Professional Documents

Culture Documents

Engineering Specification of Hot and Cold Insulation

Engineering Specification of Hot and Cold Insulation

Uploaded by

Joe Grosir0 ratings0% found this document useful (0 votes)

5 views9 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views9 pagesEngineering Specification of Hot and Cold Insulation

Engineering Specification of Hot and Cold Insulation

Uploaded by

Joe GrosirCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 9

Job No. :

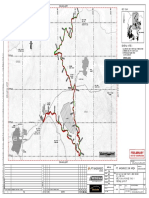

ENGINEERING SPECIFICATION ee) Ls

PETROKIMIA oF Document No A\

GRESIK HOT AND COLD INSULATION S4-T-01-42-8000-08

‘9 Sheets (With Cover)

Project :

PEMBANGUNAN PABRIK ALF 3 - I

Owner :

PT PETROKIMIA GRESIK

Location :

GRESIK — EAST JAVA,

(0 | issueo FoR constauction | 20-08-2019 S$: @_| oe

0 | ISSUED FOR APPROVAL 37-07-2013 | FDY ow KH

REV Description Date Prepared | Checked | Approved

‘THE INFORMATION CONTAINED HEREIN IS CONFINDENTIAL AND THE PROPERTY OF PT PETROKIMIA GRESIK AND NOT FOR

PUBLICATION, THE INFORMATION IS ISSUED ON THE UNDERSTANDING THAT NO PART THERE OF SHALL BE COPIED OR

(COMMUNICATED TO A THIRD PARTY WITHOUT AUTHORIZATION IN WRITING FROM PI PETROKIMIA GRESIK,

PETROKIMIA

GRESIK

ENGINEERING SPECIFICATION

OF

HOT AND COLD INSULATION

Job No)

24 NON 2019

Document No.

34-J7-01-42-3000-03

pe

Sheet : 1 of 8

Section

General

Conflict

Design

4.1 General

CONTENTS

Reference Specification

4.2 Hot Thermal insulation

43 Cold Thermal insulation

5. Material

5.1 Specification for Main Insulation Material

5.2 Specification for Auxiliary Material

6. Application

6.1 General

62 Application Detail

TABLE

Table |

Table I!

Table lit.

Table IV ..

Wun vwewunnnnnn

Job No. :

ENGINEERING SPECIFICATION ee nomen) vA

PETROKIMIA OF Document No

GRESIK

HOT AND COLD INSULATION re)

Sheet: 20f8

1. General

This specification covers the general requirement for the materials and application of

external for equipment and piping in hot service either heat conservation or personnel

protection, and cold service.

2. Reference Specification

The following standards are generally referred to herein:

ASTM American Society for Testing and Materials

C680 Heat Gain or Loss, and Surface Temperature of Insulated Pipe and

Equipment.

3. Conflict

This specification shall be strictly adhered to in all respect, if any deviation shall be

approved PT Petrokimia Gresi

4, Design

41 General

a. Equipment and Piping shall be insulated in accordance with this specification.

(1) The term “Equipment” includes towers, vessels, tanks, exchangers, pumps

and the like

(2) The term “Piping” includes pipes, valves, flanges, and the like.

b. Equipment and Piping shall be insulated as required for heat conservation,

heat control or personnel protection.

c. The operating temperature shown on the Insulation Equipment List, Insulation

‘Summary List for Piping and attached Drawing shall be applied for computing

and selection of required insulation thickness.

4.2 Hot Thermal Insulation

‘a. Unless a cooling is desired, Equipment and Piping operating at temperature of

100°C when it is necessary to limit heat losses which may affect the process or

to maintain minimum temperatures.

b. Insulation for personnel protection shall be provided to surface normally

operating above 70°C, and are situated such that personnel can easily come in

contact with that surface.

cc. The design of the insulation shall be based on the following data :

~ Ambient design temperature 33°.

~ Limiting external surface temperature 55°C max.

- (Unless otherwise specified on the Insulation Equipment List, Insulation

‘Summary List for Piping and attached Drawing)

d. The external surface is to be clad with aluminium sheet, sealed against ingress

of moisture.

e. The following equipment and parts of equipment shall not be insulated unless

otherwise specified.

= _ Blowers and compressors

Job No.

ete ENGINEERING SPECIFICATION NON ZO9| ne

oat or cemeten | A\

HOT AND COLD INSULATION nor

Sheet : 3 of 8

= Mechanical equipment such as Rubber expansion, rotation joints, slide

valves, etc.

- Exchanger channel sections

= Code inspection certificate plates, name plate.

f. Flanges, unions and valves in the hot lines shall not be insulated, except as

follows

~ Those in steam line to drivers and process equipment shall be insulated.

= Those in superheated steam lines when the steam temperature is less than

35°C above the saturated steam temperature shall be insulated.

- Those in process lines where heat loss is critical in its effect on operation

and where heat conservation is specifically required, shall be insulated,

43 Cold Thermal insulation

a. The cold themal insulation shall be required to the equipment and Piping

operating at temperature of So C and below when it is necessary to conserve

refrigeration, control of fluid temperature or control of surface condensation.

b. In addition to the requirement losted above for Hot Thermal Insulation, The

Cold Thermal Insulation used must prevent the ingress of moisture and the

cold metal surface must be coated with dense bitumastic paint before

application of the insulation.

5. Materials

5.1 Specification for Main Insulation Material

a. Calcium Silicate Board and Pipe Section Main ingredient is calcium silicate

bonded with Asbestos fibber and pressure moulded into a sheet form and

crystallized under steam-heat.

‘Compared with ordinary high temperature insulating materials, this is superior

in high resistance to elevated heat, lighter in weight, stronger in mechanical

strength, it is water resistant because hardening is obtained by chemical

reaction instead of the use of adhesives and does not show any signs of

deterioration even after long years of service.

Density : Max. 0.22 g/cm3

Service temp. Limit Under 650°C

Thermal conductivity £0,046 + 0.0001 © Kcal/m hr °C

e Temp. °C

Bending Stress Min. 3.0 Kg/em2

Coefficient of contraction: max. 2.0%

b. Rock Wool Board, Rock Wool Wired Mat & Rack Wool Pipe Section Rock Wool

is the name given to the product which has an excellent heat resistance as in

mineral fibber and a light density and low thermal conductivity as in glass fiber.

= Rock wool Board

Density : Max. 0.16 g/cm3

Service temp. limit 400°C

Thermal conductivity :0.027 + 0.00014 @ Kcal /m hr °C

6 :Temp.°C.

= Rock wool Wired Mat

Job No

a ENGINEERING SPECIFICATION aA norez013) on

& OF Document No. i\

GRESIK

HOT AND COLD INSULATION SANTEE 00-08

[ sheet: 4of8

Rock wool wired mat is a lightly bonded rock wool mattress stitched to 20

mm galvanized wire mesh,

Density : Max. 0.16 g/em3

Service temp. limit 600°C

Thermal conductivity 0.027 + 0.00014 @ Keal /m hr °C

e Temp.°C

= Rock Wool Pipe section

Density

Service temp. limit

Thermal conductivity :0.027 + 0.00014 © Keal /m hr °C

° jemp.°C

c. Foam Polyurethane Board & Pipe Section

This material is made from the mixture of polystyrene resin and foaming agent,

by exclusive foaming process. This product has excellent properties such as low

thermal conductivity, water penetration resistance, high structural strength

and low weight.

Density

Service temp. limit

Thermal conductivity

°

5.2. Specification for Auxiliary Material

a. Flat Aluminium Sheet with polykraft maoisture barrier of 0.5 mm Thickness

External dressing material if insulation for pipe or equipment.

b. Stainless Steel SUS 304 Wire of 1.0 mm dia.

For pipe and equipment up to NPS 350 mm for hot and cold thermal insulation.

c. Band

Stainless Steel (SUS 304)

19mmWx0.SmmT — Inner layer of NPS 350 mm and above piping and

equipment, temperature above 400°C

d. Stainless steel Screw

4mm dia. X 13 mm long.

e. Stud Bolt

MB (SUS 304)

6. Application

: Min, 0.025 g/em3

10°C

,030 + 0.00012 @ Kcal /m hr °C

:Temp.c

6.1 General

a. Surface to be insulated shall be thoroughly cleaned from loose rust, dirt and

grease that affect insulating performance, more over surface shall be coated

with dense bitumastic paint in the case of cold thermal insulation.

. All insulation shall be free from moisture and shall be maintained in a dry

condition prior to the application of weatherproofing jacket.

. Insulation shall be installed only after hydrostatic test.

Name — plates shall always be visible.

e. Otherwise specified, insulation material shall be in accordance with attached

TABLE |, Il

&

ENGINEERING SPECIFICATION

PETROKIMIA

GRESIK Or

HOT AND COLD INSULATION

Job No.

24 NON 2019

Document No.

34.J7-01-42-3000-03

Rev

A\

Sheet : Sof 8

f. Otherwise specified, insulation thickness shall be in accordance with attached

TABLE Ill, IV

8, Rockwool insulation for hot service will be installed in single layer up to 120

mm thick.

h. Polyurethane insulation for cold service will be installed in single layer up to SO

mm thick, double layer up to 120 mm thick.

i. In case of double layer insulation, all longitudinal and circumferential joints

shall be staggered.

j. Allseams of external sheet shall be located to shed water

6.2 Application Details

Application details are specified by drawings

Job No

ENGINEERING SPECIFICATION 28 NONZDI2 on

Eee OF Document No. /\

GRESIK

HOT AND COLD INSULATION See

Sheet : 6 of 8

TABLE

HOT THERMAL INSULATION MATERIAL LIST

WOT THERMAL INSULATION & PERSONNEL

DESIGNATION PROTECTION

UPTO 400°C WOPCR ABOVE

Upwnrs |, ROCK WOOLPIPE

Tom | SECTION OF ROCK WOOL CALCIUM SILICATE PIPE SECTION|

BOARD (OR CALCIUM SILICATE PIPE

EQUIPMENT | ps 350 SECTION

mm | ROCK WOOL BOARD +

name | vate |e csteness ROCK WOOL BOARD

eae ‘CALCIUM SILICATE

NPS 800mm | ROCK WOOL BOARD BOARD

ems +ROCK WOOL BOARD

VALVE & FITTING ROCK WOOL WIRED MAT

TIEWIRE | UB TONPS STAINLESS STEEL

te wire | NPS 350mm

poles STAINLESS STEEL

EXTERNALDRESSING | FLAT ALUMINIOM SHEET WITH POLYRRAFT MAOISTURE

(GACKETING) BARRIER

TABLE II

COLD THERMAL INSULATION MATERIAL LIST

DESIGNATION ‘COLD THERMAL INSULATION

FROM 5°C TO - 40°C

‘UP TO NPS 350 mm] FORM POLYURETHANE PIPE SECTION

EQUIPMENT

mn Gm NPS 350 mm

mere PS2s0mm | FORM POLYURETHANE BOARD

FORM POLYURETHANE BOARD & PIPE

VALVE & FITTING pore

‘TIE BAND STAINLESS STEEL BAND

‘AUXILIARY

MATERIAL EXTERNAL DRESSING | FLAT ALUMINIUM SHEET WITH

(UACKETING) POLYKRAFT MAOISTURE BARRIER

PETROKIMIA

GRESIK

ENGINEERING SPECIFICATION

OF Document No. :

HOT AND COLD INSULATION

Job No.

24NON 2019,

34-J7-01-42-3000-03

Sheet: 70f8

TABLE Ill

‘THICKNESS FOR HOT THERMAL INSULATION AND PERSONNEL PROTECTION

Ws

(om)

FLAT

35 | 20 | 25 | 32 | a | 30 | 6s | 80 | 100 | 128] 150 | 200 | 280 | 300 | soeeace |

emp CC) |

100 | 20 |20 |20 | 20 | 20 }20 | 20 | 20 | 20 }20 J2s | 2s | 2s | 2s | 2s

180 |20 }20 | 20 | 20 |2s | 2s | 30 |30 }30 |30 | 30 | 40 | 40 | 40 | 40

20 20 }2s | 2s | 30 |30 | 30 | 40 | 40 | 40 | 40 | so | so | so | so 50

250 |30 |30 |30 | 40 | 40 | 40 | 50 | 50 | s0 | s0 |so Jos | 6s | 6s | 65

300 | 40 | 40 | 40 | 40 | 40 | 50 | s0| soos | os fos fas | 5 | 25 | 75

350 |40 | s0 | s0 |so | so |so Jes [os J 75 | 75] 25] 90 | 90 | 90 %0

400 | 50 | 50 | os Jos jos |os | 2s | 25 | 75 | 90 | 90 | 90 | 100 | 100 | 100

aso [65 | 65 ] 65 ]75 ]7s Jas | 5 Jas | 25 25 | 25 | as | 2s | 25 | 90

-|-f-]- |=]. ]- |= |] os | 6s | os | os | 65 | 90

so [6 | 65 [75 ]7s [75 [30 [40 [so [40 [40 Jao | 40 | ao | 40 ] 50

~ |= |= |= [= | 50 | 50 | 50 | 50 | 6s fos | os | os | 6s 90

sso [49 |40 [40 |40 | 50 | 50 | 50 |s0 |s0 | s0 Jos | os | os | os 6s

40 }40 | 40 | 40 | 40 | 40 | 50 | 50 |s0 Jas jos | 6s | 65 | 65 | 90

oo [50 |50|50 |6s |os Jas |os |os |os | os Js [7s | 75 | 7s | 90

30 Jao |40 | 40 | 65 6s | os | os |os os | 6s | 6s | 65 | 65 | 90

aso [65 |65 |65 |es Jos 75 | 75 | 75 [a0 ] a0 | 90 | 90 | so | 100 | 11s ]

30 |40 |40 | 40 | 40 | 40 | 50 | s0 |s0 | 30 |s0 | 6s | 6s | 6s | 90

Tob No

ENGINEERING SPECIFICATION ETD ne

PETROKIMIA a Document. No.

GRESIK 34-s7-01-42-3000-03

HOT AND COLD INSULATION

Sheet: 8 of 8

TABLE IV

‘THICKNESS FOR COLD THERMAL INSULATION

wy

(om) FLAT

1s | 20 | 25 | 32 | 40 | so | 6s | 80 | 100] 125| 150 | 200 | 250 | 300 | LAT

emp C0)

s | 2s | 30 | 30 | 30] 30}30 J 40 Jao | 40 so | ao | 4 | ao | ao | 40

0 |x | 30 | 4 | 40 | Jso Jao Jao | ao Jao | so | so | so | so | 50

so | a fa | ao {ao | so] so} so} so] so] so} as | os | os jos | os

| ao | so | so | so | so | os Jos fos fos jos | rs | ms Js las | ts

ao | so | so | 6s | 6s fos | 6s | 6s fs Jas rs | rs | 2s | as | 100 | 100

40 | 6s | 6s | 6s Jos fos | rs | as | rs | 2s | rs | 100 | 100 | 100 | 100 | 100

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Datasheet For Safety Device ConveyorDocument6 pagesDatasheet For Safety Device ConveyorJoe GrosirNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Fire Fighting BoqDocument13 pagesFire Fighting BoqJoe GrosirNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Datasheet For Rotary Valve (V-3164)Document1 pageDatasheet For Rotary Valve (V-3164)Joe GrosirNo ratings yet

- Fabric Expansion JointDocument20 pagesFabric Expansion JointJoe GrosirNo ratings yet

- Engineering Specification For GroundingDocument8 pagesEngineering Specification For GroundingJoe GrosirNo ratings yet

- Datasheet For Hopper (D-3103)Document1 pageDatasheet For Hopper (D-3103)Joe GrosirNo ratings yet

- Datasheet For Table Feeder Splitter Gate (M-3107-1)Document1 pageDatasheet For Table Feeder Splitter Gate (M-3107-1)Joe GrosirNo ratings yet

- Induction Motor & Load List (Low Voltage)Document6 pagesInduction Motor & Load List (Low Voltage)Joe GrosirNo ratings yet

- Mech Calculation of ConveyorDocument20 pagesMech Calculation of ConveyorJoe Grosir100% (1)

- Datasheet For Weigh Feeder (M-3131)Document1 pageDatasheet For Weigh Feeder (M-3131)Joe GrosirNo ratings yet

- Layout Flow and Crowd Control Mandalika - GP - 01 - A0 Scale 6500mtrDocument1 pageLayout Flow and Crowd Control Mandalika - GP - 01 - A0 Scale 6500mtrJoe GrosirNo ratings yet

- Expansion Joint No-8&10Document1 pageExpansion Joint No-8&10Joe GrosirNo ratings yet

- Kebutuhan Pengecoran Lantai (Beton)Document1 pageKebutuhan Pengecoran Lantai (Beton)Joe GrosirNo ratings yet

- Martin Air Cannon PresentationDocument44 pagesMartin Air Cannon PresentationJoe GrosirNo ratings yet

- Overall Layout PlanDocument1 pageOverall Layout PlanJoe GrosirNo ratings yet

- 30Document1 page30Joe GrosirNo ratings yet

- Project Experience PUMA CompressedDocument36 pagesProject Experience PUMA CompressedJoe GrosirNo ratings yet

- 14 - Desain Konstruksi Tempat Penyimpanan (Tampak Atas, Samping Depan)Document1 page14 - Desain Konstruksi Tempat Penyimpanan (Tampak Atas, Samping Depan)Joe GrosirNo ratings yet

- Kebutuhan Ac+cyclone-R1Document24 pagesKebutuhan Ac+cyclone-R1Joe GrosirNo ratings yet

- Operation Hours of CrusherDocument13 pagesOperation Hours of CrusherJoe GrosirNo ratings yet

- Testing Electrical Equipment 26 08 00Document99 pagesTesting Electrical Equipment 26 08 00Joe GrosirNo ratings yet

- Helix T6 Calculation Conveyor 2500 TPHDocument31 pagesHelix T6 Calculation Conveyor 2500 TPHJoe GrosirNo ratings yet

- Conveyor Design Summary: PT. Siko TechnoDocument37 pagesConveyor Design Summary: PT. Siko TechnoJoe GrosirNo ratings yet

- Subject: Job Application: HRD Dept-RecruitmentDocument10 pagesSubject: Job Application: HRD Dept-RecruitmentJoe GrosirNo ratings yet

- Planing Setting Area Untuk Loading Unit CrusherDocument5 pagesPlaning Setting Area Untuk Loading Unit CrusherJoe GrosirNo ratings yet

- Schedule Removal Anti BlockingDocument1 pageSchedule Removal Anti BlockingJoe GrosirNo ratings yet

- ModulautocadDocument1 pageModulautocadJoe GrosirNo ratings yet