Professional Documents

Culture Documents

Firetube Removal and Installation Process 1

Firetube Removal and Installation Process 1

Uploaded by

حسين مهديOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Firetube Removal and Installation Process 1

Firetube Removal and Installation Process 1

Uploaded by

حسين مهديCopyright:

Available Formats

Phone: 403-945-3561 www.nrgps.

ca

FIRETUBE REMOVAL AND INSTALLATION PROCESS

FIRETUBE REMOVAL AND INSTALLATION PROCESS

It is very important to remove and install treater firetubes appropriately to eliminate to possibility of damage to the vessel or the

firetube. We have created a step by step process to perform a firetube removal and installation to help usurp the possibility of

damage. Large cranes have a lot of power and can bend a firetube if used to both lift and side in at the same time. We have not

included any points for safety as this usually set out by the company through their safety program. We have merely laid out the

action and the field set up of the equipment foe a safe and efficient process.

Phone: 403-945-3561 www.nrgps.ca

Step 1. The small truck mounted crane/service truck decks off their trailer to the left of the treater so that the stack and flame

arrestor can be placed on it (1). The crew then backs the truck up to the treater (6) and removes the flame arrestor

and stack and place them on the trailer.

Step 2. Crane/Service Truck then backs up to the firetube (2) and uses the deck of the truck (3) as a platform to remove the

firetube bolts. Bolts are placed in a pail so they can be cleaned and lubricated in preparation for reinstallation.

Step 3. Crane/Service Truck (3) relocates and then pulls the firetube out about half way.

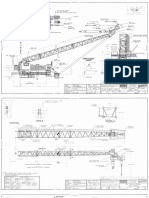

Step 4. Large crane (4) arrives and decks off trailer (5) to its left to be ready for the firetube. Then backs in at 90 degrees to

the treater centered on the firetube flange. The large crane then straps to the center of gravity point of the firetube.

Step 5. Both cranes work together to remove the firetube from the treater. Once the firetube is out the small crane can

disconnect and the large crane then sets the firetube on the large trailer. The firetube can then be hauled to the wash

area or tub.

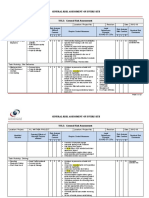

Step 6. Re installation. The crew may want to attach the gasket to back of the firetube flange. The two cranes then work

together much the same way as the firetube was removed by following the steps in reverse order.

Step 7. Prior to bolt up it is important to ensure that the two flanges are perfectly aligned and there are no pinch points on the

gasket. Improper alignment can cause the gasket to squeeze out and fail prematurely. On order to be sure that the

flanges are aligned a Vernier caliper should be used to measure the match up. It may be necessary to jack up the

back end of the firetube for a perfect fit.

Step 8. The appropriate torquing and tightening sequence should be used for installation (See NRG Treater manual). The

tightening/torqueing should be done in at least three stages with a star pattern around the oval firetube flange.

You might also like

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Propeller RemovalDocument10 pagesPropeller RemovalMedha Jog Katdare100% (1)

- 1 Tonne, Quick Lift, Folding Engine Crane: Instructions ForDocument6 pages1 Tonne, Quick Lift, Folding Engine Crane: Instructions ForAnwar MohamedNo ratings yet

- 99-T1660-166 Service ManualDocument114 pages99-T1660-166 Service Manualma.powersourceNo ratings yet

- Supervisors - HSE ChecklistDocument2 pagesSupervisors - HSE Checklistchikkam50% (4)

- McCLOSKEY ST80-MANUAL-KUBOTADocument29 pagesMcCLOSKEY ST80-MANUAL-KUBOTAPitupy100% (1)

- ATRA 41TE Rebuild (Chrysler A 604)Document115 pagesATRA 41TE Rebuild (Chrysler A 604)Patricio Bacigalupi100% (4)

- Crane Safety PosterDocument2 pagesCrane Safety PosterJuzer MotorwalaNo ratings yet

- Cabina Del OperadorDocument20 pagesCabina Del OperadorIlarion Ciobanu100% (1)

- General: 1. Overhead Guard 2. Counterweight 3. Hood 4. Floor Plate 5. FrameDocument10 pagesGeneral: 1. Overhead Guard 2. Counterweight 3. Hood 4. Floor Plate 5. FrameweldsaidiNo ratings yet

- Bomba PattersonDocument26 pagesBomba PattersonJorge Inostroza100% (1)

- BSG - tp01 - SW - 07004 - Rev 00 Swms For Bored PileDocument10 pagesBSG - tp01 - SW - 07004 - Rev 00 Swms For Bored Pilekhairul barsriNo ratings yet

- 2 - Tesco Top Drive Safety ManualDocument18 pages2 - Tesco Top Drive Safety Manualzanella88100% (1)

- DS50 Operators Manual Manitex Manitowoc 190014ADocument21 pagesDS50 Operators Manual Manitex Manitowoc 190014AEdson EscobedoNo ratings yet

- Oil and Gas Well Completion TaskDocument4 pagesOil and Gas Well Completion Taskapi-370721250% (2)

- 1 Rotary Drilling Rig ComponentsDocument6 pages1 Rotary Drilling Rig ComponentsRAPtile100% (2)

- HB Construction CoordinatorsDocument31 pagesHB Construction CoordinatorsespinozcristianNo ratings yet

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversFrom EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversRating: 5 out of 5 stars5/5 (2)

- MastilDocument14 pagesMastilMONTACARGAS AVSNo ratings yet

- Owner WTSP (Solar) 2005Document48 pagesOwner WTSP (Solar) 2005Brian StevensNo ratings yet

- Monsoon PrecautionDocument7 pagesMonsoon Precautionajayjanardhankasle67% (3)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Terex T340-1XL Service ManualDocument1,499 pagesTerex T340-1XL Service ManualQuinn Sharp100% (3)

- Double Suction Split Case PumpsDocument27 pagesDouble Suction Split Case Pumpsgbogboiwe100% (1)

- Cranes and HoistsDocument3 pagesCranes and HoistsAditya Raj MishraNo ratings yet

- Hazmat - Vehicle - 2023 12 08 17 45 10Document115 pagesHazmat - Vehicle - 2023 12 08 17 45 10Sunil MishraNo ratings yet

- Manitex M1768Document5 pagesManitex M1768Anonymous sqFTF5tu100% (1)

- Main Switchboard Maintenance PDFDocument17 pagesMain Switchboard Maintenance PDFAzman HanafiahNo ratings yet

- Marine Warranty SurveyDocument2 pagesMarine Warranty SurveyNavalArchitecture100% (1)

- Method Statement For Tower Crane InstallationDocument17 pagesMethod Statement For Tower Crane Installationjoselito reigNo ratings yet

- Erection & Installation ProcedureDocument3 pagesErection & Installation ProcedureForos IscNo ratings yet

- MAM L2000 - M2000 - F2000 Construction Period 1992-2005 Service ManualDocument198 pagesMAM L2000 - M2000 - F2000 Construction Period 1992-2005 Service ManualOroszi Gábor100% (1)

- Bucket Elevator ManualDocument57 pagesBucket Elevator ManualZeljkoSipcicNo ratings yet

- Hydraulic Hitch Crane: Owner'S ManualDocument12 pagesHydraulic Hitch Crane: Owner'S Manualramses9No ratings yet

- Erection Manual For Light Cow (Rev. C)Document25 pagesErection Manual For Light Cow (Rev. C)remon79No ratings yet

- Chip Conveyor Manual (Direct Drive)Document10 pagesChip Conveyor Manual (Direct Drive)Roberto RamírezNo ratings yet

- Chip Conveyor Manual (Direct Drive)Document10 pagesChip Conveyor Manual (Direct Drive)Roberto RamírezNo ratings yet

- Manual de Seleção e Manutenção de Soprador IndustrialDocument39 pagesManual de Seleção e Manutenção de Soprador IndustrialEleno RibeiroNo ratings yet

- Richards Bay Minerals: General RBM ProcedureDocument7 pagesRichards Bay Minerals: General RBM ProcedureHuzaifa KtkNo ratings yet

- 02 - Portable Flare StackDocument2 pages02 - Portable Flare Stackweldsv1No ratings yet

- Sidney Manufacturing: Side Wall Return Drag Conveyor Installation InstructionsDocument13 pagesSidney Manufacturing: Side Wall Return Drag Conveyor Installation InstructionsNuzuliana EnuzNo ratings yet

- Manual de Servicio Hyster N40xtaDocument15 pagesManual de Servicio Hyster N40xtaMONTACARGAS AVSNo ratings yet

- Operation & Maintenance Manual For End Suction Type Pumps: Patterson Pump CompanyDocument25 pagesOperation & Maintenance Manual For End Suction Type Pumps: Patterson Pump CompanyvaisakhpillaiNo ratings yet

- Operation & Maintenance Manual For End Suction Type Pumps: Patterson Pump CompanyDocument25 pagesOperation & Maintenance Manual For End Suction Type Pumps: Patterson Pump CompanySaif MohammadNo ratings yet

- Slr250 RidgidDocument80 pagesSlr250 RidgidAlex HammilionNo ratings yet

- B Self Supporting Bridge Crane - 0407Document9 pagesB Self Supporting Bridge Crane - 0407Azali IshakNo ratings yet

- 4000 Winch NarDocument14 pages4000 Winch NarJITENDRA KUMAR SHARMANo ratings yet

- Ring Pocket RRS Rev005a PDFDocument22 pagesRing Pocket RRS Rev005a PDFFelomyn Abance SobrevillaNo ratings yet

- Matrix FF InstallDocument22 pagesMatrix FF Installgcu93No ratings yet

- 1000Kg Foldable Engine Crane Crane: Owner'S Manual Product Code: 1001Document14 pages1000Kg Foldable Engine Crane Crane: Owner'S Manual Product Code: 1001CARLOS ANDRES CAICEDO PEREZNo ratings yet

- Ring and Pinion Installation InstructionsDocument8 pagesRing and Pinion Installation InstructionsJonathanNo ratings yet

- Rocket Sprocket InstallDocument18 pagesRocket Sprocket InstallJulio AlarconNo ratings yet

- 1961 Service ManualDocument28 pages1961 Service ManualBrett BulkinNo ratings yet

- 2-Ton Hydraulic Engine Crane Owner'S Manual: Item# 46219Document27 pages2-Ton Hydraulic Engine Crane Owner'S Manual: Item# 46219arnaldo hernan padillaNo ratings yet

- Micro Hauler InstructionDocument4 pagesMicro Hauler InstructionAbdul MalikNo ratings yet

- Method Statement Pipe JackingDocument1 pageMethod Statement Pipe JackingNur Neyna0% (1)

- MS Erection of PH Activities 63mtr 25.12.21Document8 pagesMS Erection of PH Activities 63mtr 25.12.21AltafNo ratings yet

- Dismantling and Reassmbling 3 Jaw Chuck ReportDocument9 pagesDismantling and Reassmbling 3 Jaw Chuck Reporttylerminter1998No ratings yet

- Method Statement For Assembly of 200 Ton Crawler CraneDocument7 pagesMethod Statement For Assembly of 200 Ton Crawler CraneAnjo MolinaNo ratings yet

- 93840Document20 pages93840lNo ratings yet

- Cilindros de LevanteDocument16 pagesCilindros de LevanteMilton GarcesNo ratings yet

- Clam Quick-Set Escape ShelterDocument8 pagesClam Quick-Set Escape Shelterjrrjr71No ratings yet

- Overhead Crane Safety:: Safety Is in Your HandsDocument7 pagesOverhead Crane Safety:: Safety Is in Your Handsjoepz1982No ratings yet

- Brillia CHX30 ManualDocument72 pagesBrillia CHX30 ManualBrilliaStoreNo ratings yet

- 3-Well Complation PDFDocument4 pages3-Well Complation PDFDodi DodoNo ratings yet

- 200JinmaSL10 Mounting InstructionsDocument6 pages200JinmaSL10 Mounting Instructionstemppi54No ratings yet

- 42 01 1382 Opman Ver 6 2013 01 22 SM PDFDocument24 pages42 01 1382 Opman Ver 6 2013 01 22 SM PDFtopbedrtNo ratings yet

- Aluminium Dome Roof InstallationDocument7 pagesAluminium Dome Roof Installationmuhammad.younisNo ratings yet

- UntitledDocument4 pagesUntitledJUANNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Boiler Base Descale ProcedureDocument3 pagesBoiler Base Descale Procedureحسين مهديNo ratings yet

- Insomnia BNFDocument7 pagesInsomnia BNFحسين مهديNo ratings yet

- The Role of Nitric Oxide in Heart FailureDocument7 pagesThe Role of Nitric Oxide in Heart Failureحسين مهديNo ratings yet

- Blowdown in Boiler - Boiler Blowdown Calculation Formula & Calculator...Document7 pagesBlowdown in Boiler - Boiler Blowdown Calculation Formula & Calculator...حسين مهديNo ratings yet

- The Thin Film Approximation in Hydrodynamic, Including Elastohydrodynamic, LubricationDocument43 pagesThe Thin Film Approximation in Hydrodynamic, Including Elastohydrodynamic, Lubricationحسين مهديNo ratings yet

- SEMINOLE A Pagine PDFDocument6 pagesSEMINOLE A Pagine PDFAndrei AndreiNo ratings yet

- Link Belt 50tonDocument20 pagesLink Belt 50tonLucita VallejoNo ratings yet

- ICrevisionRRCQuestions 210102 203504Document15 pagesICrevisionRRCQuestions 210102 203504Shabin ShabiNo ratings yet

- Henry GoodrichDocument2 pagesHenry GoodrichRyanPhillips50No ratings yet

- Victoria Heavy Equipment LimitedDocument3 pagesVictoria Heavy Equipment LimitedChristopher KalanderopoulosNo ratings yet

- Research PaperDocument60 pagesResearch PaperChavan VivekNo ratings yet

- Project Name: Myanmar Aquarium Project: 1 Year 165Document3 pagesProject Name: Myanmar Aquarium Project: 1 Year 165mcgNo ratings yet

- Standard Hand Signals: For Controlling Mobile Crane OperationsDocument2 pagesStandard Hand Signals: For Controlling Mobile Crane OperationsJoao OliveiraNo ratings yet

- Industrial TraningDocument15 pagesIndustrial TraningHimanshu RaiNo ratings yet

- Thesis On Construction Technology and Management PDFDocument8 pagesThesis On Construction Technology and Management PDFpsmxiiikdNo ratings yet

- AL - WATHBA PROJECT General - Risk - Assessment-OHSDocument27 pagesAL - WATHBA PROJECT General - Risk - Assessment-OHSMuhammad YounasNo ratings yet

- Industrial Training ReportDocument23 pagesIndustrial Training ReportSudeep100% (1)

- Grove Rt890e - PM - 225275Document829 pagesGrove Rt890e - PM - 225275mariojoaofreireNo ratings yet

- THIELE Grade100 A5 English PDFDocument44 pagesTHIELE Grade100 A5 English PDFAlberth Mauricio Casteblanco GomezNo ratings yet

- Port Operations - Short NoteDocument17 pagesPort Operations - Short NoteAsel PereraNo ratings yet

- Drive Solution - Catalog - EN - (05) - 211014Document58 pagesDrive Solution - Catalog - EN - (05) - 211014ALROTEK CRNo ratings yet

- WHP CraneDocument15 pagesWHP CraneFred Eldian ElloNo ratings yet

- Torittu AnttiDocument86 pagesTorittu AnttiosamaNo ratings yet