Professional Documents

Culture Documents

Thermiculite 815

Uploaded by

Aji HatmantoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thermiculite 815

Uploaded by

Aji HatmantoCopyright:

Available Formats

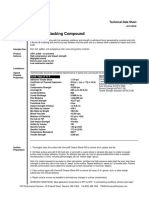

PDS238– 12/17 Rev4

PRODUCT DATASHEET

THERMICULITE®

815

Thermiculite® 815 is a high

temperature, chemically

Service: Materials:

resistant sheet sealing Thermiculite® 815 is comprised of a Facing material: Thermiculite®

material comprising tanged 316 Stainless Steel core faced

with a high performance vermiculite

Reinforcement: Tanged 316 Stainless Steel

exfoliated vermiculite based sealing material. The metallic

UNS S31600

core provides improved blow out Bond Type: Mechanical

reinforced with a tanged resistance, handling and cutting

Note:

stainless steel core. characteristics.

This product is NOT intended for, and is NOT

Thermiculite® 815 is suitable for suitable for use as the facing for Flexitallic

use in a wide range of sealing Flexpro™ gaskets.

applications. The material is capable

of effecting a high integrity seal at API607 Fire-Safe

extremes of temperature. Typical

applications involve sealing Availability:

superheated high pressure steam, Sheet size:

strong oxidising media and high 1.0m x 1.0m

temperature gas & exhaust systems. 1.5m x 1.5m

For gaskets outside sheet size please contact

Maximum recommended Flexitallic Applications Engineering Department

temperature:

10500C (19200F) Thickness range:

1.0mm to 3.0mm

Maximum service pressure:

20MPa (200 bar; 2900 psi)

Colour: Golden

This Data Sheet refers to the material as

supplied. The information contained herein

is given in good faith, but no liability will be

accepted by the Company in relation to same.

Typical Physical Properties:

We reserve the right to change the details

Thickness 1.5mm 3.0mm

given on this Data Sheet as additional Facing Density 1.2gcm-3 1.2gcm-3

information is acquired. Customers requiring

the latest version of this Data Sheet should ASTM F36A Compressibility 44% 44%

contact our Applications Engineering ASTM F36A Recovery 9% 8%

Department.

BS 7531 Gas Permeability 0.13mL/min 0.17mL/min

The information given and, in particular,

any parameters, should be used for guidance BS 7531 Stress Retention @ 3000C 31MPa 17MPa

purposes only. The Company does not give

Sulphur Content < 50ppm < 50ppm

any warranty that the product will be suitable

for the use intended by the customer. Chloride Ion Content < 50ppm < 50ppm

Health & Safety

For further Health and Safety information

please see the relevant Material Safety

Datasheets or contact Flexitallic UK Ltd.

Tel. +44 (0)1274 851273 Fax. +44 (0)1274 300303 www.flexitallic.eu Email. enquiries@flexitallic.eu

You might also like

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- CHP For AjmerDocument343 pagesCHP For AjmerHarsh Shah33% (3)

- Thermiculite 815Document1 pageThermiculite 815Benoit LabreNo ratings yet

- Thermiculite 815Document1 pageThermiculite 815Aji HatmantoNo ratings yet

- Thermiculite 835: Product DatasheetDocument2 pagesThermiculite 835: Product DatasheetBenoit LabreNo ratings yet

- Thermiculite 715: Product DatasheetDocument1 pageThermiculite 715: Product DatasheetBenoit LabreNo ratings yet

- Flexpro Therm 845Document1 pageFlexpro Therm 845Benoit LabreNo ratings yet

- Product Datasheet: Service: AvailabilityDocument2 pagesProduct Datasheet: Service: AvailabilityShayan Hasan KhanNo ratings yet

- Flexitallic I-Flex 'High Temperature' Flange Insulating SetDocument2 pagesFlexitallic I-Flex 'High Temperature' Flange Insulating SetJandri JacobNo ratings yet

- Thermiculite 835 SWGDocument2 pagesThermiculite 835 SWGISEDAC21No ratings yet

- Sigma 500Document1 pageSigma 500Homer SilvaNo ratings yet

- Flexitallic SF 3300: 6915 HWY 225, Deer Park, TX 77536 USA TEL: 281.604.2400 FAX: 281.604.2415Document2 pagesFlexitallic SF 3300: 6915 HWY 225, Deer Park, TX 77536 USA TEL: 281.604.2400 FAX: 281.604.2415ebastien2No ratings yet

- Thermiculite 894Document2 pagesThermiculite 894Benoit LabreNo ratings yet

- Gee Graphite Technical Datasheet: GEEGRAF Tanged Stainless Steel Reinforced SheetDocument1 pageGee Graphite Technical Datasheet: GEEGRAF Tanged Stainless Steel Reinforced SheettempeltonNo ratings yet

- Vermiculite Filler 835 Spiral Wound Gasket - 957562Document1 pageVermiculite Filler 835 Spiral Wound Gasket - 957562deden okNo ratings yet

- Flexicarb SR Data SheetDocument2 pagesFlexicarb SR Data SheetkarthikNo ratings yet

- #1618 HTDocument1 page#1618 HTaleerossNo ratings yet

- Flexitallic Thermiculite 815Document1 pageFlexitallic Thermiculite 815Bảo Trung LêNo ratings yet

- Flexicarb RGS3 DatasheetDocument1 pageFlexicarb RGS3 DatasheetbenoitNo ratings yet

- Thermiculite GasketDocument5 pagesThermiculite GasketthanakomNo ratings yet

- Spiral Wound Gasket MaterialsDocument1 pageSpiral Wound Gasket MaterialsneelavathyNo ratings yet

- Aerogel Aisla TermicoDocument3 pagesAerogel Aisla Termicob asesNo ratings yet

- SISfirepro F-180 Synixtor ENGLISHDocument4 pagesSISfirepro F-180 Synixtor ENGLISHPaloma Carralon FlorezNo ratings yet

- JZ-20220423 Siliocne Composite Tape Bochure-ENDocument12 pagesJZ-20220423 Siliocne Composite Tape Bochure-ENLongsun KejiNo ratings yet

- MultimediaDocument4 pagesMultimediaabdulrahimtahir100No ratings yet

- Klinger Kammprofiles Austr PDFDocument5 pagesKlinger Kammprofiles Austr PDFAnonymous nw5AXJqjdNo ratings yet

- Mil I 19166Document2 pagesMil I 19166Abdou Karim DiopNo ratings yet

- High Performance Backing Compound: Technical Data SheetDocument2 pagesHigh Performance Backing Compound: Technical Data SheetNiku SamarthNo ratings yet

- Data SF 2400Document2 pagesData SF 2400Francisco SalazarNo ratings yet

- Automotive: Technical Data SheetDocument2 pagesAutomotive: Technical Data Sheetvaibhav dhandeNo ratings yet

- Sealfl Ex: Description Method of UseDocument4 pagesSealfl Ex: Description Method of UseramiNo ratings yet

- 9485 & 926 Transfer Tapes: Product Data SheetDocument3 pages9485 & 926 Transfer Tapes: Product Data SheetvijaygalaxyNo ratings yet

- Sealing Gasket (ENKA)Document6 pagesSealing Gasket (ENKA)Apras TyoNo ratings yet

- Flexitallic Thermiculite 715Document1 pageFlexitallic Thermiculite 715Bảo Trung LêNo ratings yet

- Maxiflex Spiral Wound Gaskets Product DocumentDocument5 pagesMaxiflex Spiral Wound Gaskets Product DocumentPham Thien TruongNo ratings yet

- Thermaline Heat Shield PDSDocument4 pagesThermaline Heat Shield PDSfrosted296No ratings yet

- Klingermilam-PSS Gasket Datasheet 1Document2 pagesKlingermilam-PSS Gasket Datasheet 1noodlehead675No ratings yet

- EuTronic Arc Spray 595ASDocument2 pagesEuTronic Arc Spray 595ASEdwinNo ratings yet

- Wound SpiralDocument2 pagesWound SpiralMircea Dan StanciuNo ratings yet

- Terokal 5089-EN PDFDocument2 pagesTerokal 5089-EN PDFLuis Velasquez SilvaNo ratings yet

- Ultrapaste Cu 12 SF - 2017 (E)Document1 pageUltrapaste Cu 12 SF - 2017 (E)HANIF AKBARNo ratings yet

- Catalog of Products Pini Si ClipsuriDocument60 pagesCatalog of Products Pini Si ClipsuriamaliabohusNo ratings yet

- Cera Board 100Document2 pagesCera Board 100Javier TrujillanoNo ratings yet

- TDS - Premcote 101 TropicalDocument1 pageTDS - Premcote 101 TropicalThomas C. LaneNo ratings yet

- HD5403AA - New - Revision September 2020Document2 pagesHD5403AA - New - Revision September 2020AthonioMourinhoNo ratings yet

- Hilti Firestop Submittal - Balamand UniversityDocument32 pagesHilti Firestop Submittal - Balamand UniversitybasbousrNo ratings yet

- Akfix Eng Technical Catalog 2022 Rev16Document211 pagesAkfix Eng Technical Catalog 2022 Rev16ahmed.serefNo ratings yet

- Flange Insulation Kits: DescriptionDocument6 pagesFlange Insulation Kits: DescriptionLis RincónNo ratings yet

- Hilti CP 601S PDFDocument7 pagesHilti CP 601S PDFMuhammad AsimNo ratings yet

- Special Specification 4604 Stay CablesDocument15 pagesSpecial Specification 4604 Stay CablesAbok Cai NginumNo ratings yet

- Isotape enDocument8 pagesIsotape enssingaram1965No ratings yet

- PDS Polyken 980 955 V3 Jan19 Aarps 0285Document2 pagesPDS Polyken 980 955 V3 Jan19 Aarps 0285Irawan FajarNo ratings yet

- Tape Scotch 27Document2 pagesTape Scotch 27Victor Javier Reyes NavarroNo ratings yet

- Pds Covalence Htlp80 v3 Dec16 Aarps 0199Document2 pagesPds Covalence Htlp80 v3 Dec16 Aarps 0199Benaknaik S GajannavarNo ratings yet

- Hvac Flexible DuctsDocument4 pagesHvac Flexible Ductssharique hasanNo ratings yet

- Poly GlasDocument2 pagesPoly Glasmk779900mkNo ratings yet

- Covalence HTLP80: Product Data SheetDocument3 pagesCovalence HTLP80: Product Data SheetJuan Carlos Contreras CherresNo ratings yet

- Primer EP61 Datenblatt Renitherm enDocument2 pagesPrimer EP61 Datenblatt Renitherm enMuhammad ArslanNo ratings yet

- Hyperplas Polyester Membrane - TDS PDFDocument4 pagesHyperplas Polyester Membrane - TDS PDFGanesh MurthyNo ratings yet

- A F 984 Technical Data SheetDocument1 pageA F 984 Technical Data SheetdneradNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Volkswagen Passat R Line Price ListDocument2 pagesVolkswagen Passat R Line Price ListDr Uvarani Sp Care Rawang TinNo ratings yet

- Application & Registration Form MSC International Business Management M2Document11 pagesApplication & Registration Form MSC International Business Management M2Way To Euro Mission Education ConsultancyNo ratings yet

- Carbon Fiber 395GPA Structural Ansys ReportDocument13 pagesCarbon Fiber 395GPA Structural Ansys ReportKrish KrishnaNo ratings yet

- Jurnal Chapter 1 Diesel Bhs - InggrisDocument4 pagesJurnal Chapter 1 Diesel Bhs - Inggrisandino yogaNo ratings yet

- Bank Statement - Feb.2020Document5 pagesBank Statement - Feb.2020TRIVEDI ANILNo ratings yet

- Metrobank (Strengths)Document6 pagesMetrobank (Strengths)Hera IgnatiusNo ratings yet

- EN Vibrating Screens EDT-N EDT-2N PDFDocument4 pagesEN Vibrating Screens EDT-N EDT-2N PDFMichael DavenportNo ratings yet

- Ease Us Fix ToolDocument7 pagesEase Us Fix ToolGregorio TironaNo ratings yet

- V3 Hyundai Price ListDocument4 pagesV3 Hyundai Price Listdeepu kumarNo ratings yet

- Isbn 978-602-61467-0-0Document20 pagesIsbn 978-602-61467-0-0Sofhiya LbNo ratings yet

- Manual de Usuario PLECSIM 4.2Document756 pagesManual de Usuario PLECSIM 4.2juansNo ratings yet

- Fortran 77 BookDocument211 pagesFortran 77 Bookjohn effiongNo ratings yet

- Week 4 - Vapor-Liquid Separation (Multicomponent Distillation)Document19 pagesWeek 4 - Vapor-Liquid Separation (Multicomponent Distillation)psychopassNo ratings yet

- Maluno Integrated School: Action Plan On Wins ProgramDocument1 pageMaluno Integrated School: Action Plan On Wins ProgramSherlymae Alejandro Avelino100% (2)

- Tendon Grouting - VSLDocument46 pagesTendon Grouting - VSLIrshadYasinNo ratings yet

- 5c X-Tend FG Filter InstallationDocument1 page5c X-Tend FG Filter Installationfmk342112100% (1)

- IAB Annual Report 2013-1-1-FinalDocument12 pagesIAB Annual Report 2013-1-1-FinalmunimNo ratings yet

- EE 4702 Take-Home Pre-Final Questions: SolutionDocument11 pagesEE 4702 Take-Home Pre-Final Questions: SolutionmoienNo ratings yet

- WS Soln 2 6A RationalFunctionsDocument6 pagesWS Soln 2 6A RationalFunctionsSiddhant ShahNo ratings yet

- Mergers and Acquisitions in Pharmaceutical SectorDocument37 pagesMergers and Acquisitions in Pharmaceutical SectorAnjali Mehra100% (2)

- MCD2000CM4 T1 014 (8 7 12) - CompleteDocument1,062 pagesMCD2000CM4 T1 014 (8 7 12) - CompletePablo Marchant TorresNo ratings yet

- American Bar Association American Bar Association JournalDocument6 pagesAmerican Bar Association American Bar Association JournalKarishma RajputNo ratings yet

- Class 10th IMO 5 Years EbookDocument71 pagesClass 10th IMO 5 Years EbookAdarsh Agrawal100% (1)

- Design of Earth Air Tunnel To Conserve Energy - FinalDocument19 pagesDesign of Earth Air Tunnel To Conserve Energy - FinalApurva AnandNo ratings yet

- Masonry: Department of EducationDocument6 pagesMasonry: Department of EducationFatima AdilNo ratings yet

- SWVA Second Harvest Food Bank Spring Newsletter 09Document12 pagesSWVA Second Harvest Food Bank Spring Newsletter 09egeistNo ratings yet

- Fridge Zanussi ZK2411VT5 ManualDocument14 pagesFridge Zanussi ZK2411VT5 ManualDragos MoscuNo ratings yet

- Ansoff Matrix of TescoDocument2 pagesAnsoff Matrix of TescoMy GardenNo ratings yet

- ILSDocument35 pagesILSDawood waheedNo ratings yet