Professional Documents

Culture Documents

HDPE Duct Cleaning Test-756

Uploaded by

Md. BorhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HDPE Duct Cleaning Test-756

Uploaded by

Md. BorhanCopyright:

Available Formats

MECON LIMITED SPECIFICATION OF OPTICAL FIBER CABLE

DELHI & HDPE DUCT LAYING & ASSOCIATED WORKS

ELECT. & INST. SPECIFICATION No. : MEC / S / 05 / E5 / T / 001

SECTION Rev. 0 Page 20 of 20

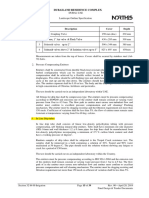

1) Duct Cleaning:

Following steps are to be followed for cleaning the laid HDPE conduit:

♦ Compressed air should be blown through the duct in order to remove any dirt

and water that has accumulated inside the duct with the help of air

compressor. A short blast of air of about 1 bar shall be blown through the duct

for about 1 minute.

♦ Duct sponges will be blown through the duct to further remove any dirt and

water from the duct segment. Sponges should be blown into the duct clean and

a dry sponge comes out of the duct.

2) Duct Calibration and integrity Test:

♦ This test is to be done to check the roundness and the integrity of the duct.

During installation or backfill process there is possibility of flattening,

twisting or

kinking of the duct. This testing process shall be conducted by blowing a plug

or probe through the duct segment with compressed air.

♦ Calibration shall be done by a simple sender like small probe,which shall be

blown through the duct by compressed air. This probe shall be detectable

using a HF Detector.

♦ The calibration process shall be considered completed once the probe exits the

duct at the other end after an uninterrupted pass.

♦ When obstruction in the duct are found, these obstruction have to be removed

by removing the damaged or deformed portion of the duct and placing a new

section of duct.

3) Air Pressure Test :

♦ A static pressure test is to be carried out in order to verify air tightness for the

purpose of cable blowing as well as to prevent ingress of water or dirt during

the lifetime of the duct.

♦ To verify the air tightness, pressure inside the duct should be brought up to 10

bar for two minutes. A pressure drop of 0 to 0.5 bar per minute of the test is

acceptable. If a higher-pressure drop is detected, no further test should be

conducted until the leak has been located and repaired.

♦ After pressure teasing duct ends should be sealed with the help of duct plugs

to prevent entering of any dirt and water inside it.

After testing the duct any obstruction both the ends of HDPE conduit shall be plugged

again using end plugs.

You might also like

- 06 Sec. 4 Sewer TestingDocument22 pages06 Sec. 4 Sewer TestinglingamkumarNo ratings yet

- Method Statement Construction & Casting of Concrete Manholes P-4Document6 pagesMethod Statement Construction & Casting of Concrete Manholes P-4a.nunezNo ratings yet

- 330130Document7 pages330130Cool SharyNo ratings yet

- MWWSSB 11 Sewer TesRTRting and InpectionDocument5 pagesMWWSSB 11 Sewer TesRTRting and InpectionZeeshan ShaikNo ratings yet

- Pipeline TestingDocument4 pagesPipeline Testingveljko2008100% (1)

- Section 02ADocument3 pagesSection 02AFAHAD HASSANNo ratings yet

- Section 3810 - Gravity Sewer Leakage Tests Part 1 - General 1.1 Scope of WorkDocument3 pagesSection 3810 - Gravity Sewer Leakage Tests Part 1 - General 1.1 Scope of WorkJong Dollente Jr.No ratings yet

- Aama 501 - Ensayo de CampoDocument3 pagesAama 501 - Ensayo de CampoLeonardo SpinelliNo ratings yet

- Aama 501.2-83Document3 pagesAama 501.2-83Abdul Raqeeb67% (3)

- Testing Sewer LineDocument21 pagesTesting Sewer LinehantuutmNo ratings yet

- Pipe Test NocDocument2 pagesPipe Test NocsahanthacNo ratings yet

- Air, Water TestDocument2 pagesAir, Water TestKun San LimNo ratings yet

- SECTION 02660 Pipeline Testing: Hcss 02660-1 June 2008Document8 pagesSECTION 02660 Pipeline Testing: Hcss 02660-1 June 2008moyassine7139No ratings yet

- Jointing Instructions Dec 20123Document2 pagesJointing Instructions Dec 20123Gabi CristacheNo ratings yet

- Field Hydrotest Manual UndergroundDocument8 pagesField Hydrotest Manual UndergroundPhuoc PhuNo ratings yet

- Leak Testing of Underground Drainage PipesDocument1 pageLeak Testing of Underground Drainage PipesplanningNo ratings yet

- Leak Testing of Underground Drainage PipesDocument1 pageLeak Testing of Underground Drainage PipesplanningNo ratings yet

- Leakage TestDocument3 pagesLeakage Testasr.engineering2023No ratings yet

- Pre-Commissioning and CommissioningDocument9 pagesPre-Commissioning and CommissioningSaurabh Sharma100% (6)

- Installation, Operation and Maintenance - LOK-FLANGE ® Multitube Heat ExchangersDocument5 pagesInstallation, Operation and Maintenance - LOK-FLANGE ® Multitube Heat ExchangersCLIFFORDPANo ratings yet

- Qualified Channel Bottom and Sand FillingDocument4 pagesQualified Channel Bottom and Sand Fillinghello_lakho633No ratings yet

- Addendum To Method Statement For Installation of Plumbing System 1. Hydrostatic Pressure Test of Water Services PipingDocument4 pagesAddendum To Method Statement For Installation of Plumbing System 1. Hydrostatic Pressure Test of Water Services PipingSIBINNo ratings yet

- Air Leak TestDocument2 pagesAir Leak TestWaqas Waqas100% (1)

- WATER SUPPLY EditDocument7 pagesWATER SUPPLY EditJia100% (1)

- Plumbing Ventilation and TrapsDocument5 pagesPlumbing Ventilation and TrapscessNo ratings yet

- Summary of HDD WorksDocument3 pagesSummary of HDD WorksSeif ElsaieNo ratings yet

- Standard Specification For Waste Water - TestingDocument5 pagesStandard Specification For Waste Water - Testingpopperoo00No ratings yet

- Sewer Test ProcedureDocument22 pagesSewer Test ProcedureislamakthamNo ratings yet

- STD 15144Document4 pagesSTD 15144kkkhattabbbNo ratings yet

- Review Materials For PlumbingDocument4 pagesReview Materials For PlumbingMark Anthony Agnes AmoresNo ratings yet

- Tube Expansion: Methods and Procedures by C.P.ParekhDocument20 pagesTube Expansion: Methods and Procedures by C.P.ParekhJustin Alwar100% (1)

- Pressure Test - Flushing - Pickling - Passivation Hyd-Cw-GrDocument12 pagesPressure Test - Flushing - Pickling - Passivation Hyd-Cw-GrVidal Choque N.100% (1)

- Sectional Testing of Pipe LineDocument2 pagesSectional Testing of Pipe LinesumitanuragNo ratings yet

- Methodology Fume CupboardDocument3 pagesMethodology Fume CupboardNeguib FarahNo ratings yet

- Leak Test MethodologyDocument3 pagesLeak Test MethodologyJojoMagnoNo ratings yet

- Diesel Pipeline Flushing and PurgingDocument3 pagesDiesel Pipeline Flushing and PurgingVaradaraj CkNo ratings yet

- Procedure For Hydro Testing: Pressure TestDocument5 pagesProcedure For Hydro Testing: Pressure TestDevang ShahNo ratings yet

- Acceptance Testing For Sanitary SewersDocument22 pagesAcceptance Testing For Sanitary Sewersshaik.jakeerNo ratings yet

- National Plumbing Code of The PhilippinesDocument30 pagesNational Plumbing Code of The PhilippinesKchana AmorenNo ratings yet

- Leak Test PDFDocument48 pagesLeak Test PDFdaniel oliveira100% (1)

- CPAA Field Testing of Concrete Pipelines and JointsDocument12 pagesCPAA Field Testing of Concrete Pipelines and JointsSameh BelalNo ratings yet

- Instruction Manual Vacuum CondenserDocument12 pagesInstruction Manual Vacuum CondenserGarry BernzNo ratings yet

- Cleanout Operations: Appendix IDocument2 pagesCleanout Operations: Appendix IPrince VarunNo ratings yet

- Bobbin Filters - Instructions and Operation ManualDocument37 pagesBobbin Filters - Instructions and Operation Manual8nqm4p3veNo ratings yet

- Concrete Construction Article PDF - Grouting Post-Tensioning DuctsDocument3 pagesConcrete Construction Article PDF - Grouting Post-Tensioning Ductsالمصفوفة الحديثةNo ratings yet

- TEst Guide FOr PLDocument3 pagesTEst Guide FOr PLPBDC MEPFSNo ratings yet

- Portfolio Vacuum ProcedureDocument2 pagesPortfolio Vacuum ProcedureAli SalmanNo ratings yet

- Drip Tube SpecDocument1 pageDrip Tube SpecashwinNo ratings yet

- Installation Guidelines For C&I Installation of Pneumatic LineDocument6 pagesInstallation Guidelines For C&I Installation of Pneumatic LineCharu ChhabraNo ratings yet

- Annex1 - Technical Specifications PDFDocument64 pagesAnnex1 - Technical Specifications PDFabdelkader benabdallahNo ratings yet

- Sewer Leakage and Infiltration TestingDocument3 pagesSewer Leakage and Infiltration Testingmujahed_muhammedNo ratings yet

- Hydrostatic Test ProcedureDocument3 pagesHydrostatic Test Proceduredep_vin100% (4)

- Trap Seals.Document18 pagesTrap Seals.Emanuel SajutNo ratings yet

- Tests On DrainsDocument2 pagesTests On DrainsBenzoh QsNo ratings yet

- Sti p3 InstallationDocument6 pagesSti p3 InstallationnjkasdncjkdNo ratings yet

- University of Technology: 3rd Year, II Semester, 2020-2021 Sanitary Engineering Lab. II Civil Engineering DepartmentDocument5 pagesUniversity of Technology: 3rd Year, II Semester, 2020-2021 Sanitary Engineering Lab. II Civil Engineering DepartmentEilya Al-mafrajjeNo ratings yet

- SewerDocument1 pageSewerشريف علي علاءNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Laboratory Rules and SafetyDocument9 pagesLaboratory Rules and SafetyMehul KhimaniNo ratings yet

- Laboratory Autoclaves IcanclaveDocument8 pagesLaboratory Autoclaves IcanclaveХачатрян ГеворгNo ratings yet

- Assignment-7question and SolutionDocument3 pagesAssignment-7question and SolutionTusharNo ratings yet

- Sintered (Uranium-Plutonium) Dioxide Pellets-Fast Reactor FuelDocument4 pagesSintered (Uranium-Plutonium) Dioxide Pellets-Fast Reactor Fuelmohammed ;arasnehNo ratings yet

- Iso 527 2 2012 PDFDocument16 pagesIso 527 2 2012 PDFRafael CastroNo ratings yet

- Cavitation ConcreteDocument6 pagesCavitation Concretefiligrana2012No ratings yet

- ACI522RDocument5 pagesACI522Rraja qammarNo ratings yet

- Zoznam NoriemDocument4 pagesZoznam NoriemPeter TvardzíkNo ratings yet

- Is549 Evaluation of Alkali Silica Reactivity (Asr) Mortar Bar Testing (Astm c1260 and c1567) at 14 Days and 28 DaysDocument4 pagesIs549 Evaluation of Alkali Silica Reactivity (Asr) Mortar Bar Testing (Astm c1260 and c1567) at 14 Days and 28 DaysSandro MendesNo ratings yet

- 2020Document7 pages2020JEORJENo ratings yet

- Aluminum-Promoted Tungstated Zirconia CatalystDocument12 pagesAluminum-Promoted Tungstated Zirconia CatalystzahiraNo ratings yet

- Periodic Test-I (2021-22) : XII/ Chemistry/1 of 2Document2 pagesPeriodic Test-I (2021-22) : XII/ Chemistry/1 of 2Aryan BhardwajNo ratings yet

- Stability of ColumnsDocument45 pagesStability of ColumnsjemnesNo ratings yet

- CAPE Chemistry Mock Exams U2 2015Document19 pagesCAPE Chemistry Mock Exams U2 2015Nicholas CharlesNo ratings yet

- Catalogo - Sispro S.A.Document21 pagesCatalogo - Sispro S.A.JUAN CNo ratings yet

- Department of Structural Engineering, Faculty of Engineering, M.B.M. Engineering College, Jai Narain Vyas University, JodhpurDocument10 pagesDepartment of Structural Engineering, Faculty of Engineering, M.B.M. Engineering College, Jai Narain Vyas University, JodhpurAjayvidyanand SharmaNo ratings yet

- Awareness Poster of Pesticides Waste Management (AlZaShaNi)Document1 pageAwareness Poster of Pesticides Waste Management (AlZaShaNi)Mohammad Bin OthmanNo ratings yet

- Solid State Physics - 04 GrapheneDocument45 pagesSolid State Physics - 04 GrapheneMassimo GiordanoNo ratings yet

- Excel First Review and Training Center, Inc.: Cebu: Davao: Manila: BaguioDocument3 pagesExcel First Review and Training Center, Inc.: Cebu: Davao: Manila: BaguioJohn Anthony YumulNo ratings yet

- 11 Repair KitsDocument2 pages11 Repair KitsbuddhansamratNo ratings yet

- LR Weld Certification Guide v1.3 SubscribeDocument24 pagesLR Weld Certification Guide v1.3 SubscribeSergio Jesus SanjurjoNo ratings yet

- 2016 - Thermal Performance Calculation and Analysis of Heat Transfer Tube in Super Open Rack VaporizerDocument10 pages2016 - Thermal Performance Calculation and Analysis of Heat Transfer Tube in Super Open Rack VaporizerLong Nguyễn HoàngNo ratings yet

- Slump of Hydraulic Cement Concrete Fop For Aashto T 119Document2 pagesSlump of Hydraulic Cement Concrete Fop For Aashto T 119anbertjonathanNo ratings yet

- Introduction To RCCDocument17 pagesIntroduction To RCCdasapathri jahnaviNo ratings yet

- Waste Management PDFDocument16 pagesWaste Management PDFKunal ThakurNo ratings yet

- Lldpe Ga564189Document3 pagesLldpe Ga564189xy2zjgNo ratings yet

- Lead, Zinc and Strontium Distribution in The Oxidation ZoneDocument11 pagesLead, Zinc and Strontium Distribution in The Oxidation ZoneAnonymous Lrw61wNo ratings yet

- Urban Transformers Safety and Environmental ChallengesDocument8 pagesUrban Transformers Safety and Environmental ChallengesNicodemus Ervino MandalaNo ratings yet

- New Microsoft Excel WorksheetDocument4 pagesNew Microsoft Excel WorksheetRaheel Neo AhmadNo ratings yet

- Determination of Alcohol Content in Alcoholic BeveragesDocument7 pagesDetermination of Alcohol Content in Alcoholic BeveragesKaye Danielle HilomenNo ratings yet