member's fitness. In addition, pregnant crew members should

not be exposed to dangerous vapours.

It is also essential to ensure that there is always an escape route for fire-fighting personnel despite

the limitations due to narrow exit paths and the danger of falling overboard.

Identification of the dangerous good(s) involved

It is essential to identify the dangerous good(s) involved in the fire in order that the specific EmS FIRE

SCHEDULE(S) for the cargo(es) may be consulted and appropriate action taken. This is important

because some dangerous goods are incompatible with some fire-fighting media and could exacerbate

the situation (e.g. use of a water-based extinguishing medium on water-reactive cargoes).

An identification number with four digits preceded by the letters "UN" is assigned to all dangerous

goods. From the UN Number, it is possible to find the appropriate EmS FIRE SCHEDULE. The

Dangerous Goods List in part 3, chapter 3.2 of the IMDG Code contains the names and the UN

numbers, as well as the EmS SCHEDULE NUMBERS. The special Dangerous Goods Manifest and

the detailed Stowage Plan required by SOLAS regulation VII/4.2 will also contain the proper shipping

name and UN number of the dangerous good(s) concerned. Packages will usually be labelled as well.

Specific information as to properties of dangerous goods may also be found in the Dangerous Goods

List in the IMDG Code. Dangerous goods are classified and labelled according to their hazards.

Labels and marks on packages provide a warning of the general risks to be encountered. Personnel

should understand the labelling system.

Emergency preparedness should form part of the ship's SMS as required by the ISM Code. Prepared

information can reduce errors during a fire emergency. Therefore, it is recommended that the EmS

SCHEDULE(S) be identified and included on the Dangerous Goods Manifest and Stowage Plan

recording the stowage position of the cargo. That will enable key members of the crew to know in

advance which emergency procedures could be necessary. In the event of a fire, the allocation of a

specific EmS FIRE SCHEDULE via identification of cargo via the UN number takes time and is open

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 15

to error, especially in mixed cargoes in one container. Furthermore, some fire-fighting procedures

may require specific media and operations could be affected by the stowage location of such media.

The advice given in the EmS FIRE SCHEDULE should be directly usable based on the stowage

information, without time-consuming identification and location of the cargo involved.

Cool and suffocate

In general, fires require heat (energy) and oxygen to start burning. Only a limited number of chemicals

do not need oxygen from the air. Therefore, the aim of fire fighting is to exclude oxygen and to cool

the cargo(es). On board ship, this is generally carried out by using water spray or gas extinguishing

systems.

Some burning cargoes will need special fire-fighting media (like dry inert material) to suffocate the fire.

In such circumstances, normal fire-fighting procedures are often impracticable, and concentrating on

cooling nearby cargo and ship structures is recommended in such cases.

Firefighters should be made aware of the hazards of opening doors of an over-heated space or freight

container which is suspected of containing cargo on fire. There may be a lack of oxygen inside and

fresh air from outside the space may instantly start a fire, and cause a flashback that could injure the

firefighters. Cool down the container first!

FIRE-FIGHTING MEDIA

Water

Water is the obvious fire-fighting medium at sea and is recommended for most fires involving

dangerous goods. However, it should be noted that shore-based firefighters may use a different

medium.

When water is applied to a burning cargo, the temperature is reduced and the fire will be extinguished

when the temperature drops below the ignition point. However, water is not suitable to extinguish all

fires involving dangerous goods. Different fire-fighting media should be used if so indicated on the

specific EmS FIRE SCHEDULE.

If the fire is under deck, consideration should be given to the stability of the ship when flooding the

hold with water.

Some dangerous goods will react chemically with water, producing flammable and/or toxic gases. The

most effective way to extinguish a fire involving these dangerous goods is to smother them with a dry

inert powdered material. However, the availability of suitable inert material on board is limited. It may

also be dangerous to approach the fire in order to use inert material properly. Consequently, the most

appropriate method of extinguishing the fire may be to use copious quantities of water. This would

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 16

have an overall cooling effect on the fire even though the water may react with the dangerous goods

involved.

Ships are equipped with a number of dual-purpose spray/jet nozzles as required by SOLAS. Most

EmS FIRE SCHEDULES recommend that the nozzles be set to spray when used to fight fires. Water

spray may also be achieved by using water jets from some distance. This method of producing water

spray is generally recommended. However, it is dangerous to direct a water jet onto the fire at close

range because this could result in the spread of burning material.

The term "copious quantities of water" used within the EmS FIRE SCHEDULES refers to the minimum

total quantities of water provided for optimal fire fighting using four jets of water, as required by

SOLAS regulation II-2/10. The master and crew should know the practical limitations that may be

encountered at specific stowage locations in this respect.

Following the advice "use copious quantities of water" or "water spray from as many hoses as

possible" may interfere with the safety of the ship with regard to the ship's stability. Stress forces on

the hull due to increased quantities of water in the ship should be considered.

Fixed gas fire-extinguishing systems

If a fixed gas fire-extinguishing system is used for incidents under deck, all hatches and vent dampers

should be closed and ventilation shut off before the system is activated. If smoke is seen coming from

around the hatches, the leaks should be sealed with any suitable material available.

The majority of the fixed gas fire-extinguishing systems use carbon dioxide (CO2), but some use

nitrogen (N2) as the extinguishing medium. The instructions on board should be followed. The fire

control plan will sometimes specify a given volume of gas to be applied to a given space. No

advantage will be gained by exceeding this volume of gas where burning dangerous goods are

involved.

It is important to realize that it will take an appreciable time for the space to cool after the fire has

been extinguished. Therefore it would be extremely dangerous to reopen the hatches since the

extinguishing gas would escape and air would enter the space again, thus allowing the fire to reignite.

The ship's onboard instructions for such cases should be followed.

Fixed gas fire-extinguishing systems are not effective against all fires. EmS FIRE SCHEDULES may

contain specific information in this regard.

Fixed pressure water spraying systems

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 17

In some ships (e.g. ro-ro ships and car ferries), some cargo spaces may be fitted with a water

drencher or spray system instead of a fixed gas fire-extinguishing system. There will be instructions

on board which should be followed.

A closed cargo space should be ventilated to clear it of smoke and toxic gases after the fire has been

extinguished and the space has cooled. The ventilation equipment should be of a certified safe type

for smoke removal. Evidence that the space is cooling down can be obtained by monitoring adjacent

bulkheads and decks. Thereafter, a fire-fighting team should look for any small remaining fires and

inspect the surrounding cargo. After the fire has been extinguished, the cargo should be kept under

surveillance until its normal temperature is reached.

Foam

In general, foam is an effective fire-fighting medium for fires involving flammable liquids. The foam

forms a layer on the liquid thereby excluding oxygen and reducing heat. However, it is less effective

on solid substances on fire. Most foams contain water and should not be used on fires where the use

of water is restricted because of adverse chemical reaction.

Dry chemicals

Dry chemicals may be an effective extinguishing medium for fires involving water-reactive substances

and metals. The dry chemical should not react with the dangerous goods involved in the fire. Some

dangerous goods require a specific dry chemical to extinguish a fire.

SPECIAL NOTES ON CLASSES OF DANGEROUS GOODS

Explosives – class 1

In the event of a fire, everything should be done to prevent the spread of the fire to containers which

contain class 1 goods. If it is not possible to prevent the spread of the fire, all personnel should

immediately withdraw from the area.

Many explosives will burn to the point of an explosion. The master's main concern will be whether or

not there is likely to be a mass explosion. Such an explosion could damage the ship. If goods of

division 1.1 or division 1.5 are involved, this likelihood will exist. The time between fire reaching the

explosives and the subsequent mass explosion will be of the order of a few seconds to minutes. The

master should ascertain how large a quantity of such explosives is involved. A few kilograms are

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 18

unlikely to sink the ship, but above this a clear risk to the safety of the crew and the stability of the

ship should be considered. Sudden or short-term events may endanger the safety of the ship.

Explosives of divisions 1.2, 1.3, 1.4, and 1.6 are unlikely to explode en masse. Irrespective of the

division of the explosives, any fire fighting should take place from behind substantial cover. If the risk

to firefighters is too high, hoses could be lashed to the rail or other suitable fixtures and left

unmanned.

Neither exclusion of air nor the use of smothering material is likely to be effective against a fire

involving explosives. The use of the largest possible quantity of water in the shortest possible time is

the only means of attempting to prevent a rise in temperature that could affect the chemical stability of

the explosives.

Some dangerous goods of this class have been wetted or immersed in water. As they dry, they

become unstable. The master should seek advice (see section 4 above).

Gases – class 2

Gases are substances usually transported in cylinders, flasks, portable tanks, aerosol dispensers and

bottles under varying degrees of pressure. The gases may be flammable, toxic or corrosive and may

be compressed, liquefied or refrigerated.

Gases will not start burning at the valve, unless there has been an ignition source nearby (e.g. fire or

heat). The location of the burning gas needs to be identified because it may be the heart of the fire.

The heating of the receptacle is the most serious danger because of the possibility of rupture,

rocketing or explosion. In the event of a fire, receptacles containing gas should be liberally sprayed

with water to keep them as cool as possible.

Non-burning leakages from receptacles of flammable gases may give rise to explosive mixtures in air.

If a fire caused by the ignition of leaking gas is extinguished within a cargo space before the leak is

stopped, accumulation of gas will occur. This will result in an explosive mixture or a toxic or

suffocating atmosphere. The EmS SPILLAGE SCHEDULES should be consulted.

Extremely low temperatures around leakages of some liquefied gases are an additional hazard (other

than flammability and toxicity). Emergency teams should avoid contact with such leakages and the

immediate vicinity.

Flammable liquids – class 3

It is dangerous to direct a jet of water onto a fire involving flammable liquids. Many flammable liquids

float on water and the water jet would spread the liquid, thus creating a greater danger. Closed

containers exposed to fire will become pressurized and a rupture will occur.

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 19

Heated flammable liquid will release vapours that may start burning instantly with explosive effect.

Consequently, fire-fighting personnel should stay in a well-protected position and use water spray on

the area of the fire. This will cool down the temperature of the liquid and the air-vapour mixture.

Flammable solids – class 4.1

This class of substances includes flammable solids, water-wetted explosives (i.e. desensitized

explosives) and self-reactive substances.

Flammable solids will easily ignite, and the appropriate EmS FIRE SCHEDULE should be consulted.

In the event of a fire, water-wetted explosives (i.e. desensitized explosives) will effectively have the

properties of a class 1 product. The special notes on class 1 explosives (see 10.1) and the relevant

EmS FIRE SCHEDULES should be consulted.

Self-reactive substances are sometimes transported under temperature controlled conditions where

the control temperature will depend upon the specific properties of the substance being transported. If

the control temperature is exceeded, the refrigeration unit has to be inspected. If the temperature

control cannot be restored, the manufacturer should be consulted as soon as possible. The

manufacturer should be similarly consulted if smoke is observed. The cargo should then be kept

under surveillance.

Spontaneously combustible substances – class 4.2

This class of substances includes pyrophoric substances, which will instantly burn on contact with air,

and self-heating substances, which lead to spontaneous combustion.

Although the use of dry inert powdered material to smother the fire would be the preferred option, in

most circumstances such a procedure may not be possible. Two methods of dealing with such fires

are possible:

.1 controlled burning: stay in a well-protected position. Let the goods burn. Many goods of this

class react dangerously with water: refer to the relevant EmS FIRE SCHEDULE. In such

cases, contact with water may intensify burning. Therefore, it is not recommended to apply

water directly on the burning goods. When portable water monitors providing water shield

function are available: generate a water screen to prevent spread of fire. The fire involving the

goods should be left to burn out completely. If the fire hasalready spread to the adjacent

cargo which is not reacting with water (see relevant EmS FIRE SCHEDULE): fight this fire

from a safe distance;

.2 fight the fire from a safe distance: if the location of the fire makes it possible, copious

quantities of water should be used immediately. Although the goods on fire will react with

water and create heat, a large quantity of water will cool down the reaction and prevent

further heat radiation. However, water should not be used when the location of the fire makes

it impossible to apply copious amounts of water directly onto the goods. Refer to the relevant

EmS FIRE SCHEDULE.

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 20

Substances dangerous when wet – class 4.3

This class of substances reacts violently with water, evolving flammable gases. The heat of the

reaction is sometimes sufficient to initiate a fire.

Although the use of dry inert powdered material to smother the fire would be the preferred option, in

most circumstances such a procedure may not be possible. Two methods of dealing with such fires

are possible:

.1 controlled burning: stay in a well-protected position. Let the goods burn. All goods of this class

react dangerously with water: refer to the relevant EmS FIRE SCHEDULE. Contact with water

will intensify burning. Therefore, it is not recommended to apply water directly on the burning

goods. When portable water monitors providing water shield function are available;

.2 generate water screen to prevent spread of fire. The fire involving the goods should be left to

burn out completely. If the fire has already spread to adjacent cargo which is not reacting with

water (see relevant EmS FIRE SCHEDULE): fight this fire from a safe distance;

.3 fight the fire from a safe distance: refer to the relevant EmS FIRE SCHEDULE, since it is

possible that fire fighting with water may intensify the fire and generate the evolution of

flammable gases which could explode in mixtures with air.

Oxidizing substances – class 5.1

This class of substances is liable to evolve oxygen and therefore to accelerate a fire. These

substances, while in themselves not necessarily combustible, may cause the combustion of other

material (e.g. sawdust or paper) or contribute to the fire, leading to an explosion.

Fires in which these substances are present are difficult to extinguish, because the ship's fire fighting

installation may not be effective. Everything possible should be done to prevent the spread of fire to

containers containing these dangerous goods. However, if fire reaches the cargo, personnel should

be withdrawn immediately to a well-protected position.

Organic peroxides – class 5.2

This class of substances is liable to burn vigorously. Some substances have a low decomposition

temperature and are transported under temperature controlled conditions, where the control

temperature will depend upon the specific properties of the substance being transported.

If the temperature control cannot be restored, the manufacturer should be consulted as soon as

possible even if evolution of smoke has ceased. The cargo should then be kept under surveillance.

The surrounding area should be kept isolated because liquid may be ejected from relief

arrangements.

Toxic substances – class 6.1

Substances of this class are poisonous by contact or inhalation, and the use of self-contained

breathing apparatus and firefighters' outfits is therefore essential.

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 21

Infectious substances – class 6.2

These are substances which are known or reasonably expected to contain pathogens, (i.e. micro-

organisms that are known or reasonably expected to cause infectious disease in humans or animals).

Pathogens may survive the fire and self-contained breathing apparatus should therefore be used.

Radioactive material – class 7

Many radioactive materials are transported in packages designed to retain their containment and

shielding in accidents. However, under extreme fire conditions, failure of containment or loss of

shielding or criticality safety could result in significant hazard to personnel. Long-term exposure of any

class 7 package to extreme heat should be avoided and in emergencies they should be kept as cool

as possible using copious quantities of water. If a packaging of radioactive material has been exposed

to any significant fire, expert advice should be sought. Suspected contamination of safety and fire-

fighting equipment should be removed as quickly as possible.

Some packages may have a class 7 label and other hazard labels. Such additional hazards may be

greater than the radiation hazard. In that case, actions as specified in the applicable EmS FIRE

SCHEDULE should be followed.

Although radiation monitors are not required by regulation on board ships, applicable relevant

provisions on segregation, separation or radiation protection programmes (e.g. paragraphs 1.5.2 and

7.1.4.5.18 of the IMDG Code) or the INF Code may require monitors on board. For ships carrying

radiation monitoring equipment, monitoring of radiation levels is recommended.

Corrosive substances – class 8

These substances are extremely dangerous to humans, and many may cause destruction of safety

equipment. Burning cargo of this class will produce highly corrosive vapours. Consequently, wearing

self-contained breathing apparatus is essential.

Miscellaneous dangerous substances and articles – class 9

This class includes those substances, materials and articles which are deemed to possess some

danger, but which are not classified within the criteria of classes 1 to 8. No general guidelines are

applicable to these goods. They have been allocated to the relevant EmS FIRE SCHEDULE

according to their hazards in the event of a fire.

Marine pollutants

A number of substances within all of the above classes have also been designated as marine

pollutants. Packages containing these substances will bear a Marine Pollutant mark.

In the case of leakage resulting from burning cargo, it is important to be aware that any spillage of a

marine pollutant which is washed overboard will pollute the sea. It is, however, more important to fight

a fire on board a ship rather than to prevent pollution of the sea.

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 22

INVESTIGATE AND

04 COMPILE REPORTS ON

INCIDENTS INVOLVING

FIRE

ASSESSMENT OF CAUSE OF INCIDENTS INVOLVING FIRE

Very serious casualty

preliminary information as indicated in annex 1 information as indicated in annexes 2 and 3, as well

as other relevant annexes a full investigation report in all cases

Serious casualty

preliminary information as indicated in annex 1* information as indicated in annexes 2 and 3, as well

as other relevant annexes a full investigation report only in cases of important lessons to be learnt

regarding IMO regulations

Less serious casualty and marine incident information as indicated in annexes 1, 2 and 3, as well as

other relevant annexes, only in cases of important lessons to be learnt regarding IMO regulations a

full investigation report only in cases of important lessons to be learnt regarding IMO regulations

Information to be submitted for casualties/incidents as indicated below

Information from casualties involving dangerous goods or marine pollutants in packaged form on

board ships and in port areas

→ annex 4

Damage cards and intact stability records

→ annex 5

Fire casualty record

→ annex 6

Global Maritime Distress and Safety System (GMDSS)

→ annex 7

Fatigue as a contributory cause to maritime accidents - Fatigue factors data compilation sheet

→ annex 8

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 23

Incidental spillage of liquids of 50 tonnes or more

→ annex 9

Life-saving appliance casualty record

→ annex 10

GENERAL PROVISIONS

PURPOSE

The objective of this Code is to provide a common approach for States to adopt in the conduct of

marine safety investigations into marine casualties and marine incidents. Marine safety investigations

do not seek to apportion blame or determine liability. Instead a marine safety investigation, as defined

in this Code, is an investigation conducted with the objective of preventing marine casualties and

marine incidents in the future. The Code envisages that this aim will be achieved through States:

.1 applying consistent methodology and approach, to enable and encourage a broad ranging

investigation, where necessary, in the interests of uncovering the causal factors and other

safety risks; and

.2 providing reports to the Organization to enable a wide dissemination of information to assist

the international marine industry to address safety issues.

A marine safety investigation should be separate from, and independent of, any other form of

investigation. However, it is not the purpose of this Code to preclude any other form of investigation,

including investigations for action in civil, criminal and administrative proceedings. Further, it is not the

intent of the Code for a State or States conducting a marine safety investigation to refrain from fully

reporting on the causal factors of a marine casualty or marine incident because blame or liability, may

be inferred from the findings.

This Code recognizes that under the Organization’s instruments, each flag State has a duty to

conduct an investigation into any casualty occurring to any of its ships, when it judges that such an

investigation may assist in determining what changes in the present regulations may be desirable, or

if such a casualty has produced a major deleterious effect upon the environment.

The Code also takes into account that a flag State shall cause an inquiry to be held, by or before a

suitably qualified person or persons into certain marine casualties or marine incidents of navigation on

the high seas. However, the Code also recognizes that where a marine casualty or marine incident

occurs within the territory, including the territorial sea, of a State, that State has a right to investigate

the cause of any such marine casualty or marine incident which might pose a risk to life or to the

environment, involve the coastal State’s search and rescue authorities, or otherwise affect the coastal

State.

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 24

NOTIFICATION

When a marine casualty occurs on the high seas or in an exclusive economic zone, the flag State of a

ship, or ships, involved, shall notify other substantially interested States as soon as is reasonably

practicable.

When a marine casualty occurs within the territory, including the territorial sea, of a coastal State, the

flag State, and the coastal State, shall notify each other and between them notify other substantially

interested States as soon as is reasonably practicable.

Notification shall not be delayed due to the lack of complete information.

Format and content: The notification shall contain as much of the following information as is readily

available:

.1 the name of the ship and its flag State;

.2 the IMO ship identification number;

.3 the nature of the marine casualty;

.4 the location of the marine casualty;

.5 time and date of the marine casualty;

.6 the number of any seriously injured or killed persons;

.7 consequences of the marine casualty to individuals, property and the environment; and

.8 the identification of any other ship involved.

FLAG STATE’S AGREEMENT WITH ANOTHER SUBSTANTIALLY INTERESTED STATE TO

CONDUCT A MARINE SAFETY INVESTIGATION

Without limiting the rights of States to conduct their own separate marine safety investigation, where a

marine casualty occurs within the territory, including territorial sea, of a State, the flag State(s)

involved in the marine casualty and the coastal State shall consult to seek

agreement on which State or States will be the marine safety investigating State(s) in accordance with

a requirement, or a recommendation acted upon, to investigate under this Code.

Without limiting the rights of States to conduct their own separate marine safety investigation, if a

marine casualty occurs on the high seas or in the exclusive economic zone of a State, and involves

more than one flag State, then the States shall consult to seek agreement on which State or States

will be the marine safety investigating State(s) in accordance with a requirement, or a

recommendation acted upon, to investigate under this Code.

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 25

For a marine casualty referred to in paragraph 7.1 or 7.2, agreement may be reached by the relevant

States with another substantially interested State for that State or States to be the marine safety

investigating State(s).

Prior to reaching an agreement, or if an agreement is not reached, in accordance with paragraph 7.1,

7.2 or 7.3, then the existing obligations and rights of States under this Code, and under other

international laws, to conduct a marine safety investigation, remain with the respective parties to

conduct their own investigation.

By fully participating in a marine safety investigation conducted by another substantially interested

State, the flag State shall be considered to fulfil its obligations under this Code, SOLAS regulation I/21

and article 94, section 7 of the United Nations Convention on the Law of the Sea.

OBTAINING EVIDENCE FROM SEAFARERS

Where a marine safety investigation requires a seafarer to provide evidence to it, the evidence shall

be taken at the earliest practical opportunity. The seafarer shall be allowed to return to his/her ship, or

be repatriated at the earliest possible opportunity. The seafarers human rights shall, at all times, be

upheld.

All seafarers from whom evidence is sought shall be informed of the nature and basis of the marine

safety investigation. Further, a seafarer from whom evidence is sought shall be informed, and allowed

access to legal advice, regarding:

.1 any potential risk that they may incriminate themselves in any proceedings subsequent to the

marine safety investigation;

.2 any right not to self-incriminate or to remain silent;

.3 any protections afforded to the seafarer to prevent the evidence being used against them if

they provide the evidence to the marine safety investigation.

DRAFT MARINE SAFETY INVESTIGATION REPORTS

Subject to paragraphs 13.2 and 13.3, where it is requested, the marine safety investigating State(s)

shall send a copy of a draft report to a substantially interested State to allow the substantially

interested State to make comment on the draft report.

Marine safety investigating State(s) are only bound to comply with paragraph 13.1 where the

substantially interested State receiving the report guarantees not to circulate, nor cause to circulate,

publish or give access to the draft report, or any part thereof, without the express

consent of the marine safety investigating State(s) or unless such reports or documents have already

been published by the marine safety investigating State(s).

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 26

The marine safety investigating State(s) are not bound to comply with paragraph 13.1 if:

.1 the marine safety investigating State(s) request that the substantially interested State

receiving the report to affirm that evidence included in the draft report will not be admitted in

civil or criminal proceedings against a person who gave the evidence; and

.2 the substantially interested State refuses to provide such an affirmation.

The marine safety investigating State(s) shall invite the substantially interested States to submit their

comments on the draft report within 30 days or some other mutually agreed period. The marine safety

investigating State(s) shall consider the comments before preparing the final report and where the

acceptance or rejection of the comments will have direct impact on the interests of the State that

submitted them, the marine safety investigating State(s) shall notify the substantially interested State

of the manner in which the comments were addressed. If the marine safety investigating State(s)

receives no comments after the 30 days or the mutually agreed period has expired, then it may

proceed to finalize the report.

The marine safety investigating State(s) shall seek to fully verify the accuracy and completeness of

the draft report by the most practical means.

MARINE SAFETY INVESTIGATION REPORTS

The marine safety investigating State(s) shall submit the final version of a marine safety investigation

report to the Organization for every marine safety investigation conducted into a very serious marine

casualty.

Where a marine safety investigation is conducted into a marine casualty or marine incident, other than

a very serious marine casualty, and a marine safety investigation report is produced which contains

information which may prevent or lessen the seriousness of marine casualties or marine incidents in

the future, the final version shall be submitted to the Organization.

The marine safety investigation report referred in paragraphs 14.1 and 14.2 shall utilize all the

information obtained during a marine safety investigation, taking into account its scope, required to

ensure that all the relevant safety issues are included and understood so that safety action can be

taken as necessary.

The final marine safety investigation report shall be made available to the public and the shipping

industry by the marine safety investigating State(s), or the marine safety investigating State(s) shall

undertake to assist the public and the shipping industry with details, necessary to access the report,

where it is published by another State or the Organization.

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 27

PRINCIPLES OF INVESTIGATION

Independence: A marine safety investigation should be unbiased to ensure the free flow of

information to it.

In order to achieve the outcome in paragraph 16.1, the investigator(s) carrying out a marine safety

investigation should have functional independence from:

1. the parties involved in the marine casualty or marine incident;

2. anyone who may make a decision to take administrative or disciplinary action against an

individual or organization involved in a marine casualty or marine incident; and

3. judicial proceedings.

The investigator(s) carrying out a marine safety investigation should be free of interference from the

parties in .1, .2 and .3 of paragraph 16.1.1 with respect to:

1. the gathering of all available information relevant to the marine casualty or marine incident,

including voyage data recordings and vessel traffic services recordings;

2. analysis of evidence and the determination of causal factors;

3. drawing conclusions relevant to the causal factors;

4. distributing a draft report for comment and preparation of the final report; and

5. if appropriate, the making of safety recommendations.

Safety focused: It is not the objective of a marine safety investigation to determine liability, or

apportion blame. However, the investigator(s) carrying out a marine safety investigation should not

refrain from fully reporting on the causal factors because fault or liability may be inferred from the

findings.

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 28

INSPECT AND SERVICE

05

FIRE-DETECTION AND FIRE-

EXTINGUISHING SYSTEMS

AND EQUIPMENT

REQUIREMENTS FOR STATUTORY AND CLASSIFICATIONS SURVEYS

SOLAS Chapter II-2

Fire protection, fire detection and fire extinction: This chapter elaborates the means and measure for

fire protection in accommodation, cargo spaces and engine room for the passenger, cargo and tanker

ship. This chapter is divided into 7 parts, explaining the various requirement for fire safety system

installed on a ship.

Part A contains regulations 1 to 3 which explains the “Application” of this chapter on ships

construction date and the regulations also explains the “Definition” of different terminology which is

used in the chapter and the objective and functional requirement of this chapter.

Part B of this chapter specifies the requirement to prevent fire and explosion on cargo ship including

tankers. It has 3 regulations from Regulation 4 to regulation 6; Regulation 4 giving the details of how

to prevent the ignition of a combustible source present on ships including the limitations and

arrangements on the use of fuel and lube oils used onboard, and prevention of fire in the cargo areas

of the tanker ship.

Regulation 5 laid down the requirement to curb the growth of the fire in different spaces on the ship,

which includes cutting any one side of the fire triangle, i.e. to control either air supply, oil supply or the

heat source (using protection materials like insulation, linings etc.) in the potential hazardous space.

Regulation 6 of this part focus on reduction of hazards to human life from products which release

smoke and toxic gases (such as paint, varnish etc.).

Part C of this chapter comprises of 5 regulations (Regulation 7 to Regulation 11) and focuses on

requirement to suppress the fire at the earliest, including detection and control of smoke and flames,

containment requirements, structural integrity of the space to prevent spreading of fire and firefighting

systems and equipment to be used on ships machinery, accommodation and cargo spaces.

Part D focuses on the escape of the seafarers or passengers in case of fire or any other emergency.

Regulation 13 explains the various requirement for means of escape for different types of ships (cargo

ship, passenger ship, RoRo ship etc.), equipment and systems which helps in escaping from the

hazardous place etc.

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 29

Part E of chapter II-2 consist of Regulation 14 to regulation 16 providing information on the

maintenance of the fire detection, fighting, and control equipment on cargo ships including tankers

and passenger ships. It also explains the requirement for training and drills to be carried out on fire

safety onboard ship. Regulation 16 focuses on the fire safety booklet which should be kept on board

ship for all types of vessel.

FIRE DETECTION AND EXTINGUISHING SYSTEMS AND EQUIPMENT

MAINTENANCE AND TESTING

Onboard maintenance and inspections must be carried out in accordance with the ship’s maintenance

plan, which must include as a minimum the requirements stated in this Notice.

Certain maintenance procedures and inspections may be performed by competent crew members as

described in Section 14, while others should be performed by persons specially trained in the

maintenance of such systems. The onboard maintenance plan should indicate which parts of the

inspections and maintenance are to be completed by trained personnel.

Inspections should be carried out by the crew to ensure that the indicated weekly, monthly, quarterly,

annual, two-year, five-year and ten-year actions are taken for the specified equipment, if required.

Records of the inspection must be carried on board the ship and may be computer-based. In cases

where the inspections and maintenance are carried out by trained service technicians other than the

ship’s crew, inspection reports must be provided at the completion of the testing.

In addition to the onboard maintenance and inspections stated in this Notice, manufacturer’s

maintenance and inspection guidelines must be followed. The quality of water in automatic sprinkler

systems is of particular importance and must be maintained, tested and recorded on board. All such

procedures should be in accordance with manufacturer guidelines.

WEEKLY TESTING AND INSPECTIONS

1. Fixed fire detection and alarm systems

verify all fire detection and fire alarm control panel indicators are functional by operating the

lamp/indicator test switch.

2. Fixed gas fire-extinguishing systems

verify all fixed fire-extinguishing system control panel indicators are functional by operating the

lamp/indicator test switch; and

verify all control/section valves are in the correct position.

3. Fire doors

verify all fire door control panel indicators, if provided, are functional by operating the

lamp/indicator switch.

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 30

4. Public address and general alarm systems

verify all public address systems and general alarm systems are functioning properly.

5. Breathing apparatus

examine all breathing apparatus and EEBD cylinder gauges to confirm they are in the

correct pressure range.

6. Low-location lighting

verify low-location lighting systems are functional by switching off normal lighting in selected

locations.

7. Water mist, water spray and sprinkler systems

verify all control panel indicators and alarms are functional;

visually inspect pump unit and its fittings; and

check the pump unit valve positions, if valves are not locked, as applicable.

MONTHLY TESTING AND INSPECTIONS

Monthly inspections must be carried out to ensure that the indicated actions are taken for the

specified equipment.

1. Fire mains, fire pumps, hydrants, hoses and nozzles

verify all fire hydrants, hose and nozzles are in place, properly arranged and are in

serviceable condition;

operate all fire pumps to confirm that they continue to supply adequate pressure; and

emergency fire pump fuel supply adequate, and heating system in satisfactory condition, if

applicable.

2. Fixed gas fire-extinguishing systems

verify containers/cylinders fitted with pressure gauges are in the proper range and the

installation free from leakage.

3. Foam fire-extinguishing systems

verify all control and section valves are in the proper open or closed position, and all

pressure gauges are in the proper range.

4. Water mist, water spray and sprinkler systems

verify all control, pump unit and section valves are in the proper open or closed position;

verify sprinkler pressure tanks or other means have correct levels of water; test automatic

starting arrangements on all system pumps so designed;

verify all standby pressure and air/gas pressure gauges are within the proper pressure

ranges; and

test a selected sample of system section valves for flow and proper initiation of alarms.

(Note – The valves selected for testing should be chosen to ensure that all valves are tested

within a one-year period.)

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 31

5. Firefighter’s outfits

verify lockers providing storage for fire-fighting equipment contain their full inventory and

equipment is in serviceable condition.

6. Fixed dry chemical powder systems

verify all control and section valves are in the proper open or closed position, and all

pressure gauges are in the proper range.

7. Fixed aerosol extinguishing systems

verify all electrical connections and/or manual operating stations are properly arranged, and

are in proper condition; and

verify the actuation system/control panel circuits are within manufacturer’s specifications.

8. Portable foam applicators

verify all portable foam applicators are in place, properly arranged, and are in proper

condition.

9. Wheeled (mobile) fire extinguishers

verify all extinguishers are in place, properly arranged, and are in proper condition.

10. Fixed fire detection and alarm systems

test a sample of detectors and manual call points so that all devices have been tested within

five years. For very large systems the sample size should be determined by the Ship

Registry.

QUARTERLY TESTING AND INSPECTIONS

Quarterly inspections must be carried out to ensure that the indicated actions are taken for the

specified equipment:

1. Fire mains, fire pumps, hydrants, hoses and nozzles

verify international shore connection(s) is in serviceable condition.

2. Foam fire-extinguishing systems

verify the proper quantity of foam concentrate is provided in the foam system storage tank.

3. Ventilation systems and fire dampers

test all fire dampers for local operation.

4. Fire doors

test all fire doors located in main vertical zone bulkheads for local operation.

ANNUAL TESTING AND INSPECTIONS

Annual inspections must be carried out to ensure that the indicated actions are taken for the specified

equipment:

1. Fire mains, fire pumps, hydrants, hoses and nozzles

REV. NO. 01 STCW ADVISORY 2019-05 REFRESHER – ADVANCED FIRE FIGHTING

EXCELLENCE AND COMPETENCY TRAINING CENTER, INC. 32

visually inspect all accessible components for proper condition;

flow test all fire pumps for proper pressure and capacity. Test emergency fire pump with

isolation valves closed;

test all hydrant valves for proper operation;

pressure test a sample of fire hoses at the maximum fire main pressure, so that all fire

hoses are tested within five years;

verify all fire pump relief valves, if provided, are properly set;

examine all filters/strainers to verify they are free of debris and contamination; and

confirm nozzle size/type correct, maintained and working.

2. Fixed fire detection and fire alarm systems

test all fire detection systems and fire detection systems used to automatically release fire-

extinguishing systems for proper operation, as appropriate;

visually inspect all accessible detectors for evidence of tampering obstruction, etc., so that

all detectors are inspected within one year; and