Professional Documents

Culture Documents

WSS M99P32 D1

Uploaded by

jose luisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WSS M99P32 D1

Uploaded by

jose luisCopyright:

Available Formats

ENGINEERING MATERIAL SPECIFICATION

PERFORMANCE, ACOUSTICAL AND INSULATORS, INTERIOR ASSEMBLIES WSS-M99P32-D1

1. SCOPE

This specification defines the minimum durability requirements of all interior and luggage compartment

sound absorption/insulation applications, where various materials are combined to provide an assembly

having acoustical sound absorption/barrier/insulation and/or functional features. This does not include

engine (hood) compartment insulators, thermal insulators, and/or exhaust shields. In addition, ultra high

temperature parts exposed to heat from turbochargers, EGR systems and exhaust pipes are not included.

2. APPLICATION

This specification was released originally for materials used as interior, luggage compartment, for sound

absorption/insulation applications. This specification excludes the following:

• Acoustic wheel arch/well liners. Use WSS-M99P32-D2 and D3 (latest)

• Underbody Shields. Use WSS-M99P32-D4 and D5 (latest)

• Engine/Hood/Tunnel Insulators/. Use WSS-M99P32-D6 (latest)

3. REQUIREMENTS

Materials used in interior applications must meet the Performance, Vehicle Interior Environment Quality

Material/Component Requirements outlined in WSS-M99P2222-D1 (latest). Data must be included in

material submission package.

3.1 STANDARD REQUIREMENTS FOR PRODUCTION MATERIALS

Material suppliers and part producers must conform to the Company's Standard Requirements for

Production Materials (WSS-M99P1111-A (latest)).

3.2 FINISHED PART REQUIREMENTS

Detailed part construction must be submitted along with test data for initial approval. Data must be

submitted via the Ford Materials Database (FMD) template. Design Verification (DV) is done on the

part to verify supplier feasibility and Product Verification Testing (PV) is done on production parts.

DV/PV and sample sizes are defined in Table 1.

In addition to the following minimum requirements, production assemblies must withstand normal

handling during shipping, installation, use, and service, without tearing, breaking, or permanently

deforming.

3.3 APPEARANCE

(FLTM BI 109-01)

All appearance properties of exposed materials shall meet the requirements of the relevant

Engineering Department.

Date Action Revisions Rev. 0

2015 02 20 Released C. Kay, D. Murtonen, NA

Controlled document at www.MATS.ford.com Copyright © 2015, Ford Global Technologies, LLC Page 1 of 6

ENGINEERING MATERIAL SPECIFICATION

WSS-M99P32-D1

3.4 WEIGHT

(FLTM BN 106-01)

Weight of each layer of a composite and/or total composite shall be included on Engineering

Drawing.

3.5 ODOR

(FLTM BO 131-03, Variant C) Rating 3 max

3.6 FOGGING

(SAE J1756, 3 h at 100 °C heating, 21 °C

cooling plate, post test conditioning 16 h)

Fog Number 70 min

The formation of a clear (oily) film, droplets or crystals is cause for rejection.

3.7 FLAMMABILITY

(SAE J369/ISO 3795)

Flammability is affected by the material thickness and density. Conduct testing on the full range of

material thicknesses and densities on part.

Burn Rate 100 mm/minute max

Flame should be applied to the exposed side of the component, which under certain conditions

may include inner/outer surfaces. Supplier shall document test conditions in their Control Plan (for

PV).

3.8 CONSTRUCTION PROPERTIES

3.8.1. Resistance to Mildew

Test Method

Cut specimens from the various thicknesses in the part and/or test all material thicknesses.

Specimen size is 200 x 200 mm unless part size is smaller.

Expose for 7 days in a humidity cabinet maintained at 98 +/- 2% relative humidity and 38 +/-

2 °C.

Evaluation

Remove the part from the cabinet and evaluate immediately. The part shall exhibit no

visible evidence of mildew growth and/or objectionable odor after 7 days exposure in a

humidity cabinet maintained at 98 +/- 2% relative humidity and 38 +/- 2 °C.

Copyright © 2015, Ford Global Technologies, LLC Page 2 of 6

ENGINEERING MATERIAL SPECIFICATION

WSS-M99P32-D1

3.8.2. Environmental Cycling (Heat, Humidity and Cold)

Test Method

Conduct with the NVH or approved surrogate assembly mounted on an actual or simulated

production support foundation with the approved retention methods.

5 h at -30 +/- 2 °C

30 minutes at 23 +/- 2 °C and 50% R.H.

5 h at 80 +/- 2 °C

30 minutes at 23 +/- 2 °C and 50% R.H.

2 h at 50 +/- 2 °C and 95 +/- 5% R.H.

30 minutes at 23 +/- 2 °C and 50 % R.H.

5 h at -30 +/- 2 °C

30 minutes at 23 +/- 2 °C and 50% R.H.

5 h at 80 +/- 2 °C

Evaluation

Remove the assembly from the cabinet and evaluate immediately. The part shall exhibit no

visible and objectionable appearance such as distortion, blistering, delamination,

expansion, shrinkage or warpage which will interfere with normal function or cause

objectionable and unsightly gaps. No mold formation shall be present.

In addition, any objectionable appearance observed during the test should be reported.

3.8.3 Heat Aging

(7 days at 80 +/- 2 °C)

Test one assembly.

Evaluation

Remove the assembly from the cabinet and evaluate immediately. The part shall exhibit no

visible and objectionable appearance such as distortion, blistering, delamination,

expansion, shrinkage or warpage which will interfere with normal function or cause

objectionable and unsightly gaps.

In addition, any objectionable appearance observed during the test should be reported.

3.8.4 Resistance of Insulators to various Test Reagents

(ASTM D896)

The finished or surrogate part shall not dissolve, exhibit tackiness or delaminate when

immersed in each of the following test reagents for a 4 hour period. Use a separate

specimen for each test reagent.

Test Reagents:

1. Deionized water

2. 3% (by weight) Salt (NaCl) solution in deionized water

3. Windex or similar commercial window cleaner

3.8.5 Corrosiveness to Steel Rating 4 min

(SAE J1389)

Copyright © 2015, Ford Global Technologies, LLC Page 3 of 6

ENGINEERING MATERIAL SPECIFICATION

WSS-M99P32-D1

3.9 PHYSICAL PROPERTIES

3.9.1 Breaking Strength (non-foam materials only)

(ASTM D5034, for test set-up and procedure, exception of speed 25 mm/minute)

Report value of load at break

Specimens to be cut from flat areas of the finished part and distance between clamps at

beginning of test should be 100 mm.

3.9.1.1 Original Report Only, N

Individual values to be reported with the data submission package.

For the below, test requirement is -30% max change from average original

breaking strength. Test requirement can be met if the change is greater than 30%,

but the resulting value is above original value.

3.9.1.2 Change After Humidity Aging Report % of

(48 h at 38 +/- 2 °C and 95 +/- 2% R.H.; 1 h at change

room temperature)

3.9.1.3 Change After Heat Aging Report % of

(Conditions per para.3.8.3.1) change

3.9.1.4 Change After Immersion in Water Report % of

(48 h in distilled water at room temperature) change

3.9.2 Tear Resistance Test (foam materials only)

(ASTM D3574 Test F) Report Value, kPa

3.9.3 Compression Force Deflection Test (foam materials only)

(ASTM D3574 Test C) Report Value, kPa

Shall not compress more than 70% of the original thickness after loading with 35 kg.

Upon removing the load, the material shall recover at least 65% of the compressed

distance.

3.9.4 Constant Deflection Compression Set Test (foam materials only)

(ASTM D3574 Test D)

Original Report Value, %

3.9.4.1 Steam Autoclave Aging Exposure +/- 40% max from

(ASTM D3574 Test J2, 5 hours at 120 C +/- 5 °C Original Value

Followed by Constant Deflection Compression

Set Test (ASTM D3574 Test D)

Copyright © 2015, Ford Global Technologies, LLC Page 4 of 6

ENGINEERING MATERIAL SPECIFICATION

WSS-M99P32-D1

3.9.4.2 Dry Heat Aging Exposure +/-10% max from

(ASTM D3574 Test K) Original Value

22 hours at 140 °C or maximum temperature as mutually agreed

upon, followed by Constant Deflection Compression Set Test

(ASTM D3574 Test D)

3.9.5 Peel Strength (Interior Laminates only)

(FLTM BN 151-05, Method B)

Samples must meet at least one of the following requirements:

- Achieve peel strength value of 6 N/50 mm, min

- Adhesion of the covering material must exceed cohesive strength of the substrate

3.9.6 Moisture Absorption 30% max

Cut a 200 x 200 +/-10 mm specimen from the part to be tested and seal any cut edges, e.g.

with wax. Weigh the specimen nearest to 0.1 g.

Condition part/section in suspended position at 38 +/- 2 °C and 95 +/- 2% R.H. for 24 h.

After 1 h at 23 +/- 2 °C and 50 +/- 2% R.H. weigh the part/section to the nearest 0.1 g and

determine increase of weight in percent based on the original weight.

4. GENERAL INFORMATION

The information given below is provided for clarification and assistance in meeting the requirements of

this specification. Contact gmfs@ford.com for questions concerning Engineering Material Specifications.

4.1 FUNCTIONAL REQUIREMENTS

Component supplier shall meet the NVH program specific targets as directed by Ford D&R activity

through the Request for Quote document. These targets are program dependent and run at Ford

NVH facilities.

4.1.1 Sound Absorption:

The component shall meet the Sound Absorption Target Curve in the 400 Hz to 10 kHz

frequency range as specified in the Request for Quote. The measurements should be

conducted in the Ford Alpha Cabin. The target curve should be specified on the

Engineering Drawing.

4.1.2 Sound Transmission Loss:

The component shall meet the Sound Transmission Loss Target Curve in the 200 Hz to 10

kHz frequency range as specified in the Request for Quote. The measurements should be

conducted in the Ford Sound Transmission Loss Chamber. The target curve should be

specified on the Engineering Drawing.

4.1.3 Sound Insulation:

The component shall meet the Sound Insulation Loss Target Curve in the 100 Hz to 10 kHz

frequency range as specified in the Request for Quote. The measurements should be

conducted in the Ford APAMAT Chamber. The target curve should be specified on the

Engineering Drawing.

Copyright © 2015, Ford Global Technologies, LLC Page 5 of 6

ENGINEERING MATERIAL SPECIFICATION

WSS-M99P32-D1

Test method:

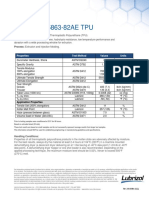

Shoddy

A1: Felt or

A2: PU Foam

A3: EPP Foam

Fleece

A4: Non-woven

A5: Glass Fiber

Sample size required for DV and PV.

Weight

3.4 FLTM BN106-01: Substrate and 3(DV+PV) 3(DV+PV) 3(DV+PV) 3(DV+PV) 3(DV+PV)

Total Weight

3(DV+PV) 3(DV+PV) 3(DV+PV) 3(DV+PV) 3(DV+PV)

Odor

3.5 per per per per per

FLTM BO131-03

condition condition condition condition condition

Fogging

3.6 3(DV+PV) 3(DV+PV) 3(DV+PV) 3(DV+PV) 3(DV+PV)

SAE J1756 (Photometric)

Flammability

3.7

Interior Burn Rate 100mm/min 5(DV+PV) 5(DV+PV) 5(DV+PV) 5(DV+PV) 5(DV+PV)

maximum

3.8.1. Resistance to Mildew 1(DV) 1(DV) 1(DV) 1(DV) 1(DV

3.8.2 Environmental Cycling 1(DV+PV) 1DV+PV) 1(DV+PV) 1(DV+PV) 1(DV+PV)

3.8

Construction 3.8.3 Heat Aging 1(DV+PV) 1DV+PV) 1(DV+PV) 1(DV+PV) 1(DV+PV)

Properties

1(DV) per 1(DV)per 1(DV) per 1(DV)per 1(DV)per

3.8.4 Resistance to Test Reagents

reagent reagent reagent reagent reagent

3.8.5 Corrosiveness to Steel 1(PV) 1(PV) 1(PV) 1(PV) 1(PV)

3.9.1.1 Breaking Strength- Original 5(PV) 5(PV) 5(PV)

3.9.1.2 Change After Humidity Aging 5(PV) 5(PV) 5(PV)

3.9.1.3 Change After Heat Aging 5(PV) 5(PV) 5(PV)

3.9.2 Tear Resistance 3(PV) 3(PV)

3.9.3 Compression Force Deflection 3(PV) 3(PV)

3.9 Physical

Properties Constant Deflection Compression-

3.9.4 3(PV) 3(PV)

Original

After Steam Autoclave Aging

3.9.4.1 3(PV) 3(PV)

Exposure

After Dry Heat Aging Exposure

3.9.4.2 3(PV) 3(PV)

Peel Strength (Laminates only)

3.9.5 3(PV) 3(PV) 3(PV) 3(PV) 3(PV)

3.9.6 Moisture Absorption 1(PV) 1(PV) 1(PV) 1(PV) 1(PV)

Copyright © 2015, Ford Global Technologies, LLC Page 6 of 6

You might also like

- Performance, Acoustical and Insulators, Interior Assemblies WSS-M99P32-E1 1. ScopeDocument6 pagesPerformance, Acoustical and Insulators, Interior Assemblies WSS-M99P32-E1 1. Scopeerik0007No ratings yet

- Engineering Material Specification: Controlled Document at Page 1 of 6Document6 pagesEngineering Material Specification: Controlled Document at Page 1 of 6erik0007No ratings yet

- Trim Assembly, Enclosed Luggage WSS-M15P32-D Compartment Covering 1. ScopeDocument11 pagesTrim Assembly, Enclosed Luggage WSS-M15P32-D Compartment Covering 1. Scopeerik0007No ratings yet

- WSS M4D924 B11.Document8 pagesWSS M4D924 B11.JOSENo ratings yet

- WSS M8P16 BDocument16 pagesWSS M8P16 Berik0007No ratings yet

- Engineering Material SpecificationDocument3 pagesEngineering Material SpecificationRicardo VitorianoNo ratings yet

- WSS M5G58 A2Document5 pagesWSS M5G58 A2Muthu GaneshNo ratings yet

- Powder Coat Performance Spec WSS M70J5 C1Document9 pagesPowder Coat Performance Spec WSS M70J5 C1Michal BílekNo ratings yet

- WSS M16J19 BDocument10 pagesWSS M16J19 BJuan Angel DechimaNo ratings yet

- Worldwide Engineering Standards: Procedures For High Humidity TestDocument3 pagesWorldwide Engineering Standards: Procedures For High Humidity TestAkmal NizametdinovNo ratings yet

- P Toyota-TSM0502G-C1-Rev10Document37 pagesP Toyota-TSM0502G-C1-Rev10Michael PengNo ratings yet

- GMW3232 PDFDocument15 pagesGMW3232 PDFIvan Dario Oyola RaveloNo ratings yet

- Ford WSS-M8P25-CDocument5 pagesFord WSS-M8P25-CPablo AnguianoNo ratings yet

- Textured HDPE Geomembrane Technical Data SheetDocument1 pageTextured HDPE Geomembrane Technical Data SheetAndrew Zapanta Jr.No ratings yet

- Ford - Wsk-m4d684-A2 Abs - PC ConsoleDocument5 pagesFord - Wsk-m4d684-A2 Abs - PC ConsoleCamila SanchesNo ratings yet

- Performance, Engine Compartment and Underbody WSS-M15P50-B Plastic Components 1. ScopeDocument9 pagesPerformance, Engine Compartment and Underbody WSS-M15P50-B Plastic Components 1. ScopeJaqueline PereiraNo ratings yet

- Fogging Characteristics of Trim Materials: Worldwide Engineering StandardsDocument11 pagesFogging Characteristics of Trim Materials: Worldwide Engineering StandardsJefferson CruzNo ratings yet

- Non Shrink Grout Material TestingDocument4 pagesNon Shrink Grout Material TestingMonirul Islam BadalNo ratings yet

- A143Document16 pagesA143Luis Jorge Nahle OrtizNo ratings yet

- ISSA Microsurfacing A143-2010Document16 pagesISSA Microsurfacing A143-2010Roger Molero PachecoNo ratings yet

- Ford M2C938-ADocument7 pagesFord M2C938-Acolive.ptNo ratings yet

- Scotchkote: Fusion-Bonded Epoxy Coating 206N LGDocument1 pageScotchkote: Fusion-Bonded Epoxy Coating 206N LGSohail TisekarNo ratings yet

- 98d033a3 PDFDocument3 pages98d033a3 PDFergun tutukNo ratings yet

- T 375R3Document3 pagesT 375R3조준장No ratings yet

- Cycom 823 RTM 031912Document6 pagesCycom 823 RTM 031912juanpalomo74No ratings yet

- C 509 - 94 R99 - Qzuwos1sruqDocument6 pagesC 509 - 94 R99 - Qzuwos1sruqGustavo Adolfo Vargas MorantesNo ratings yet

- Engineering Material SpecificationDocument9 pagesEngineering Material SpecificationVeysel Emre BozkurtNo ratings yet

- TMS6900Document14 pagesTMS6900Josue Garcia QuiniNo ratings yet

- WALLTITE ECO Technical Data SheetDocument6 pagesWALLTITE ECO Technical Data SheetHo Dac ThanhNo ratings yet

- Test Method For Determining The Flammability of Interior Trim MaterialsDocument18 pagesTest Method For Determining The Flammability of Interior Trim MaterialsJefferson CruzNo ratings yet

- Perfecto T Range: DescriptionDocument2 pagesPerfecto T Range: Descriptiondforsythe639No ratings yet

- Perform JaguarDocument8 pagesPerform JaguarSeda De DrasniaNo ratings yet

- T350R03Document5 pagesT350R03조준장No ratings yet

- 0850 02Document5 pages0850 02janiNo ratings yet

- Perfecto XPG 32: DescriptionDocument3 pagesPerfecto XPG 32: DescriptionArthur Sanda LayukNo ratings yet

- D 1970 - 00 Rde5nzatukveDocument7 pagesD 1970 - 00 Rde5nzatukvedaovandongpktNo ratings yet

- TDS 48342 Jotatemp 1000 Euk GBDocument5 pagesTDS 48342 Jotatemp 1000 Euk GBhenryNo ratings yet

- D 3332 - 99 - RdmzmziDocument8 pagesD 3332 - 99 - RdmzmziStuartNo ratings yet

- Whitechem Polyurea Pa 1005-EnDocument4 pagesWhitechem Polyurea Pa 1005-EnBien PangilinanNo ratings yet

- Ducom Macro Pin On Disc - Technical InformationDocument4 pagesDucom Macro Pin On Disc - Technical Informationteshome derejeNo ratings yet

- CFSEN04018 Technical Requirements for Cab PartsDocument6 pagesCFSEN04018 Technical Requirements for Cab PartsCEMRE YAŞLINo ratings yet

- PR308 - 2+00+en - Invecchiamento BMWDocument10 pagesPR308 - 2+00+en - Invecchiamento BMWAnonymous 8Z2HZ5JP7100% (1)

- Castrol Perfecto XPG 46 - Data SheetDocument3 pagesCastrol Perfecto XPG 46 - Data Sheetanibal_rios_rivasNo ratings yet

- GMW 14670 - May 2007 - Organic Coat For Finish WheelsDocument4 pagesGMW 14670 - May 2007 - Organic Coat For Finish WheelsatulmkaushalNo ratings yet

- PC Abs Spec SheetDocument2 pagesPC Abs Spec SheetAli YudiNo ratings yet

- Impact Copolymer: For Injection Moulded ProductsDocument1 pageImpact Copolymer: For Injection Moulded ProductsarthymanicNo ratings yet

- Jotafloor TC EDocument6 pagesJotafloor TC ERidwanSalminNo ratings yet

- Marathon 1000 GF Technical Data SheetDocument5 pagesMarathon 1000 GF Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Organic Coat GMW 14670 PDFDocument4 pagesOrganic Coat GMW 14670 PDFYosua Dimas Agus SriyantoNo ratings yet

- Self Adhering Sheet Waterproofing Bituthene 3000 and Bituthene Low Temperature GSWP 003A v2Document5 pagesSelf Adhering Sheet Waterproofing Bituthene 3000 and Bituthene Low Temperature GSWP 003A v2200365530No ratings yet

- D 3903 - 00 - Rdm5mdmtukveDocument5 pagesD 3903 - 00 - Rdm5mdmtukvePrakash MakadiaNo ratings yet

- Pellethane 5863-82AE TPU: Technical Data SheetDocument2 pagesPellethane 5863-82AE TPU: Technical Data SheetaNo ratings yet

- Worldwide Engineering Standards: Tape Adhesion Test For Paint FinishesDocument9 pagesWorldwide Engineering Standards: Tape Adhesion Test For Paint FinishesAkmal NizametdinovNo ratings yet

- Ficha Tecnica Castrol Perfecto X RangeDocument3 pagesFicha Tecnica Castrol Perfecto X Rangeel pro jajaja GonzalezNo ratings yet

- Toyota Engineering StandardDocument10 pagesToyota Engineering StandardAkash Kumar100% (2)

- Mobil DTE 10 Excel SeriesDocument3 pagesMobil DTE 10 Excel SeriesSuprastowo Bin SarinoNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Iso 6452 2007Document20 pagesIso 6452 2007jose luisNo ratings yet

- WSS M99P1111 ADocument3 pagesWSS M99P1111 Ajose luisNo ratings yet

- TL 52608 enDocument6 pagesTL 52608 enerik00070% (1)

- Copia de 463CB100Document2 pagesCopia de 463CB100jose luisNo ratings yet

- Engineering Material Specification: Controlled Document at Page 1 ofDocument8 pagesEngineering Material Specification: Controlled Document at Page 1 ofjose luisNo ratings yet

- Copia de ASTM D 816Document6 pagesCopia de ASTM D 816jose luisNo ratings yet

- 2015 12 09 WSS-M15P20-B1Document6 pages2015 12 09 WSS-M15P20-B1jose luisNo ratings yet

- Lab Week 10 Ecw341 (Jar Test) - Ec1105m - Group3Document8 pagesLab Week 10 Ecw341 (Jar Test) - Ec1105m - Group3Muhammad IrfanNo ratings yet

- Away Fire - Resistant - Gypsum - Board-FR-2019 PDFDocument3 pagesAway Fire - Resistant - Gypsum - Board-FR-2019 PDFMatijaNo ratings yet

- Economy of Salt in Chloral Kali ManufactureDocument10 pagesEconomy of Salt in Chloral Kali ManufactureIbrahim ahmedNo ratings yet

- W Abrasives Steel Shot & Grit SpecificationsDocument7 pagesW Abrasives Steel Shot & Grit SpecificationsSama UmateNo ratings yet

- Total Immersion Corrosion Test For Aircraft Maintenance ChemicalsDocument4 pagesTotal Immersion Corrosion Test For Aircraft Maintenance ChemicalsJuanNo ratings yet

- Water Absorption and AbrasionDocument6 pagesWater Absorption and AbrasionMarielle Jane B. TapangNo ratings yet

- Bio - 3 - (Novel Biotechnological Applications For Waste To Value Conversion) Dan Bahadur Pal, Pardeep Singh - Utilization of Waste Biomass in Energy, Environment and Catalysis-CRC Press (2022)Document357 pagesBio - 3 - (Novel Biotechnological Applications For Waste To Value Conversion) Dan Bahadur Pal, Pardeep Singh - Utilization of Waste Biomass in Energy, Environment and Catalysis-CRC Press (2022)kkNo ratings yet

- GCSE Biology - Enzymes - How They Work - Worksheet 11Document2 pagesGCSE Biology - Enzymes - How They Work - Worksheet 11Risali KarunarathnaNo ratings yet

- Physical Science The AtomDocument26 pagesPhysical Science The AtomTanaka ChirawuNo ratings yet

- Hydro Marine Standard ItemsDocument9 pagesHydro Marine Standard ItemsmaaathanNo ratings yet

- TilesDocument84 pagesTilesgagan raoNo ratings yet

- Lime Provides An Economical Way of Soil StabilizationDocument1 pageLime Provides An Economical Way of Soil StabilizationCalynn Tiffany YapNo ratings yet

- Corrosion of Reinforcing Bars in Concrete PaperDocument33 pagesCorrosion of Reinforcing Bars in Concrete PaperMamta BaxlaNo ratings yet

- What Is Ozone LayerDocument4 pagesWhat Is Ozone LayerJoseph Gratil100% (1)

- Astm B152 B152MDocument6 pagesAstm B152 B152MdesignNo ratings yet

- Riesgos Por Desprendimiento de Recubrimientos de TuberíaDocument16 pagesRiesgos Por Desprendimiento de Recubrimientos de TuberíaDon plexNo ratings yet

- 103 DR Fixit Repellin WRDocument3 pages103 DR Fixit Repellin WRMohiuddin MuhinNo ratings yet

- NuFlo EZ-In User Manual - PEDDocument32 pagesNuFlo EZ-In User Manual - PEDsarkaft100% (1)

- Safety Relief Valves Flanged Type: Makali Valves and Engineering ServiceDocument6 pagesSafety Relief Valves Flanged Type: Makali Valves and Engineering ServiceHetal Patel100% (1)

- First Quiz Epp Vi: Maburac Elementary SchoolDocument2 pagesFirst Quiz Epp Vi: Maburac Elementary SchoolRyan BajoNo ratings yet

- CHM3201 Lab Report S2 2019-2020Document42 pagesCHM3201 Lab Report S2 2019-2020Halimatun MustafaNo ratings yet

- JACKS 3-2-1 Feed Chart: (Per Gallon)Document1 pageJACKS 3-2-1 Feed Chart: (Per Gallon)Augusto TorresNo ratings yet

- Pa0001en 52900315 Pac2021 LRDocument216 pagesPa0001en 52900315 Pac2021 LRErvita DianNo ratings yet

- A GUIDE TO PHYTOCHEMICAL ANALYSIS Ijariie9430Document10 pagesA GUIDE TO PHYTOCHEMICAL ANALYSIS Ijariie9430Franca OkechukwuNo ratings yet

- Active IngredientsDocument7 pagesActive IngredientsJESRYL PAULITENo ratings yet

- 10 4 Archimedes Principle PDFDocument2 pages10 4 Archimedes Principle PDFBalo BaloisNo ratings yet

- Narayana IIT Academy Phase Test Physics, Chemistry, MathDocument12 pagesNarayana IIT Academy Phase Test Physics, Chemistry, MathAbhinav CringeartistNo ratings yet

- 2009-06-15 AB-3P Technical Reference Manual R6Document73 pages2009-06-15 AB-3P Technical Reference Manual R6Faiz SabianNo ratings yet

- Basic Chemical Calculations-MergedDocument184 pagesBasic Chemical Calculations-MergedVishwajeet DhanwadeNo ratings yet

- C779-C779M - 12 Standard Test Method For Abrasion of Horizontal Concrete SurfacesDocument7 pagesC779-C779M - 12 Standard Test Method For Abrasion of Horizontal Concrete SurfacesFahad RedaNo ratings yet