Professional Documents

Culture Documents

Application of CFB (Circulating Fluidized Bed)

Uploaded by

jomolt41559Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application of CFB (Circulating Fluidized Bed)

Uploaded by

jomolt41559Copyright:

Available Formats

Application of CFB (Circulating Fluidized Bed)

to Sewage Sludge Incinerator

Akira Nakamura*, Toshihiko Iwasaki**, Takashi Noto*,

Hisanao Hashimoto***, Nobuyuki Sugiyama**** and Masahiro Hattori*****

* Senior Research Engineer, Environmental Plant systems Dept., Engineering Research Center

** Team Manager, Environmental Plant systems Dept., Engineering Research Center

*** Manager, Planning Dept., Water and Waste Water Engineering Division

**** Manager, Water Treatment Engineering Dept., Water and Waste Water Engineering Division

***** Engineer, Water Treatment Engineering Dept., Water and Waste Water Engineering Division

CFB (Circulating Fluidized Bed) is widely used for coal-fired boilers. For combusting sewage sludge in CFB, a

suitable fluidization mode for damp material is required. Experiments for combusting sewage sludge were carried

out using a pilot-scale CFB incinerator. As a result, a desirable combustion method was established by optimizing

the fluidization mode and controlling the profiles of the temperature and pressure. The results indicated that CFB is

applicable to sewage sludge incineration.

the combustion chamber are hindered when the furnace

1. Introduction size is increased. In contrast, even large-size CFB incin-

In line with the development of sewage systems, sewage erators are expected to maintain excellent combustion

sludge is now being generated in Japan at a rate of ap- because sufficient agitation and mixing are carried out by

proximately 2 million tons per year (equivalent solid sub- high-velocity fluidization.

stance weight). Most of this sludge is subjected to vol- In CFB combustion, part of the bed material and un-

ume-reducing treatment by incineration after de-watering. burned char carried out from the top of the riser (com-

Sewage sludge cake obtained by de-watering is a damp bustion chamber) are captured by the cyclone and circu-

substance that has a high water content of 70 to 85%. lated through the system, and are completely combusted.

Bubbling fluidized bed incinerators are generally used for Therefore, it is most suitable for combusting coal that

incinerating sewage sludge cake because this type of in- contains much fixed carbon and hence it is widely ap-

cinerator enables stable combustion with a relatively sim- plied to coal-fired boilers. In contrast, sewage sludge

ple structure1). cake has a high water content and in many cases, its solid

In the past several years, Japanese manufacturers of portion contains volatile matters of nearly 70%. The

sewage sludge incinerators have proposed applying CFB properties are significantly different from those of coal,

(Circulating Fluidized Bed) for incinerating sewage and so different fluidization and combustion technologies

sludge cake. CFB incinerators have a higher gas velocity are required when applying the same CFB technology to

(4-6 m/s) inside the furnace compared to the bubbling sewage sludge cake. The general properties of coal and

fluidized bed incinerators and allows the height of the sewage sludge are compared in Table 1.

combustion zone to be raised. Therefore, it is possible to NKK carried out a series of experiments using a CFB

obtain a higher combustion load per unit horizontal cross pilot plant that has a riser of inner diameter of 300 mm

section, which reduces the construction area required for and height of 12m. It was confirmed that the CFB fur-

installing the furnace. Further, combustion air is supplied nace is satisfactory for incinerating sewage sludge cake.

in two stages: primary air (fluidizing air) and secondary The results are summarized below.

air, and so the power load of the fluidizing blower is re-

duced. Two-stage combustion is also expected to lower

the environmental impact. Bubbling fluidized bed incin-

erators have a drawback in that agitation and mixing in

NKK TECHNICAL REVIEW No.86 (2002) –30–

Application of CFB (Circulating Fluidized Bed) to Sewage Sludge Incinerator

Table 1 Properties of coal and sewage sludge cake

Bituminous coal Sewage sludge cake

Moisture % 0~8 70~85

Volatile matter dry-% 13~40 50~75

Fixed carbon dry-% 75~85 8~10

Ash dry-% 2~5 15~40

Low heating value MJ/kg 20~25 0.4~2.5

2. Experimental setup and conditions

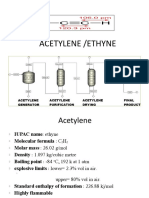

Fig.1 is a flow diagram of the pilot plant used for the

experiments. Photo 1 is its exterior view. The CFB section

is composed of a riser that works as a combustion chamber,

a hot cyclone that captures circulating particles, a loop seal

that prevents back-flowing of unburned gas from the fur- Photo 1 Pilot plant

nace bottom, etc. The pilot plant also has a flue gas treat-

ment section. The riser has the inner diameter of 300 mm Four types of sewage sludge cake were used in the ex-

and the height of 12 m and is lined by refractory. It is periments. Table 2 shows their properties. Each of the four

composed of a wind box, a distributor with primary air types of sewage sludge cake has the following characteris-

feed nozzles, secondary air injection ports, a sewage tics.

sludge cake feeder, an oil gun for feeding auxiliary fuel A: Sewage sludge cake generated at a municipal sewage

(kerosene), etc. Primary air is supplied from the wind box treatment plant. It has a comparatively low water content

into the riser through the distributor. The bed material and high heating value.

(fluidizing particles) is blown up from the bottom of the B: Sewage sludge cake from wastewater including in-

riser by primary air and secondary air. Sewage sludge cake dustrial origins. Its solid portion has a high oxygen con-

is rigorously agitated and mixed with the bed material, tent.

dried, and burned. Part of the bed material and unburned C: Digested sewage sludge cake that has a high ash

char carried out from the top of the riser are captured by content and extremely low heating value. Its solid portion

the cyclone as circulating particles, and returned back to has a high sulfur content.

the riser through the loop seal. Combustion flue gas dis- D: Sewage sludge cake from a local mid- to small-scale

charged from the cyclone is cooled down by the gas cooler municipality that has a high water content. Its solid portion

and dust contained in it is removed by the bag filter. The has a high nitrogen content.

flue gas is then drawn out by the IDF (Induced Draft Fan),

and discharged from the stack. Table 2 Properties of sewage sludge cake

Sewage sludge cake A B C D

Moisture % 76.6 78.8 80.1 84.9

Ash dry% 17.5 19.9 40.3 15.0

Combustibles dry% 82.5 80.1 59.7 85.0

High heating value MJ/dry–kg 19.7 19.2 13.3 20.2

Gas cooler

Cyclone Low heating value MJ/kg 2.3 1.8 0.4 0.7

Riser

C dry% 44.3 42.5 31.1 44.9

φ300mm×H12m Bag filter

H dry% 6.2 6.1 4.8 6.4

N dry% 5.3 4.4 4.5 8.3

O dry% 26.0 26.5 18.1 24.6

S dry% 0.7 0.6 1.3 0.8

Sewage sludge

Fly ash

Secondary air Table 3 shows the experimental conditions. In the ex-

Kerosene Loop seal periments, silica sand (major constituent: SiO2) was used

Primary air as the bed material. The air ratio was approximately 1.3.

Stack

IDF Primary air was supplied at the temperature of around

Fig.1 Pilot plant diagram 400°C, and secondary air at around 200°C.

–31– NKK TECHNICAL REVIEW No.86 (2002)

Application of CFB (Circulating Fluidized Bed) to Sewage Sludge Incinerator

Table 3 Experimental conditions

12

Sewage sludge feed rate kg/h 40~60

Kerosene feed rate L/h 13~19 10

O2 (Cyclone ext.) in flue gas % 4.4~5.4

Bed material diameter dP50 8

mm 0.13~0.30

(Silica sand)

Height , m

Superficial gas velocity

m/s 4.4~5.6 6

(800℃)

4

3. Results and discussion

3.1 Investigation on fluidization mode

2

As an operational guideline for CFB furnace, a fluidiza-

tion mode most suitable for each type of material to be 0

burned needs to be established; in other words, it is neces- 0 0.5 1

P'

sary to investigate what type of fluidizing state is to be

formed in each zone of the riser2). First, an optimum flu- Fig.2 Pressure profile in riser

idization mode for sewage sludge cake, which is charac-

terized by a high water content, was studied. The lower zone of the riser has a high pressure, which

When sewage sludge cake is charged into the riser, first indicates that a dense bed with a high particle density is

it is necessary to fully evaporate its water content and dry formed there. The zone up to the height where P’ is 0.2 in

it out in the lower zone of the riser. To do this, a dense bed the above equation was defined to be a dense bed zone.

must be formed in the lower zone of the riser below the Above this dense bed zone with hights over 2.0m, the

secondary air injection port. Here, the dense bed means a pressure slightly increases with the hight due to the sec-

zone that has a high particle density of the bed material ondary air injection. After this slight increase, the pressure

and is in a fluidizing state where the gas velocity is low as gradually decreases toward the top of the riser, which in-

in the conventional bubbling fluidized bed furnace. In dicates that the upper zone is in a high-velocity fluidizing

contrast, in the upper zone of the riser above the secondary state.

air injection port, it is necessary to completely combust the This fluidization mode was judged to be the optimal one

gas formed in the dense bed zone and unburned combusti- for combusting a damp substance, and its combustion

ble matters contained in the dried sewage sludge cake. To characteristics were investigated as follows.

do this, it is considered desirable to form a high-velocity 3.2 Optimization of dense bed zone

fluidizing state in the upper zone and promote thorough In order to maintain the combustion of a damp sub-

agitation and mixing. stance in the CFB furnace, it is necessary to promote pri-

Suitable conditions for particle sizes of the bed material mary combustion in the dense bed zone while vaporizing

and allocation between primary air and secondary air were the water content. In doing so, it is extremely important to

investigated to realize these states in the riser. As an ex- maintain the temperature of the dense bed zone above the

ample, Fig.2 shows the results obtained when sewage temperature that can maintain the combustion.

sludge cake A was used. This figure shows the pressure The dense bed temperatures were measured while com-

profile along the height of the riser. The values were made busting sewage sludge cake A under identical conditions

dimensionless using the following equation and allocating except that the ratio of primary air to secondary air was

unity to the value at the bottom of the riser (immediately varied. Fig.3 shows the results. The primary air ratio

above the distributor) and zero to the value at the top of shown on the horizontal axis is the ratio of the primary air

the riser. to the total amount of air required for combusting both

sewage sludge cake and kerosene fed into the riser. The

P’ = (P - P1)/(P0 - P1) figure indicates that the highest dense bed temperature is

obtained when the primary air ratio is 0.6. When the pri-

Where, P: Pressure at each measuring point, P1: Pres- mary air ratio is increased further, the dense bed tempera-

sure at the top of the riser, and P0: Pressure immediately ture decreases, which is considered to occur because the

above the distributor. heat generated by the combustion of the sewage sludge

NKK TECHNICAL REVIEW No.86 (2002) –32–

Application of CFB (Circulating Fluidized Bed) to Sewage Sludge Incinerator

cake and auxiliary fuel tends to move upward in the riser. 3.3 Combustion characteristics in entire zone of riser

Another probable cause of the temperature decrease is that Combustion characteristics in the entire zone of the riser

the heat capacity in the lower zone of the riser is lowered were investigated. Fig.5 shows the profiles of the oxygen

because the particle density decreases as the gas velocity concentration and temperature in the riser when sewage

increases. Conversely, when the primary air ratio is de- sludge cakes A and D were combusted. It is clear that the

creased from 0.6, the minimum combustion required for oxygen supplied by the primary air is almost completely

maintaining the temperature is no longer carried out and consumed in the dense bed zone below the secondary air

hence the dense bed temperature decreases. injection port, and a reducing atmosphere is formed. The

The primary air ratio determines the conditions in the temperatures in this zone are comparatively low at 700 to

early stage of combustion and therefore affects the flue gas 800°C, and it is considered that the water content in the

properties. Fig.4 shows the results of measuring the CO sewage sludge cake is evaporated and combustible matters

concentration at the exit of the cyclone when the plant was are gasified there. Above the secondary air injection port

operated under the same conditions as in Fig.3. The CO of the height of around 2 m, oxygen is gradually consumed

concentration decreases with decreasing the primary air with increasing height. The temperatures in this zone are

ratio. The probable cause is that a suitable thermal around 850°C. This is probably because combustible mat-

decomposition of the sewage sludge cake occurs in the ters gasified in the dense bed zone undergo complete

dense bed zone, and combustible constituents generated combustion in the wide zone above the secondary air in-

there undergo complete combustion in the upper zone jection port, and a sufficiently wide high-temperature field

above the secondary air injection port. All types of sewage is formed there.

sludge cake indicated almost identical trends.

12

750 800

Temperature,℃

,℃

10

600

2 2

temperature

ppm-12%O

700

, ppm-12%O

400 8

bedBed

650

COCO,

Height , m

200

Dense

6

Dense

600 0

0.5 0.6 0.7 0.8 0.9 0.5 0.6 0.7 0.8 0.9 4

Primary Air

Primary air Ratio

ratio Primary Air ratio

Ratio

Primary air

Fig.3 Influence of primary Fig.4 Influence of pri- 2

air ratio on dense mary air ratio on

bed temperature CO emissions

0

0 5 10 15 600 800 1000

Photo 2 shows the state of the dense bed zone photo-

O2 , % Temperature , ℃

graphed by a CCD camera when sewage sludge cake A Sludge A

was combusted at the primary air ratio of 0.6. The black Sludge D

spherical substances are sewage sludge cakes. The photo- Fig.5 Profiles of O2 and temperature in riser

graph indicates that stable combustion is maintained in the

dense bed zone. 3.4 Flue gas properties

From the above, it was concluded that the optimum pri- Sewage sludge cake contains a higher nitrogen content

mary air ratio for the CFB furnace is around 0.6. compared to municipal solid wastes or plastic wastes.

Hence, NOx and N2O concentrations in the flue gas dis-

charged to the atmosphere are serious concerns. Since

CFB furnace has a higher gas velocity in the furnace com-

pared to bubbling fluidized bed furnace, incomplete com-

bustion due to a shorter gas residence time is another con-

cern. Therefore, we investigated how to reduce the

emissions of various harmful gases. Table 4 shows proper-

Photo 2 State of dense bed zone ties of flue gas measured at the exit of the cyclone.

–33– NKK TECHNICAL REVIEW No.86 (2002)

Application of CFB (Circulating Fluidized Bed) to Sewage Sludge Incinerator

Table 4 Properties of flue gas from cyclone exit bents such as limestone (major constituent: CaCO3)

Sewage sludge A B C D

charged directly into the furnace are expected to perform

O2 % 5.3 5.1 5.0 4.4

desulfurization effectively. This method has been already

CO ppm–12%O2 27 17 8 17 used for coal-fired boilers. This method does not need flue

CO2 % 11 10 12 10 gas desulfurization and associated wastewater treatment

NOx ppm–12%O2 48 65 31 54 and helps reduce space and running costs. However, CaO

N2 O ppm–12%O2 38 – – 62 generated by decomposition of limestone works as a cata-

DXNs ng–TEQ/Nm3 0.00028 – – – lyst for forming NOx from NH3, and might have adverse

effects on the NOx concentration, depending on the com-

All of CO, NOx, and N2O emissions from every type of bustion conditions.

sewage sludge cake were suppressed to low levels at the Experiments of in-furnace desulfurization were carried

air ratio of approximately 1.3. The reasons for the reduc- out under various conditions. Limestone was charged into

tion of each of these emissions were as follows: the riser at the Ca/S molar ratio of 3.0 to 4.5 while sewage

(1) NOx sludge cakes A, B, and C were combusted at the air ratio

When sewage sludge cake is combusted in the fluidiza- of approximately 1.3. A desirable temperature for a desul-

tion mode as described above, nitrogenous compounds are furizing reaction by using limestone is thought to range

turned into NH3, HCN, etc. in the dense bed zone that has from 800 to 850°C. In the riser, this temperature zone cor-

a reducing atmosphere. They then undergo complete responds to the zone above the secondary air injection port,

combustion in the upper zone where secondary air is in- as shown in Fig.5. In order to fluidize the limestone in this

jected. This two-stage combustion helps reduce the NOx zone and promote the reaction, pulverized limestone was

concentration. used. Table 5 shows the results.

(2) N2O

When the furnace has the temperature profile as de- Table 5 Results of de-SOx experiment

scribed above, N2O is decomposed in the sufficiently wide Sewage sludge A B C

high-temperature field in the upper zone of the riser. Molar ratio (Ca/S) – 3.0 4.5 4.2

Therefore, it becomes possible to simultaneously reduce SO2 (Estimated*) ppm–12%O2 134 81 123

both NOx and N2O, which are generally considered to SO2 (Measured) ppm–12%O2 1.9 4.2 2.3

have a tradeoff relation with regard to their emission be- SO2 removal % 98.6 94.8 98.1

NOx ppm–12%O2 44 66 31

haviors3),4).

*Conversion ratio=100%

(3) CO

The gas in the upper zone of the riser is fully agitated For each type of sewage sludge cake, it was found that

and mixed, and undergoes complete combustion in the more than roughly 95% of SO2 is removed out of the esti-

high-temperature field that spans the wide area in this zone. mated SO2 concentration (*) that would have been emitted

Therefore, the CO emissions are suppressed. if all the sulfur in the sewage sludge cake had been con-

(4) Dioxins verted to SO2 (conversion ratio=100%). Further, the NOx

These also undergo complete combustion in the concentration that posed a concern was almost at the same

high-temperature field that spans the wide area in the up- level as when in-furnace desulfurization was not per-

per zone of the riser. Therefore, the dioxins emissions are formed.

suppressed to extremely low levels. Thus, it was proved that in-furnace desulfurization in

3.5 In-furnace desulfurization the CFB can achieve a high efficiency without affecting

Sewage sludge cake contains a higher sulfur content the NOx concentration.

than municipal solid wastes and plastic wastes, and tends 3.6 Leaching test of fly ash and bed material

to emit a high concentration of SOx when incinerated. Fly ash captured by the bag filter and bed materials

Therefore the flue gas is usually passed through a desulfu- extracted from the riser were subjected to leaching tests.

rization scrubber that uses caustic soda (NaOH) solution Table 6 shows the results. For all types of sewage sludge

before being released from a stack. cake, no leaching of hazardous substances from fly ash or

Since CFB furnace provides a high contact efficiency bed material was detected.

between the bed material and gas, desulfurization absor-

NKK TECHNICAL REVIEW No.86 (2002) –34–

Application of CFB (Circulating Fluidized Bed) to Sewage Sludge Incinerator

Table 6 Results of leaching test for fly ash and bed material

Fly ash Bed material

A+ B+ C+ A+ B+

Sewage sludge A Lime– Lime– C Lime– D A Lime– Lime–

stone stone stone stone stone

Cd mg/l <0.01 <0.01 <0.01 <0.01 <0.01 <0.01 <0.005 <0.005 <0.005

–

CN mg/l <0.05 <0.05 <0.05 <0.05 <0.05 <0.05 <0.05 <0.05 <0.05

P mg/l <0.05 <0.05 <0.05 <0.05 <0.05 <0.05 0.07 <0.05 <0.05

Pb mg/l <0.01 <0.01 <0.01 <0.01 <0.01 <0.01 <0.005 <0.005 <0.005

Total–Cr mg/l <0.05 <0.05 0.07 <0.05 <0.05 <0.05 <0.05 <0.05 0.07

Cr6+ mg/l <0.04 <0.04 <0.04 <0.04 <0.04 <0.05 <0.04 <0.04 <0.04

As mg/l 0.04 <0.05 <0.05 <0.01 <0.01 0.03 <0.05 <0.05 <0.05

Total–Hg mg/l <0.0005 <0.0005 <0.0005 <0.0005 <0.0005 <0.0005 <0.0005 <0.0005 <0.0005

Alkyl–Hg mg/l <0.0005 <0.0005 <0.0005 <0.0005 <0.0005 <0.0005 <0.0005 <0.0005 <0.0005

PCB mg/l <0.0005 <0.0005 <0.0005 <0.0005 <0.0005 <0.0005 <0.0005 <0.0005 <0.0005

References

1) Tsuboi, H. et al. “Comprehensive Fluidization Technology”. NKK

4. Conclusions

Giho. No.123, pp.2–9(1988).

Four types of sewage sludge cake, each having different 2) Muchi, I. et al. “Reaction Engineering of Fluidized Bed”. Baihukan,

properties, were subjected to combustion experiments us- Tokyo, 1984, pp.270–274.

ing the pilot-scale CFB incinerator. As a result, the fol- 3) Suzuki, Y. et al. “N2O Generation in Circulating Fluidized Bed Com-

lowing conclusions were obtained regarding the applica- bustion of Coal”. Journal of Japan Fuel Association. Vol.6, No.12,

pp.1146–1151(1990).

bility of the CFB furnace to sewage sludge incineration.

4) Shimizu, T. et al. “Seminar on Basic Coal Science (X)”. Journal of

(1) The CFB furnace can be used to incinerate a wide vari- Japan Energy Society, Vol.75, No.9, pp.851–859(1996).

ety of sewage sludge cakes by forming a fluidization mode 5) Horio, M. et al. “Fluidization Handbook”. Baihukan, Tokyo, 1999,

optimized for damp material in the riser. p.432.

(2) It is possible to simultaneously reduce both NOx and

<Please refer to>

N2O by utilizing two-stage combustion and the

Akira Nakamura

high-temperature field in the upper zone of the riser. It is Environmental Plant Systems Dept., Engineering Research Center

also possible to reduce the CO concentration, giving com- Tel : (81) 44-322-6305

plete combustion. E-mail : anakamu@lab.keihin.nkk.co.jp

Hisanao Hashimoto

(3) It is possible to reduce the SOx concentration by

Planning Dept., Water and Waste Water Engineering Division

in-furnace desulfurization. Tel : (81) 45-505-7622

(4) No leaching of hazardous substances from fly ash or E-mail : hashimh@eng.tokyo.nkk.co.jp

bed material was detected.

It was proven that the CFB technology developed for

coal-fired boilers is satisfactory for sewage sludge incin-

eration.

Therefore, CFB combustion can be applied to coal that

has a high fixed carbon content and sewage sludge cake

that has a high water content. The CFB technology may

thus be applicable to combusting a variety of fuels and

wastes as a means of effectively utilizing energy that will

become increasingly diversified. For sewage sludge treat-

ment in particular, the technology has the potential to

achieve mixed combustion with screenings, grit, or other

types of wastes, including energy recovery.

Based on the results obtained in these experiments, we

are continuing to develop the CFB technology.

–35– NKK TECHNICAL REVIEW No.86 (2002)

You might also like

- 1A2. Circulating Fluidized Bed Combustion Technology (CFBC)Document1 page1A2. Circulating Fluidized Bed Combustion Technology (CFBC)kumarmm1234No ratings yet

- 2A2. Circulating Fluidized-Bed Combustion Technology (CFBC)Document1 page2A2. Circulating Fluidized-Bed Combustion Technology (CFBC)Deepak JhaNo ratings yet

- CFBC & PFBC Technology OverviewDocument18 pagesCFBC & PFBC Technology OverviewomiitgNo ratings yet

- CFBC & PFBC Technology OverviewDocument18 pagesCFBC & PFBC Technology OverviewJessica SimpsonNo ratings yet

- CCT Overview Part 2 - Circulating Fluidized-bed Combustion TechnologyDocument1 pageCCT Overview Part 2 - Circulating Fluidized-bed Combustion TechnologyanbarasanNo ratings yet

- Fine Tuning A CFBC Boiler PDFDocument12 pagesFine Tuning A CFBC Boiler PDFrikumohanNo ratings yet

- Kiln Burning Systems: Raw Mill From Storage Feed RateDocument43 pagesKiln Burning Systems: Raw Mill From Storage Feed RateMuhammad Kureshi100% (1)

- Study of Reactor Parameters for Carbon Black ProductionDocument58 pagesStudy of Reactor Parameters for Carbon Black ProductionRishya Prava ChatterjeeNo ratings yet

- CFBC BoilersDocument11 pagesCFBC BoilersManoj DesaiNo ratings yet

- Paper 4 Air Preheater Basket Cleaning PDFDocument43 pagesPaper 4 Air Preheater Basket Cleaning PDFMateus Pinheiro100% (2)

- Acetylene Production-2023 4Document31 pagesAcetylene Production-2023 4Divyansh NagarNo ratings yet

- Waste CFB CombustionDocument15 pagesWaste CFB CombustionmihugirNo ratings yet

- Gasifier Modification Methods for Tar ReductionDocument16 pagesGasifier Modification Methods for Tar ReductionisttNo ratings yet

- HP4b - 2 - Vogels - Rev0604 - European Study For H2 Produ From Biomass PDFDocument7 pagesHP4b - 2 - Vogels - Rev0604 - European Study For H2 Produ From Biomass PDFJaydeep PatelNo ratings yet

- Asian Paints Boiler Report AnalysisDocument10 pagesAsian Paints Boiler Report AnalysisPrakash WarrierNo ratings yet

- Bypass SystemDocument9 pagesBypass SystemirfanNo ratings yet

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"From EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"No ratings yet

- Indian BOE Coaching Services: Gujarat BOE-2016 Paper-2 (Boiler Engg-2) SolutionDocument7 pagesIndian BOE Coaching Services: Gujarat BOE-2016 Paper-2 (Boiler Engg-2) SolutionAlok DoshiNo ratings yet

- DryerDocument4 pagesDryerJAGDISHNo ratings yet

- Operation & Maintenance Manual For 17 KG/HR Biomass Gasifier System For Cooking ApplicationDocument18 pagesOperation & Maintenance Manual For 17 KG/HR Biomass Gasifier System For Cooking ApplicationAdhavan ThamizhanNo ratings yet

- Kiln ChemistryDocument29 pagesKiln Chemistrykonstantina13986% (7)

- Case Studies of Biomass and Coal Co-combustion in ASEANDocument16 pagesCase Studies of Biomass and Coal Co-combustion in ASEANJanelle D. Puti-anNo ratings yet

- Ablative Flash Pyrolysis of Straw and Wood Bench-Scale ResultsDocument9 pagesAblative Flash Pyrolysis of Straw and Wood Bench-Scale ResultsGiriraj JoshiNo ratings yet

- JEA Ash Handling Systems Topical Report Rev 1Document22 pagesJEA Ash Handling Systems Topical Report Rev 1Sarfaraz KhanNo ratings yet

- Gasification and Power from Woody BiomassDocument6 pagesGasification and Power from Woody BiomasschaniefNo ratings yet

- Biomass in BoilerDocument13 pagesBiomass in Boilermbkluimp100% (1)

- Dry Quenching of Hot Coke - IspatGuruDocument10 pagesDry Quenching of Hot Coke - IspatGurukaustavNo ratings yet

- 1.1 Salient Features of CFBC BoilerDocument17 pages1.1 Salient Features of CFBC BoilerJAY PARIKHNo ratings yet

- CalcinationDocument7 pagesCalcinationVelu ManiNo ratings yet

- Chemical Cleaning of Paper MillDocument11 pagesChemical Cleaning of Paper Millsubrata guhaNo ratings yet

- Comparative Process Study of Biomass Gas PDFDocument6 pagesComparative Process Study of Biomass Gas PDFhmpackingNo ratings yet

- Production of Large Size Parts by MIM Process: T. Shimizu, A. Kitazima, M. Nose, S. Fuchizawa, T. SanoDocument4 pagesProduction of Large Size Parts by MIM Process: T. Shimizu, A. Kitazima, M. Nose, S. Fuchizawa, T. SanoAbhishek AnandNo ratings yet

- Thermal Conversion ProcessesDocument27 pagesThermal Conversion ProcessesBhavi PatelNo ratings yet

- 19 Densification of SolidsDocument18 pages19 Densification of Solids315038 ktr.chem.17No ratings yet

- Design, Process Simulation and Construction of An Atmospheric Dual Fluidized Bed CombustionDocument9 pagesDesign, Process Simulation and Construction of An Atmospheric Dual Fluidized Bed Combustionapi-3799861No ratings yet

- Boiler-Questions - AnswersDocument38 pagesBoiler-Questions - AnswersKapil_1983100% (3)

- Profitable Calcining of Non-Calcinable Pet Coke PDFDocument4 pagesProfitable Calcining of Non-Calcinable Pet Coke PDFDedik DermadyNo ratings yet

- Combustion and Emission Characteristics of Rice Husk in A Rectangular Fluidized Bed CombustorDocument4 pagesCombustion and Emission Characteristics of Rice Husk in A Rectangular Fluidized Bed CombustorfelramNo ratings yet

- Renewable Energy Unit-5Document4 pagesRenewable Energy Unit-5homoxos344No ratings yet

- Reheating Scrubbed Flue Gas from Coal-Fired Power PlantDocument20 pagesReheating Scrubbed Flue Gas from Coal-Fired Power PlanthuyNo ratings yet

- Fluidized Bed CombustionDocument23 pagesFluidized Bed CombustionHawk EyeNo ratings yet

- FGD Presentation (ILFS)Document40 pagesFGD Presentation (ILFS)proloy12100% (1)

- Boiler QuestionsDocument39 pagesBoiler Questionssk3146100% (11)

- PyrolysisDocument18 pagesPyrolysishope worldNo ratings yet

- 1 s2.0 092058618785006X MainDocument21 pages1 s2.0 092058618785006X MainAnelisa Lima das MercesNo ratings yet

- 2.2 Boilers - Revised (Table Format)Document11 pages2.2 Boilers - Revised (Table Format)Gajanan JagtapNo ratings yet

- GasificationDocument6 pagesGasificationHADINo ratings yet

- Sodium Bicarbonate Carbon CaptureDocument15 pagesSodium Bicarbonate Carbon CaptureDimitriNo ratings yet

- NFL PPTDocument46 pagesNFL PPTvipin6kumar-718654No ratings yet

- QI Heater Tube Cleaning and VerificationDocument10 pagesQI Heater Tube Cleaning and VerificationOmid LarkiNo ratings yet

- Experience On Operation and Maintenance of CFBC Boiler at KLTPS - Kutchh - Gujarat PDFDocument49 pagesExperience On Operation and Maintenance of CFBC Boiler at KLTPS - Kutchh - Gujarat PDFanbarasanNo ratings yet

- Agroni KokbidoniDocument14 pagesAgroni KokbidoniVisi GjNo ratings yet

- Biomass Clean Up SystemDocument6 pagesBiomass Clean Up SystemAndre SyahputraNo ratings yet

- Gasification Is A Process That Converts Organic or Fossil Based Carbonaceous MaterialsDocument11 pagesGasification Is A Process That Converts Organic or Fossil Based Carbonaceous MaterialsEric CookNo ratings yet

- Methods to Capture Carbon from Combustion EmissionsDocument30 pagesMethods to Capture Carbon from Combustion EmissionsRamana Kumar SkvNo ratings yet

- Fundamentals of Fluidized-Bed Chemical Processes: Butterworths Monographs in Chemical EngineeringFrom EverandFundamentals of Fluidized-Bed Chemical Processes: Butterworths Monographs in Chemical EngineeringNo ratings yet

- Synthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsFrom EverandSynthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsTilman J. SchildhauerNo ratings yet

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementFrom EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNo ratings yet

- 16.11.22 - EDT - Prof. Ziad Al-Ani - NotesDocument3 pages16.11.22 - EDT - Prof. Ziad Al-Ani - NotesAarya Haridasan NairNo ratings yet

- 20 Common Defense Mechanisms for AnxietyDocument8 pages20 Common Defense Mechanisms for AnxietyAbhishek NegiNo ratings yet

- TQ International Course Guide - CompressedDocument40 pagesTQ International Course Guide - CompressedgermanNo ratings yet

- VisitAberdeen City Centre MapDocument2 pagesVisitAberdeen City Centre MapZarko MikicNo ratings yet

- Workshop 1Document2 pagesWorkshop 1Chathura PallawalaNo ratings yet

- Social Sciences & Humanities: Joseph Ching VelascoDocument20 pagesSocial Sciences & Humanities: Joseph Ching VelascoNely Noer SofwatiNo ratings yet

- RecipesDocument102 pagesRecipesmajaklipa100% (3)

- Condenser TemperatureDocument10 pagesCondenser TemperatureBerkay AslanNo ratings yet

- Dokumen - Tips - Chapter 17 Job Order Costing Costing Chapter 17 Learning Objectives 1 DistinguishDocument25 pagesDokumen - Tips - Chapter 17 Job Order Costing Costing Chapter 17 Learning Objectives 1 DistinguishNouman SheikhNo ratings yet

- Application 1 (Basic Steps in Accounting)Document2 pagesApplication 1 (Basic Steps in Accounting)Maria Nezka Advincula86% (7)

- SCHNEIDER NABCEP PV Resource Guide 10 4 16 W PDFDocument174 pagesSCHNEIDER NABCEP PV Resource Guide 10 4 16 W PDFbacuoc.nguyen356100% (1)

- Unit 5 - Standard TestDocument5 pagesUnit 5 - Standard Testma rika100% (1)

- Financial Times Europe 14 November 2023Document18 pagesFinancial Times Europe 14 November 2023Nikola JovanovNo ratings yet

- 4g 6 Traits Writing Rubric StudentDocument3 pages4g 6 Traits Writing Rubric Studentapi-295344358No ratings yet

- International SellingDocument28 pagesInternational SellingShoaib ImtiazNo ratings yet

- Module 9 PresentationDocument28 pagesModule 9 PresentationJerico CastilloNo ratings yet

- NITI AayogDocument6 pagesNITI Aayogs100% (1)

- Malbog Sulfuric Hot SpringDocument2 pagesMalbog Sulfuric Hot SpringMark-Christopher Roi Pelobello MontemayorNo ratings yet

- PresentationDocument5 pagesPresentationAnsh RebelloNo ratings yet

- Picasso's Blue Period - WikipediaDocument24 pagesPicasso's Blue Period - WikipediaDinesh RajputNo ratings yet

- "A Study On Inventory Management" Statement of ProblemDocument3 pages"A Study On Inventory Management" Statement of ProblemSandhiya GovindNo ratings yet

- Women Beware WomenDocument12 pagesWomen Beware WomenomitevskiNo ratings yet

- Petronas Approved Medical Examiner List 2017 (Latest Updated Version)Document4 pagesPetronas Approved Medical Examiner List 2017 (Latest Updated Version)Zulfadli RaniNo ratings yet

- Indofood Dynamic Strategic.Document7 pagesIndofood Dynamic Strategic.Cha IndraNo ratings yet

- Horno Industrial HC1 v1.1Document30 pagesHorno Industrial HC1 v1.1Cristian urielNo ratings yet

- P3am 7642 enDocument205 pagesP3am 7642 enAmine SEMRANINo ratings yet

- Land Titling and Transfer Legal Services in Trece Martirez and DasmarinasDocument1 pageLand Titling and Transfer Legal Services in Trece Martirez and DasmarinasMark RyeNo ratings yet

- Around The DubaiDocument11 pagesAround The DubaiGayane HovhannisyanNo ratings yet

- Oracle vs Google copyright caseDocument1 pageOracle vs Google copyright caseRobert BasanNo ratings yet